In the realm of coffee brewing technology, the intricacies of machine components play a crucial role in achieving optimal performance. A well-structured representation of these elements can greatly enhance one’s understanding of the functionality and maintenance of the device. By exploring the arrangement of various components, users can identify key parts that contribute to the overall efficiency and reliability of the brewing process.

The exploration of this schematic overview allows enthusiasts and professionals alike to navigate the complexities of their equipment. Familiarity with each component’s location and purpose aids in troubleshooting issues and ensuring proper care. Whether for routine maintenance or addressing specific concerns, having a clear visual guide is invaluable.

Moreover, such detailed information fosters a deeper appreciation for the craftsmanship involved in designing these machines. Recognizing how each element interacts with the others provides insights into the innovation behind modern coffee brewing technologies. This understanding empowers users to make informed decisions regarding their equipment, ultimately leading to a superior coffee experience.

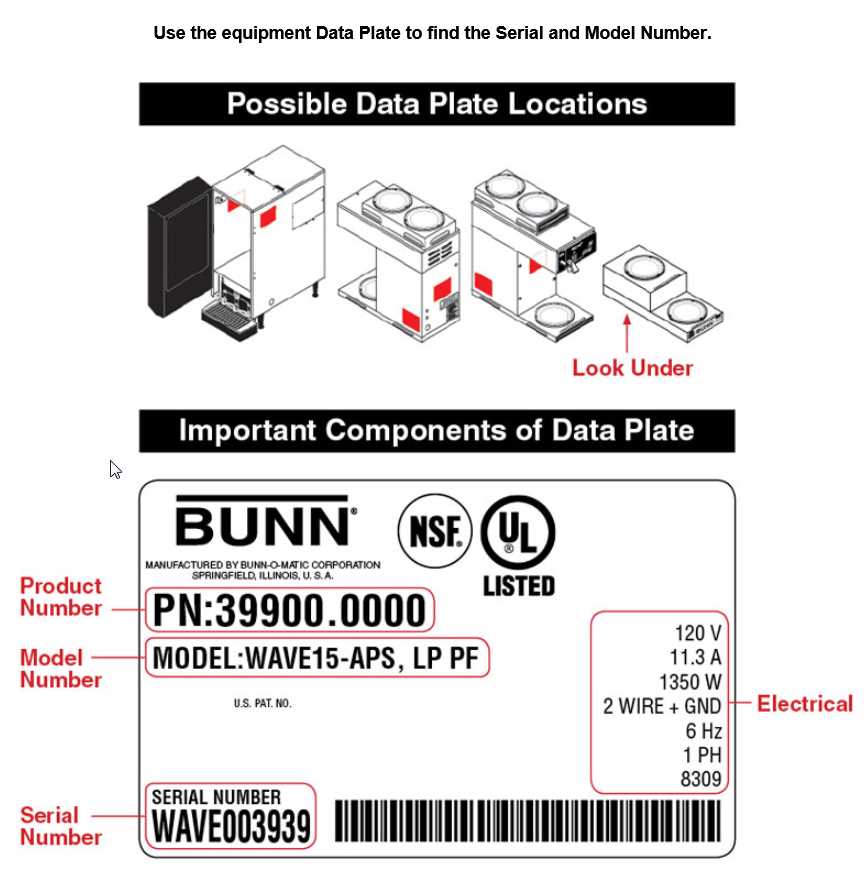

Overview of Bunn GRX W

This section provides an insight into a popular coffee brewing machine known for its efficiency and reliability. It serves as a vital tool in various establishments, catering to the demands of coffee enthusiasts and professionals alike. The design focuses on optimizing the brewing process while ensuring ease of use and maintenance.

Key Features

The equipment boasts several noteworthy characteristics that enhance its functionality. Users appreciate the robust construction and user-friendly interface, making it suitable for both casual users and commercial settings. Furthermore, it incorporates advanced technology to ensure consistent brewing quality, meeting the expectations of even the most discerning coffee drinkers.

Specifications

| Feature | Description |

|---|---|

| Capacity | Designed to brew multiple servings simultaneously, accommodating high demand. |

| Heating Element | Equipped with an efficient heating system to ensure optimal brewing temperatures. |

| Control System | User-friendly interface with programmable settings for customizable brewing options. |

| Durability | Constructed from high-quality materials to withstand heavy usage. |

Key Components of the Machine

This section delves into the essential elements that contribute to the efficient functioning of the device. Each part plays a crucial role in ensuring optimal performance and enhancing the user experience. Understanding these components helps in better maintenance and troubleshooting.

Brewing Mechanism

The brewing mechanism is the heart of the system, where water and coffee interact to produce a rich and flavorful beverage. It typically includes a heating element that ensures water reaches the ideal temperature for extraction. This component is vital for achieving the desired taste profile.

Control System

The control system governs the operation of the machine, allowing users to customize settings according to their preferences. It may feature buttons, switches, or digital interfaces for easy adjustments. A well-designed control system enhances usability and ensures precise brewing cycles.

