In the world of mechanical tools, the functionality and reliability of lifting devices play a crucial role in various applications. Whether in a workshop or a garage, these machines are essential for elevating heavy loads with ease and efficiency. A clear understanding of their construction and the elements involved can significantly enhance their maintenance and overall performance.

The intricate design of these hydraulic tools involves several key components that work in harmony to ensure safe and effective operation. By familiarizing oneself with these elements, users can identify potential issues, streamline repairs, and enhance the longevity of the equipment. Such knowledge not only promotes better performance but also instills confidence when operating these powerful machines.

Additionally, having access to detailed representations of the internal mechanisms aids technicians and enthusiasts alike in troubleshooting and conducting necessary repairs. This understanding empowers individuals to manage their lifting tools effectively, making it easier to tackle a wide range of tasks with precision and safety.

Overview of Blackhawk Floor Jack

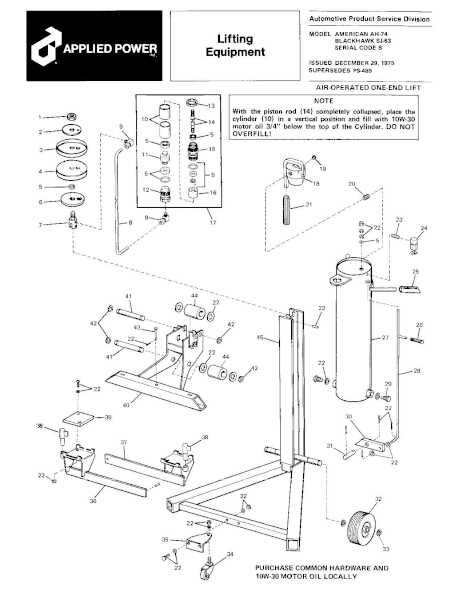

This section provides a comprehensive examination of a lifting device designed to elevate vehicles for maintenance and repair tasks. Understanding its components and functionality is crucial for effective usage and safety considerations.

Manufactured to offer reliable performance, this tool is utilized in various settings, from professional garages to home workshops. Its design ensures stability while lifting heavy loads, enabling users to work efficiently beneath vehicles. Familiarity with its features enhances operational knowledge, promoting both safety and effectiveness during vehicle servicing.

Attention to detail in construction and material quality plays a significant role in the durability and functionality of this lifting mechanism. Regular maintenance and proper usage techniques are essential to prolong its lifespan and ensure optimal performance, making it a valuable addition to any maintenance toolkit.

Key Components of the Jack

Understanding the essential elements of a lifting device is crucial for both effective usage and maintenance. Each component plays a significant role in the overall functionality, ensuring that the mechanism operates safely and efficiently. Familiarity with these elements helps users appreciate how they contribute to the performance and durability of the tool.

