In the world of construction and heavy machinery, a clear comprehension of the various components and their functions is essential. Each element plays a crucial role in the overall operation, ensuring efficiency and productivity on the job site. This section delves into the intricate layout of a specific type of heavy machinery, shedding light on its essential features.

By exploring the relationships between different sections, users can gain valuable insights into how these components interact to facilitate seamless operation. This knowledge is not only beneficial for operators but also for technicians who need to maintain and repair these complex machines.

Moreover, understanding the structure enhances safety protocols and operational effectiveness. Familiarity with the arrangement of components empowers users to make informed decisions during operation and troubleshooting, ultimately contributing to smoother workflows and improved outcomes in various projects.

Key Components of Excavators

Understanding the essential elements of heavy machinery is crucial for optimal performance and maintenance. These significant units work in harmony to facilitate various tasks, ensuring efficiency and effectiveness in construction and excavation activities. Each component plays a vital role in the overall functionality of the equipment.

Hydraulic System: This system is pivotal for generating the force needed to move the various attachments. It utilizes pressurized fluid to enable the operation of buckets, arms, and other tools, providing the necessary power for digging and lifting.

Track Assembly: The mobility of the machine relies heavily on its undercarriage. This assembly, which typically includes tracks and rollers, ensures stability and traction on diverse terrains, allowing for smooth operation across challenging landscapes.

Cabin: The operator’s workspace is designed for comfort and visibility. It houses controls and displays that facilitate the management of functions and provide crucial information about the machine’s performance, ensuring safety and efficiency during operation.

Engine: The heart of the machinery, the engine delivers the power required to operate all functions. Its efficiency directly affects fuel consumption and performance, making it a critical aspect of any heavy-duty machine.

Attachment Interface: This component allows for the quick connection of various implements, such as buckets and hammers. It enhances versatility, enabling the machinery to adapt to different tasks and environments.

Importance of Hydraulic Systems

The significance of fluid-driven mechanisms in heavy machinery cannot be overstated. These systems serve as the backbone of operations, facilitating the smooth and efficient transfer of power throughout the equipment. By converting hydraulic energy into mechanical force, they enable a wide range of functionalities crucial for various tasks.

Enhanced Performance and Efficiency

Hydraulic systems are designed to optimize the performance of machinery, allowing for precise control and swift operations. They enhance the efficiency of tasks by providing a substantial amount of force in a compact design. This capability is vital for achieving high productivity levels in demanding environments.

Maintenance and Reliability

Regular maintenance of fluid-driven systems is essential for ensuring their longevity and reliability. By adhering to maintenance protocols, operators can prevent unexpected breakdowns and extend the lifespan of the machinery. A well-maintained system not only functions better but also reduces operational costs over time.

| Aspect | Benefit |

|---|---|

| Power Transfer | Efficient movement of heavy loads |

| Precision Control | Enhanced accuracy in operations |

| Compact Design | Space-saving while maximizing power |

| Maintenance | Increased reliability and lower costs |

Understanding the Boom and Arm

The boom and arm are essential components in heavy machinery that significantly influence operational capabilities. These elements work in unison to provide the necessary reach and lifting power, allowing the machine to perform various tasks efficiently. Their design and functionality are pivotal in determining the overall effectiveness of the equipment in construction and excavation projects.

Functionality of the Boom

The boom serves as a primary support structure, enabling vertical and horizontal movement. Its length and angle can be adjusted to achieve optimal positioning, thereby enhancing the machine’s ability to handle heavy loads at varying distances. Understanding the boom’s role is crucial for maximizing productivity and ensuring safety during operations.

Role of the Arm

The arm connects the bucket or attachment to the boom, facilitating precise movements. It allows for effective digging, lifting, and placement of materials. The arm’s design impacts its strength and flexibility, making it vital for different applications in construction and demolition tasks.

| Component | Description | Function |

|---|---|---|

| Boom | Main structural element providing reach | Supports vertical and horizontal movement |

| Arm | Connects bucket to the boom | Facilitates digging and lifting tasks |

Functionality of the Bucket Assembly

The bucket assembly serves as a crucial component in various heavy machinery, playing an integral role in material handling and excavation tasks. Its design facilitates the efficient movement of soil, debris, and other materials, enhancing the overall productivity of the machinery. Understanding how this assembly operates is essential for maximizing performance and ensuring effective operation.

