Exploring the intricacies of equipment design offers valuable insights into their functionality and maintenance. A comprehensive understanding of how various elements interconnect enhances troubleshooting and repair processes. This section delves into the arrangement of crucial components, revealing their relationships and operational significance.

By examining the configuration of individual pieces, one can better appreciate their roles within the entire assembly. Recognizing these connections not only simplifies the repair tasks but also ensures that users can maintain optimal performance over time. Detailed visual representations serve as essential tools in navigating the complexities of mechanical systems, guiding users through the maintenance journey.

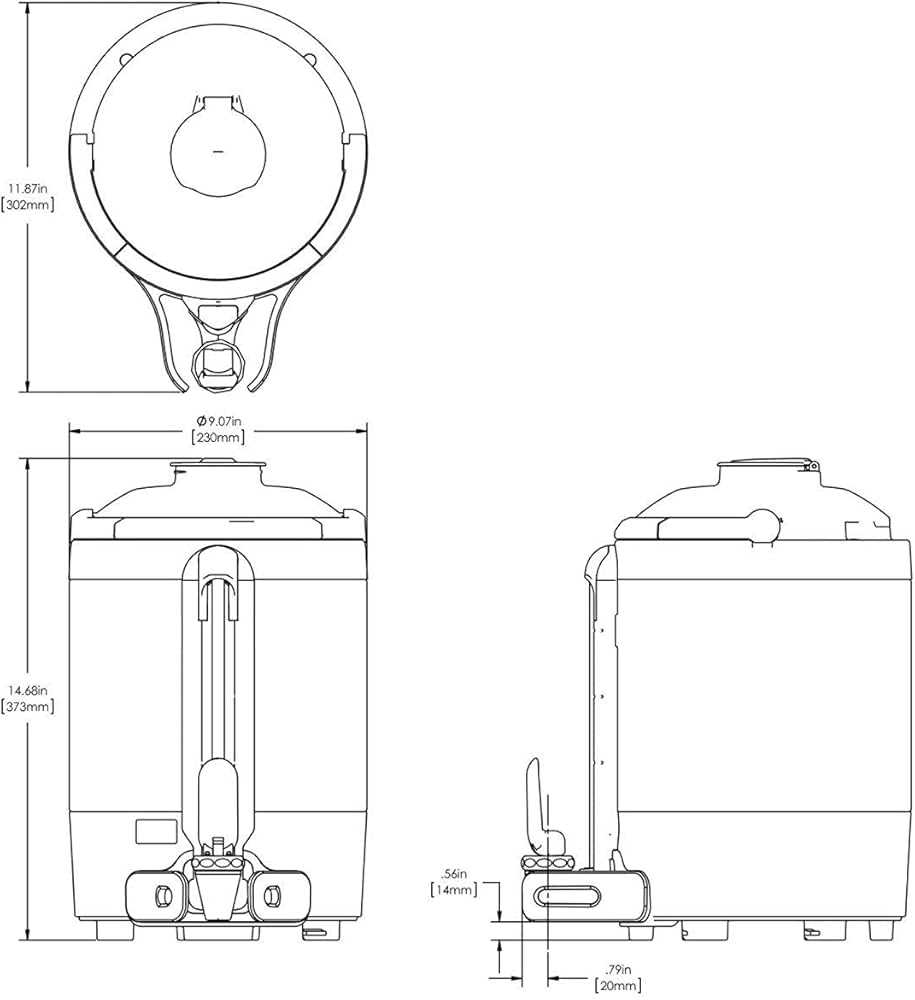

Understanding the Bunn BTX-B Model

This segment delves into the intricacies of a popular coffee brewing apparatus, highlighting its essential components and functionalities. Designed for efficiency, this machine caters to the needs of coffee enthusiasts, ensuring optimal performance during operation.

