The understanding of tool mechanisms is essential for efficient maintenance and operation. When users delve into the intricacies of their equipment, they can ensure optimal performance and longevity. This section aims to elucidate the various elements that constitute a specific pneumatic device, enabling users to navigate its functionality effectively.

By familiarizing oneself with the essential components, users can troubleshoot issues and make informed decisions regarding repairs or replacements. Comprehensive knowledge of the internal structure fosters a deeper appreciation for the tool’s capabilities and enhances overall user experience.

Through a detailed examination of these components, we provide insights into their roles and interactions, ultimately empowering users to maximize the efficiency and reliability of their equipment.

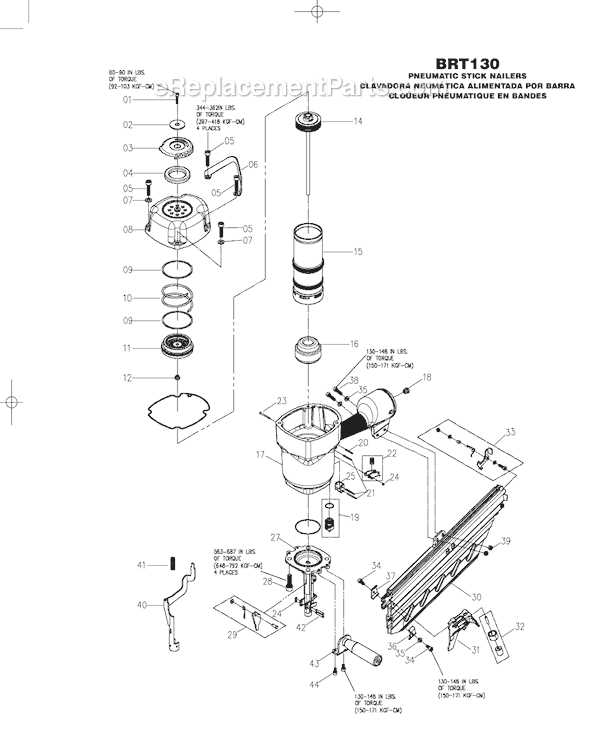

This section provides a comprehensive overview of the components associated with a specific tool model. Understanding each element’s function and interaction can significantly enhance maintenance and troubleshooting efforts.

Key Components

Each unit consists of various essential components that play vital roles in its overall functionality. Familiarizing yourself with these parts can help in identifying issues and ensuring smooth operation.

Understanding Assembly

Grasping how each element fits into the overall structure is crucial. This knowledge aids in effective repairs and replacements, prolonging the lifespan of the equipment.

| Component Name | Function | Replacement Part Number |

|---|---|---|

| Housing | Encloses internal parts | 123456 |

| Trigger | Controls operation | 789012 |

| Motor | Powers the device | 345678 |

| Cylindrical Sleeve | Guides the fastener | 901234 |

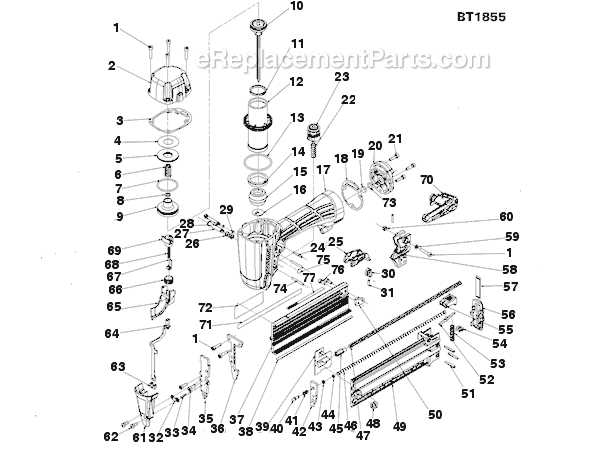

Key Components of BT1855

This section explores the essential elements that contribute to the functionality and efficiency of the tool. Understanding these components is crucial for effective maintenance and optimal performance, ensuring that the device operates smoothly for various tasks.

Essential Parts

Every tool comprises several key elements that work together to deliver performance. These parts play significant roles in the overall operation and durability of the equipment.

| Component | Function |

|---|---|

| Housing | Protects internal mechanisms and provides a grip. |

| Trigger | Controls the operation of the device. |

| Drive Mechanism | Engages the fastening elements. |

| Pneumatic Cylinder | Generates the necessary force for operation. |

| Exhaust Port | Releases excess air for efficient functioning. |

Maintenance Tips

To ensure longevity and reliability, regular inspection and upkeep of these components are essential. Addressing wear and tear promptly can prevent further damage and enhance the tool’s performance.

Understanding the Parts Diagram

Comprehending the layout of components within a tool is essential for effective maintenance and troubleshooting. This section will provide insights into how to interpret the visual representation of various elements, ensuring a clearer understanding of their functions and interrelations.