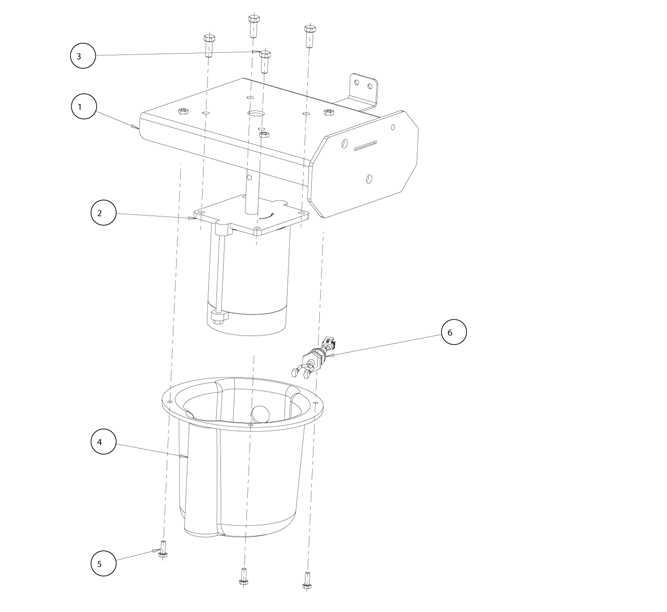

Understanding the Parts Diagram

In any mechanical system, a comprehensive visual representation is essential for recognizing the components and their interrelations. This visual guide serves as a crucial tool for users to grasp the configuration of elements, facilitating maintenance and troubleshooting. By examining this illustration, one can identify each element’s role, ensuring the system operates efficiently.

Key Components and Their Functions

Each element depicted plays a significant role in the overall functionality. Familiarizing oneself with these components enables a deeper understanding of how they work together. For instance, certain sections may control temperature, while others manage fluid movement. This interconnectedness highlights the importance of each part in achieving optimal performance.

Interpreting the Visual Guide

When reviewing the visual representation, it is beneficial to note the labeling conventions and reference numbers. These details assist in pinpointing specific items, streamlining the process of sourcing replacements or conducting repairs. Paying attention to these nuances can significantly enhance one’s proficiency in maintaining and operating the system effectively.

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your brewing equipment requires regular care and attention. Implementing simple maintenance practices can significantly enhance the quality of your beverages and extend the lifespan of your machine.

-

Regular Cleaning:

Make it a habit to clean all components frequently. This includes the brew basket, water reservoir, and any removable parts. Use mild detergent and warm water to remove any residue that may affect flavor.

-

Descaling:

Mineral buildup can impact performance over time. Descale your machine every few months using a recommended descaling solution to keep it operating smoothly.

-

Check Water Quality:

Using filtered water can reduce mineral deposits and improve taste. Regularly check your water supply for contaminants and consider using a filtration system if necessary.

-

Inspect Electrical Components:

Periodically examine the electrical connections and cords for any signs of wear or damage. Ensure that all components are securely connected to prevent any operational issues.

-

Replace Filters:

If your machine uses filters, replace them according to the manufacturer’s recommendations. This will help maintain the quality of the brewed beverages.

-

Routine Servicing:

Consider scheduling professional maintenance at least once a year. A technician can perform a thorough inspection and address any underlying issues that may not be visible.

By following these essential maintenance tips, you can ensure that your brewing apparatus continues to deliver exceptional performance and quality for years to come.

Common Issues and Solutions

In the world of coffee brewing equipment, users often encounter various challenges that can affect performance and efficiency. Understanding these typical problems and their remedies is essential for maintaining optimal functionality. This section aims to highlight frequent issues and provide effective solutions to enhance the overall experience.

Temperature Control Problems

One of the most prevalent issues faced by users is inconsistent water temperature during the brewing process. To resolve this, ensure that the heating element is functioning properly and that the thermostat is calibrated correctly. Regular maintenance, such as descaling, can also help maintain consistent temperatures and prevent buildup that might hinder performance.

Leakage Issues

Another common concern is water leakage, which can arise from worn seals or loose connections. Addressing this requires checking all gaskets and fittings for signs of wear or damage. Replacing worn components can significantly reduce the likelihood of leaks. Regular inspections can help identify potential issues before they escalate, ensuring a reliable brewing experience.

Importance of Regular Cleaning

Maintaining cleanliness is essential for ensuring optimal performance and longevity of equipment. Regular maintenance helps prevent the buildup of residues and contaminants that can impair functionality, leading to costly repairs and decreased efficiency.

There are several key reasons why consistent upkeep is crucial:

- Enhanced Performance: A clean unit operates more effectively, producing better results and maintaining consistent quality.

- Prolonged Lifespan: Regular cleaning reduces wear and tear, extending the life of the equipment and minimizing the need for replacements.

- Improved Safety: Removing dirt and debris prevents potential hazards that could lead to accidents or malfunctions.

- Cost Efficiency: Preventative maintenance can save money over time by avoiding emergency repairs and minimizing downtime.

Incorporating a systematic cleaning routine into daily operations ensures that the equipment remains in peak condition, ultimately benefiting both users and overall performance.

