In this guide, we will delve into the intricate assembly of a powerful off-road machine. Each element of this vehicle has been engineered to deliver superior performance in challenging terrains, ensuring durability and maximum efficiency. Understanding how these various elements come together is crucial for both maintenance and customization, enhancing the vehicle’s capability and your driving experience.

The focus here will be on identifying key sections and understanding their functionality. From the suspension system to the engine structure, every detail plays a vital role in the overall mechanics. Whether you’re upgrading or simply maintaining your ride, having a clear overview of the setup will provide you with a better grasp of what makes this vehicle exceptional in its class.

As we move forward, we’ll examine each section individually, offering insights into how these components contribute to the performance and safety of the vehicle. This knowledge will equip you with the necessary information to make informed decisions about adjustments, repairs, or enhancements.

Exploring the Structure of Can-Am Maverick X3

The mechanical design of this high-performance off-road vehicle reveals an intricate assembly of components that work together to ensure reliability and versatility in challenging terrains. Its frame, suspension, and various systems are crafted to handle extreme conditions, providing both durability and comfort for the rider. This section delves into the core elements that make this vehicle’s structure highly efficient and adaptable to diverse environments.

Chassis and Suspension System

One of the key aspects of the vehicle’s structure is its lightweight yet sturdy chassis, which plays a crucial role in maintaining balance and stability. Paired with an advanced suspension system, it allows for smooth handling and responsive control, even on uneven surfaces. The integration of cutting-edge technology in its suspension ensures that the vehicle can absorb shocks and bumps effectively, enhancing the overall driving experience.

Powertrain and Control Mechanisms

The powertrain is engineered to deliver optimal performance, seamlessly coordinating with the control mechanisms to provide precision and power when needed. With an emphasis on efficiency and control, the design ensures that the vehicle responds intuitively to the driver’s commands, maintaining a perfect balance between speed and maneuverability. The interaction between the drivetrain and the control system highlights the vehicle’s capability to adapt to varying demands during operation.

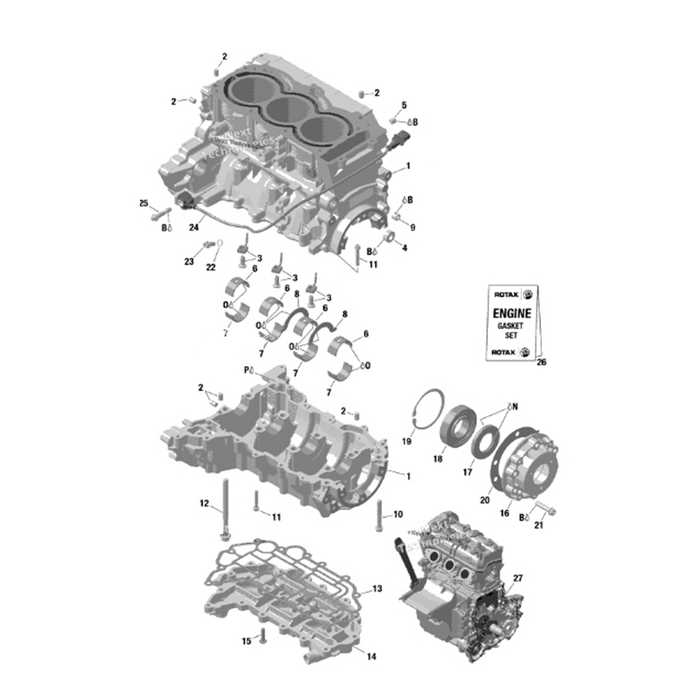

Engine Components Overview

The engine is a complex system that consists of multiple interconnected parts working in harmony to provide power and efficiency. Each component has a vital role in ensuring the machine operates smoothly and efficiently, contributing to overall performance. Understanding how these elements interact can help maintain and optimize the system for longevity and functionality.

Main Structural Components

The primary structural elements of the engine include essential sections that provide support and housing for moving parts. These structures not only protect the internal mechanisms but also help dissipate heat and maintain stability under intense operational conditions.

Key Functional Elements

The functional components are responsible for energy conversion and distribution. These parts ensure the proper mixture of air and fuel, facilitate combustion, and manage the resulting forces. Additionally, they play a crucial role in regulating the power flow and controlling emissions, ultimately affecting performance and environmental impact.

