Exploring the intricacies of essential office equipment unveils a world of functionality and design. This examination provides valuable insights into the various elements that contribute to the overall efficiency and usability of these devices. Gaining a deeper understanding of these components can enhance one’s ability to select, maintain, and effectively utilize them in everyday tasks.

Familiarity with the individual elements enhances the appreciation of how they work together to achieve seamless operation. Recognizing each component’s role aids in troubleshooting common issues and empowers users to extend the lifespan of their tools. Through this exploration, one can uncover the significance of proper assembly and maintenance, ensuring optimal performance in various applications.

By delving into the specific characteristics and functions of each part, users can equip themselves with the knowledge necessary for informed decision-making. Whether considering repairs or upgrades, this understanding lays the foundation for more effective engagement with essential office machinery, fostering both productivity and satisfaction.

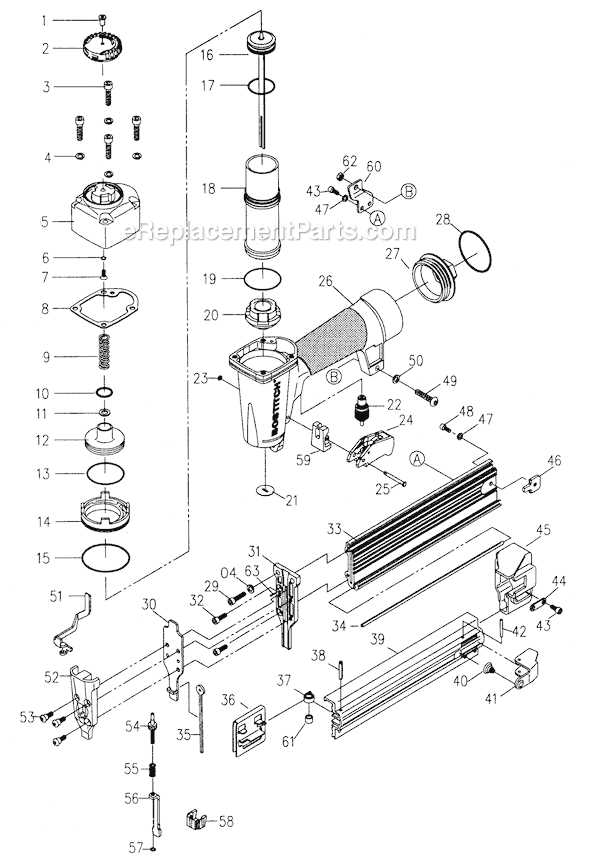

