In the realm of heavy machinery, a comprehensive understanding of the engine’s configuration is crucial for optimal performance and maintenance. Each element plays a vital role in ensuring that the engine operates smoothly and efficiently. By exploring the various components, one can gain insights into their functions and interrelations, which is essential for both troubleshooting and upgrades.

Engine assemblies are intricate systems composed of multiple units, each serving a specific purpose. These units work in harmony to provide the necessary power and functionality required for demanding tasks. Analyzing the layout of these components not only aids in maintenance but also enhances one’s ability to identify potential issues before they escalate.

Furthermore, a detailed visual representation can significantly assist technicians and enthusiasts alike in comprehending the complexity of these systems. By examining the configuration, one can appreciate the meticulous engineering behind heavy-duty engines and the importance of each element in contributing to the overall performance and longevity of the machinery.

Overview of Cat C12 Engine

The engine in question is a highly regarded power unit known for its robust performance and reliability in various heavy-duty applications. It has been engineered to meet the demanding needs of industries such as transportation and construction. This overview will delve into its essential features, components, and operational benefits, highlighting why it remains a preferred choice among professionals.

Key Features

- High power-to-weight ratio

- Advanced fuel injection technology

- Durable construction for extended service life

- Efficient cooling system to prevent overheating

- Emission-compliant design for reduced environmental impact

Benefits of the Engine

- Reliability: Proven performance in challenging conditions.

- Efficiency: Optimized fuel consumption for cost savings.

- Maintenance: Easy access to components for routine servicing.

- Versatility: Suitable for various applications from trucks to machinery.

This engine exemplifies a perfect blend of power, efficiency, and durability, making it an invaluable asset in heavy-duty operations. Its design reflects a commitment to excellence, ensuring that it continues to perform reliably in a range of demanding environments.

Key Components of Cat C12

The engine assembly consists of various essential elements that work in harmony to ensure optimal performance and efficiency. Understanding these components is crucial for maintenance, repair, and enhancement of overall functionality.

Engine Block: This sturdy structure forms the core of the power unit, housing the cylinders and providing a foundation for the entire assembly. It plays a pivotal role in supporting various engine systems.

Piston: This cylindrical element moves up and down within the cylinder, converting the pressure generated from combustion into mechanical energy. The piston’s motion is integral to the engine’s operation.

Cylinder Head: Positioned atop the engine block, this component contains the intake and exhaust valves. It is vital for regulating airflow into and out of the cylinders, influencing combustion efficiency and power output.