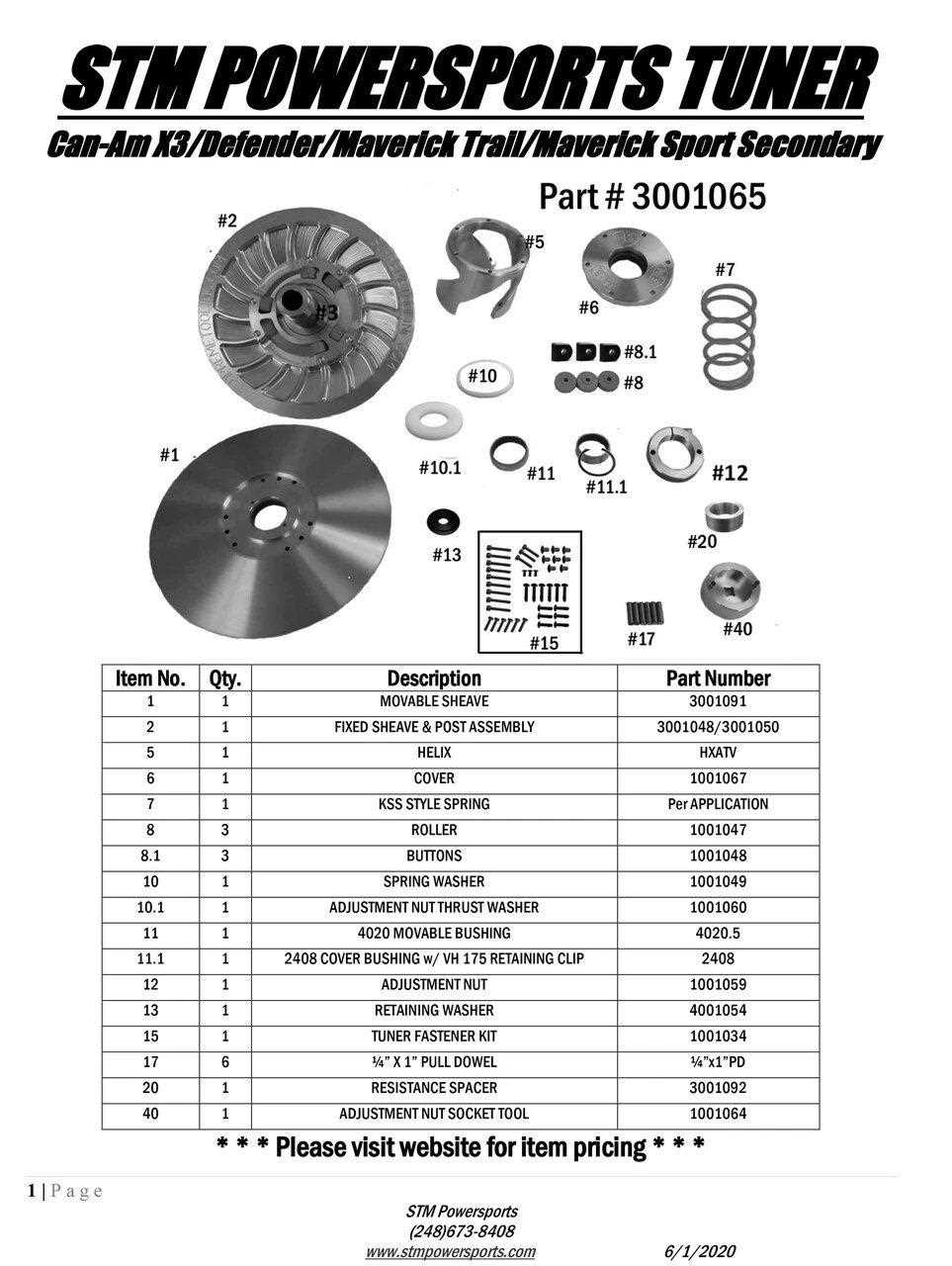

Transmission System Breakdown

The transmission system is a crucial component responsible for transferring power from the engine to the wheels. It ensures efficient power distribution, allowing the vehicle to operate smoothly in various conditions. Understanding the layout and function of each element within this system is essential for optimal performance and maintenance.