Key Components Overview

Familiarizing oneself with the primary elements illustrated in the layout allows users to identify necessary parts during repairs or replacements. Each section usually highlights specific functionalities that contribute to the overall operation of the equipment.

How to Utilize the Visual Representation

To effectively utilize the visual representation, one must approach it methodically. Begin by locating the component of interest, then examine its connections and relationships with adjacent parts. This can aid in diagnosing issues and facilitating proper reassembly.

| Component | Description |

|---|---|

| Housing | The outer shell that protects internal components. |

| Trigger Mechanism | Controls the activation of the tool. |

| Pneumatic Cylinder | Generates the necessary force for operation. |

| Safety Features | Prevents accidental activation and ensures user safety. |

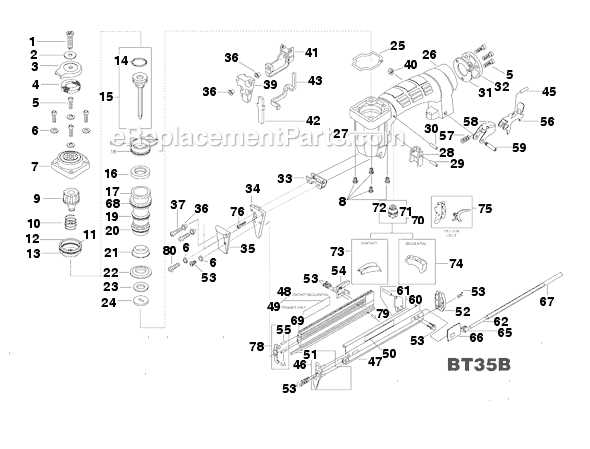

How to Use the Diagram

This section provides guidance on how to effectively utilize a visual representation of components for better understanding and maintenance of your equipment. A well-structured illustration can significantly simplify the process of identifying and replacing various elements within the tool.

Understanding the Components

Begin by familiarizing yourself with the key elements represented in the visual aid. Each section typically corresponds to a specific area of the device, making it easier to locate parts and understand their functions.

Step-by-Step Replacement Process

Follow these steps to ensure a smooth replacement experience:

| Step | Description |

|---|---|

| 1 | Identify the component you need to replace using the illustration. |

| 2 | Gather the necessary tools and new parts based on your findings. |

| 3 | Refer back to the visual to ensure correct installation of the new part. |

| 4 | Test the equipment to confirm proper functionality after replacement. |

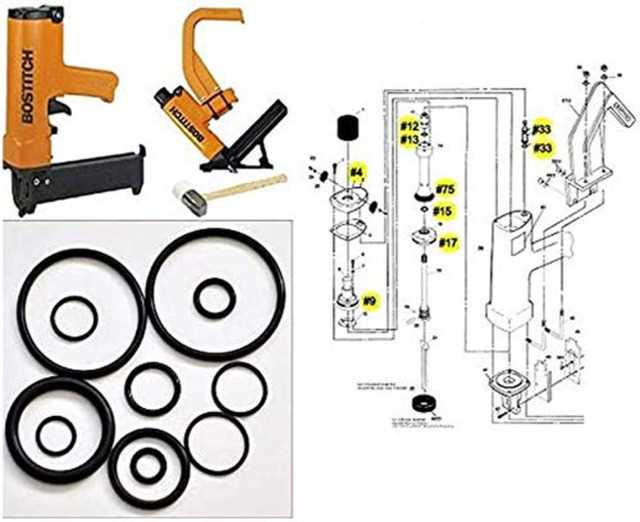

Common Replacement Parts

Maintaining tools requires understanding which components are frequently subject to wear and tear. Knowing these elements can help ensure your equipment operates smoothly and efficiently.

One of the most commonly replaced items is the trigger mechanism, which can become less responsive over time. Additionally, seals and gaskets often need replacement to prevent leaks and maintain optimal performance. The magazine is another crucial component, as it can wear down with repeated use, impacting loading and firing capabilities.

Springs play an essential role in the overall functionality, and replacing them can enhance tool reliability. Lastly, drivers and nose assemblies may require attention, especially if they show signs of damage or wear. Keeping these components in good condition ensures the longevity and efficiency of your tool.

Troubleshooting Common Issues

When using your tool, you may encounter various challenges that can hinder performance. Understanding these common problems and their potential solutions can help you maintain efficiency and extend the lifespan of your device.

Here are some typical issues and ways to address them:

- Device Not Powering On:

- Check the power source to ensure it is functioning properly.

- Inspect the battery for any signs of damage or depletion.

- Verify all connections are secure.

- Jamming:

- Ensure the loading mechanism is properly aligned.

- Clear any debris or obstructions in the feed path.

- Regularly clean and lubricate moving parts to prevent sticking.

- Inconsistent Performance:

- Check the material being used to ensure compatibility with the device.

- Inspect for wear and tear on the internal components.

- Adjust settings as needed to optimize operation.