Key features include various elements that work in unison to deliver a satisfying brewing experience. Below is a summary of these critical components:

| Component | Function |

|---|---|

| Heating Element | Maintains the ideal temperature for brewing |

| Water Reservoir | Stores water needed for the brewing process |

| Brewing Basket | Holds the coffee grounds during brewing |

| Dispensing Mechanism | Controls the flow of brewed coffee |

| Control Panel | Allows user to set brewing parameters |

Key Components of the Machine

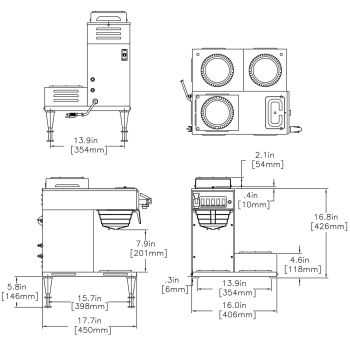

This section explores the essential elements that contribute to the functionality of the device. Understanding these components provides insight into how the equipment operates and ensures optimal performance. Each part plays a vital role in delivering the expected results.

Essential Functionalities

The main functionalities of the device rely on several critical elements that work together seamlessly. These elements include mechanisms for heating, brewing, and dispensing. Their integration is crucial for achieving consistency and quality in the output.

Mechanical Structure

The mechanical structure encompasses various components that support the device’s operation. These include housing, supports, and connectors, which are designed to ensure stability and facilitate maintenance.

| Component | Description |

|---|---|

| Heating Element | Responsible for reaching and maintaining the required temperature for optimal extraction. |

| Water Reservoir | Holds the water needed for the brewing process, ensuring a consistent supply. |

| Brewing Chamber | Where the extraction of flavors occurs, combining water with the grounds. |

| Dispensing Mechanism | Facilitates the delivery of the brewed beverage to the user. |

| Control Panel | Allows users to set preferences and monitor the brewing process. |

Functionality of Brewing Mechanism

The brewing mechanism serves as the core component responsible for transforming raw ingredients into a delicious beverage. This process involves several key actions that ensure optimal extraction and flavor development, catering to diverse preferences. Each part of the system plays a crucial role in maintaining the right temperature and pressure, ultimately delivering a consistent and satisfying experience for users.

At the heart of this operation lies the heating element, which rapidly raises the temperature of the water to the ideal brewing range. Once the water reaches the appropriate heat, it flows through the grounds, extracting essential oils and flavors. The precise timing of this interaction is vital, as it influences the final taste profile. After the extraction phase, the brewed liquid is directed to a holding vessel, ensuring that it remains at a stable temperature until served.

Additionally, the brewing assembly incorporates various controls and sensors that monitor and regulate the entire process. These components work together to guarantee a seamless experience, providing users with the ability to enjoy their favorite beverage at any moment. Overall, the efficient functioning of this system highlights the intricate design and engineering that goes into creating an exceptional brewing experience.

Common Issues and Solutions

When operating complex brewing equipment, users may encounter a variety of challenges that can impact performance and efficiency. Recognizing these common complications is the first step toward ensuring a seamless brewing experience. Addressing these concerns promptly can help maintain optimal functionality and extend the lifespan of the machine.

Water Temperature Fluctuations: Inconsistent heating can lead to suboptimal brewing results. To resolve this, check the heating element for proper operation and inspect the thermostat settings. Regular calibration may also help in achieving the desired temperature.

Leakage: Any signs of leakage should not be ignored, as they can cause significant damage over time. Examine seals and gaskets for wear or damage, and replace them as necessary. Ensuring tight connections at all joints can prevent future leaks.

Brewing Delays: If the brewing process takes longer than usual, it may indicate a blockage in the system. Clean filters and hoses regularly to ensure uninterrupted water flow. Additionally, verify that the pump is functioning correctly.

Noise Issues: Unusual sounds during operation can indicate mechanical issues. Inspect moving parts for wear or misalignment and lubricate where appropriate. If the noise persists, consulting a technician may be necessary.

Electrical Problems: Equipment failures related to power supply can halt operations. Check power cords for damage and ensure all connections are secure. If problems continue, it may be essential to examine the internal wiring or consult a professional for assistance.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your appliance requires regular attention and care. Implementing effective maintenance practices can significantly enhance performance and reduce the likelihood of issues arising over time.

Regular Cleaning: Keeping surfaces clean prevents buildup that can interfere with functionality. Wipe down components frequently, and consider using a soft cloth and mild detergent to remove any residue.

Periodic Inspection: Frequently check the equipment for any signs of wear or damage. Early detection of minor issues can save time and costs associated with major repairs.

Proper Storage: When the device is not in use, store it in a dry and safe environment. This protects it from external elements that could lead to deterioration.

Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule provided by the manufacturer. This includes routine servicing and specific care instructions that ensure optimal functionality.

Use Compatible Accessories: Always opt for accessories and replacements that are designed for your specific model. Using inappropriate components may cause malfunctions or void warranties.

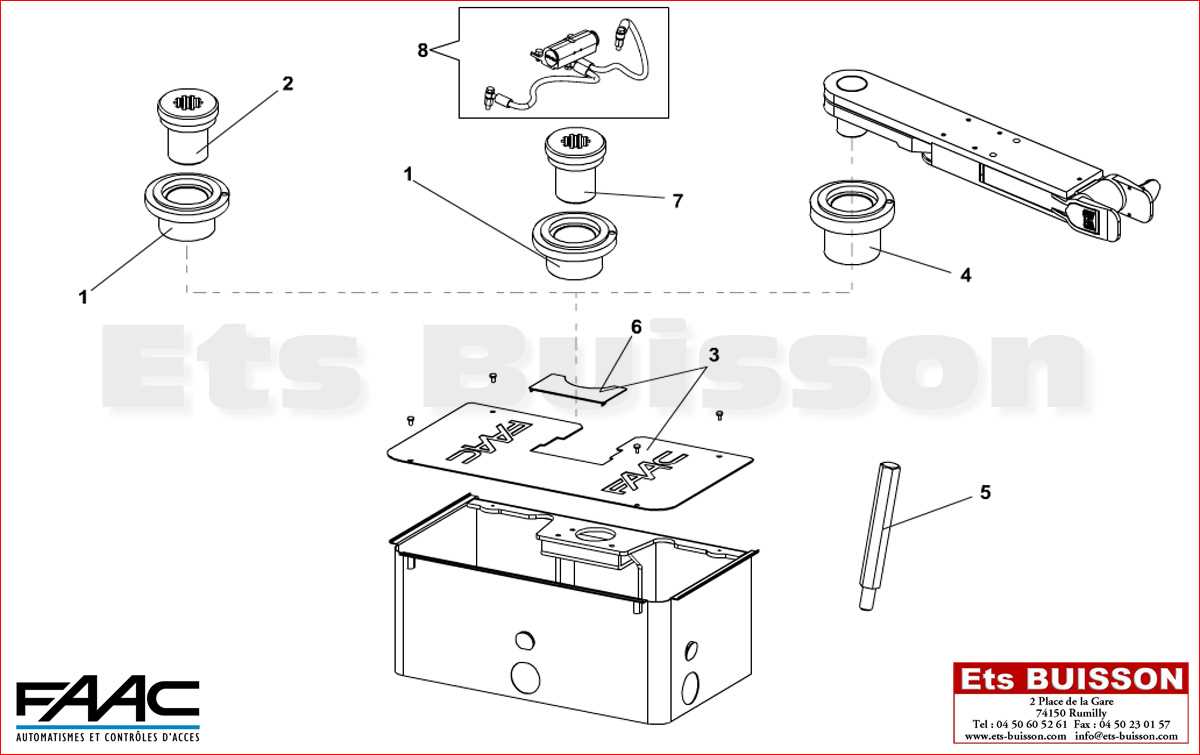

Exploring Replacement Parts Options

When it comes to maintaining and enhancing your beverage equipment, understanding the availability of various components can significantly improve performance and longevity. By exploring suitable alternatives, users can ensure that their devices continue to operate efficiently while meeting their specific needs.

Types of Components Available

There are numerous types of replacements that can be sourced, catering to different aspects of functionality. These may include heating elements, water reservoirs, and other essential mechanisms that contribute to the overall operation of the appliance. Selecting the right options is crucial for achieving optimal results.