Hydraulic System

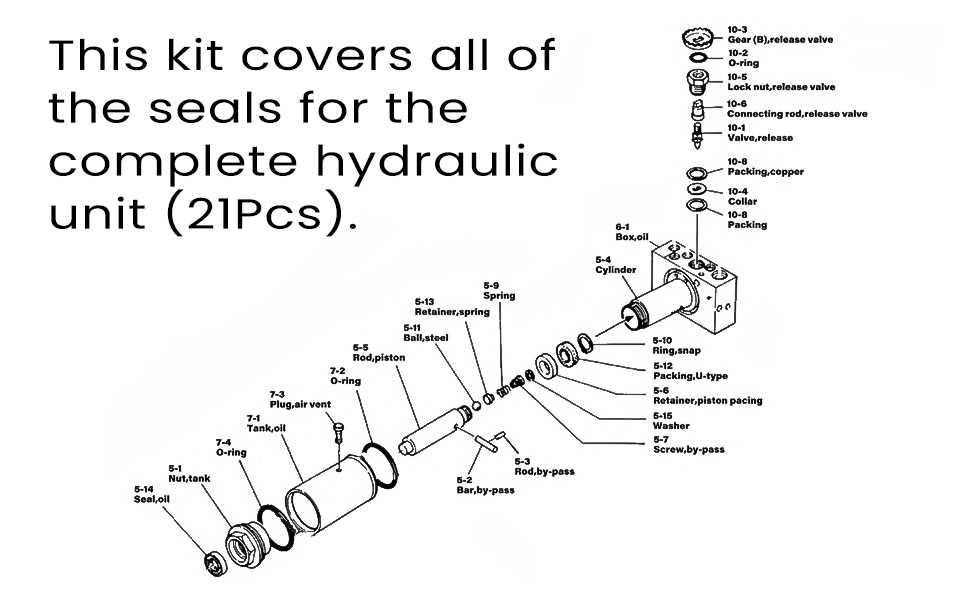

The hydraulic system is the heart of the mechanism, responsible for lifting heavy loads with minimal effort. It utilizes fluid pressure to generate force, allowing for smooth and controlled elevation. Regular inspection of the hydraulic fluid level and the integrity of hoses is essential for maintaining optimal performance.

Base and Frame

The base and frame provide stability and support during operation. Constructed from durable materials, these components are designed to withstand significant weight while ensuring the safety of the user. It is vital to check for any signs of wear or damage, as this can compromise the entire lifting operation.

