In the realm of fine art and detailed projects, the functionality of a precision instrument is paramount. A thorough grasp of its individual elements can significantly enhance performance and ensure optimal results. This exploration delves into the intricate components that contribute to the seamless operation of such a device.

By familiarizing oneself with the various elements involved, users can troubleshoot effectively, perform maintenance with confidence, and unlock the full potential of their equipment. The significance of each component becomes clear when considering how they interact to create a flawless output.

Furthermore, understanding these intricacies fosters a deeper appreciation for craftsmanship. Whether you are an experienced artisan or a novice, knowledge of the inner workings can transform your approach and elevate your artistic expression. Join us as we dissect and analyze the key features of this essential tool.

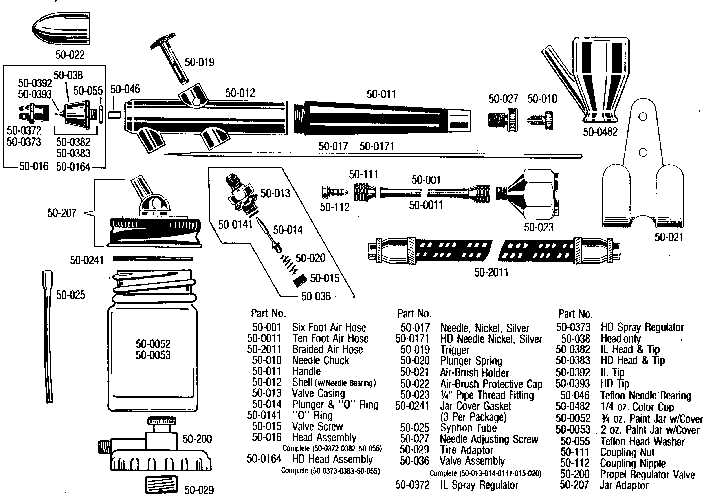

Understanding Badger 200 Airbrush Design

The design of precision painting tools plays a crucial role in achieving fine details and smooth finishes. By examining the structural components and their functions, users can enhance their understanding of how these instruments operate effectively. This knowledge allows for improved handling and maintenance, leading to better artistic outcomes.

At the core of these devices lies the combination of a nozzle and needle system, which work in harmony to control the flow of medium. The adjustment of these elements affects the spray pattern and consistency, enabling artists to create a wide range of effects. Additionally, the construction of the body provides comfort and control, allowing for extended use without fatigue.

Moreover, the incorporation of an efficient air supply mechanism is vital for optimal performance. Understanding how air pressure influences the medium delivery helps users adapt their technique for different applications. Each element, from the trigger to the cup, contributes to the overall functionality and user experience.

In summary, a comprehensive grasp of the intricacies involved in these tools empowers users to maximize their potential. By recognizing the importance of each component and its role in the painting process, artists can develop their skills and achieve greater precision in their work.

Key Components of Badger 200

This section explores the essential elements that contribute to the functionality and performance of a particular fine spray tool. Understanding these components is crucial for anyone looking to enhance their crafting or artistic skills.

Airflow Mechanism

The airflow mechanism plays a vital role in controlling the spray pattern and consistency. It ensures an even distribution of the medium, allowing for detailed work and broad coverage alike. Mastery of this component is essential for achieving the desired effects.

Needle and Nozzle Assembly

The needle and nozzle assembly is critical for regulating the flow and precision of the spray. A well-maintained assembly enhances accuracy and helps in creating intricate designs. Regular cleaning and proper handling of these components will ultimately improve overall performance.

Functionality of Each Airbrush Part

This section delves into the various components of a spray tool and their specific roles in achieving precise and controlled application of paints and inks. Understanding how each element functions is crucial for both beginners and experienced users, as it enhances the overall effectiveness of the device.

Nozzle: The nozzle serves as the exit point for the fluid, determining the spray pattern and width. Its design influences the consistency and distribution of the application, making it essential for achieving the desired results.

Needle: The needle works in tandem with the nozzle, controlling the flow of the medium. By adjusting the needle’s position, users can fine-tune the spray’s intensity and volume, allowing for detailed work or broad coverage.