- Gearbox: The gearbox modulates the engine’s output, adjusting speed and torque to match the driving demands. It houses multiple gears that engage and disengage based on input.

- Clutch: The clutch enables a seamless connection and disconnection between the engine and gearbox, providing control over power transmission during shifts or halts.

- Drive Belt: The belt transmits energy from the gearbox to the differential, playing a critical role in ensuring consistent power delivery to the wheels.

- Differential: This mechanism allows the wheels to rotate at different speeds, especially during turns, by distributing torque between them.

- Shifting Mechanism: The shifting mechanism allows the operator

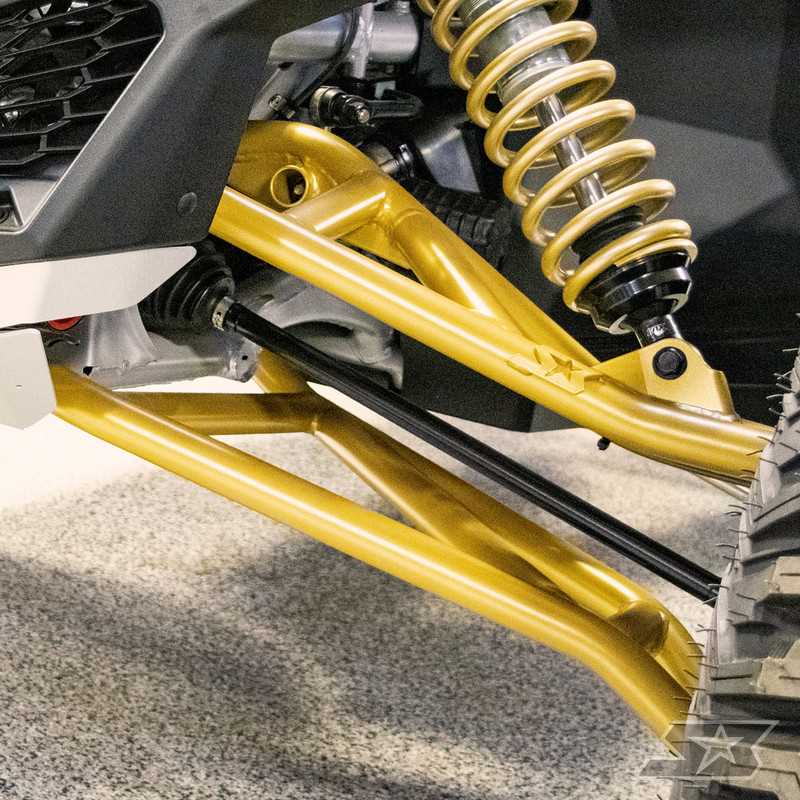

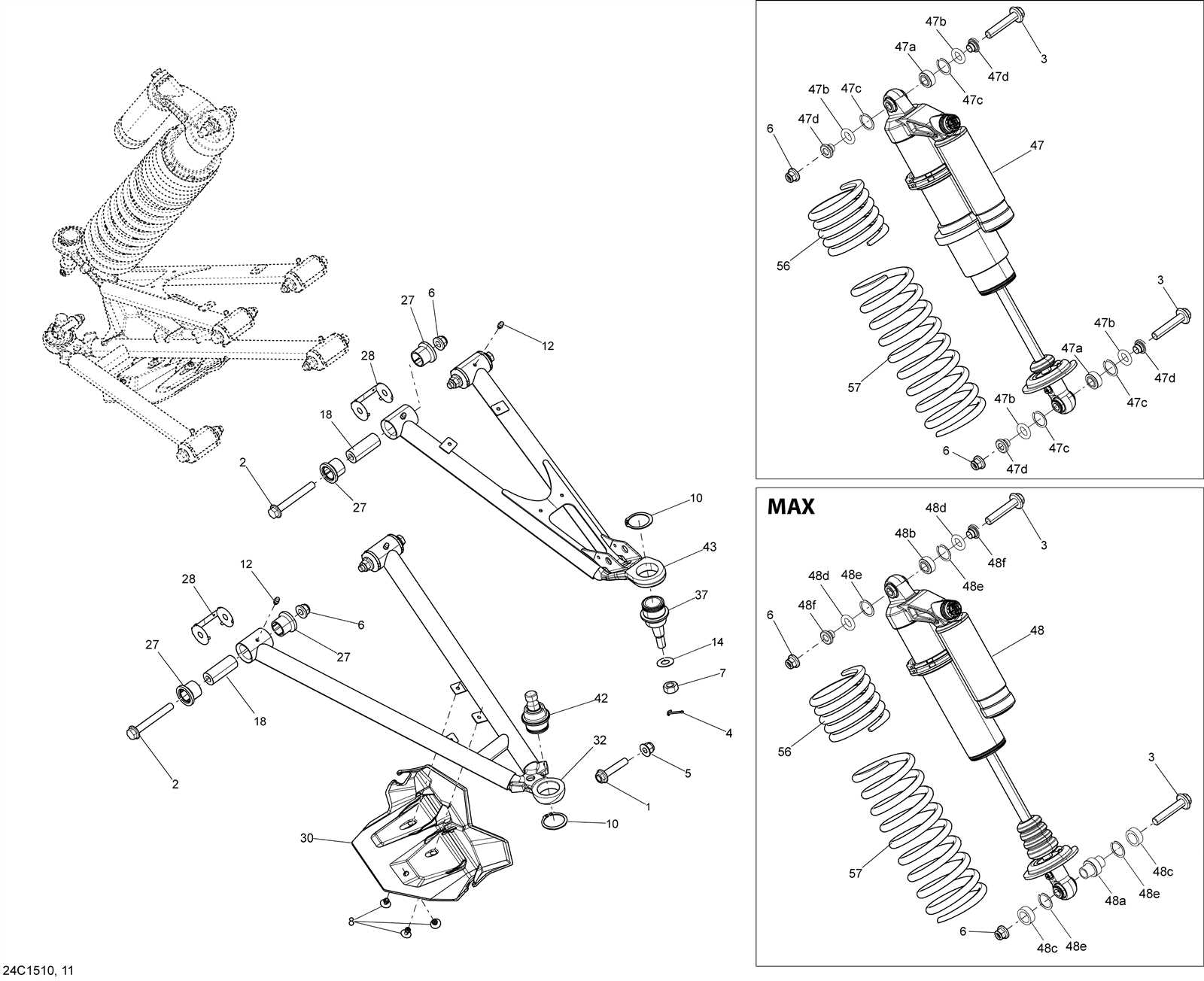

Suspension Parts Explained

The suspension system plays a crucial role in off-road vehicles, ensuring a smooth and controlled ride over various terrains. This section will provide an overview of the essential components that contribute to the overall performance of the system, helping to absorb shocks and maintain stability.

Main Components

- Shock absorbers: These dampen the impact from rough surfaces, allowing the vehicle to maintain contact with the ground while reducing vibrations.

- Control arms: These connect the wheel assembly to the vehicle’s frame, providing flexibility and range of motion while steering or driving over uneven ground.

- Springs: Paired with the shock absorbers, springs help to cushion the vehicle’s movements and return it to its normal position after compression.

How It All Works Together