Key Functions of the Bucket Assembly

One of the primary functions of the bucket assembly is to excavate or remove material from the ground. The shape and size of the bucket are engineered to allow for optimal digging capabilities, enabling operators to achieve desired depths and volumes with precision. Moreover, the assembly’s capacity to hold and transport materials is vital in construction and landscaping projects, where efficiency is paramount.

Durability and Design Considerations

The bucket assembly is constructed from robust materials to withstand the rigors of demanding environments. Durability is a key aspect, ensuring that it can endure wear and tear while maintaining functionality. Additionally, various designs are available to cater to specific tasks, such as digging, grading, or loading, making the bucket assembly a versatile tool in heavy machinery operations.

Exploring the Chassis Structure

The framework of heavy machinery plays a crucial role in ensuring stability and durability during operation. Understanding its composition and function is essential for maintenance and optimal performance. This section delves into the various components that constitute this vital structure, highlighting their significance in the overall design.

Framework Integrity is paramount, as it bears the load and absorbs stress from various operations. The chassis is designed to withstand harsh conditions while providing a solid base for other mechanisms.

Connection Points serve as essential elements where different systems integrate, facilitating seamless communication between various components. Proper alignment and durability of these points are critical for the efficient operation of the machinery.

Role of the Swing Mechanism

The swing mechanism is a vital component in heavy machinery, facilitating rotational movement that enhances operational efficiency. This system allows the equipment to pivot, providing versatility in various tasks, from digging to lifting. By enabling smooth rotation, the mechanism ensures that the machine can perform complex maneuvers without needing to reposition its base.

Functionality and Importance

The primary function of the swing mechanism is to allow the attachment to move in a circular motion around the machine’s frame. This capability is crucial for tasks that require precision, such as placing materials in specific locations. Moreover, the design of this system helps distribute weight evenly, improving stability during operation.

Impact on Performance

Efficient swing operation significantly impacts overall performance and productivity. A well-functioning mechanism reduces wear and tear on other components, leading to lower maintenance costs and longer service life. Furthermore, it enhances the operator’s ability to execute tasks quickly and accurately, contributing to improved project timelines.

Electrical System Components Explained

The electrical system of heavy machinery plays a crucial role in ensuring efficient operation and functionality. This intricate network is designed to facilitate the transmission of energy, enabling various components to work harmoniously together. Understanding the individual elements of this system is essential for maintenance and troubleshooting.

Power Supply: At the heart of the electrical framework is the power source, which provides the necessary energy for operation. It typically comprises a battery that stores electrical energy, ensuring reliable startup and continuous performance.

Wiring Harness: This network of cables connects various components, allowing for seamless communication and power distribution. Proper insulation and routing are vital to prevent electrical shorts and ensure longevity.

Switches and Relays: These components serve as control mechanisms within the system. Switches allow operators to turn functions on and off, while relays help manage larger currents, providing protection and enhancing efficiency.

Sensors and Monitors: Integrated sensors play a vital role in collecting real-time data about the machine’s performance. These devices help monitor parameters such as temperature, pressure, and voltage, enabling proactive maintenance and enhancing safety.

Control Modules: The brain of the electrical system, control modules process signals from various inputs and send commands to different components. These modules ensure the machine operates according to the operator’s commands, providing precision and responsiveness.

Maintenance of Excavator Parts

Regular upkeep of machinery components is crucial for ensuring optimal functionality and longevity. Proper care not only enhances performance but also minimizes the risk of unexpected failures, which can lead to costly downtime. A proactive maintenance approach is essential for any operator looking to maximize productivity and efficiency in their operations.

Key Maintenance Practices

- Regular Inspection: Conduct thorough examinations to identify any wear or damage.

- Lubrication: Ensure all moving elements are properly lubricated to reduce friction.

- Cleaning: Keep components free of dirt and debris to prevent clogging and corrosion.

- Calibration: Adjust settings according to manufacturer specifications for accurate performance.

- Replacement: Swap out worn or damaged components promptly to avoid further issues.