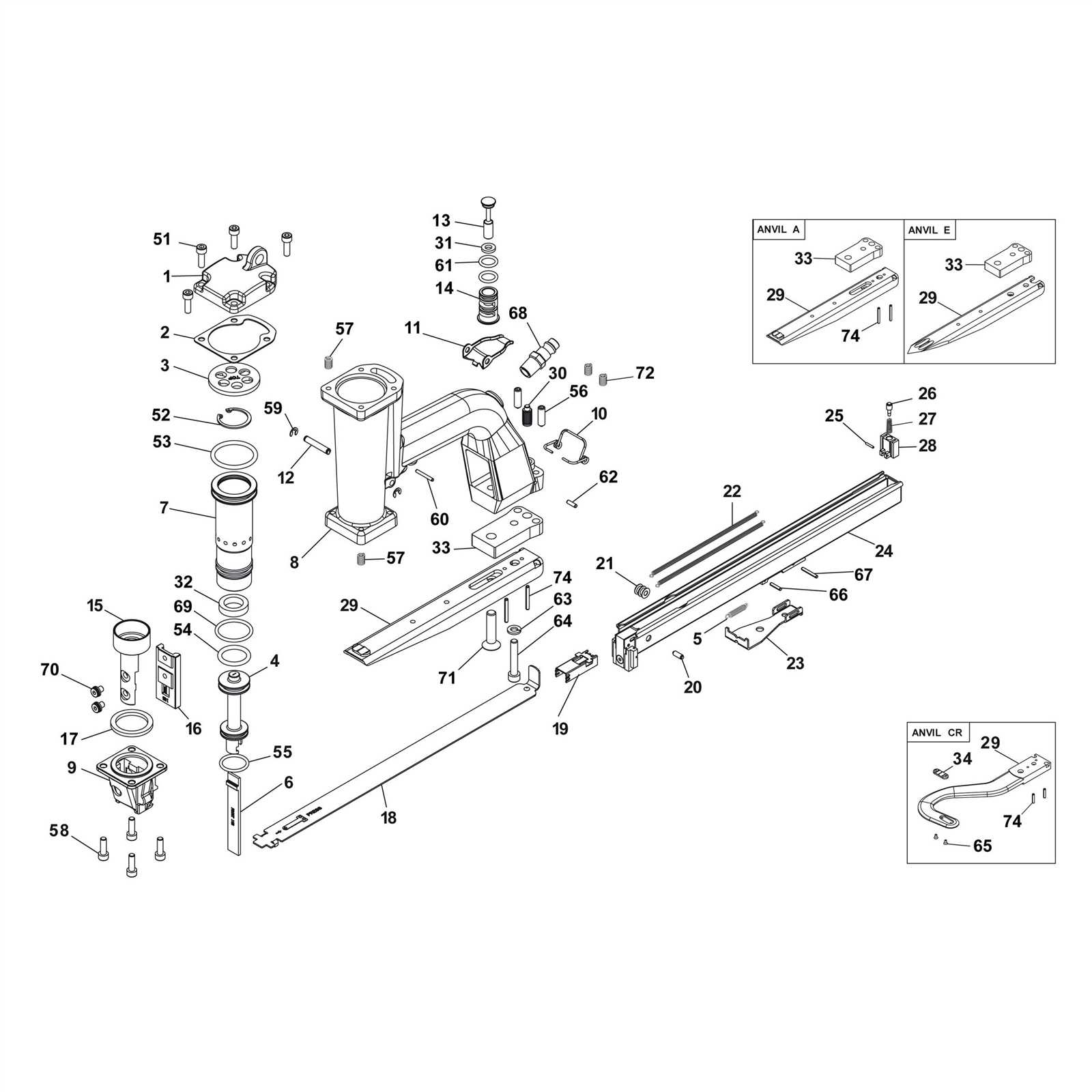

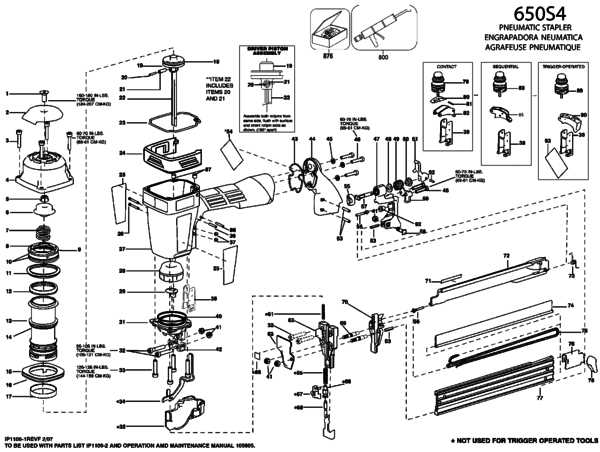

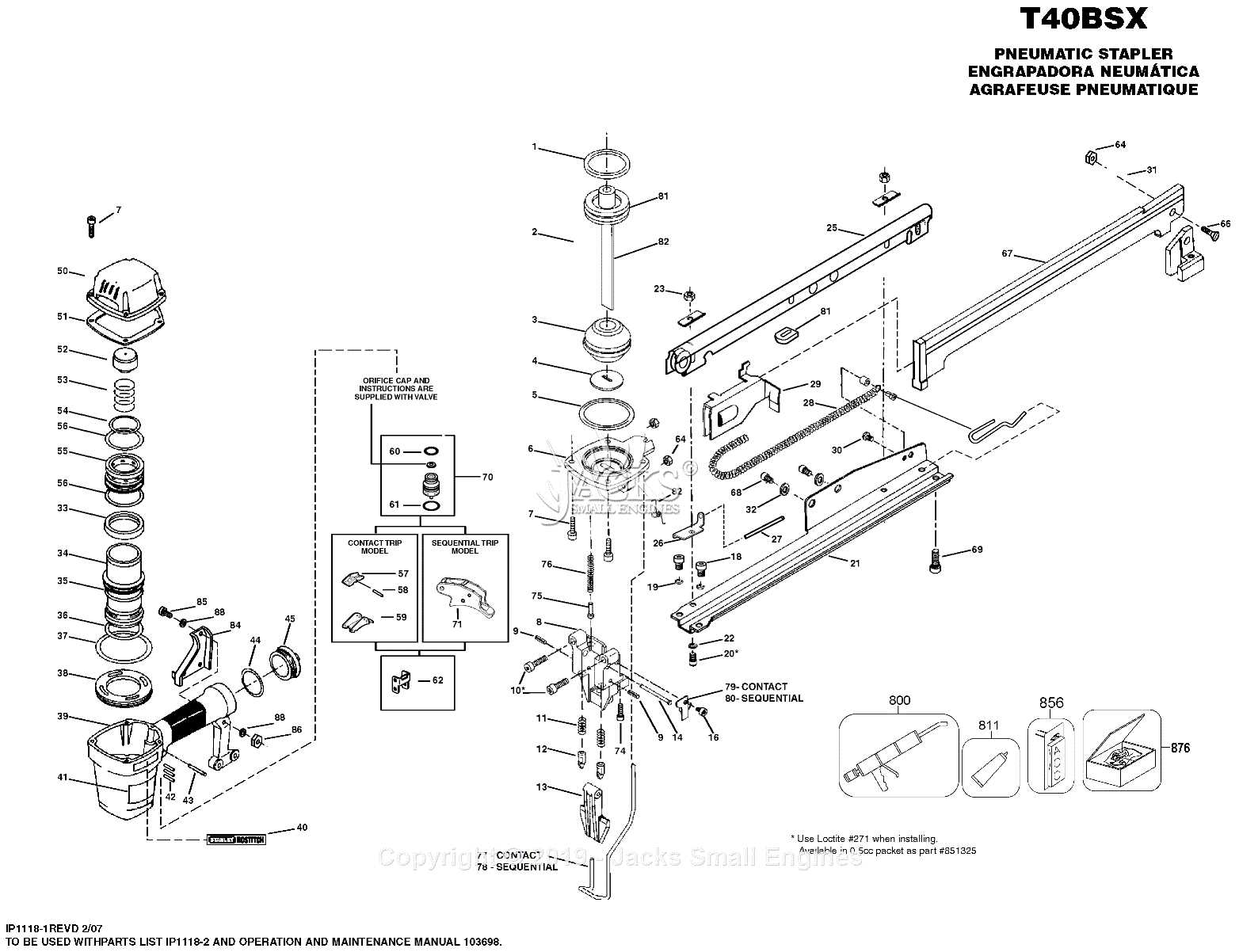

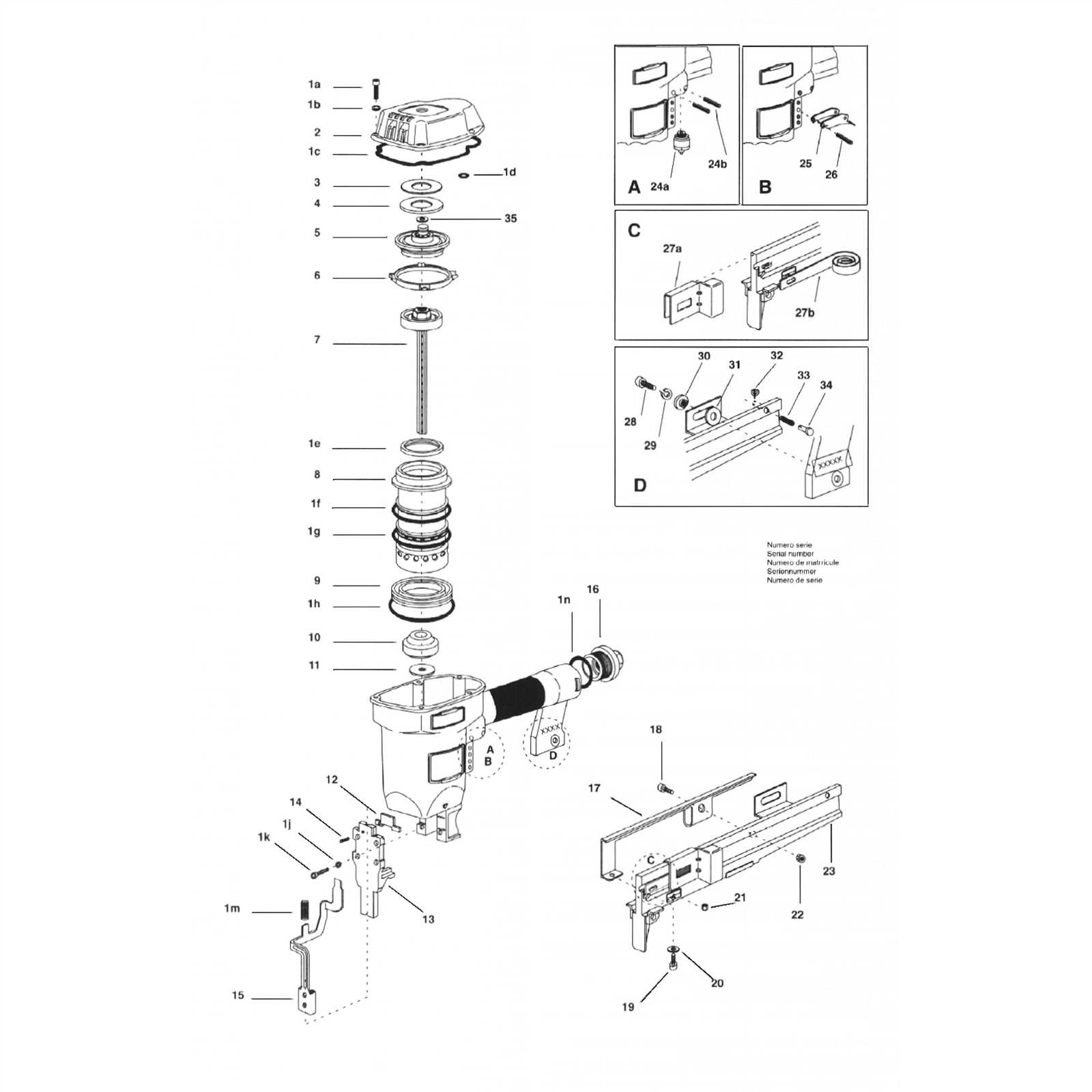

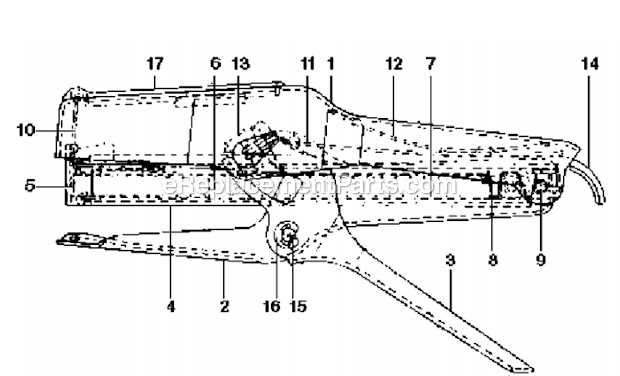

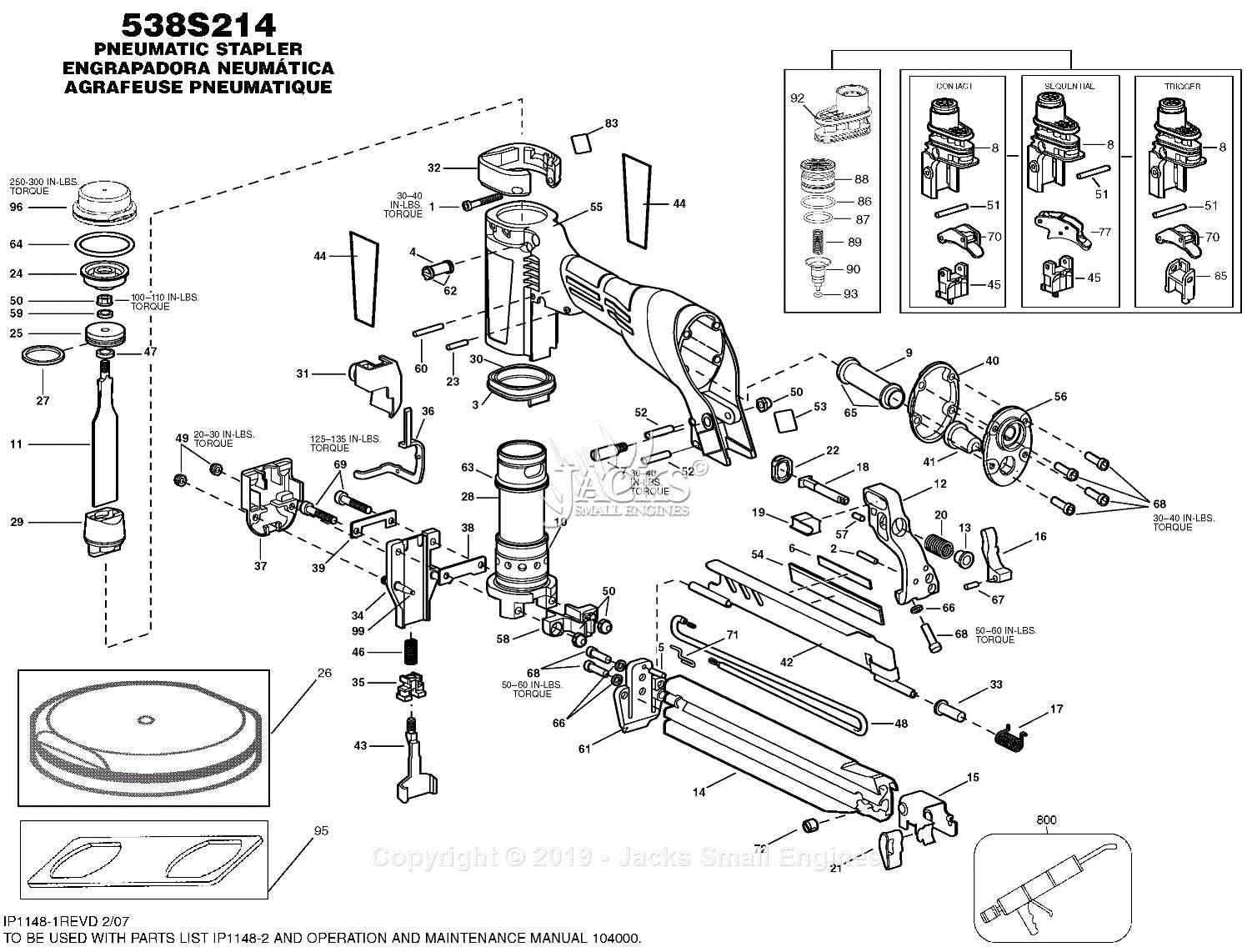

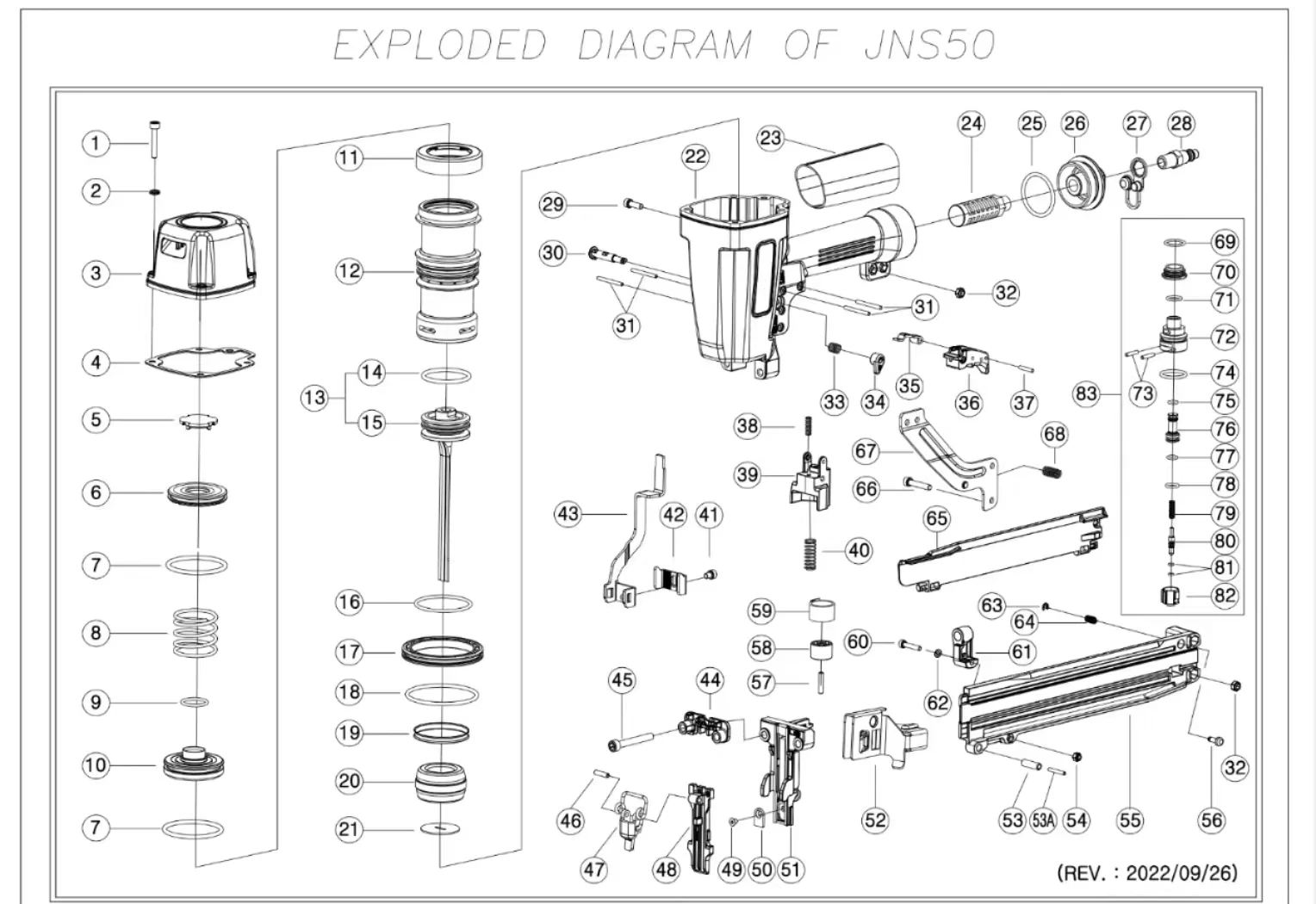

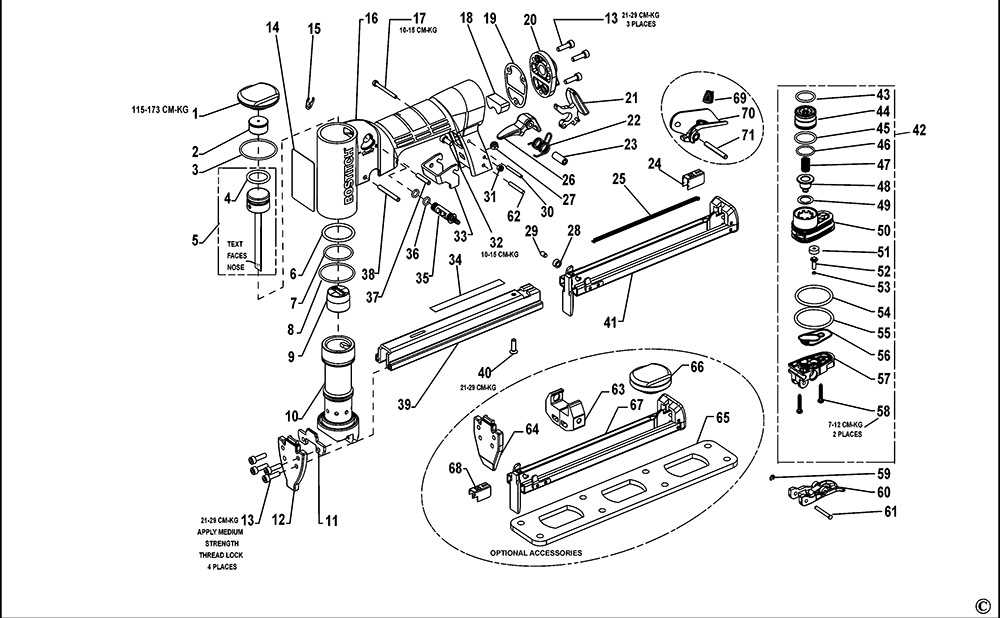

This section delves into the essential components of a fastening device, exploring their functions and interactions. Understanding these elements is crucial for anyone looking to enhance their knowledge of how these devices operate and maintain efficiency in their tasks.

