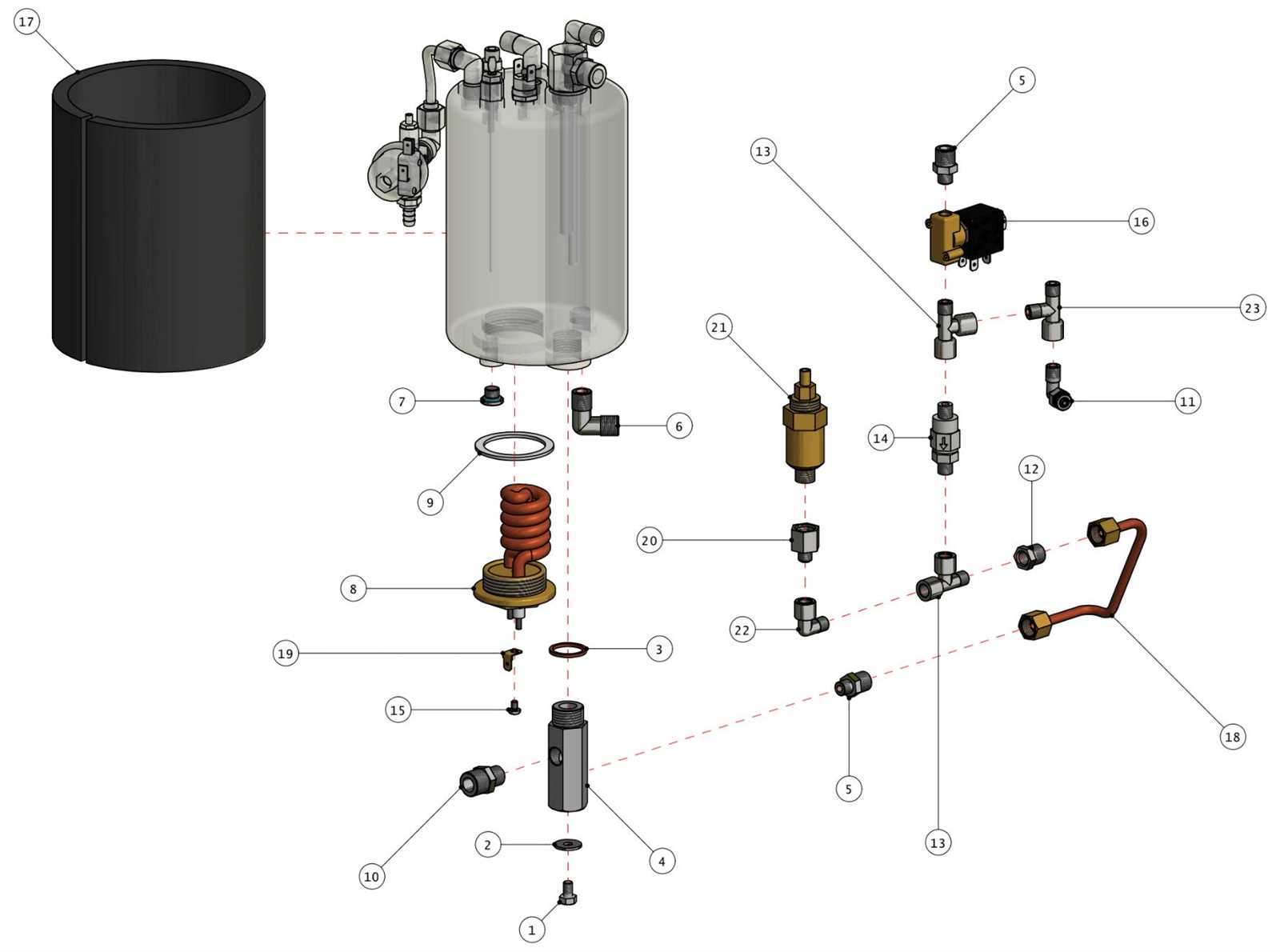

In any mechanical tool designed for the application of liquids, every element plays a critical role in ensuring effective performance. The combination of various elements forms a cohesive system that ensures the proper handling and delivery of the liquid substance. Each section has its specific responsibility, whether it’s regulating the flow, maintaining pressure, or protecting the unit from damage.

The structure of this device consists of multiple sections, each designed for a specific function. From controlling the release of liquid to managing air and pressure, understanding how these pieces work together helps in maintaining and repairing the equipment. Identifying individual elements and their relationships is key to ensuring long-term use and proper functionality.

By breaking down the key elements of the assembly, users can more easily identify any malfunction and quick

Understanding the Key Components of B&G Sprayers

Efficient liquid dispersal systems are designed with a variety of interconnected elements that ensure precision and reliability. These elements work together to control the flow and application of liquids, whether for industrial, agricultural, or household use. By examining each core component, one can better understand how these devices achieve their functionality and durability.

