In any mechanical device, a thorough comprehension of its individual components is crucial for effective operation and maintenance. Each element plays a significant role in ensuring the machinery functions seamlessly, making it essential for users to familiarize themselves with the arrangement and functionality of these parts. This knowledge can greatly enhance the user experience and prolong the lifespan of the equipment.

By delving into the various sections of the device, users can gain insights into how each component interacts with others. This understanding can assist in identifying potential issues and facilitate easier troubleshooting when problems arise. Moreover, having a clear mental image of the internal structure can boost confidence when performing repairs or upgrades.

In this section, we will explore the layout and relationship of the different components, providing clarity on their functions and importance. Whether you are a novice or an experienced user, this knowledge will empower you to handle your tool with greater efficiency and care.

This section provides a comprehensive introduction to a popular tool commonly used in construction and woodworking. The focus is on understanding its components and functionality, essential for both novice and experienced users. By familiarizing oneself with the parts of this device, users can enhance their operational efficiency and maintenance practices.

Key elements to consider include:

- Type of tool and its primary applications

- General specifications and features

- Common use cases in various industries

- Importance of knowing the individual components for effective troubleshooting

Understanding how the tool functions can greatly assist users in achieving better results and ensuring longevity. The following sections will delve into specific components and their roles in the overall operation.