Each element of the system works in tandem to deliver a comfortable experience by balancing the vehicle’s weight, absorbing impacts, and ensuring proper alignment. Regular checks and maintenance of these components are key to maximizing performance and longevity.

Brake System Details

The braking mechanism is a crucial component for ensuring safety and control during high-performance activities. This section provides an overview of how the system operates, highlighting key elements responsible for delivering effective stopping power and smooth handling in various conditions. Understanding these elements helps in maintaining optimal performance and ensuring longevity.

Component Description Brake Calipers These devices apply pressure to the brake pads, pressing them against the rotors to reduce speed or stop the vehicle. Brake Pads The pads are responsible for creating friction against the rotors, which slows down the wheels. Rotors The rotors are discs that rotate with the wheels, providing a surface for the brake pads to press against and create the necessary friction for stopping. Fuel System Configuration

The configuration of the fuel system is crucial for optimal performance and efficiency. This system is responsible for the delivery and management of fuel to the engine, ensuring that the combustion process is both effective and efficient. A well-designed configuration helps maintain proper fuel flow, enhances power output, and minimizes emissions.

Components of the Fuel System

The primary components of a typical fuel system include the fuel tank, pump, filter, injectors, and pressure regulator. Each element plays a vital role in ensuring that fuel is delivered to the engine at the right pressure and in the right quantity. Understanding how these components interact can aid in troubleshooting and optimizing performance.