Trigger: The trigger is the primary control mechanism, enabling users to start and stop the flow of the medium with ease. Its responsiveness is key for achieving smooth transitions and dynamic effects during application.

Reservoir: The reservoir holds the paint or ink before it is released through the nozzle. Its capacity impacts the length of time one can work without needing to refill, making it an important factor for efficiency.

Cap: The cap protects the nozzle and needle while also influencing the airflow. It helps to prevent clogging and ensures a consistent spray pattern, contributing to the overall performance of the tool.

Body: The body houses all the components and is designed for comfortable handling. Its ergonomic shape facilitates ease of use, allowing for prolonged operation without strain.

By mastering the functionality of each element, users can enhance their skills and creativity, ultimately leading to more successful and satisfying results in their artistic endeavors.

Common Issues with Badger 200 Parts

Understanding the frequent complications that arise with these painting tools can greatly enhance the user experience. Many enthusiasts encounter similar hurdles, which can often be resolved with a bit of knowledge and attention to detail. By identifying and addressing these common challenges, users can ensure smoother operation and prolonged lifespan of their equipment.

Clogging Problems

One of the most prevalent issues users face is the clogging of the nozzle. This can occur due to dried paint or debris accumulating within the mechanism. Regular cleaning and proper maintenance routines are essential to prevent this from happening. Using the right thinning agents and ensuring the paint is adequately prepared before use can also mitigate this concern.

Leakage and Sealing Issues

Another frequent complication involves leakage, which can be caused by worn-out seals or improper assembly. Ensuring that all components are tightly fitted and that seals are replaced when they show signs of wear can help maintain a proper pressure balance. Regular inspections of the entire setup are recommended to identify any potential issues before they escalate.

Maintenance Tips for Longevity

Ensuring the durability of your precision tool requires regular care and attention. Proper maintenance not only enhances performance but also extends the lifespan of the equipment, allowing for consistent and high-quality results. Implementing a few essential practices can make a significant difference in the efficiency and reliability of your device.

1. Regular Cleaning: After each use, clean the components thoroughly to remove any residue or paint build-up. Utilize appropriate cleaning solutions and tools designed for delicate parts to prevent damage. This routine will help maintain optimal functionality and prevent clogging.

2. Proper Storage: Store your equipment in a safe, dry place away from direct sunlight. Use protective cases or covers to shield it from dust and physical impacts. A stable environment reduces the risk of deterioration caused by external factors.

3. Routine Inspections: Regularly inspect the internal and external components for signs of wear or damage. Look for cracks, leaks, or any irregularities. Identifying issues early can prevent costly repairs or replacements down the line.

4. Lubrication: Apply a suitable lubricant to moving parts as needed. This reduces friction and helps maintain smooth operation. Follow manufacturer recommendations for specific lubricants to ensure compatibility.

5. Avoid Overuse: Allow your equipment to rest between uses. Prolonged operation without breaks can lead to overheating and premature wear. Schedule regular intervals for downtime to preserve the integrity of the device.

By following these maintenance tips, you can ensure that your precision tool remains in excellent condition, delivering outstanding performance for years to come.

How to Clean Airbrush Components

Maintaining the cleanliness of your spraying tools is essential for optimal performance and longevity. Proper care not only ensures smooth operation but also prevents clogs and ensures consistent results. This guide outlines effective methods for keeping your equipment in top shape.

| Step | Action | Notes |

|---|---|---|

| 1 | Disassemble | Carefully take apart all components to access interior areas. |

| 2 | Rinse | Use warm water to rinse each piece, removing any residual material. |

| 3 | Soak | Soak stubborn components in a cleaning solution for better results. |

| 4 | Brush | Utilize a soft brush to scrub away any remaining deposits. |

| 5 | Dry | Thoroughly dry all parts before reassembling to avoid moisture-related issues. |

Following these steps regularly will help maintain your tools and enhance their functionality, ensuring that you achieve the ultimate results in your creative projects.

Tools Required for Repairs

To ensure effective maintenance and restoration of intricate devices, having the right tools is essential. This section outlines the necessary instruments that will aid in the repair process, allowing for a smoother and more efficient experience.