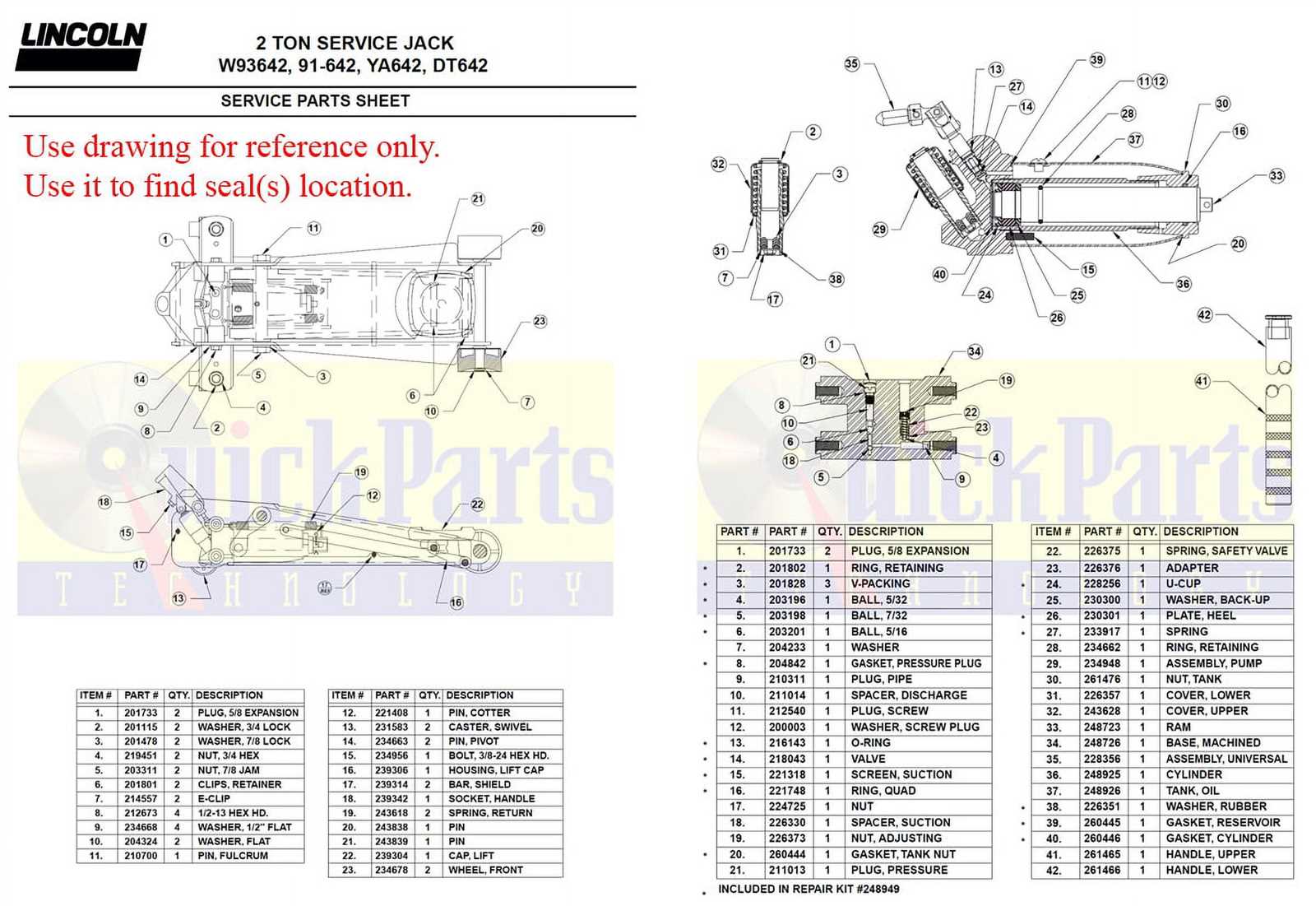

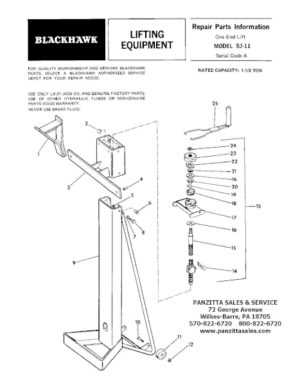

Understanding the Parts Diagram

Comprehending the assembly layout is crucial for effective maintenance and troubleshooting of equipment. By familiarizing yourself with the various components and their functions, you can enhance your understanding of how the system operates and identify any issues that may arise.

The layout typically includes several essential elements, each playing a specific role in the overall functionality. Here are some key features to consider:

- Structure: This refers to the frame or base that supports the entire mechanism.

- Control Mechanisms: These are the elements used to operate the system, such as levers and pedals.

- Hydraulic Components: Critical for the lifting process, these parts include cylinders and pumps.

- Safety Features: Mechanisms designed to prevent accidents, such as pressure relief valves.

- Accessories: Optional attachments or tools that enhance functionality.

When analyzing the layout, it is beneficial to follow these steps:

- Identify each component and its corresponding function.

- Refer to the accompanying labels or numbers for clarification.

- Understand the relationship between different elements, noting how they interact during operation.

- Use this knowledge to facilitate repairs or adjustments as necessary.

Ultimately, mastering the assembly layout not only empowers you to perform effective maintenance but also instills confidence in handling any challenges that may arise in the future.

Importance of Each Component

Understanding the significance of each element within a hydraulic lifting device is crucial for ensuring its optimal performance and longevity. Every individual piece plays a specific role that contributes to the overall functionality, safety, and efficiency of the system. A well-designed apparatus relies on the seamless interaction between these components, which enhances user experience and minimizes the risk of mechanical failure.

Key Elements and Their Functions

Among the primary components, the hydraulic cylinder serves as the heart of the mechanism, converting fluid pressure into lifting force. This crucial part enables the apparatus to elevate heavy loads with ease. Additionally, the pump mechanism is responsible for generating the pressure needed for the lifting action, highlighting its importance in achieving the desired height.

Impact on Performance and Safety

The integrity of supporting elements, such as the frame and wheels, cannot be overlooked. A robust frame ensures stability during operation, while quality wheels facilitate smooth maneuverability. Regular maintenance of these components not only enhances performance but also ensures safety during use, preventing accidents and equipment damage.

Common Issues and Solutions

When utilizing hydraulic lifting equipment, users may encounter several typical challenges that can impede functionality and safety. Understanding these common problems and their remedies is essential for maintaining optimal performance and prolonging the lifespan of the equipment.

Frequent Problems

- Fluid leaks

- Inadequate lifting capacity

- Slow or unresponsive operation

- Excessive noise during operation

- Difficulty in lowering the equipment

Recommended Solutions

- For fluid leaks, inspect all seals and connections for wear and replace as necessary.

- If the lifting capacity is insufficient, check for overload conditions and ensure the device is not exceeding its rated capacity.

- To address slow or unresponsive movement, verify the fluid levels and look for air in the hydraulic system, bleeding it if needed.

- Excessive noise can often be resolved by lubricating moving parts and ensuring all components are properly tightened.

- If lowering is difficult, examine the release valve for blockages or damage and repair or replace as required.