Fuel Delivery Process

The fuel delivery process begins with the fuel tank, where the fuel is stored. The pump draws fuel from the tank and sends it through the filter to remove impurities. The clean fuel then travels to the injectors, which spray it into the combustion chamber at precise intervals. The pressure regulator maintains the appropriate fuel pressure throughout this process, ensuring that the engine receives a consistent supply.

Component Function Fuel Tank Stores the fuel until needed Fuel Pump Delivers fuel from the tank to the engine Fuel Filter Removes impurities from the fuel Fuel Injectors Inject fuel into the combustion chamber Pressure Regulator Maintains optimal fuel pressure Exhaust System Layout

The exhaust assembly is a critical component that ensures optimal performance and efficiency of an off-road vehicle. This system is designed to manage the expulsion of gases produced during combustion, facilitating a smoother operation while minimizing noise and emissions. Understanding its configuration is essential for maintenance and upgrades.

The layout of the exhaust system typically includes several key elements:

- Header: Collects exhaust gases from the engine’s cylinders and directs them into the system.

- Mid-pipe: Connects the header to the muffler, allowing for the flow of gases.

- Muffler: Reduces noise produced by the exhaust gases and helps in controlling back pressure.

- Tailpipe: Discharges exhaust gases safely away from the vehicle.

Each component plays a vital role in the overall functionality, affecting everything from performance to sound. Regular inspections of these parts can help in identifying wear and tear, ensuring longevity and efficiency in operations.

When considering modifications, it’s important to evaluate how changes to one component may impact the entire system. Upgrading to high-performance options may enhance power and sound, but proper integration is key to achieving desired results.

Electrical Wiring and Connectors

This section delves into the intricate web of electrical systems and their interconnections within off-road vehicles. Understanding how various components interact through wiring and connectors is essential for effective maintenance and troubleshooting.

The electrical layout plays a crucial role in ensuring optimal functionality and reliability. Key areas to consider include:

- Wiring Harness: The backbone of the electrical system, facilitating communication between components.

- Connectors: Essential for secure and efficient connections, minimizing the risk of electrical failure.

- Grounding Points: Critical for proper operation, ensuring that electrical circuits function without interference.

When working with the electrical system, it is important to:

- Inspect wiring for signs of wear or damage, which can lead to malfunctions.

- Ensure connectors are clean and free from corrosion to maintain good conductivity.

- Follow correct wiring procedures to prevent shorts or open circuits.

By paying attention to these aspects, one can enhance the longevity and performance of the electrical system.

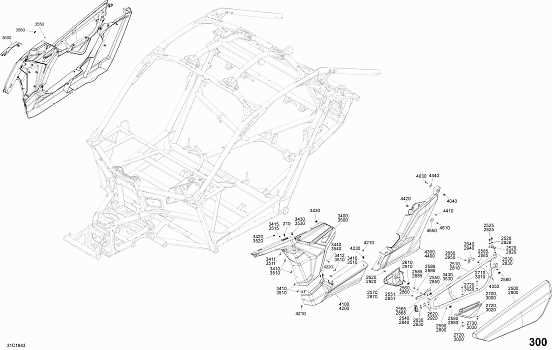

Chassis and Frame Parts Guide

This section provides an overview of the essential components that contribute to the structural integrity and performance of an off-road vehicle. Understanding these elements is crucial for maintenance, upgrades, and ensuring a safe riding experience.

Key Components

- Frame: The backbone of the vehicle, supporting all other components.

- Suspension System: Absorbs shocks from uneven terrain, enhancing stability.

- Skid Plates: Protect the undercarriage from obstacles and debris.

- Roll Cage: Provides safety for occupants by preventing cabin intrusion during rollovers.

Maintenance Tips

- Regularly inspect the frame for any signs of wear or damage.

- Ensure that all suspension components are securely fastened and in good condition.

- Clean skid plates after each ride to remove dirt and debris.

- Check the roll cage for any signs of corrosion or structural integrity issues.

Cooling System Parts Description

The cooling mechanism is vital for maintaining optimal operating temperatures in high-performance vehicles. This system comprises various components designed to efficiently regulate engine heat, ensuring reliability and longevity. Understanding the function of each element can aid in proper maintenance and enhance performance.