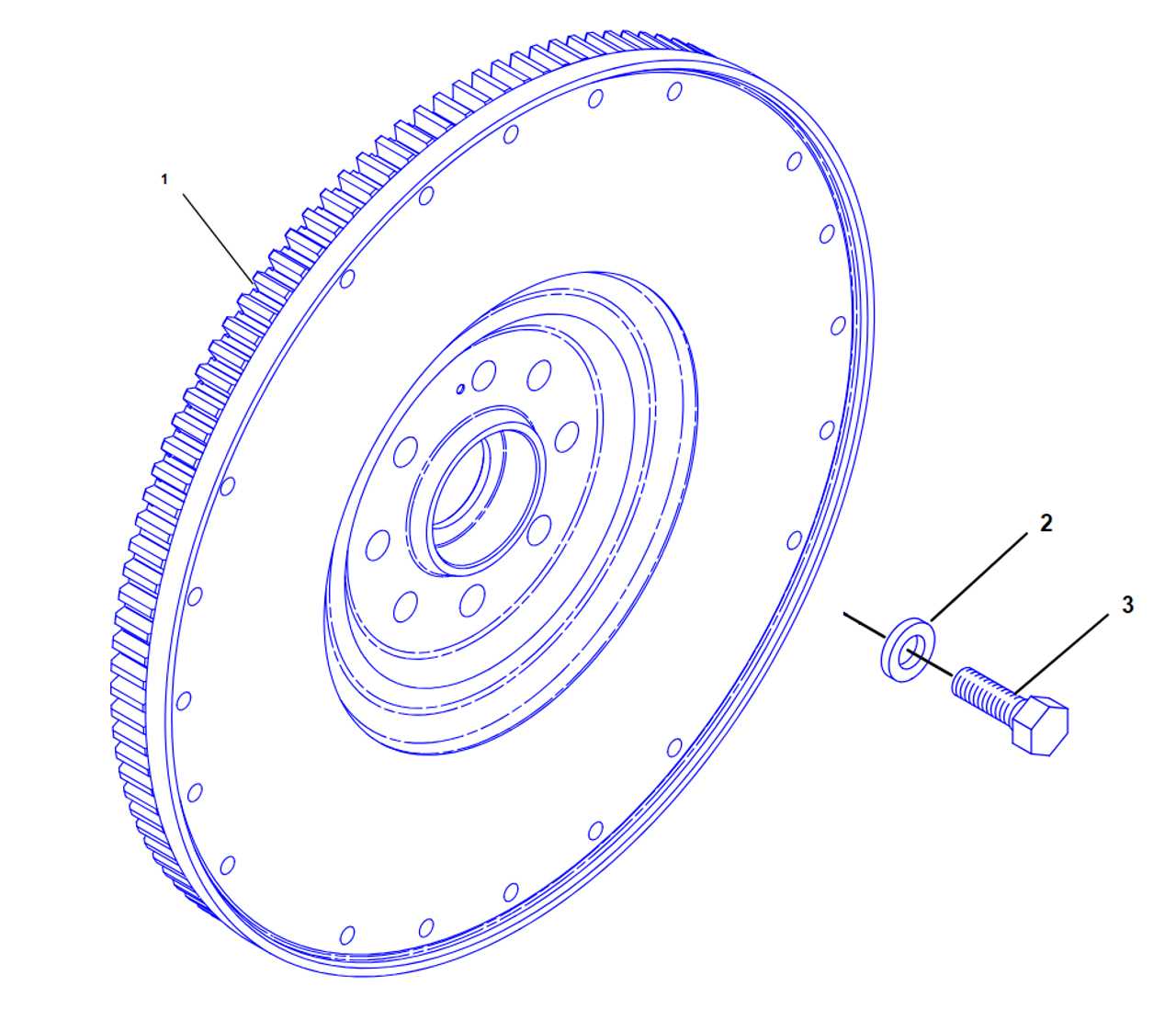

Crankshaft: The crankshaft transforms the linear motion of the pistons into rotational energy, which ultimately powers the drivetrain. Its design is crucial for smooth operation and effective power delivery.

Fuel System: This system comprises various components, including fuel injectors and pumps, responsible for delivering the right amount of fuel into the combustion chamber, ensuring optimal performance and efficiency.

Cooling System: Maintaining optimal operating temperatures is essential for engine longevity. This system circulates coolant through the engine to dissipate heat, preventing overheating and ensuring reliable operation.

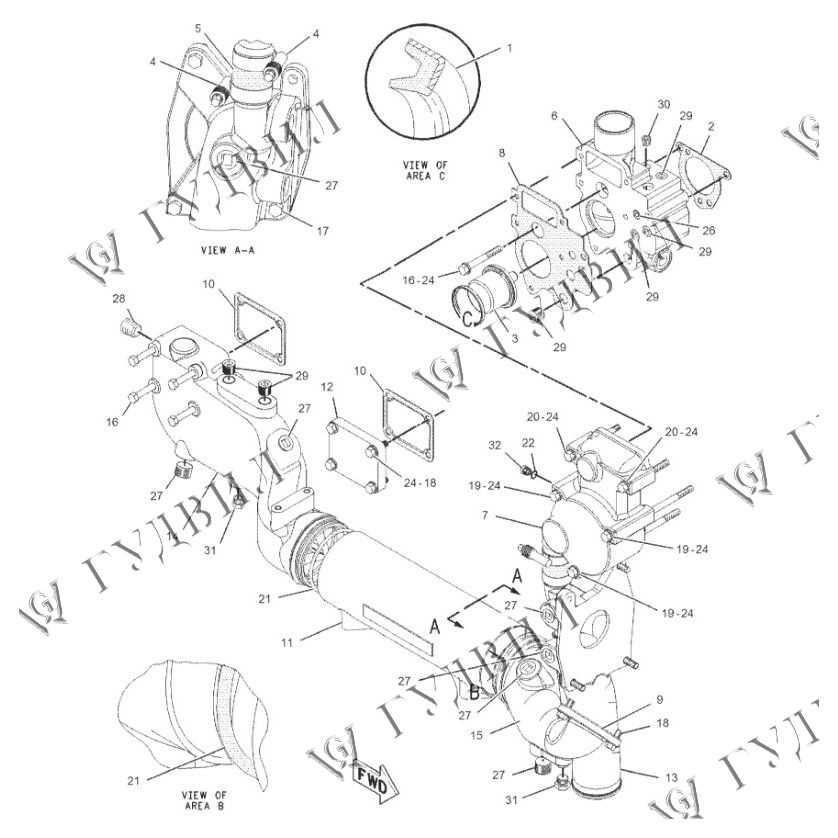

Exhaust System: Responsible for directing exhaust gases away from the engine, this system minimizes back pressure and helps maintain engine efficiency. It also plays a role in reducing emissions.

