The intricate design of two-wheeled vehicles requires a thorough comprehension of their various elements and how they interconnect. Each segment plays a crucial role in the overall performance and safety of the machine. By visualizing the arrangement of these components, enthusiasts and mechanics can enhance their understanding and facilitate maintenance and repairs.

In this exploration, we will delve into the detailed representation of the essential elements of a motorcycle. This guide serves as a valuable resource for both seasoned riders and newcomers, providing insights into the arrangement and function of different sections. Whether you’re looking to replace a malfunctioning piece or simply want to familiarize yourself with the structure, this knowledge is fundamental.

As we navigate through the layout of a motorcycle, the clarity of each component’s position becomes paramount. Recognizing how these individual pieces contribute to the vehicle’s overall functionality not only aids in effective upkeep but also enriches the riding experience. Join us in this informative journey as we uncover the essentials of motorcycle structure.

Understanding CBR 125 Component Layout

The arrangement of various elements within a motorcycle plays a crucial role in its overall functionality and performance. Analyzing how these components interact provides valuable insights into the engineering behind two-wheeled vehicles. Each segment is designed to work harmoniously, ensuring that the bike operates efficiently while maintaining rider comfort and safety.

In this exploration, the emphasis is on recognizing the significance of each part within the assembly. From the engine assembly to the chassis, every section contributes to the bike’s capability. Understanding the layout allows enthusiasts and mechanics to identify potential issues, streamline repairs, and optimize performance.

Furthermore, a comprehensive grasp of the configuration fosters appreciation for the design process. It highlights how engineers meticulously plan the placement of every piece, considering factors like weight distribution, accessibility, and aerodynamics. This knowledge not only enhances maintenance practices but also enriches the overall riding experience.

Ultimately, delving into the arrangement of components reveals the intricate craftsmanship behind motorcycle design. Recognizing the interdependence of each element is essential for anyone looking to deepen their knowledge and expertise in the field of motorbikes.

Overview of CBR 125 Structure

The design of this motorcycle embodies a seamless blend of aesthetics and functionality, contributing to an impressive riding experience. Its frame serves as the backbone, ensuring stability and durability while maintaining a lightweight profile. The engineering behind this model incorporates various components that work in harmony, from the engine placement to the suspension system, resulting in an agile and responsive ride.

The chassis is constructed with precision, enhancing the overall strength and allowing for better handling dynamics. With strategically positioned elements, the balance between performance and comfort is achieved, making it suitable for both urban commuting and longer journeys. Attention to detail is evident in the arrangement of each part, ensuring that every aspect contributes to a smooth operation.

This vehicle features an ergonomic design that prioritizes rider comfort and control. The seating position is optimized for extended rides, reducing fatigue and enhancing the overall experience. Furthermore, the integration of advanced technologies ensures that safety and efficiency are not compromised, providing peace of mind on every adventure.

Essential Parts of CBR 125 Model

This section explores the key components that make up the structure and functionality of a specific motorcycle model. Understanding these elements is crucial for maintenance, upgrades, or simply appreciating the engineering behind the machine.

Key Components

- Engine: The heart of the motorcycle, responsible for converting fuel into motion.

- Frame: The skeleton that supports the entire bike and provides stability.

- Suspension: The system that absorbs shocks and ensures a smooth ride.

- Braking System: Crucial for safety, it allows the rider to slow down or stop the motorcycle effectively.

- Wheels and Tires: Essential for traction and maneuverability on various terrains.

Additional Elements

- Fuel Tank: Stores fuel and plays a role in the overall design.

- Exhaust System: Responsible for directing exhaust gases away from the engine.

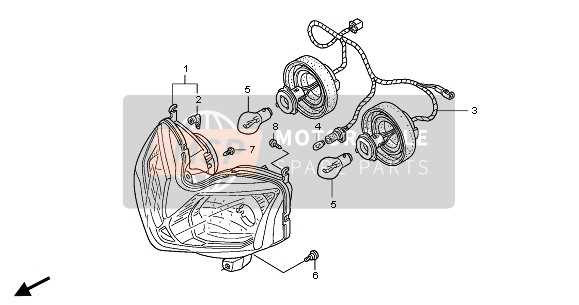

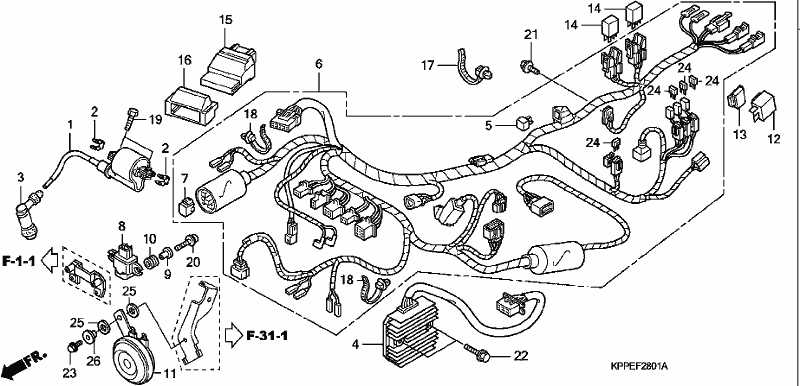

- Electrical System: Powers lights, ignition, and other electronic components.