Where to Find Quality Replacements

Identifying reputable suppliers is essential for acquiring reliable components. Many online retailers and specialty stores offer a wide selection of items. It is advisable to consider customer reviews and ratings to gauge the quality of the offerings.

| Component Type | Description | Recommended Source |

|---|---|---|

| Heating Element | Essential for maintaining optimal water temperature. | Online Retailers |

| Water Reservoir | Stores water needed for brewing. | Specialty Stores |

| Brewing Mechanism | Critical for the brewing process and efficiency. | Manufacturer’s Website |

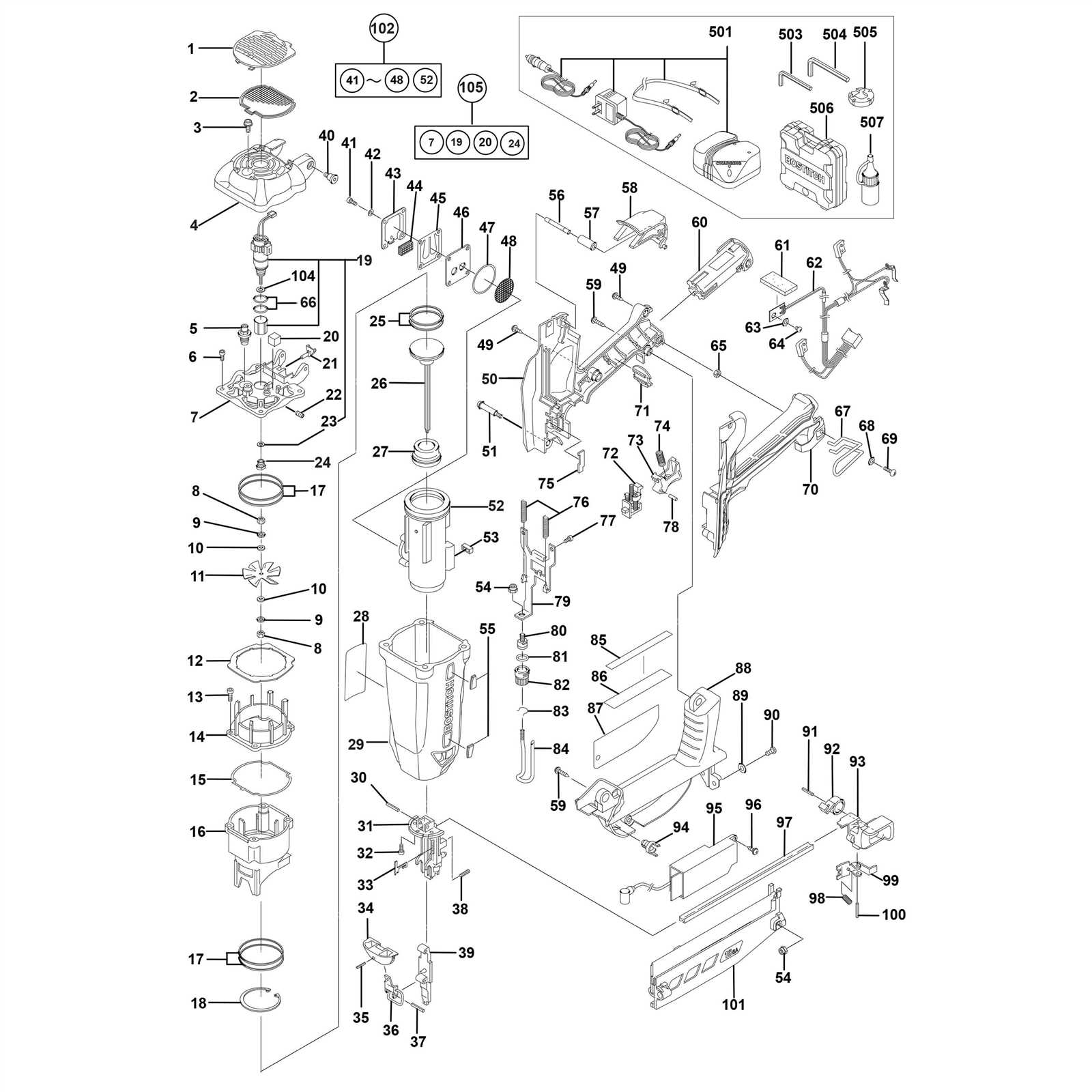

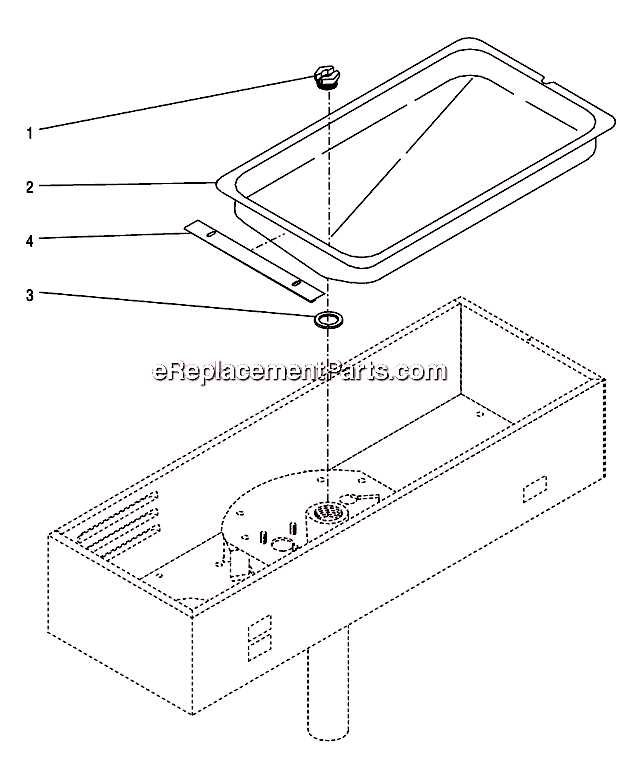

How to Disassemble the Unit

Disassembling the appliance requires a systematic approach to ensure all components are safely removed without damage. This process involves careful attention to detail and the right tools to facilitate a smooth operation.

Necessary Tools

- Screwdriver set

- Pliers

- Tweezers

- Container for small parts

Step-by-Step Process

- Begin by unplugging the device to ensure safety.

- Remove any detachable components, such as lids or trays.

- Using the appropriate screwdriver, take out the screws from the base and sides.