The system typically consists of a control valve, which regulates the amount of liquid released, and a durable nozzle that determines the spray pattern. A robust container serves as the main reservoir, constructed to hold substantial volumes of fluid while maintaining stability under pressure. Additionally, the inclusion of a pump mechanism is vital for maintaining consistent pressure, ensuring a smooth and efficient output.

Other crucial elements include a

Internal Mechanisms and Their Functions

The inner workings of this device are designed to optimize performance by ensuring precision and efficiency. Each component is carefully engineered to contribute to the overall functionality, from the flow control to pressure regulation, allowing for smooth operation and durability.

Flow Control System

At the core of the system is the flow control mechanism, which manages the amount of liquid distributed. This system includes a series of valves and passages that direct the movement of the liquid, ensuring an even and controlled output.

- Adjustable valves for controlling output rate

- Sealed pathways to prevent leaks

- Precision nozzles for accurate distribution

Pressure Regulation

Another vital aspect is the

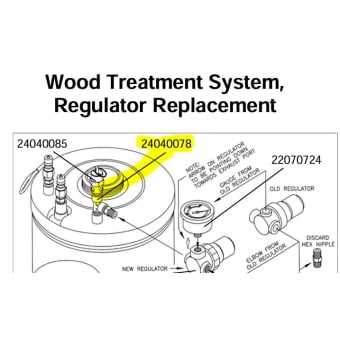

Replacement Parts for Efficient Maintenance

Maintaining equipment in optimal condition is crucial for long-term reliability and performance. Regular upkeep ensures that all components function as intended, preventing breakdowns and extending the lifespan of the system. To achieve this, it’s essential to understand which elements may need replacing over time.

Below are some of the most common items to consider when planning for efficient servicing:

- Seals and Gaskets – These elements can wear out due to constant use and exposure to different substances. Replacing them at regular intervals prevents leaks and maintains functionality.

- Valves – Key to controlling flow, these need periodic checks and replacement to ensure smooth operation and avoid failures.

- Handles and Grips – Over time, thes

How to Identify Common Malfunctions

Understanding the frequent issues that can arise during equipment use is essential for maintaining functionality and preventing downtime. By recognizing typical symptoms, you can quickly troubleshoot and restore optimal performance.

Signs of Performance Decline

- Reduced pressure or inconsistent output during operation.

- Unusual sounds indicating internal component wear or misalignment.

- Fluid leakage from areas that should remain sealed.

Key Areas to Inspect

- Examine connections and seals for wear or improper fitting.

- Check the fluid pathway for blockages that might impede functionality.

- Ensure that all moving mechanisms are clean and free of debris.

By regularly inspecting these

Nozzle Types and Their Applications

Various nozzle designs offer distinct advantages depending on the task at hand. Each type serves a specific purpose, whether it’s ensuring precise coverage, controlling flow, or managing spray patterns. Selecting the right option is crucial for achieving optimal results and maintaining efficiency.

- Fan Nozzles: These are designed to distribute liquid in a wide, even pattern. They are ideal for tasks requiring consistent coverage over large surfaces.

- Cone Nozzles: Known for their circular dispersion, cone nozzles are suited for applications where more focused or fine distribution is needed, such as for delicate materials.

- Adjustable Nozzles: Offering versatility, these allow users to change the spray pattern from a fine mist to a direct stream, making them useful for a variety of settings.

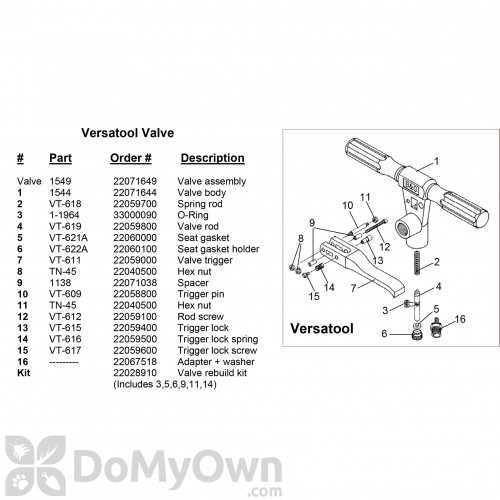

- Grip: The part where the user holds, often made from materials that provide comfort and prevent slipping.

- Support Frame: A rigid structure that connects the grip to the main body, ensuring stability during operation.

- Trigger Mechanism: Allows users to activate the device, often designed for quick and easy access.

- Connection Points: Areas where the assembly attaches to other components, enabling seamless integration.

Tank Construction and Material Choices

Understanding the design and composition of storage units is essential for optimizing their functionality and durability. The selection of appropriate materials influences not only the structural integrity but also the overall performance of the equipment. Various factors such as weight, resistance to chemicals, and environmental conditions play a critical role in determining the best choices for construction.

