In the world of mechanical devices, comprehending the intricate assembly of individual elements is crucial for optimal performance and maintenance. Each component plays a specific role, contributing to the overall functionality of the equipment. Whether you’re a professional craftsman or a weekend hobbyist, familiarizing yourself with these parts can enhance your experience and efficiency.

Identifying the elements within your tool not only aids in troubleshooting but also empowers you to perform routine checks and repairs. A comprehensive visual reference can simplify this process, allowing you to pinpoint any issues with ease. With an organized breakdown of each section, users can quickly locate what they need to ensure their machinery runs smoothly.

Moreover, understanding the assembly can facilitate better decision-making when it comes to upgrades or replacements. Knowledge of the various components opens up a world of possibilities for customization and enhancement, ultimately leading to improved performance. Whether you’re looking to extend the life of your device or enhance its capabilities, a clear overview of its makeup is essential.

Bostitch N66C Overview

This section provides an insightful look into a well-regarded fastening tool that has become essential for various construction and woodworking applications. Known for its reliability and efficiency, this device is designed to streamline the process of securing materials together, making it a favorite among professionals and DIY enthusiasts alike.

Engineered with precision, this tool boasts a robust build that ensures durability under demanding conditions. Its ergonomic design enhances user comfort, allowing for prolonged use without fatigue. The innovative mechanism facilitates quick adjustments, enabling users to switch between different fastening tasks effortlessly.

With a reputation for high performance, this tool delivers consistent results, ensuring that projects are completed to a high standard. The versatility it offers makes it suitable for a wide range of materials, making it an indispensable asset for any toolkit.

In summary, this fastening solution exemplifies a blend of functionality and user-friendly features, solidifying its place in both professional and home settings. Its continued popularity speaks volumes about its effectiveness and the value it brings to various tasks.

Key Features of Bostitch N66C

This section explores the essential characteristics of a popular fastening tool, emphasizing its unique design and functionality that cater to various construction needs.

- Lightweight and ergonomic design for enhanced user comfort.

- Durable construction materials ensuring long-lasting performance.

- Adjustable depth control for precise fastening in different materials.

- Quick-load magazine for efficient and uninterrupted operation.

- Versatile capabilities allowing for use with various fasteners.

These features make this tool an ultimate choice for both professionals and DIY enthusiasts, ensuring reliable performance in diverse applications.