Cat C12 Parts Identification

This section focuses on recognizing and categorizing various components within a specific engine model. Understanding these elements is essential for maintenance, repairs, and performance enhancements. Proper identification helps in ensuring that the right parts are used during servicing, contributing to the overall efficiency and longevity of the machinery.

Key Components Overview

Several critical components play vital roles in the operation of the engine. Familiarity with these elements aids technicians and operators in diagnosing issues and performing effective repairs. Below is a summary of some significant components, their functions, and identification features:

| Component | Function | Identification Features |

|---|---|---|

| Crankshaft | Converts linear motion into rotational motion | Heavy metal rod with journal bearings |

| Piston | Creates compression in the combustion chamber | Cylindrical shape, often with a connecting rod attached |

| Turbocharger | Increases engine efficiency and power output | Two connected turbines with a distinct housing |

| Fuel Injector | Delivers fuel to the combustion chamber | Compact design with a nozzle for spray delivery |

| Oil Pump | Circulates oil for lubrication and cooling | Gear-driven, typically mounted on the engine block |

Identification Tips

When identifying components, it is crucial to refer to the engine’s specifications and consult the manufacturer’s resources. Use visual inspections, part numbers, and reference materials to confirm the correct components. Regular training and experience further enhance the ability to recognize and differentiate between various parts effectively.

Common Issues with Cat C12 Parts

When working with heavy machinery engines, certain components may exhibit wear or malfunction over time, leading to decreased performance and potential failures. Understanding the typical challenges associated with these elements can help in identifying symptoms early and ensuring efficient operation.

One frequent problem arises from inadequate lubrication, which can lead to increased friction and overheating. This often results in premature wear of bearings and other moving parts. Additionally, improper sealing may cause fluid leaks, which not only compromise performance but also pose risks to safety and environmental standards.

Another common issue is related to electrical connections, where corrosion or loose fittings can lead to intermittent operation or complete failure of critical systems. Regular inspections and maintenance are essential to mitigate these problems.

Moreover, the buildup of contaminants in fuel or air systems can lead to reduced efficiency and increased emissions. Routine cleaning and replacing filters can help maintain optimal operation.

Finally, vibration can cause components to loosen or break over time, emphasizing the importance of regular checks and proper mounting to ensure longevity and reliability.

Maintenance Tips for Cat C12

Proper upkeep of heavy machinery is essential to ensure longevity and optimal performance. Regular attention to various components can prevent unexpected failures and enhance efficiency. This section provides key maintenance recommendations to keep your equipment running smoothly.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 250 hours | Use high-quality oil to prevent wear. |

| Filter Replacement | Every 500 hours | Change fuel and air filters to maintain performance. |

| Coolant Check | Monthly | Ensure coolant levels are sufficient to avoid overheating. |

| Belt Inspection | Every 100 hours | Look for signs of wear or damage. |

| Battery Maintenance | Monthly | Clean terminals and check for corrosion. |

Regular adherence to these maintenance practices will significantly contribute to the operational reliability and efficiency of your equipment. Always refer to the manufacturer’s guidelines for specific recommendations tailored to your model.

Replacement Parts for Cat C12

Ensuring optimal performance of heavy machinery often requires timely updates and replacements of various components. Quality replacements enhance the reliability and efficiency of the equipment, minimizing downtime and extending its lifespan. Identifying suitable substitutes is essential for maintaining the functionality of your machinery.

| Component | Description | Part Number |

|---|---|---|

| Fuel Injector | Delivers fuel to the combustion chamber, ensuring proper engine function. | 123-4567 |

| Oil Filter | Removes contaminants from engine oil, protecting internal components. | 234-5678 |

| Turbocharger | Increases engine efficiency by forcing more air into the combustion chamber. | 345-6789 |

| Water Pump | Circulates coolant to maintain optimal operating temperature. | 456-7890 |

| Timing Belt | Synchronizes the rotation of the crankshaft and camshaft. | 567-8901 |

Cat C12 Engine Specifications

This section provides a comprehensive overview of the key characteristics and technical details of a specific engine model renowned for its performance and reliability in various applications. Understanding these specifications is crucial for maintenance, performance assessment, and compatibility with different machinery.