| Component Name | Description |

|---|---|

| Base | The sturdy foundation that supports the entire assembly. |

| Handle | The lever used to initiate the fastening process, providing leverage for efficient operation. |

| Slide Mechanism | Facilitates the movement of fasteners from the magazine to the point of application. |

| Magazine | The compartment that holds the fasteners, ensuring a steady supply during use. |

| Driver Blade | A critical component that pushes the fastener into the material being secured. |

| Spring | Provides the necessary tension to return the mechanism to its starting position after use. |

| Adjustment Knob | Allows users to modify the depth of the fastener based on material thickness. |

| Safety Mechanism | Prevents accidental activation, ensuring user safety during operation. |

| Release Button | Enables the removal of jammed fasteners and maintenance access. |

| Cover | Protects internal components from dust and damage, maintaining the device’s functionality. |

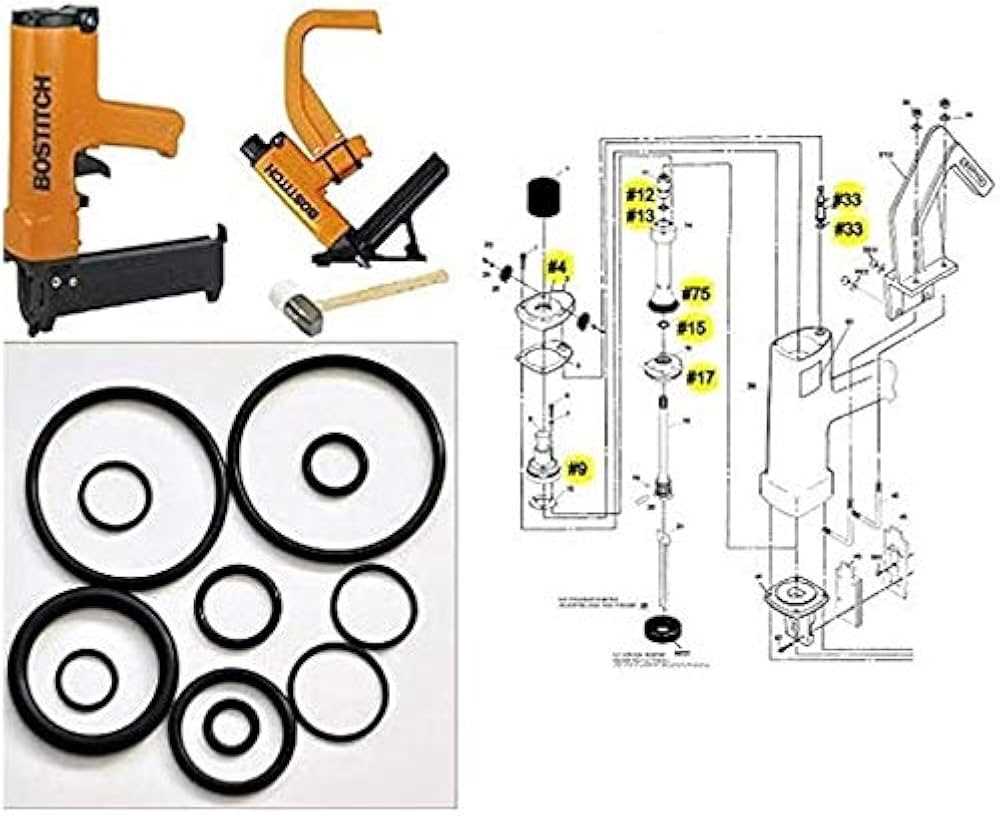

Key Components of Bostitch Models

Understanding the essential elements of these fastening devices is crucial for effective use and maintenance. Each model comprises a variety of crucial features that enhance functionality and performance. Recognizing these components can aid in selecting the appropriate device for specific tasks, as well as troubleshooting any issues that may arise.

Drive Mechanism: This is the core system that propels the fasteners into the material. A reliable mechanism ensures consistent performance and reduces the risk of jams.

Loading Chamber: This area is designed for inserting the fasteners. An easy-to-access loading chamber facilitates quick refills, allowing users to maintain workflow without interruptions.