Essential Instruments

The following tools are fundamental for tackling repair tasks:

| Tool | Purpose |

|---|---|

| Precision Screwdrivers | For removing and securing small screws. |

| Needle Nose Pliers | To manipulate and hold tiny components. |

| Cleaning Brushes | To remove debris and buildup effectively. |

| Lubricants | To ensure smooth operation of moving parts. |

| Replacement Seals | For ensuring airtight connections. |

Additional Recommendations

Consider having a magnifying glass for detailed work and a suitable workspace with adequate lighting. These enhancements will ultimately improve the precision of your repair endeavors.

Upgrading Parts for Better Performance

Enhancing the efficiency of your spray tools can significantly impact your creative projects. By selecting superior components, you can achieve smoother operation, improved precision, and increased durability. This focus on quality allows for a more enjoyable and productive experience, whether for hobbyists or professionals.

Choosing High-Quality Components

Investing in premium materials is essential for elevating the overall functionality of your equipment. Look for options that boast better airflow management and reduced clogging. Upgrading elements like nozzles or needles can lead to more consistent results and finer detail work.

Regular Maintenance and Upgrades

Routine checks and timely replacements of worn-out elements ensure your tools perform at their best. Staying proactive in maintenance helps prevent issues that could hinder your creative flow. Consider implementing upgrades periodically to keep pace with evolving techniques and materials in your craft.

Differences Between Badger Models

Understanding the variations among different spray tools can enhance your experience and outcomes in artistic projects. Each model comes with unique features tailored for specific applications, influencing factors like precision, ease of use, and versatility.

Design Variations

Models differ significantly in design, impacting grip and comfort during prolonged usage. Some are engineered for detailed work, while others accommodate broader strokes, catering to various artistic styles and preferences.

Performance Characteristics

The performance of these tools can vary in terms of paint flow and air pressure management. Certain designs offer greater control, enabling artists to achieve intricate details, whereas others prioritize speed and coverage for larger surfaces.

Air Pressure Settings Explained

Understanding the nuances of pressure settings is crucial for achieving optimal results in any painting process. The right pressure can significantly influence the finish, application, and overall effectiveness of the medium being used. This section will explore how pressure impacts performance and the variables that come into play.

Optimal Pressure Levels

Each technique and medium requires different levels of pressure to function effectively. Lower pressures often lead to finer detail and controlled applications, while higher pressures can facilitate broader coverage and quicker drying times. Finding the sweet spot is essential for balancing precision and efficiency.

Common Issues with Pressure

Incorrect pressure settings can lead to a range of problems, including uneven application, spattering, or insufficient coverage. Recognizing the signs of improper pressure is vital for troubleshooting and adjusting techniques to achieve the desired effect in your projects.

Choosing the Right Paint for Use

Selecting the appropriate pigment is crucial for achieving optimal results in any artistic endeavor. The right choice can enhance the final appearance, ensuring vibrant colors and smooth application.

Types of Pigments

When exploring options, consider water-based, solvent-based, and acrylic mediums. Water-based paints are user-friendly and easy to clean, while solvent-based varieties offer durability. Acrylics provide versatility, allowing for various finishes and drying times.

Factors to Consider

Compatibility with your equipment is essential. Ensure the chosen medium works well with your tools for seamless application. Additionally, intended use plays a significant role; for instance, outdoor projects require weather-resistant formulations. Always test a small area to assess performance before committing.

Best Practices for Airbrush Technique

Mastering the art of spray painting requires more than just the right tools; it demands a keen understanding of technique and precision. To achieve stunning results, one must consider factors such as pressure control, paint consistency, and the angle of application. Implementing effective practices can significantly enhance the quality of your work and lead to more satisfying outcomes.

Preparation and Setup

Before starting, ensure that your workspace is clean and well-organized. Thoroughly clean the nozzle and other components to avoid clogs and maintain a smooth flow. Select the appropriate medium and mix it to the desired viscosity. A consistent paint mixture will prevent sputtering and create even coverage.

Application Techniques

When applying the medium, hold the tool at a consistent distance from the surface–typically between 6 to 12 inches. Experiment with different angles to find what works best for your specific project. Maintain a steady hand and use a smooth, sweeping motion to achieve a uniform finish. Remember to practice layering techniques; this allows for greater depth and complexity in your designs.