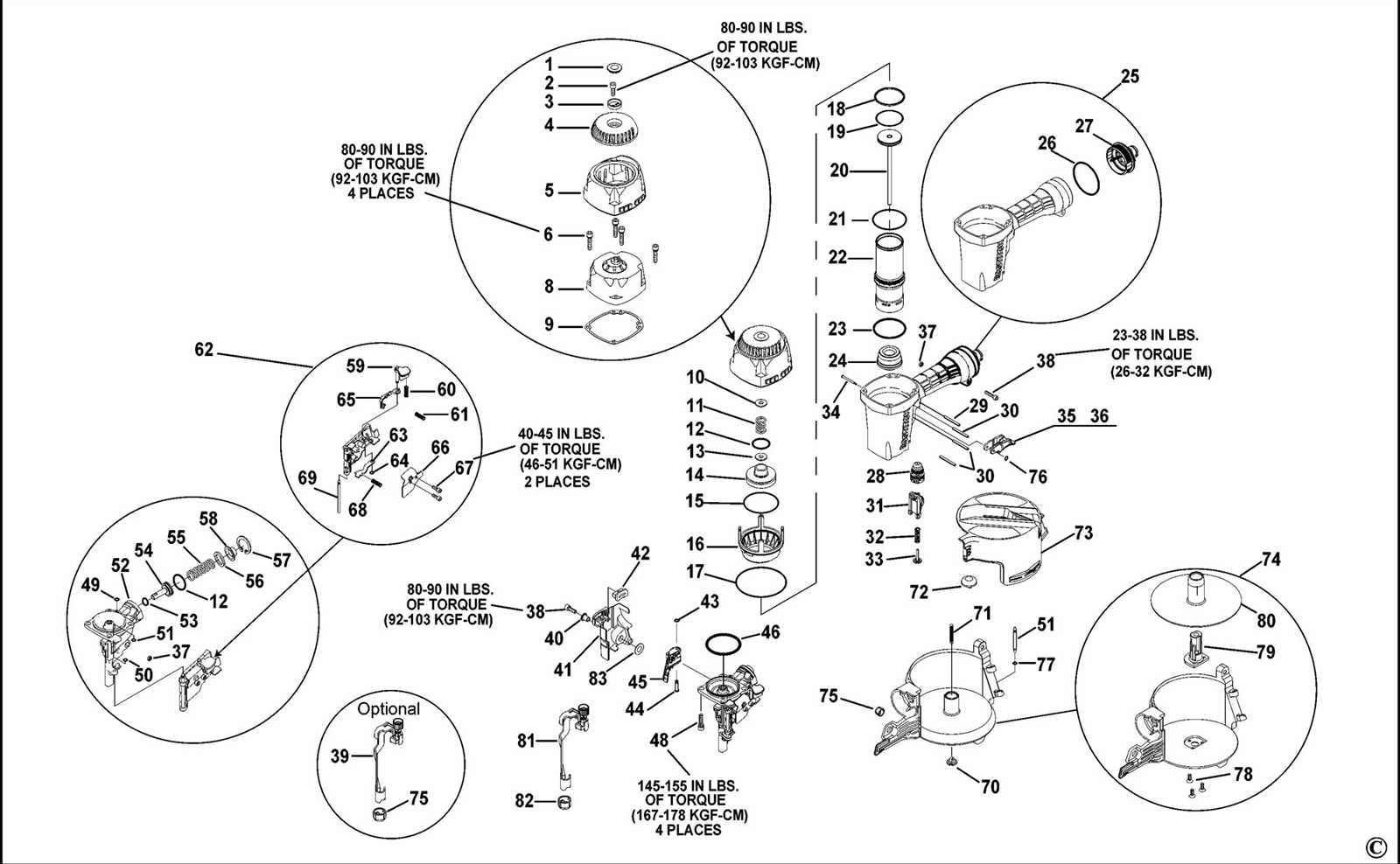

Importance of Parts Diagrams

Understanding the intricate details of mechanical assemblies is crucial for effective maintenance and repair. Visual representations that illustrate the various components within a system serve as invaluable tools for technicians and enthusiasts alike. These illustrations simplify complex machinery, allowing users to identify elements quickly and efficiently.

Enhanced Clarity: Visual aids provide clarity by breaking down complex structures into manageable sections. This allows for a more straightforward approach when diagnosing issues or replacing components, ultimately saving time and reducing frustration.

Improved Communication: In professional settings, having a common visual reference fosters better communication among team members. When everyone is on the same page regarding the specific components and their functions, collaboration becomes more efficient, leading to quicker resolutions.

Educational Value: For those new to mechanical systems, these visual guides serve as educational resources. They help individuals learn the roles and interrelations of various components, thereby building foundational knowledge for future troubleshooting and repair tasks.

Accurate Ordering: When replacement components are needed, having a clear visual reference ensures that the correct items are ordered. This minimizes the risk of errors, ensuring that repairs can be carried out without unnecessary delays.

Key Components of SX150

This section provides an overview of the essential elements that contribute to the functionality and efficiency of this specific model. Understanding these crucial components helps users appreciate how they work together to ensure optimal performance in various applications.

Power Source and Mechanism

The energy source serves as the driving force, powering the entire unit. This component is vital for initiating the mechanism that propels the fasteners. A robust and reliable power source ensures consistent operation, allowing for efficient performance during extensive tasks.

Feeding System and Fastener Holder

The feeding mechanism plays a critical role in the precise delivery of fasteners. This system is designed to seamlessly guide and secure the fasteners in place, minimizing jams and enhancing productivity. The holder is engineered to accommodate different sizes, ensuring versatility for various projects.

Understanding the Parts Layout

When working with a specific tool, having a clear comprehension of its internal structure is essential for effective maintenance and repair. Familiarity with the arrangement and function of each component can significantly enhance efficiency and troubleshooting skills.

Overview of the Configuration

The layout of components typically includes various key sections, each serving a unique purpose. Here are some common areas to consider:

- Power System: This section manages the energy required for operation.

- Drive Mechanism: This part is responsible for the movement and action of the device.

- Control Interface: This area allows the user to interact with the tool, adjusting settings as needed.

- Safety Features: These components ensure safe operation and reduce the risk of accidents.

Key Components and Their Functions

Each part plays a vital role in the overall functionality of the equipment. Understanding their roles can aid in effective troubleshooting and maintenance:

- Power Source – Provides necessary energy.

- Actuation Element – Engages and disengages the tool’s action.

- Guiding Structure – Ensures accurate movement and alignment.

- Fastening Mechanism – Secures components in place during operation.

How to Read the Diagram

Understanding a schematic representation of a tool is crucial for effective maintenance and repairs. These visual guides provide valuable insights into the components and their interconnections, allowing users to identify issues quickly and accurately. Familiarity with the symbols and layout can greatly enhance the efficiency of troubleshooting.

To begin, focus on the legend or key that explains the various symbols used in the representation. Each symbol corresponds to specific components, such as fasteners, electrical elements, or structural parts. Knowing what each symbol signifies is essential for navigating the schematic effectively.

Next, observe the layout of the visual guide. Components are usually arranged in a logical order, often reflecting the assembly process or functional relationships. This organization can help in tracing connections and understanding how each part interacts with others.

Pay attention to any annotations or notes included. These may offer additional insights or instructions regarding the installation or troubleshooting of specific components. Understanding these notes can provide critical context that aids in more effective use and repair of the tool.

Finally, practice by comparing the visual guide with the actual tool. This hands-on approach reinforces your understanding and helps you become more comfortable with identifying and addressing issues in the future.