Handle: The ergonomically designed handle provides comfort and grip during operation. A well-constructed handle minimizes user fatigue, making extended use more manageable.

Safety Features: Many models incorporate mechanisms to prevent accidental firing. These enhancements ensure user safety while allowing for precise application.

Base Plate: The sturdy base plate offers stability during use and protects surfaces from damage. A robust plate can also enhance the accuracy of fastening.

Adjustable Depth Control: This feature allows users to modify the depth at which the fastener is driven. It ensures optimal performance across various materials, accommodating specific project requirements.

Types of Fastening Devices Available

In the world of fastening solutions, a variety of tools and mechanisms are designed to secure materials together efficiently. Each type serves a specific purpose and caters to different applications, making them indispensable in various industries.

Mechanical Fasteners are widely utilized for their reliability and ease of use. These include devices such as screws, bolts, and nuts, which offer strong hold and can be easily removed or adjusted when necessary.

Adhesive Solutions provide an alternative for joining surfaces without the need for visible hardware. These products, which include glues and tapes, create bonds that can be permanent or temporary, depending on the requirements of the task.

Compression Fasteners, like clamps and clips, are particularly effective for holding objects in place under pressure. They are often employed in applications where quick assembly and disassembly are required.

Lastly, Pneumatic and Electric Tools have revolutionized fastening methods by introducing powered devices that enhance speed and efficiency. These machines simplify the fastening process and reduce manual effort, making them essential in high-volume environments.

How to Maintain Your Stapler

Proper upkeep of your fastening device ensures its longevity and efficient performance. Regular maintenance can prevent issues such as jamming and misalignment, allowing for seamless use. Here are some essential practices to keep your device in top condition.

- Keep It Clean: Regularly remove any debris or residue that accumulates in the mechanism. Use a soft cloth or compressed air to clear out dust and staples.

- Check for Damage: Inspect the device for any signs of wear or damage. Pay attention to springs and moving parts to ensure they function smoothly.

- Lubricate Moving Parts: Apply a small amount of lubricant to the moving components to ensure smooth operation. Avoid over-lubricating, as this can attract dirt.

- Use the Correct Fasteners: Always use the recommended fastening supplies designed for your model. Incorrect supplies can cause jams and reduce efficiency.

By following these simple guidelines, you can extend the lifespan of your fastening tool and maintain its performance for all your binding needs.

Identifying Common Issues and Fixes

Understanding frequent challenges that can arise with these devices is essential for maintaining their functionality. By recognizing symptoms and knowing how to address them, users can ensure efficient operation and prolong the life of their tools.

- Misalignment of Fasteners: If the mechanism is not feeding correctly, it may lead to uneven application. Check for any obstructions or debris in the loading area.

- Jammed Mechanism: A common issue that can disrupt workflow. Open the casing to clear any stuck materials, and ensure the mechanism moves freely.

- Inconsistent Pressure: If the application lacks strength, inspect the tension settings. Adjust as necessary to achieve optimal performance.

- Excessive Noise: Unusual sounds may indicate wear or insufficient lubrication. Apply appropriate lubricant to moving parts to minimize friction.

Regular maintenance and awareness of these potential problems will significantly enhance the reliability and effectiveness of the device.

Tools Needed for Repairs

Proper maintenance and repair of your device require specific implements to ensure effectiveness and safety. Having the right tools on hand not only streamlines the repair process but also minimizes the risk of damage to the equipment. This section outlines essential items that are beneficial for tackling various repair tasks efficiently.

Basic Hand Tools

To begin, a set of basic hand tools is crucial. These typically include a screwdriver set, which should encompass both flathead and Phillips types. Additionally, a pair of pliers is essential for gripping and manipulating small components. A wrench can also prove useful for loosening or tightening any nuts or bolts that may be present.

Specialized Equipment

In some cases, having specialized equipment can make a significant difference. For instance, a torque wrench is invaluable when precision is required to avoid over-tightening. Furthermore, an electric drill can expedite the process, particularly when handling multiple screws. Lastly, a magnifying glass can assist in examining small parts and ensuring everything is in good condition before reassembly.