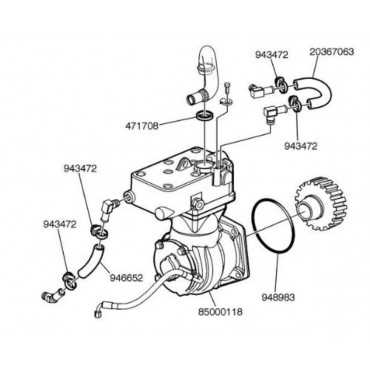

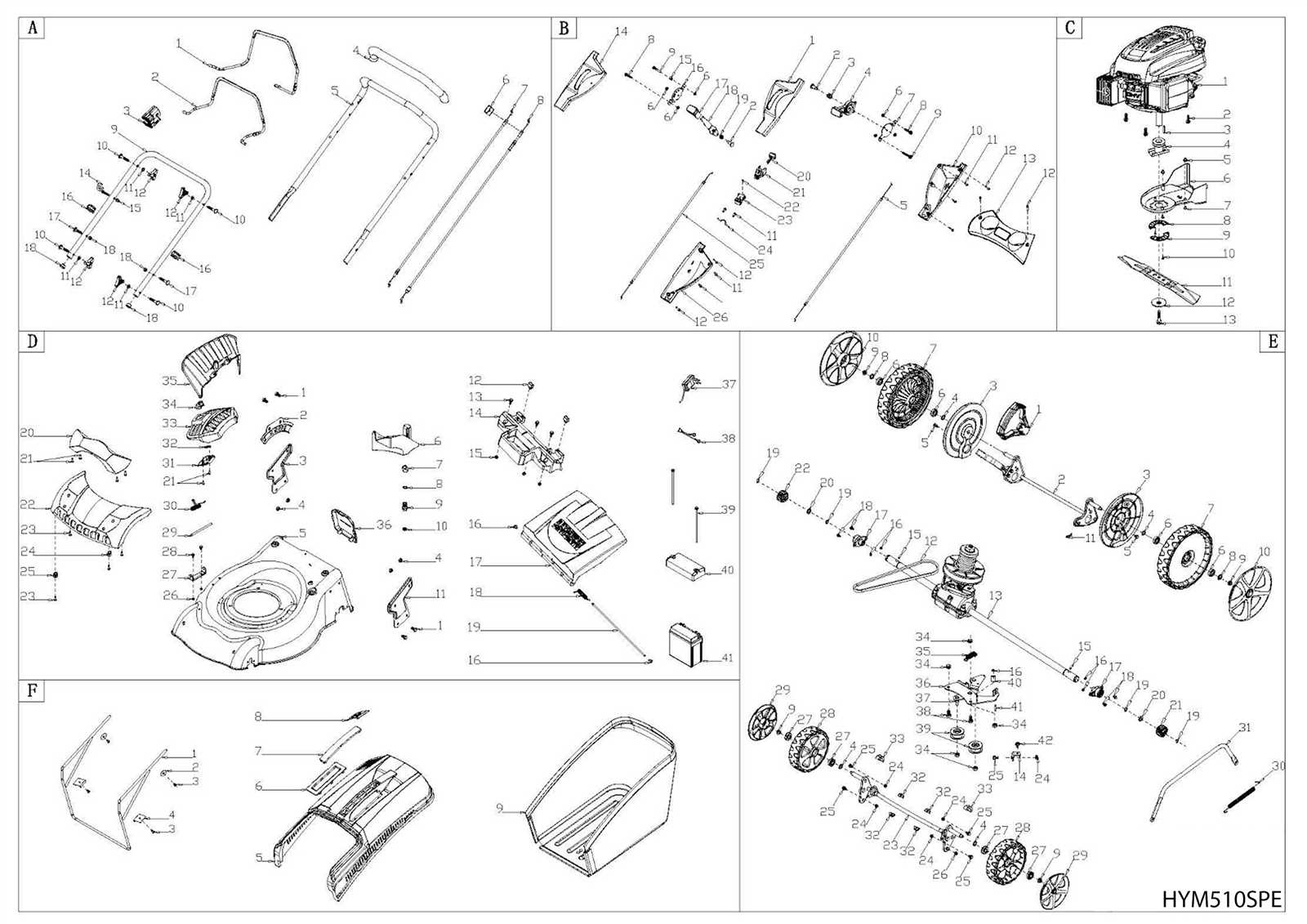

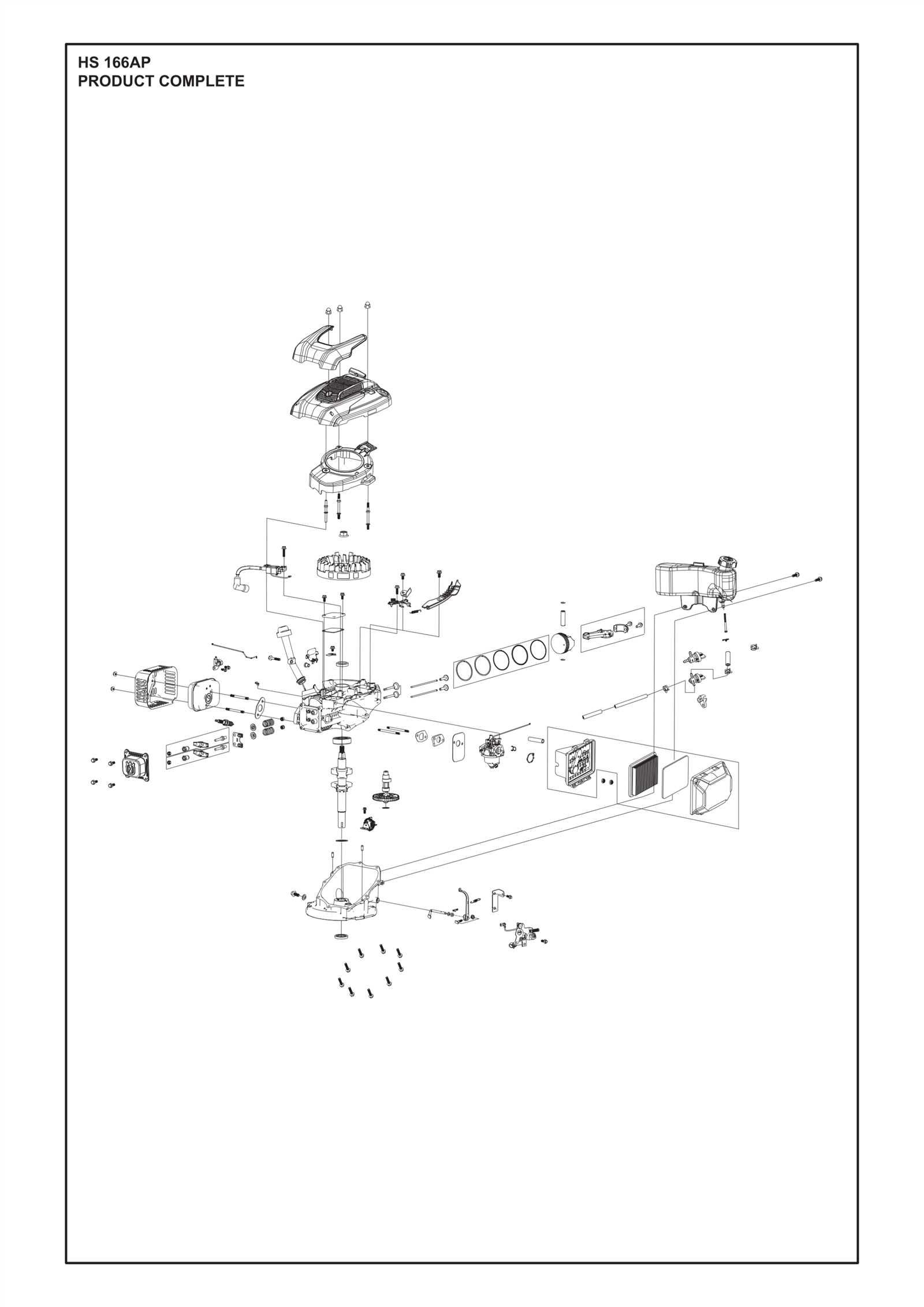

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repairs. Visual representations provide clarity, ensuring that each element is easily identified and understood. This fosters a more efficient workflow and minimizes errors during assembly or disassembly.

Benefits of Visual Representation

- Enhances comprehension of complex structures.

- Facilitates quicker troubleshooting and repair processes.

- Assists in inventory management by clearly indicating required components.

Impact on Maintenance Practices

- Reduces downtime through swift identification of issues.

- Promotes accurate reassembly, preventing future malfunctions.

- Encourages proactive maintenance by highlighting wear-prone areas.