Common Issues with Components

When working with various tools and machinery, it’s not uncommon to encounter issues related to specific components. These problems can arise from wear and tear, improper maintenance, or even manufacturing defects. Understanding the common challenges can help users troubleshoot effectively and ensure the longevity of their equipment.

Frequent Mechanical Failures

One of the most prevalent issues involves mechanical failures, which may manifest as jamming or inability to operate. These complications often stem from debris accumulation or lack of lubrication. Regular cleaning and maintenance are essential to prevent such occurrences and to keep the equipment functioning smoothly.

Electrical Component Malfunctions

Another area of concern lies within electrical components. Users may experience unexpected shutdowns or inconsistent performance, usually caused by faulty wiring or loose connections. To mitigate these issues, it’s crucial to inspect electrical systems periodically and address any signs of wear immediately.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended lifespan of any tool or equipment. Implementing a systematic maintenance routine not only enhances performance but also minimizes the likelihood of unexpected failures. By focusing on a few key practices, users can maintain optimal functionality and reliability.

Routine Cleaning

Keeping the equipment clean is vital. After each use, remove debris and dust that may accumulate. Utilize a soft brush or cloth to ensure all surfaces are free from contaminants. This simple act can significantly improve efficiency and prevent wear and tear.

Regular Inspections

Conducting periodic checks is crucial for identifying potential issues before they escalate. Examine all components for signs of damage or wear. Pay particular attention to seals, fasteners, and other critical elements. Early detection of problems can save time and resources in the long run.

Replacement Parts Availability

Access to spare components is essential for maintaining the functionality and longevity of your equipment. Ensuring that you can easily source these elements contributes to efficient operation and minimizes downtime.

Here are some key aspects to consider when looking for replacement components:

- Check with authorized distributors who specialize in equipment supplies.

- Explore online marketplaces that offer a variety of spare items.

- Consult the manufacturer’s website for specific recommendations and listings.

- Consider local hardware stores that may carry common components for quick access.

By utilizing these resources, you can effectively locate the necessary items to keep your machinery running smoothly.

Tools Required for Repairs

When undertaking maintenance or repair tasks on a pneumatic fastening device, having the right tools is essential for achieving optimal results. The proper equipment not only ensures efficiency but also enhances safety during the repair process. Below is a list of essential tools that will aid in successfully executing various repairs.

| Tool | Purpose |

|---|---|

| Socket Set | For removing and tightening screws and bolts |

| Screwdriver Set | To drive screws of various types and sizes |

| Pliers | For gripping, bending, and cutting wires |

| Hex Key Set | To adjust screws with hexagonal sockets |

| Torque Wrench | To apply a specific torque to fasteners |

| Cleaning Brushes | For removing debris and maintaining components |

Step-by-Step Repair Process

This section outlines a comprehensive approach to restoring functionality to your tool. Following these detailed instructions will guide you through identifying issues and implementing effective solutions.

1. Initial Assessment: Begin by examining the equipment for visible signs of damage or wear. Check for loose components, leaks, or obstructions that may hinder performance.

2. Gather Necessary Tools: Ensure you have the right tools at your disposal, including screwdrivers, wrenches, and any specialized instruments required for disassembly and reassembly.

3. Disassemble the Unit: Carefully take apart the equipment, noting the order of components and any connections. Use a methodical approach to avoid losing parts or damaging internal mechanisms.

4. Inspect Internal Components: Once disassembled, examine the internal parts for signs of wear or malfunction. Look for damaged seals, broken springs, or faulty wiring that could impact operation.

5. Replace or Repair Faulty Parts: If any components are found to be defective, replace them with compatible alternatives or repair them as necessary. Ensure that all replacements meet the required specifications.

6. Reassemble the Equipment: After addressing all issues, reassemble the unit carefully, ensuring that all parts are securely fastened and connected according to your initial notes.

7. Test Functionality: Finally, conduct a test run to verify that the tool operates as intended. Monitor for any unusual sounds or performance issues during operation.

By following these structured steps, you can effectively restore your tool to optimal working condition.

Resources for Further Assistance

When seeking support for maintenance or troubleshooting of your equipment, various resources can provide valuable guidance. These tools can enhance your understanding and help address specific challenges effectively.

Here are some recommended sources to consider:

| Resource Type | Description | Link |

|---|---|---|

| User Manuals | Official guides that offer detailed instructions and specifications. | View Manuals |

| Online Forums | Community platforms where users share experiences and solutions. | Join Forums |

| Customer Support | Direct assistance from knowledgeable representatives who can answer questions. | Contact Support |

| Video Tutorials | Visual guides that demonstrate various processes and repairs. | Watch Tutorials |