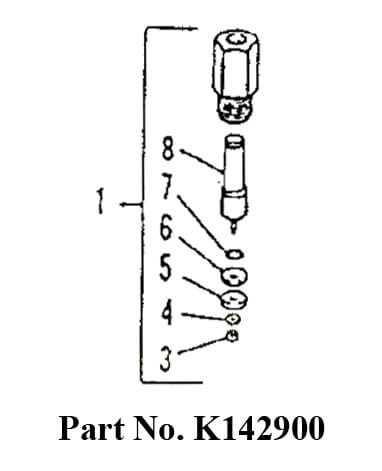

How to Identify Part Numbers

Understanding how to determine component identifiers is crucial for effective maintenance and repairs. Accurately identifying these identifiers ensures that the correct replacements or upgrades are obtained, minimizing the risk of compatibility issues. This section provides essential insights into the process of recognizing and verifying the necessary component numbers.

Utilizing Manuals and Catalogs

The first step in identifying component identifiers is to consult official manuals or catalogs. These documents typically contain detailed descriptions and illustrations, making it easier to locate the specific identifiers needed for each component. Pay close attention to the diagrams, as they often indicate the placement and relationship of various components, allowing for a clearer understanding of which numbers correspond to each item.

Online Resources and Forums

In addition to printed materials, online resources can be invaluable for identifying component identifiers. Manufacturer websites, dedicated forums, and user communities often provide extensive databases and discussions that can help clarify any uncertainties. Engaging with these resources can lead to quick solutions and expert advice, ensuring that the correct identifiers are identified without hassle.

| Identifier Type | Description |

|---|---|

| Model Number | Unique code used to identify a specific model. |

| Serial Number | Unique identifier assigned to individual units. |

| SKU | Stock Keeping Unit used for inventory management. |

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended lifespan of your equipment. By implementing a consistent maintenance routine, you can prevent wear and tear, enhance performance, and minimize the likelihood of unexpected failures. Below are some practical recommendations to help you maintain your apparatus effectively.

Routine Inspection

Conducting frequent checks is vital for identifying potential issues before they escalate. Pay attention to any unusual noises, leaks, or changes in functionality. Addressing minor concerns promptly can save you time and resources in the long run.

Cleaning Procedures

Keeping your device clean is crucial for its efficiency. Dust, dirt, and debris can accumulate over time, affecting performance. Use a soft cloth and suitable cleaning solutions to remove contaminants, ensuring that moving parts operate smoothly.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Weekly | Look for leaks and wear. |

| Cleaning | Monthly | Use appropriate cleaners. |

| Lubrication | Every 6 months | Apply lubricant to moving parts. |

| Function Test | Quarterly | Ensure all functions operate correctly. |

Safety Precautions When Using Jacks

When operating lifting equipment, ensuring safety is paramount to prevent accidents and injuries. Adhering to specific guidelines can help users maintain a secure environment while performing lifting tasks. Awareness of the equipment’s limitations and proper handling techniques plays a crucial role in promoting safety.

Before starting any lifting operation, it is essential to inspect the equipment thoroughly. Check for signs of wear, damage, or malfunction. If any issues are detected, do not proceed until the necessary repairs or replacements have been made. Regular maintenance checks can significantly enhance the longevity and reliability of the equipment.

Always utilize the lifting device on a stable and level surface. Uneven or unstable ground can lead to equipment failure and cause serious accidents. Ensure the load is properly positioned and balanced before initiating the lift. This will help prevent tipping or shifting during operation.

Employ proper lifting techniques to avoid personal injury. Bend at the knees and keep your back straight when lifting any heavy load manually. Additionally, never exceed the manufacturer’s specified weight limit, as this can compromise both the equipment’s integrity and personal safety.

Lastly, maintain clear communication with anyone involved in the lifting process. Establishing signals or using verbal commands can help coordinate efforts and ensure that everyone is aware of the operation’s status. This collaborative approach minimizes the risk of accidents and enhances overall safety.

Comparing Blackhawk with Other Brands

When evaluating different lifting equipment options, it’s essential to understand the unique attributes and advantages each brand offers. This analysis delves into how one brand stacks up against its competitors, focusing on performance, reliability, and value for money.