Engine Type: Inline 6-cylinder turbocharged diesel engine.

Displacement: 11.1 liters (677 cubic inches).

Horsepower: Available in configurations ranging from 410 to 580 horsepower, allowing for adaptability to various operational needs.

Torque: Peak torque varies between 1,450 to 1,850 lb-ft, providing substantial power for heavy-duty tasks.

Fuel System: Electronic fuel injection system designed to enhance fuel efficiency and optimize performance under different load conditions.

Cooling System: Liquid-cooled with a high-capacity radiator, ensuring efficient heat dissipation and maintaining optimal operating temperatures.

Dimensions: Overall length, width, and height specifications are designed for compatibility with standard engine mounts and frames in commercial vehicles.

Weight: Approximately 2,200 lbs, facilitating a robust construction while maintaining manageable weight for installation in various applications.

In summary, these specifications highlight the engine’s capabilities and versatility, making it a preferred choice for many users in demanding environments.

Understanding Cat C12 Assembly

This section delves into the intricate assembly of a renowned engine model, highlighting the essential components and their interconnections. By examining the structure and functionality of each element, one can gain insight into the mechanics that contribute to the engine’s performance and reliability.

Key Components and Their Functions

Every engine consists of critical elements, each serving a specific purpose. The main body forms the core, housing various internal mechanisms. The system includes components such as pistons, crankshafts, and cylinder heads, which work harmoniously to convert fuel into mechanical energy. Understanding how these parts collaborate is vital for effective maintenance and troubleshooting.

Assembly Process Overview

The assembly process involves meticulous attention to detail. Each part must be installed in a precise order to ensure optimal function. Proper torque specifications are crucial during this stage, as they affect the overall integrity of the assembly. Regular inspections and adjustments during assembly help maintain the engine’s efficiency and longevity.

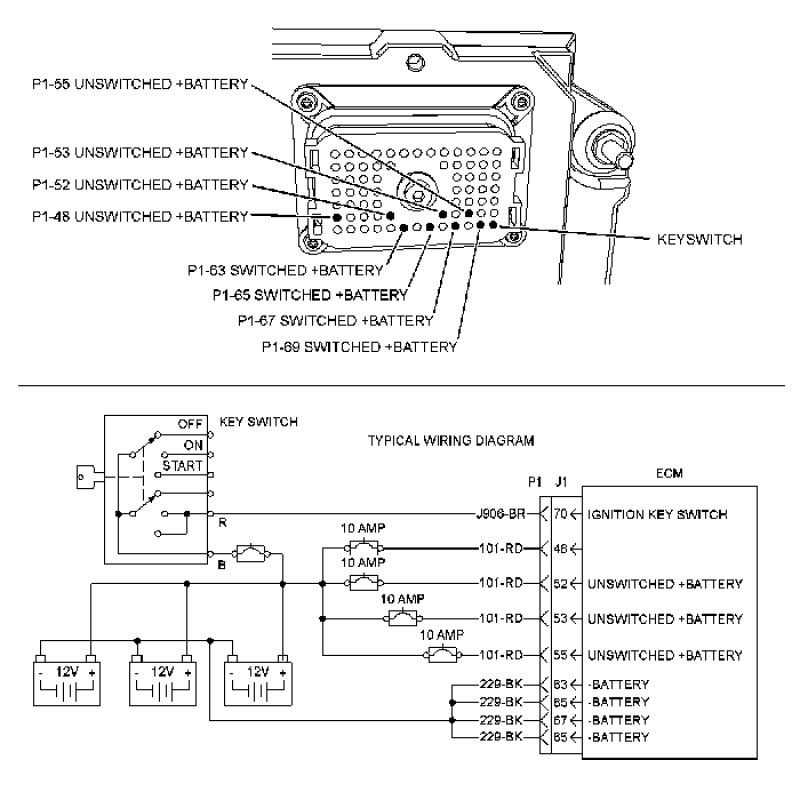

Wiring Diagrams for Cat C12

The electrical layout of heavy machinery is essential for ensuring optimal functionality and safety. Understanding the connections and configurations of various components is crucial for maintenance and troubleshooting. This section provides insights into the wiring setups that facilitate efficient operation and monitoring of the system.