- Controls: Include handlebars, throttle, and levers for an enhanced riding experience.

Functionality of Each Component

This section aims to explore the roles of various elements within a two-wheeled vehicle. Understanding how each part contributes to the overall performance and safety can enhance the maintenance and repair process, ensuring optimal functionality and longevity.

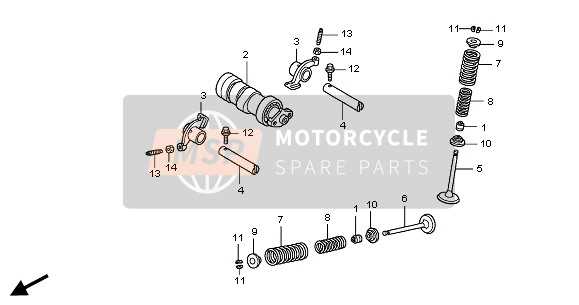

Engine and Transmission

The engine serves as the heart of the vehicle, converting fuel into mechanical energy, while the transmission system transmits this power to the wheels. Each component within these systems plays a crucial role in ensuring smooth acceleration and efficient power delivery.

Suspension and Braking Systems

The suspension system maintains stability and comfort by absorbing shocks from the road, while the braking system ensures safe stopping by converting kinetic energy into heat. Proper functioning of these components is vital for rider safety and overall driving experience.

| Component | Functionality |

|---|---|

| Engine | Converts fuel into mechanical energy for propulsion. |

| Transmission | Transmits power from the engine to the wheels. |

| Suspension | Absorbs road shocks, providing stability and comfort. |

| Brakes | Slows down or stops the vehicle by converting kinetic energy to heat. |

Identifying Key Mechanical Elements

Understanding the fundamental components of a motorcycle is essential for both maintenance and enhancement. Familiarity with these crucial mechanical elements enables riders to appreciate their machine better, troubleshoot issues, and optimize performance. This section highlights the primary features that contribute to the overall functionality of a two-wheeled vehicle.

- Engine: The heart of the vehicle, responsible for converting fuel into motion. It is essential to know its capacity, type, and configuration.

- Transmission: This component transmits power from the engine to the wheels, allowing for speed and torque adjustments. Recognizing the type of transmission, whether manual or automatic, is crucial.

- Chassis: The framework that supports the vehicle’s body, ensuring stability and strength. Understanding its material and design is vital for performance and safety.

- Suspension: This system absorbs shocks from the road, providing comfort and control. Familiarizing oneself with its components can enhance ride quality.

- Braking System: Essential for safety, this system allows the rider to slow down or stop effectively. Knowing the differences between hydraulic and mechanical brakes can impact maintenance and upgrades.

- Fuel System: Comprising the fuel tank, lines, and injectors, this system is crucial for delivering fuel to the engine efficiently.

- Electrical System: Responsible for powering lights, ignition, and other electronic components, this system requires attention to ensure reliability.

By gaining insights into these key mechanical elements, riders can make informed decisions regarding maintenance, repairs, and enhancements, ultimately leading to a better riding experience.

Wiring Diagram for CBR 125

The electrical layout for a motorcycle serves as a crucial reference for understanding the connections and functionality of various components. This schematic representation illustrates the routing of wires and the interconnection of elements, ensuring a reliable power supply and efficient communication among systems.

In this section, we will delve into the specific configurations of the wiring setup, highlighting key aspects such as color codes and the role of individual wires. Mastering this layout is essential for troubleshooting, repairs, and modifications, making it an invaluable tool for enthusiasts and technicians alike.

Understanding this electrical schematic allows for better insights into the operation of critical systems, such as lighting, ignition, and accessories. By familiarizing oneself with the layout, one can efficiently navigate potential issues and optimize the motorcycle’s overall performance.

Maintenance Tips for CBR 125 Parts

Proper upkeep of a motorcycle is essential for its longevity and performance. Regular checks and servicing can significantly enhance the reliability and efficiency of various components. This section outlines key practices to ensure that the crucial elements of your two-wheeler remain in optimal condition.