How to Replace Essential Parts

Maintaining the efficiency of your machine is crucial for optimal performance. Over time, specific components may wear out or become less effective, requiring replacement to ensure smooth operation. Understanding the process of swapping out these elements can greatly extend the lifespan of your equipment.

Identifying Components for Replacement

Before starting the replacement procedure, it’s important to recognize which elements need attention. Commonly, the following parts may require periodic changes:

- Heating elements

- Water filters

- Seals and gaskets

- Brewing baskets

Replacement Steps

- Turn Off and Unplug: Ensure the device is powered down and disconnected from the electrical source.

- Access the Component: Depending on the part, you may need to remove panels or covers to gain access.

- Remove the Old Part: Carefully detach the worn component, taking note of how it is secured.

- Install the New Part: Position the new element in place, ensuring it fits snugly and is secured properly.

- Reassemble the Device: Replace any panels or covers that were removed during access.

- Test the Operation: Plug the unit back in and run a test cycle to confirm the new component is functioning as expected.

Tools Needed for Repairs

Effective maintenance and restoration of equipment require specific instruments to ensure tasks are carried out efficiently and safely. Having the right tools at hand not only simplifies the process but also enhances the quality of repairs, minimizing the likelihood of future issues.

Essential Instruments

- Wrenches: Useful for loosening and tightening various fittings.

- Screwdrivers: Both flathead and Phillips types are necessary for accessing different components.

- Pliers: Ideal for gripping and bending wires or small parts.

- Multimeter: Essential for measuring voltage, current, and resistance, ensuring electrical components are functioning correctly.

- Utility Knife: Handy for cutting through packaging or insulation.

Safety Equipment

- Safety Glasses: Protect your eyes from debris and harmful substances.

- Gloves: Prevent cuts and provide a better grip while handling tools and components.

- Dust Mask: Useful when working with materials that may produce dust or harmful particles.

Having these tools ready will significantly facilitate the repair process, making it more organized and less time-consuming.

Safety Precautions When Servicing

When undertaking maintenance or repair tasks on any equipment, it is crucial to prioritize safety. Understanding and adhering to proper protocols can significantly reduce the risk of accidents and injuries. This section outlines essential measures to ensure a secure working environment during service activities.

- Always disconnect the power source before starting any maintenance work to prevent electric shock.

- Wear appropriate personal protective equipment (PPE), such as gloves and safety goggles, to protect against potential hazards.

- Use insulated tools when working with electrical components to minimize the risk of short circuits.

- Ensure the work area is clean and free of clutter to avoid tripping or slipping hazards.

- Follow the manufacturer’s guidelines and instructions carefully to avoid damaging the equipment.

In addition to these precautions, it is advisable to have a first aid kit readily available and to be aware of emergency procedures. Maintaining a safe working environment not only protects the technician but also enhances the longevity and performance of the equipment being serviced.

Upgrades to Enhance Functionality

Improving the efficiency and performance of your coffee brewing equipment can significantly elevate the overall experience. Several enhancements can be made to boost capabilities, optimize workflow, and ensure consistent quality in each cup. Below are some effective modifications that can lead to superior results.

Key Enhancements

- Advanced Temperature Control: Implementing a temperature control system can allow for precise adjustments, ensuring that the water is at the optimal temperature for various types of coffee.

- Upgraded Brew Basket: Opting for a larger or more efficient brew basket can increase capacity and enhance extraction, providing a richer flavor profile.

- Enhanced Filtration: Utilizing higher quality filters or integrated filtration systems can improve water quality, resulting in a cleaner and more flavorful brew.

Additional Accessories

- Programmable Timer: Allows for scheduling brewing cycles, ensuring coffee is ready when you are.

- Smart Scale: A digital scale helps achieve the perfect coffee-to-water ratio for consistency.

- Maintenance Kit: Regular maintenance ensures longevity and optimal performance of the equipment.

Incorporating these upgrades can lead to a more enjoyable brewing process and a higher-quality end product. By focusing on functionality enhancements, users can achieve the best possible coffee experience.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and troubleshooting of coffee brewing equipment. Below, you will find a compilation of questions that users frequently ask, along with concise answers to assist in resolving issues or enhancing understanding.

- What should I do if my machine isn’t brewing?

If your device fails to brew, consider the following steps:

- Check the water reservoir for sufficient liquid.

- Ensure all components are correctly assembled.

- Examine the power source and connections.

- How often should I clean my appliance?

Regular cleaning is crucial for optimal performance. It is recommended to clean the unit:

- Daily: Rinse removable parts.

- Weekly: Perform a deeper clean of all components.

- Monthly: Use a descaling solution to prevent mineral buildup.

- Where can I find replacement components?

Replacement parts can typically be obtained from:

- Official service centers.

- Authorized online retailers.

- Local kitchen appliance shops.

- What are the signs of a malfunction?

Indicators of potential issues include:

- Inconsistent brewing temperature.

- Unusual noises during operation.

- Visible leaks or water pooling.