Radiator

The radiator serves as a heat exchanger, dissipating excess heat from the coolant as it circulates through the engine. It consists of numerous small tubes and fins that increase the surface area for effective heat transfer. A well-functioning radiator is crucial for preventing overheating during intense driving conditions.

Water Pump

The water pump plays a pivotal role in circulating coolant throughout the system. It draws coolant from the reservoir and pushes it through the engine and back to the radiator. A reliable pump ensures consistent flow, enabling effective heat management and preventing engine damage.

Steering Mechanism Components

The steering system plays a crucial role in the maneuverability and control of an off-road vehicle. Understanding its various elements is essential for proper maintenance and enhancements. This section outlines the key components that contribute to the functionality of the steering mechanism.

- Steering Wheel: The primary interface for the driver, allowing input for directional changes.

- Steering Column: Connects the steering wheel to the steering gear, providing support and housing various controls.

- Steering Gear: Transforms the rotational motion from the steering wheel into lateral movement of the front wheels.

- Linkage: A series of rods and joints that connect the steering gear to the wheels, facilitating the transfer of movement.

- Ball Joints: Pivot points that allow for a smooth range of motion between the linkage and the wheel assembly.

- Power Steering Pump: Provides hydraulic assistance to make steering easier, especially at low speeds.

- Rack and Pinion: A common mechanism that converts rotational motion into linear motion for wheel direction.

These components work in harmony to ensure a responsive and stable steering experience, enabling drivers to navigate various terrains effectively.

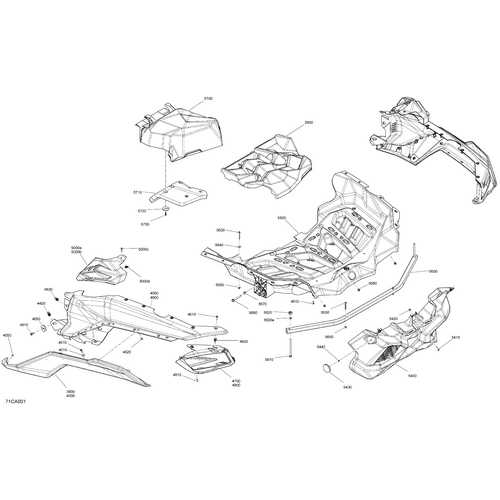

Bodywork and Exterior Panels

The outer structure of a vehicle plays a crucial role in its overall functionality and aesthetic appeal. It comprises various components that not only enhance the design but also contribute to the protection of internal systems. Understanding the different elements involved in the outer casing is essential for maintenance and upgrades.

These exterior features are crafted from durable materials that withstand the rigors of outdoor environments while ensuring optimal performance. Each section is designed to fit seamlessly with others, providing a cohesive look and functionality.

Component Description Material Front Fascia The front section that houses the headlights and grille. Polypropylene Side Panels These panels provide coverage for the sides and contribute to the vehicle’s aerodynamics. ABS Plastic Rear Cover Encloses the back of the vehicle, protecting rear components. Polyethylene Hood The top section that provides access to the engine compartment. Composite Materials Maintenance of these elements is vital for ensuring longevity and performance. Regular inspections can help identify wear or damage, allowing for timely replacements and repairs.

Wheels and Tires Assembly

The assembly of wheels and tires plays a crucial role in enhancing the performance and safety of off-road vehicles. This section delves into the components involved in this essential system, focusing on how each part contributes to the overall functionality and stability during operation.

In this context, understanding the various elements that constitute the wheel and tire assembly is fundamental. Each component interacts to ensure optimal traction, durability, and responsiveness. Below is a table summarizing the key parts involved in this assembly.

Component Description Rim The outer circular part that supports the tire and provides structure. Tire The rubber covering that provides traction and absorbs shocks. Hub The central part of the wheel that connects to the axle and allows rotation. Spokes Struts connecting the rim to the hub, providing strength and stability. Valve Stem The component that allows air to be added or removed from the tire. Each of these components must be properly assembled and maintained to ensure peak performance and safety during use. Regular inspections and proper care can significantly extend the lifespan of the wheels and tires, thereby enhancing the overall reliability of the vehicle.