Regular Inspection

Routine inspections play a vital role in identifying wear and tear before it escalates into significant issues. Key areas to focus on include:

| Component | Recommended Action |

|---|---|

| Brakes | Check pads for wear; replace if less than 2mm thickness. |

| Chain | Lubricate regularly and adjust tension as needed. |

| Fluids | Monitor oil, coolant, and brake fluid levels; top up or change as specified. |

| Tires | Inspect for pressure and tread depth; ensure even wear. |

Cleaning and Lubrication

Maintaining cleanliness is crucial for the functionality of various systems. Dirt and grime can lead to premature failure. Regularly clean components such as the air filter and chain, and apply appropriate lubricants to reduce friction and enhance performance.

Replacement Procedures for Common Parts

Over time, the mechanical components of any vehicle may require attention due to wear or damage. This section will guide you through the process of replacing some of the most frequently serviced elements, ensuring that your machine remains in optimal condition. The following steps provide an overview of each procedure, allowing for smooth and efficient maintenance.

Changing the Brake Pads

- Start by lifting the vehicle and securing it to ensure stability during the procedure.

- Remove the caliper by unscrewing the bolts that hold it in place.

- Take out the worn pads and insert the new ones, making sure they fit snugly.

- Reattach the caliper and tighten the bolts securely.

- Test the braking system before operating to ensure proper installation.

Replacing the Chain

- Loosen the rear axle to allow the wheel to move forward and relieve tension on the

Upgrades and Modifications Available

When it comes to enhancing performance and personalizing your ride, there are numerous options for both visual and technical improvements. Whether you’re looking to boost speed, refine handling, or add unique styling elements, the variety of available updates provides flexibility for every rider’s preferences.

Engine tuning is a popular way to unlock additional power and improve overall responsiveness. By adjusting fuel systems or upgrading internal components, riders can significantly enhance acceleration and top-end performance.

Suspension modifications offer another key area for refinement. High-quality shocks and adjustable components allow for smoother rides and better control during tight turns or on rough terrain.

Visual customization is also widely embraced, with options ranging from aerodynamic fairings to unique paint schemes, all contributing to a personalized look while potentially improving wind resistance and efficiency.

Resources for CBR 125 Parts

When it comes to maintaining and upgrading your two-wheeled machine, knowing where to find components is essential. Whether you need replacements for routine upkeep or are seeking specific elements for performance enhancement, having access to trustworthy resources can make a big difference. In this section, we will explore valuable sources and platforms to help you locate what you need quickly and efficiently.

Reliable Online Platforms

There are several well-established websites dedicated to providing various components for motorbikes. These platforms often feature user reviews, ensuring that you are buying from credible sellers. Many offer detailed search tools that let you narrow down your options by model year, part category, and even manufacturer.

Platform Special Features Motorcycle Parts Hub Wide selection of original and aftermarket items Biker’s Supply Depot User-friendly filters and expert advice sections Spare Finder Global shipping and extensive compatibility checks Local Dealers and Mechanics

While online options provide convenience, visiting a local dealer or mechanic can be invaluable. These professionals not only offer parts but also provide hands-on expertise and recommendations tailored to your specific needs. Many workshops also have access to rare or difficult-to-find items, which might not be readily available online.

Common Issues with CBR 125 Components

Over time, certain mechanical and electrical elements can experience wear or malfunction, especially when exposed to frequent use or harsh conditions. Identifying and addressing these issues early can help prevent more significant damage and ensure reliable performance. Understanding which areas are more prone to problems can assist in maintaining optimal functionality.

Frequent Electrical Failures

Electrical malfunctions are often observed in key circuits, especially those responsible for lighting and ignition. Wiring can become corroded or loose, leading to intermittent power loss or failure to start. Regular inspection and maintenance of electrical connections can help mitigate these concerns.

Mechanical Wear and Tear

Certain moving parts are more susceptible to wear, particularly within the engine and suspension systems. Components such as seals, bearings, and joints can degrade due to friction, causing reduced efficiency or noisy operation. Lubrication and timely replacement of worn-out elements are crucial for maintaining smooth performance.

Manufacturer Specifications and Standards

When selecting components for a specific machine, it is crucial to understand the technical requirements set by the manufacturer. These guidelines ensure that every element fits perfectly, functions efficiently, and meets safety standards. Knowing the official specifications helps in maintaining compatibility and performance over time.

Material quality and precision engineering are two essential factors defined by the producer. These criteria dictate the durability and reliability of various elements, ensuring the vehicle operates under optimal conditions without compromising safety.

Each part must comply with regulatory standards, which may include specific measurements, tolerances, and materials. Following these standards guarantees not only the longevity of the machine but also the safety of the user.