By following these guidelines, you can effectively troubleshoot and resolve common issues that may arise, ensuring optimal performance and reliability.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your equipment. By following a few straightforward guidelines, you can enhance its lifespan and maintain optimal performance.

Regular Cleaning

- Remove dust and debris from the exterior regularly.

- Use a soft cloth to wipe down surfaces, ensuring that no particles are left behind.

- Check and clear any build-up around moving parts to prevent malfunction.

Lubrication Practices

- Apply lubricant to all necessary components as per the manufacturer’s recommendations.

- Ensure that you use the right type of lubricant for specific areas.

- Regularly inspect for any signs of wear or tear, addressing issues promptly.

Tools Needed for Repairs

When undertaking maintenance or restoration tasks on equipment, having the right tools at hand is essential for efficiency and effectiveness. The correct instruments not only streamline the process but also enhance safety while working.

Basic Tools: A set of standard hand tools is fundamental. This typically includes a screwdriver set, pliers, and wrenches of various sizes. These items are crucial for loosening or tightening fasteners.

Specialty Tools: Depending on the complexity of the repair, specific tools may be required. For instance, a torque wrench ensures that components are secured to the manufacturer’s specifications.

Safety Equipment: Personal protective gear such as gloves and safety goggles should never be overlooked. They are vital in preventing injuries during any repair work.

Gathering these tools prior to starting repairs will help ensure a smooth and successful process.

Where to Buy Replacement Parts

Finding suitable components for your equipment is crucial for maintaining its efficiency and longevity. There are several reliable sources where you can acquire these necessary items, ensuring your tools continue to operate at their best.

Consider the following options for purchasing your required items:

- Manufacturer’s Website: Visiting the official site of the brand often provides access to a complete range of components and helpful resources.

- Authorized Retailers: Look for stores that are recognized by the manufacturer. They usually carry genuine items and can offer expert advice.

- Online Marketplaces: Websites like Amazon, eBay, and others can be excellent platforms to find various components, often at competitive prices.

- Local Hardware Stores: Neighborhood shops may stock common items or can order them for you, providing the advantage of immediate availability.

- Specialized Repair Shops: Some businesses specialize in repairing tools and may have a selection of components on hand or can source them for you.

Before making a purchase, ensure to verify the compatibility of the components with your specific equipment model. This will help avoid any issues during installation and use.

Compatibility with Other Models

Understanding the interchangeability of components across various devices is crucial for users looking to enhance their equipment’s functionality. This section explores how certain elements can be used across different models, ensuring versatility and efficiency in repairs and maintenance.

Shared Components and Features

Many devices in the same category share similar components, which allows for greater flexibility when sourcing replacements. Common features often include fasteners, triggers, and power mechanisms that can be utilized interchangeably, providing users with more options during repairs.

Considerations for Compatibility

When assessing compatibility, it is essential to consider the specifications and design of each model. Variations in size, power requirements, and material composition can affect performance. Therefore, always refer to user manuals and manufacturer guidelines to ensure optimal functionality.

Assembly Instructions for BT1855

Proper assembly is crucial for the efficient operation of your device. This section outlines the necessary steps to ensure all components are correctly put together for optimal performance.

Required Tools

- Screwdriver

- Wrench

- Pliers

- Safety goggles

Assembly Steps

- Begin by gathering all components and tools in a well-lit workspace.

- Refer to the instruction manual for the layout of each part.

- Start with the base unit and secure it using screws provided.

- Attach the main assembly to the base, ensuring all connections are tight.

- Connect any additional components, following the manual for guidance.

- Double-check all connections and screws for security.

- Once assembled, test the unit for proper functionality.

By following these instructions carefully, you can achieve a fully functional assembly that meets your expectations.

Safety Precautions When Repairing

When undertaking maintenance or repair tasks, ensuring personal safety and preventing accidents should be a top priority. Awareness of potential hazards and taking the necessary precautions can significantly reduce the risk of injury and equipment damage.

Personal Protective Equipment

Always wear appropriate protective gear, including safety goggles, gloves, and ear protection. This equipment helps shield against debris, sharp edges, and loud noises that may arise during repair activities.

Workspace Organization

Maintain a clean and organized workspace to minimize hazards. Ensure tools and materials are easily accessible and free from clutter, which can help prevent accidents and enhance efficiency during the repair process.

Frequently Asked Questions

This section addresses common inquiries related to the tool’s components and maintenance. Understanding these aspects can enhance the user experience and ensure optimal performance.

Common Issues and Solutions

Users often encounter various challenges while utilizing their equipment. Here are some typical problems and their corresponding resolutions:

| Issue | Solution |

|---|---|

| Tool not functioning | Check power source and connections. |

| Inconsistent performance | Inspect for debris and clean as needed. |

| Components wearing out | Refer to maintenance schedule for replacements. |

Replacement Parts Availability

For those looking to replace components, various options exist for sourcing replacements. Ensure to check compatibility before purchasing.