Benefits of Routine Maintenance

- Increased Efficiency: Well-maintained machinery operates more smoothly, improving overall productivity.

- Extended Lifespan: Regular care extends the usable life of critical components.

- Cost Savings: Preventive measures reduce the likelihood of major repairs and downtime.

- Enhanced Safety: Regular maintenance helps ensure safe operation, protecting both operators and equipment.

Common Issues in Excavator Parts

Understanding the typical challenges that can arise with heavy machinery components is essential for maintaining optimal performance and efficiency. Many factors can contribute to malfunctions, and recognizing these issues can prevent costly repairs and downtime.

Frequent Problems Encountered

- Wear and Tear: Continuous use can lead to deterioration of critical components, affecting overall functionality.

- Hydraulic Leaks: Damaged seals or hoses often result in fluid loss, leading to reduced power and efficiency.

- Electrical Failures: Corrosion or wiring issues may cause malfunctioning systems, affecting control and performance.

Maintenance Recommendations

- Regularly inspect all components for signs of damage or excessive wear.

- Ensure hydraulic fluid levels are maintained and check for leaks frequently.

- Keep electrical connections clean and secure to prevent operational issues.

Replacement Parts for Cat Excavators

Maintaining the efficiency and reliability of heavy machinery often requires the timely acquisition of suitable components. Understanding the significance of these components can ensure optimal performance and prolong the lifespan of the machinery. Whether addressing wear and tear or upgrading features, selecting the right elements is crucial for smooth operations.

Types of Components Available

Numerous varieties of elements are available for these machines, catering to different functions. From hydraulic systems to engine components, each plays a vital role in ensuring seamless functionality. Common options include:

- Hydraulic cylinders: Essential for lifting and moving heavy loads.

- Tracks and undercarriage: Provide stability and mobility on various terrains.

- Filters: Ensure clean fluids and enhance performance.

Benefits of Quality Replacement Components

Opting for high-quality replacement elements offers several advantages. Durable options can reduce downtime, enhance safety, and improve operational efficiency. Investing in reliable components not only ensures better performance but also helps in minimizing overall maintenance costs.

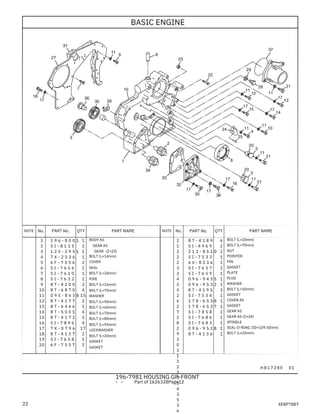

Diagrams for Easy Reference

Visual representations serve as invaluable tools for understanding complex machinery and their individual components. They provide a clear overview, making it easier to identify and locate specific elements within the overall structure. Such illustrations facilitate quicker comprehension and enhance the learning process, enabling users to navigate through intricate systems with greater ease.

These visual aids can be particularly beneficial during maintenance or repair tasks, as they offer a straightforward reference point. When equipped with a reliable illustration, operators can efficiently assess which segments need attention and how to approach their tasks. Ultimately, this resource promotes efficiency and accuracy, ensuring that work is carried out effectively.

Tips for Identifying Components

Recognizing various elements within heavy machinery is essential for effective maintenance and repairs. Understanding how to differentiate these components can streamline the diagnostic process and enhance operational efficiency.

1. Familiarize Yourself with Terminology: Knowing the specific terms related to machinery can significantly aid in identification. Use manuals or online resources to learn about the functions and characteristics of each component.

2. Utilize Visual Aids: Diagrams and illustrations can serve as valuable references. Compare real-life machinery with these visual tools to enhance your understanding of where each element is located.

3. Observe Component Markings: Many elements have unique identifiers or serial numbers. Paying attention to these markings can help in accurately identifying components and sourcing replacements if needed.

4. Seek Professional Guidance: If you are uncertain, consulting with experienced technicians or industry professionals can provide clarity. They can offer insights based on practical knowledge that can be invaluable in component identification.

5. Conduct Regular Inspections: Frequent checks on your equipment will help you become more familiar with its components. Over time, you’ll start to recognize common elements and their functions more easily.