- Carefully lift the outer casing, making sure to avoid any entangled wires.

- Continue to detach internal parts, following the layout you have observed.

- Place each component in the container to keep everything organized.

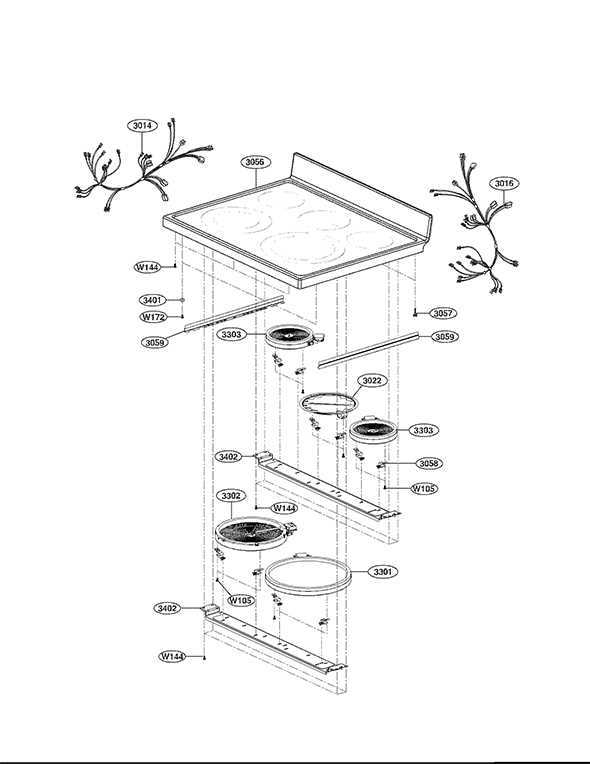

Identifying Electrical Connections

Understanding how to recognize and analyze electrical interfaces is crucial for effective maintenance and troubleshooting of any appliance. This section aims to highlight the essential elements involved in discerning these connections, ensuring optimal functionality and safety during operations.

Key Components to Consider

- Terminals: These serve as the entry and exit points for electrical currents, linking various parts of the system.

- Wires: Conductors that transmit electrical signals, available in different colors to denote specific functions.

- Connectors: Devices that join wires together, providing secure and reliable pathways for current flow.

Steps for Identifying Connections

- Inspect the appliance visually for any exposed wires or connectors.

- Refer to the accompanying documentation to match colors and labels with their respective functions.

- Utilize a multimeter to test continuity and ensure proper connectivity between components.

- Document your findings for future reference and maintenance tasks.