Key Components and Their Connections

Proper identification of key elements and their interconnections can greatly enhance the performance of the equipment. Below is a summary of significant components and their wiring specifics:

| Component | Function | Wiring Connection |

|---|---|---|

| Battery | Power supply for starting and operating the engine | Connect to starter and alternator |

| Starter Motor | Initiates engine rotation | Wired to battery and ignition switch |

| Alternator | Charges the battery and powers electrical systems | Connected to battery and electrical harness |

| ECU | Controls engine functions and diagnostics | Linked with various sensors and actuators |

Understanding the Layout

Grasping the intricate wiring configurations helps in diagnosing issues and making informed adjustments. Familiarity with these arrangements is invaluable for both technicians and operators aiming to maintain peak performance.

Cat C12 Performance Upgrades

Enhancing the efficiency and power of your heavy-duty engine can significantly improve its overall performance and longevity. Various modifications and upgrades are available that focus on boosting horsepower, torque, and fuel efficiency while ensuring optimal operation under demanding conditions.

One popular upgrade is the installation of a high-performance turbocharger. This component can increase air intake, leading to improved combustion and greater power output. Additionally, an upgraded intercooler helps to maintain optimal air temperatures, which can further enhance performance.

Another effective enhancement is the tuning of the engine control unit (ECU). By recalibrating the ECU, you can optimize fuel mapping and ignition timing, resulting in better acceleration and throttle response. Performance chips are also available, providing a convenient way to adjust settings for increased efficiency.

Incorporating a high-flow exhaust system is another valuable modification. This upgrade reduces backpressure, allowing exhaust gases to exit more freely and improving engine breathing. Coupled with performance headers, these changes can lead to significant gains in power and torque.

Lastly, investing in quality fuel injectors can ensure that the engine receives the correct amount of fuel, contributing to optimal performance. Upgraded injectors can help achieve better fuel atomization and distribution, which is crucial for maximizing power output.

Tools Required for Cat C12 Repairs

When undertaking maintenance or repair work on heavy machinery engines, having the right equipment is essential for ensuring efficiency and effectiveness. Proper tools not only facilitate the repair process but also help prevent damage to components during servicing. This section outlines the necessary instruments for successfully conducting repairs on this specific engine model.

- Wrenches: A comprehensive set of wrenches, including both standard and metric sizes, is crucial for loosening and tightening various fasteners.

- Socket Set: A high-quality socket set allows for quick access to hard-to-reach areas and can handle the torque requirements of heavy-duty applications.

- Screwdrivers: A variety of screwdrivers, including flathead and Phillips, will be needed for adjusting smaller components and securing covers.

- Torque Wrench: This tool ensures that all bolts and nuts are tightened to the manufacturer’s specifications, preventing future issues caused by over- or under-tightening.

- Impact Wrench: An impact wrench is beneficial for removing stubborn bolts and fasteners, particularly in high-tension areas.

- Diagnostic Tools: Electronic diagnostic tools can help identify engine problems quickly, saving time during troubleshooting.

- Cleaning Supplies: Cleaning agents and brushes are essential for maintaining component cleanliness, which is critical for the longevity of engine parts.

Utilizing the proper tools not only streamlines the repair process but also enhances safety and prolongs the lifespan of the equipment. Being well-equipped can significantly improve the outcomes of maintenance tasks.

Where to Buy Cat C12 Parts

When it comes to sourcing components for heavy machinery, finding reliable suppliers is essential. The market offers various options for obtaining high-quality items necessary for maintaining optimal performance. Whether you’re a professional mechanic or a dedicated DIY enthusiast, knowing where to look can save you time and ensure that you receive authentic merchandise.

Authorized Dealers

One of the most trustworthy sources is through official dealers. They provide a wide range of genuine components that meet the manufacturer’s standards. Engaging with authorized distributors guarantees that you receive items that are specifically designed for your machinery, ensuring compatibility and durability.

Online Marketplaces

In addition to physical stores, numerous online platforms offer a vast selection of components. Websites specializing in heavy machinery often feature competitive prices and user reviews, which can help you make informed decisions. When purchasing online, ensure that you verify the seller’s reputation and return policies to avoid any potential issues.