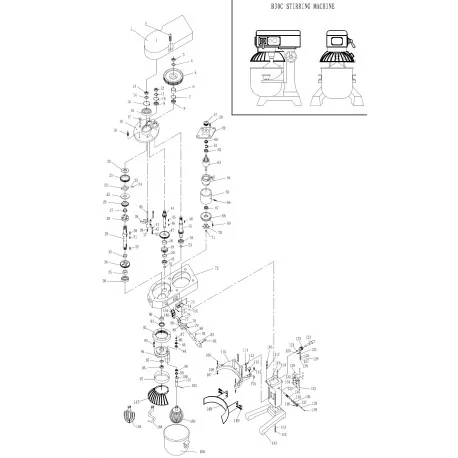

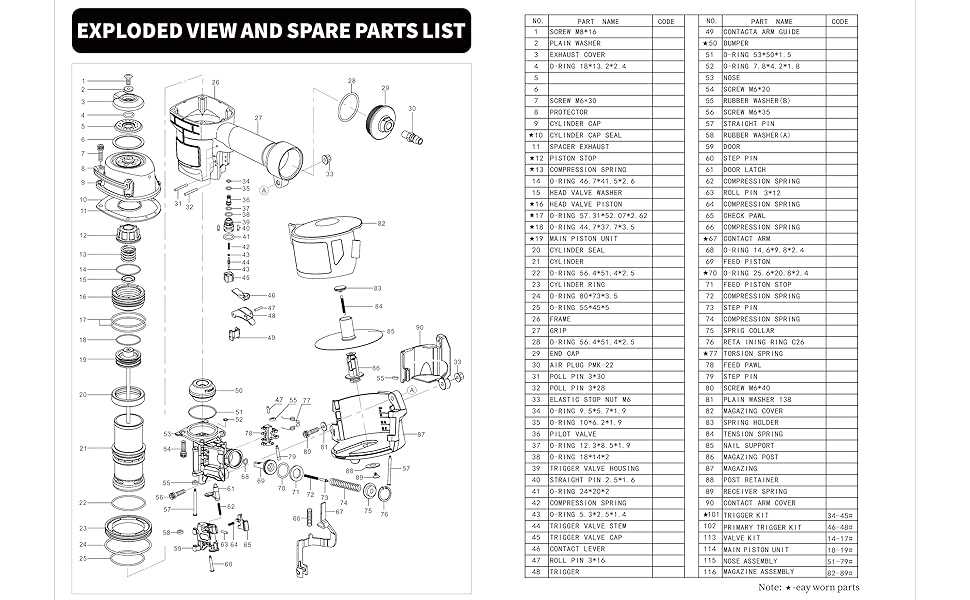

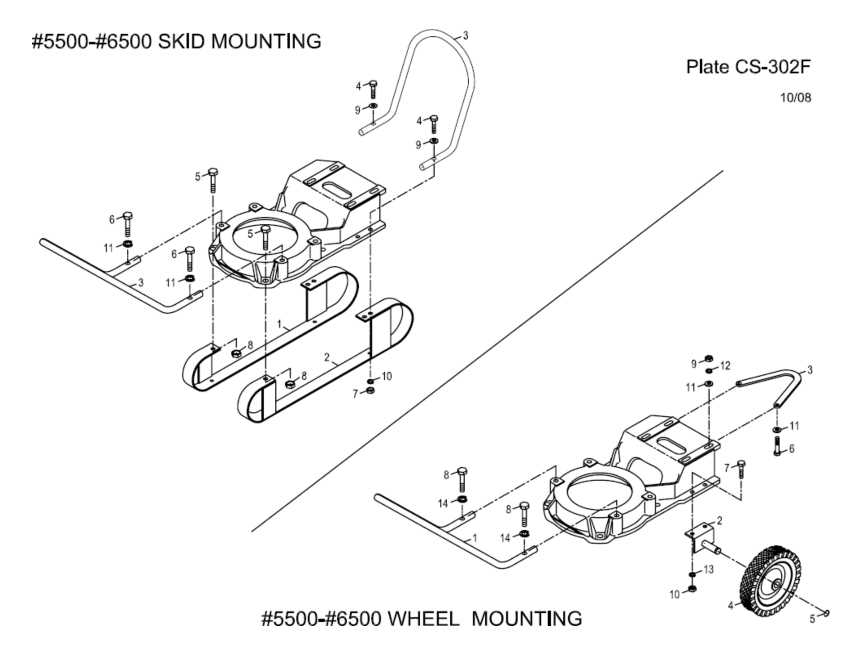

Understanding Bostitch N66C Components

Grasping the intricacies of a fastening tool’s elements is essential for effective maintenance and optimal performance. Each component plays a crucial role in ensuring that the device operates smoothly and efficiently. By familiarizing oneself with these parts, users can enhance their understanding of the tool’s functionality and troubleshoot issues as they arise.