Material Options

When considering materials for these storage units, common choices include polyethylene, stainless steel, and fiberglass. Each material presents unique benefits: polyethylene is lightweight and resistant to corrosion, while stainless steel offers superior strength and durability. Fiberglass, on the other hand, combines both lightweight properties and resistance to a wide range of chemicals.

Design Considerations

In addition to material selection, the design of the storage unit must also be carefully planned. Ergonomic shapes facilitate ease of use, while structural reinforcements ensure longevity under varying conditions. Integrating features such as reinforced seams and protective coatings can enhance resistance to wear and prolong the lifespan of the unit.

Proper Valve Maintenance for Longevity

Ensuring the durability and efficiency of any liquid dispensing mechanism requires regular attention to its components, particularly the valves. These critical elements play a vital role in controlling the flow and pressure within the system. Proper care and routine checks can significantly enhance their lifespan, prevent malfunctions, and maintain optimal performance.

Regular Inspections

Conducting periodic evaluations is essential for identifying any wear and tear or signs of malfunction. Look for leaks, corrosion, or any irregularities in operation. By addressing these issues promptly, you can prevent more significant problems down the line.

Cleaning and Lubrication

Keeping valves clean is paramount for their functionality. Dirt and debris can hinder performance, leading to inefficient operation. Regular cleaning, followed by appropriate lubrication, will ensure smooth operation and prevent sticking or jamming. Always use recommended lubricants to avoid damaging components.

Maintenance Task Frequency Description Inspection Monthly Check for leaks and signs of wear. Cleaning Every 3 months Remove dirt and debris from the valve surfaces. Lubrication Every 6 months Apply suitable lubricant to moving parts. Handle Assembly: Structure and Uses

The handle assembly plays a crucial role in the operation of various equipment, serving as the primary interface for users. Its design integrates functionality and ergonomics, ensuring ease of use while facilitating efficient control of the device. This section explores the components and applications of this assembly, highlighting its importance in overall performance.

The structure typically consists of the following components:

Understanding the functions of these elements enhances the user experience. Key uses of the handle assembly include:

- Providing leverage for better control.

- Facilitating quick adjustments during operation.

- Offering a comfortable grip to minimize fatigue.

- Ensuring reliable activation of the device’s functions.

Overall, the handle assembly is essential for maximizing efficiency and comfort in operation, contributing significantly to the effectiveness of the equipment.

Pump Mechanism Breakdown and Usage Tips

Understanding the intricacies of a liquid delivery system is crucial for effective application and maintenance. This section delves into the fundamental components responsible for generating pressure and facilitating the flow of fluids. A well-functioning mechanism ensures optimal performance, making it essential to grasp its structure and function.

The core element of this system typically consists of a motorized unit that drives a piston or diaphragm, creating the necessary pressure to propel liquids. The efficiency of this operation largely depends on the alignment and condition of the internal components. Regular checks for wear and tear can significantly extend the lifespan of the unit.

For optimal performance, ensure that the intake filter is clean and free of debris, as this can impede fluid flow. It’s also advisable to periodically lubricate moving parts to reduce friction and wear. When not in use, consider draining any residual fluid to prevent contamination and damage to the internal workings. Understanding these principles not only enhances the device’s efficiency but also promotes longevity.

Safety Features to Look Out For

When working with chemical application equipment, prioritizing safety is essential. Understanding the crucial safety features can significantly reduce the risk of accidents and ensure a secure working environment. It’s vital to choose models equipped with specific elements designed to protect the user and enhance overall operational safety.

Emergency Shut-Off Mechanisms

One of the most important features to consider is the presence of emergency shut-off mechanisms. These allow for immediate cessation of operation in case of an unforeseen issue, preventing potential harm to the user and the surrounding area. Ensure that the device has easily accessible controls that can be reached quickly during emergencies.

Protective Gear and Ergonomic Design

In addition to automatic safety functions, ergonomic design plays a vital role in user safety. Equipment that minimizes strain and provides comfort can help prevent accidents caused by fatigue or discomfort. Furthermore, using protective gear, such as gloves and goggles, is essential when handling chemicals, ensuring maximum safety throughout the application process.

Finding the Right Accessories for Your Sprayer

Choosing the appropriate add-ons for your equipment can greatly enhance its efficiency and performance. With numerous options available, it is essential to identify the specific needs of your tasks and select compatible components that align with your goals.

Key Considerations

- Compatibility: Ensure that the selected accessories are designed to work seamlessly with your equipment.

- Quality: Opt for high-quality components that guarantee durability and longevity.

- Functionality: Assess the functionalities you require, such as nozzle types or hose lengths, to optimize your operations.

Recommended Accessories

- Pressure regulators for consistent performance.

- Specialized nozzles for different applications.

- Hoses of varying lengths to reach challenging areas.

- Filters to prevent clogging and maintain efficiency.

By carefully considering these factors and recommendations, you can enhance the capabilities of your device, ensuring effective and efficient operation for all your tasks.