Water Flow System Overview

The efficiency of any brewing apparatus relies heavily on its liquid circulation mechanism. This system plays a crucial role in ensuring that the right amount of fluid is directed through various components, promoting optimal extraction and flavor profiles.

Key elements of an effective liquid management system include:

- Pumps: These components drive the flow of liquid, ensuring it reaches all necessary areas within the setup.

- Valves: They regulate the direction and flow rate, allowing for precise control over the brewing process.

- Hoses: Flexible conduits that transport the liquid between different parts of the system, designed to withstand varying temperatures and pressures.

- Reservoirs: Storage areas that hold the liquid, ensuring a consistent supply for the brewing operation.

In summary, understanding the intricacies of the liquid circulation mechanism is essential for maintaining high-quality performance in brewing equipment.

Heating Element Specifications

The heating component is crucial for the efficient operation of various brewing devices, ensuring that water reaches optimal temperatures for the perfect extraction of flavors. Understanding the specifications of this element is essential for maintenance and troubleshooting, as it directly impacts the overall performance and longevity of the equipment.

Power Rating and Efficiency

Power rating typically indicates the wattage of the heating unit, which can range significantly based on the model and intended use. Higher wattage often translates to quicker heating times, enhancing the user experience by reducing wait times. It is vital to select a component that not only meets the energy requirements but also operates efficiently to minimize energy consumption.

Temperature Control and Safety Features

Temperature control mechanisms are designed to maintain precise heat levels, preventing overheating and ensuring consistent brewing results. Many modern systems include built-in safety features, such as over-temperature protection and automatic shut-off functions, which safeguard against potential hazards while enhancing the reliability of the equipment.

Control Panel Features Explained

The control interface of a brewing system is crucial for ensuring optimal performance and user convenience. Each element on this panel plays a significant role in managing the brewing process, allowing users to monitor and adjust various parameters with ease. Understanding these features enhances the overall brewing experience, promoting efficiency and quality.

Typically, the control panel includes several essential components that contribute to its functionality:

| Feature | Description |

|---|---|

| Power Indicator | Illuminates to show when the unit is operational, ensuring users can quickly determine the machine’s status. |

| Temperature Control | Allows users to set and monitor the water temperature for brewing, crucial for achieving desired flavors. |

| Brew Timer | Facilitates precise brewing times, ensuring consistency in the brewing process for optimal results. |

| Dispensing Button | Initiates the brewing cycle, providing an easy-to-use interface for starting the coffee-making process. |

| Settings Menu | Offers access to customizable features, enabling users to tailor their brewing experience according to personal preferences. |

Understanding these components empowers users to fully utilize their brewing equipment, resulting in a superior beverage quality and an enhanced experience.

Importance of Cleanliness in Operation

Maintaining a high standard of hygiene and orderliness is crucial in ensuring the efficient functioning of equipment. Regular cleaning and maintenance prevent the buildup of residues and contaminants, which can compromise the overall performance. A clean environment not only enhances the lifespan of the equipment but also promotes the safety and satisfaction of users.

Failure to uphold cleanliness can lead to various issues, including decreased efficiency and potential malfunctions. It’s essential to implement proper cleaning protocols that address all components and surfaces regularly. This proactive approach mitigates risks and contributes to optimal functionality.

| Cleaning Task | Frequency | Purpose |

|---|---|---|

| Surface Wipe-Down | Daily | Removes dirt and spills |

| Deep Cleaning | Weekly | Prevents buildup of residues |

| Component Inspection | Monthly | Identifies wear and tear |

By adhering to a structured cleaning routine, operators can ensure their equipment remains in peak condition, ultimately enhancing operational efficiency and user experience.

Accessing the Service Manual

Obtaining the maintenance documentation is essential for effective troubleshooting and repairs. This resource provides detailed instructions and diagrams that enhance understanding of the equipment’s components and their functions. Accessing this information enables users to perform necessary adjustments, ensuring optimal performance.

Where to Find the Documentation

- Official Manufacturer’s Website

- Authorized Dealers or Distributors

- Online Repair Communities

Using the Manual Effectively

- Familiarize yourself with the layout and sections.

- Refer to the troubleshooting guides for common issues.

- Consult the diagrams for assembly and disassembly procedures.

By utilizing this valuable resource, individuals can ensure that they maintain their equipment properly and extend its lifespan.