Main Components Overview

The functionality of a fastening device hinges on several key elements. Each part is designed to contribute to the overall performance and reliability of the tool. Recognizing these components will aid in efficient usage and maintenance.

| Component | Function |

|---|---|

| Magazine | Holds and feeds fasteners into the mechanism. |

| Trigger | Initiates the fastening process when pressed. |

| Motor | Drives the mechanism to deploy fasteners. |

| Guide | Ensures accurate placement of fasteners. |

| Housing | Protects internal components and provides stability. |

Importance of Regular Maintenance

Maintaining the integrity of these components is vital for prolonged use. Regular inspection and cleaning can prevent malfunctions and enhance performance. Understanding how each part functions allows users to identify potential issues early, ensuring the tool remains in optimal condition.

Common Issues with Bostitch N66C

Tools that are designed for specific tasks often encounter a range of challenges that can hinder performance. Understanding these frequent problems can aid users in maintaining efficiency and prolonging the lifespan of their equipment.

Misfires are one of the most prevalent issues, where the tool fails to drive fasteners properly. This can be due to insufficient power or misalignment of the components.

Jamming is another common concern. Fasteners may get stuck in the feed mechanism, which often requires careful disassembly to resolve. Regular cleaning and maintenance can help prevent this from occurring.

Inconsistent depth adjustment can also be frustrating, as it leads to uneven results. Ensuring that the depth settings are properly calibrated before use is essential for optimal performance.

Lastly, air leaks may affect the tool’s efficiency, causing it to lose power. Regular inspection of hoses and fittings can mitigate this issue, ensuring a reliable operation.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your tools requires consistent care and attention. Regular maintenance not only enhances performance but also extends the lifespan of your equipment. By following some straightforward guidelines, you can keep your tools in excellent working condition.

- Regular Cleaning: Keep your tools free from dust and debris. Use a soft brush or cloth to remove any buildup after each use.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and wear. Check the manufacturer’s recommendations for suitable products.

- Inspection: Periodically check for signs of damage or wear. Look for cracks, loose components, or any unusual noises during operation.

- Proper Storage: Store tools in a dry, cool place. Use protective cases or racks to prevent accidental damage.

Implementing these practices can significantly contribute to the longevity of your equipment, ensuring it performs optimally for years to come.

Where to Find Parts Diagrams

Locating visual guides for mechanical components can significantly enhance the efficiency of repairs and maintenance. These resources provide a detailed view of individual elements, enabling users to understand assembly and disassembly processes more effectively. With the right illustrations, you can easily identify necessary components and ensure a seamless repair experience.

Official Manufacturer Websites

The primary source for accurate and detailed illustrations is the official website of the manufacturer. Most companies provide comprehensive resources that include high-quality visuals and descriptions of their products. Visiting these sites can lead you to user manuals and schematics that are specifically designed for each model.

Online Repair Forums and Communities

Engaging with online communities can also yield valuable insights. Many enthusiasts and professionals share their experiences and resources on various forums. Websites dedicated to repairs often have sections where users upload and discuss guides, making it easier to find the visual references you need.

In summary, whether you seek manufacturer resources or insights from fellow users, there are numerous avenues to obtain valuable visual aids for your repair tasks.

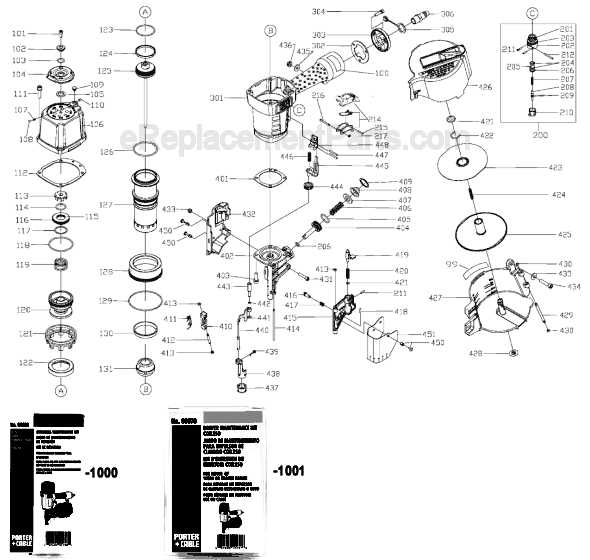

Interpreting the Parts Diagram

Understanding the components layout is crucial for effective maintenance and troubleshooting. Each element plays a specific role, and recognizing their positions and functions can streamline repairs and enhance performance.