Several key factors should be considered when making comparisons:

- Build Quality: The materials and construction methods significantly influence durability and performance. Comparing the robustness of different brands can reveal which ones stand the test of time.

- Lift Capacity: Assessing the maximum weight each model can handle is crucial for safety and effectiveness. Brands may vary in their lifting capabilities, making it important to choose the right one for specific tasks.

- Ease of Use: Features like ergonomic handles, smooth operation, and straightforward setup can enhance user experience. Evaluating how intuitive each brand is can help in selecting the most user-friendly option.

- Price Point: Budget considerations often dictate purchasing decisions. A thorough analysis of the cost relative to features and performance helps identify the best value.

- Customer Support: Reliable after-sales service, warranties, and accessible customer service can significantly impact overall satisfaction. Brands with a strong support network tend to foster greater customer loyalty.

In summary, comparing different brands involves examining various aspects such as quality, functionality, and support. This approach ensures that the most suitable choice is made for lifting equipment needs.

Where to Purchase Replacement Parts

Finding suitable components for your equipment can significantly enhance its functionality and lifespan. Whether you’re looking to repair or upgrade your tools, it’s crucial to source reliable replacements that meet quality standards. Various outlets offer these necessary items, ensuring you can keep your devices in optimal working condition.

Online Retailers

Many customers turn to online platforms for convenience and a broader selection. Websites dedicated to tool accessories provide a wide array of options, often at competitive prices. Additionally, customer reviews can help gauge the quality of the products before making a purchase. Popular e-commerce sites typically offer a user-friendly experience, making it easy to search for the specific components needed.

Local Hardware Stores

Visiting local supply stores can also be an effective way to find the required items. These establishments often have knowledgeable staff who can assist in identifying the right components for your specific needs. Furthermore, purchasing locally allows for immediate acquisition, avoiding potential shipping delays associated with online orders.

DIY Repairs: A Step-by-Step Guide

When it comes to maintaining and restoring essential tools, knowing how to perform repairs on your own can save time and money. This guide will provide you with the necessary steps to tackle common issues effectively, ensuring that your equipment remains in top condition.

Gather Your Tools and Materials

Before starting any repair project, it’s crucial to have the right tools and materials at your disposal. Here’s a list of items you may need:

- Socket set

- Wrenches

- Screwdrivers

- Replacement components

- Lubricant

- Cleaning supplies

Identify the Problem

Diagnosing the issue is the first step in the repair process. Follow these steps:

- Inspect the equipment for any visible damage.

- Test the functionality to pinpoint the problem area.

- Consult a manual or online resources for troubleshooting tips.

Once you have identified the issue, you can proceed with the necessary repairs using the steps outlined in this guide. Remember, a methodical approach is key to successful DIY repairs.

FAQs About Blackhawk Floor Jacks

This section addresses common inquiries related to a specific type of lifting equipment widely used for various applications, especially in automotive settings. Understanding these aspects can enhance user experience and ensure optimal performance.

General Questions

- What is the maximum load capacity of this equipment?

- How do I maintain my lifting tool for longevity?

- Are there any safety precautions I should follow while using this device?

Technical Support

- Where can I find replacement components if needed?

- What should I do if the equipment fails to lift?

- Is there a warranty available for this lifting tool?

Additional Resources for Users

For individuals seeking to enhance their understanding and maintenance of lifting equipment, a variety of supplementary materials are available. These resources aim to provide comprehensive insights into effective operation, troubleshooting, and repair practices, ensuring optimal performance and longevity of the equipment.

Here are some valuable resources to consider:

- User Manuals: Official manuals offer detailed instructions on operation, maintenance, and safety precautions.

- Online Forums: Community platforms allow users to share experiences, seek advice, and discuss issues related to equipment use.

- Video Tutorials: Visual guides available on various platforms demonstrate proper techniques for setup and troubleshooting.

- Manufacturer Support: Contacting the manufacturer’s customer service can provide personalized assistance and expert guidance.

- Parts Suppliers: Online retailers specializing in equipment components can assist in finding necessary replacements and upgrades.

Utilizing these resources can greatly improve user experience and ensure proper handling of lifting tools, enhancing safety and efficiency.