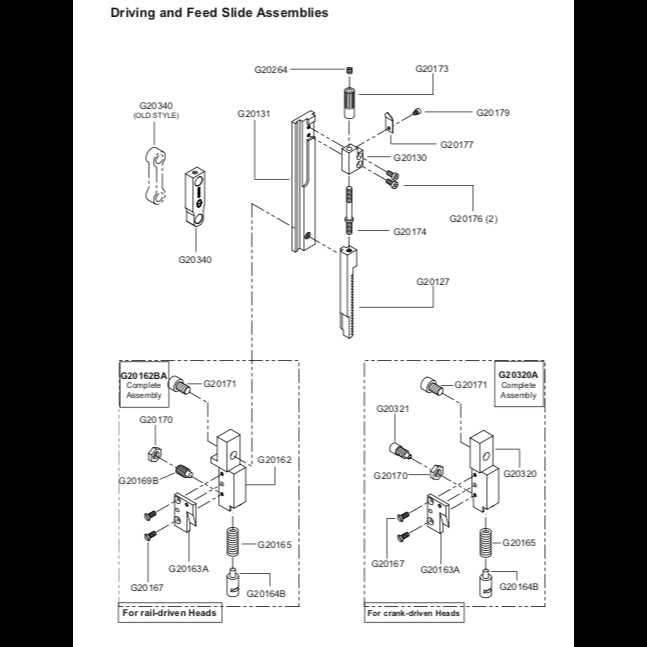

Steps for Disassembling a Stapler

Understanding how to take apart a fastening device can be useful for maintenance and repairs. The process involves a series of careful actions to ensure that each component is handled appropriately. Below are the essential steps to follow for a successful disassembly.

Preparation

- Gather necessary tools, such as a screwdriver and a small container for screws.

- Choose a clean, flat workspace to prevent losing any small parts.

- Ensure the device is empty of any fasteners before beginning.

Disassembly Process

- Locate and remove any screws that hold the exterior casing together.

- Carefully separate the top and bottom sections, being cautious not to damage any clips.

- Inspect the internal mechanisms, noting their arrangement for reassembly.

- Detach any additional components, such as springs or levers, as needed.

- Place all parts in the container to keep them organized for later reassembly.

Reassembly Process Explained

Understanding the process of putting components back together is crucial for maintaining functionality. This section outlines the essential steps and considerations to ensure a smooth reassembly, enhancing the longevity and efficiency of the device.

Gathering Required Elements

Before beginning the reassembly, ensure that all necessary components are readily available. This includes hardware and any additional tools needed for the task. Having everything organized will streamline the process and minimize the risk of missing items.

Step-by-Step Approach

Start by following a systematic method for rejoining the elements. Begin with the base structure, gradually adding each component in the order specified. Pay close attention to any alignment features, as incorrect positioning can hinder performance. Double-check that all connections are secure, and test the functionality at various stages to confirm everything is functioning correctly before completing the assembly.

Choosing Replacement Parts Wisely

When it comes to maintaining functionality and ensuring long-lasting performance, selecting the right components is essential. Whether you are repairing a common office tool or a specialized device, understanding the various elements involved in the process can greatly impact the overall efficiency and reliability of the equipment.

Assessing Quality and Compatibility

Before making a decision, it’s crucial to evaluate both the quality and compatibility of the replacements. Consider the following factors:

- Check the manufacturer’s specifications to ensure proper fit.

- Opt for high-quality materials that offer durability and reliability.

- Research reviews and ratings from other users to gauge performance.

Understanding Cost vs. Value

While price is often a deciding factor, it’s important to balance cost with value. Here are some points to consider:

- Investing in premium components may save money in the long run due to reduced replacement frequency.

- Evaluate warranty options that may accompany higher-priced items.

- Compare multiple suppliers to find the best deal without sacrificing quality.

Safety Tips When Handling Tools

Working with various implements requires a keen awareness of safety protocols to prevent accidents and injuries. Proper handling and maintenance of equipment can significantly enhance the safety of any task. This section highlights essential practices to ensure a secure working environment while utilizing implements.

General Precautions

Before engaging in any task, it’s vital to familiarize yourself with the tools you will be using. Always inspect the condition of each implement, checking for wear and damage that could pose risks. Wearing appropriate personal protective equipment, such as gloves and eye protection, is crucial to safeguarding against potential hazards.

Proper Usage Guidelines

Using tools correctly is essential for both efficiency and safety. Follow the manufacturer’s instructions and guidelines to ensure proper operation. Additionally, maintain a clean and organized workspace to minimize distractions and accidents.

| Safety Tip | Description |

|---|---|

| Inspect Tools | Always check implements for damage before use. |

| Use Personal Protective Equipment | Wear gloves and safety glasses during operations. |

| Keep Workspace Clean | A tidy area reduces the risk of accidents. |

| Follow Instructions | Adhere to guidelines provided by the manufacturer. |

| Store Tools Properly | Return implements to designated locations after use. |

Frequently Asked Questions About Staplers

Many individuals encounter queries regarding their fastening devices, as these tools play a crucial role in organizing documents and various materials. Understanding their functionality, maintenance, and features can enhance user experience and efficiency.

What should I do if my device jams? Regular maintenance is key. Ensure that you are using the correct type and size of fasteners, as this can prevent jamming issues. If a jam occurs, carefully open the mechanism to remove the stuck fasteners.

How can I extend the lifespan of my device? Proper care is essential. Keep it clean and lubricated as needed. Store it in a dry place and avoid dropping or mishandling it, as this can lead to misalignment and damage.

Are there different types available for specific tasks? Yes, various models cater to different needs. Some are designed for light-duty tasks, while others handle heavy-duty projects, making them suitable for both home and office use.

Can I use alternative fasteners? While some devices accept different types of fasteners, it’s important to consult the manufacturer’s guidelines. Using incompatible fasteners may result in malfunction or damage to the tool.