Key Elements to Focus On

When examining the visual representation, pay attention to the labeling system used. This helps identify various pieces, their connections, and potential issues that may arise.

Common Symbols and Notations

| Symbol | Description |

|---|---|

| ▲ | Indicates a critical component that requires special attention. |

| ⚙️ | Represents moving parts that may need lubrication or replacement. |

| ✏️ | Denotes areas where adjustments can be made for better functionality. |

Replacement Parts for Bostitch N66C

When it comes to maintaining your essential fastening tool, ensuring that every component functions seamlessly is crucial. Over time, wear and tear can affect performance, making it necessary to identify and procure the right replacements. This section will guide you through the various options available to restore your device to its ultimate efficiency.

Identifying Essential Components

Understanding the key elements of your tool is vital for effective replacements. Common components include the drive mechanism, nosepiece, and magazine. Each part plays a significant role in the overall operation, and recognizing signs of damage or malfunction will help you pinpoint which elements need attention.

Where to Source Quality Replacements

Quality is paramount when sourcing new components. Authorized dealers and reputable online retailers often provide authentic replacements that guarantee optimal compatibility and performance. Consider exploring user reviews and recommendations to ensure that you make informed decisions.

Tools Needed for Repair

Effective restoration of equipment requires a selection of essential instruments to ensure a smooth process. Having the right tools on hand not only facilitates efficiency but also enhances the overall quality of the repairs.

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening and tightening screws. |

| Pliers | For gripping, twisting, and cutting wire. |

| Wrench | To adjust and tighten nuts and bolts. |

| Replacement Parts | To substitute damaged or worn components. |

| Measuring Tape | For accurate measurements during repairs. |

Step-by-Step Repair Guide

This guide provides a systematic approach to fixing common issues encountered with fastening tools. Whether you’re dealing with a jam, malfunction, or wear, following these steps can help restore your equipment to optimal working condition.

Identifying the Problem

The first step in any repair process is diagnosing the issue. Observe the tool’s behavior closely. Is it failing to engage, producing unusual noises, or not firing at all? Documenting the symptoms will assist in determining the necessary actions to take.

Disassembly and Inspection

Carefully disassemble the unit using the appropriate tools. Ensure you keep track of all components. Inspect each part for damage or wear, focusing on areas that frequently experience stress. Look for broken springs, obstructions, or any debris that may impede function. Once you identify the faulty parts, you can proceed to replace or repair them as needed.

Professional vs. DIY Repairs

When it comes to fixing tools, there are two primary approaches: hiring a specialist or tackling the task yourself. Each method has its own set of advantages and potential drawbacks, depending on the situation and the individual’s skill level.

Choosing a professional service offers several benefits:

- Expertise in handling complex issues.

- Access to specialized tools and equipment.

- Time-saving, especially for intricate repairs.

On the other hand, DIY repairs can be appealing for various reasons:

- Cost-effectiveness by avoiding service fees.

- Personal satisfaction and skill development.

- Flexibility in timing and approach.

Ultimately, the decision hinges on the severity of the problem, available resources, and personal comfort with repair tasks. Assessing these factors can help determine the best path forward.

Upgrading Your Bostitch N66C

Enhancing your tool’s performance can significantly improve efficiency and effectiveness in your projects. By incorporating new components and optimizing existing features, you can transform a standard device into a powerhouse tailored to your specific needs. This section will explore various ways to elevate your equipment, ensuring it meets the demands of both professional and personal tasks.

Key Components to Consider

Focus on upgrading critical elements such as the firing mechanism and the air supply system. These enhancements can lead to increased reliability and faster operation. Additionally, consider replacing any worn-out pieces with higher-quality alternatives to improve durability and performance over time.

Maintenance Tips for Longevity

Regular upkeep is essential for maximizing the lifespan of your tool. Ensure that all moving parts are well-lubricated and free from debris. Perform routine checks on seals and connections to prevent air leaks, which can compromise efficiency. Investing time in maintenance will yield better results and save costs in the long run.