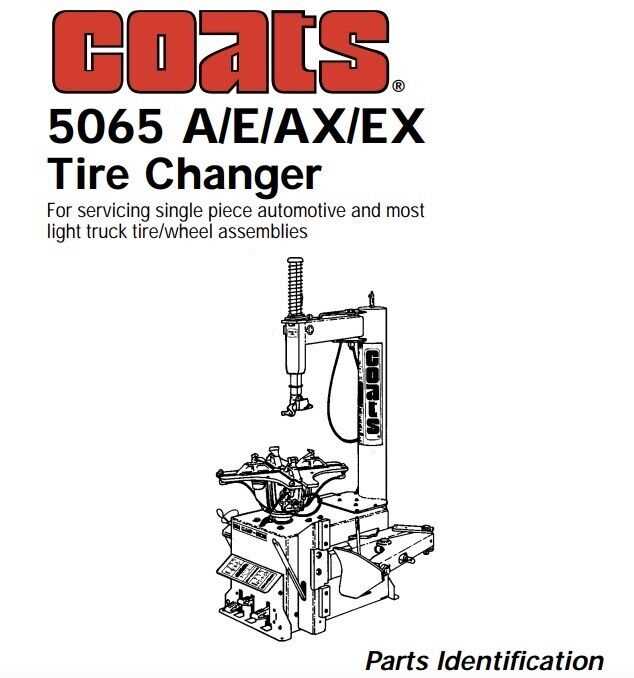

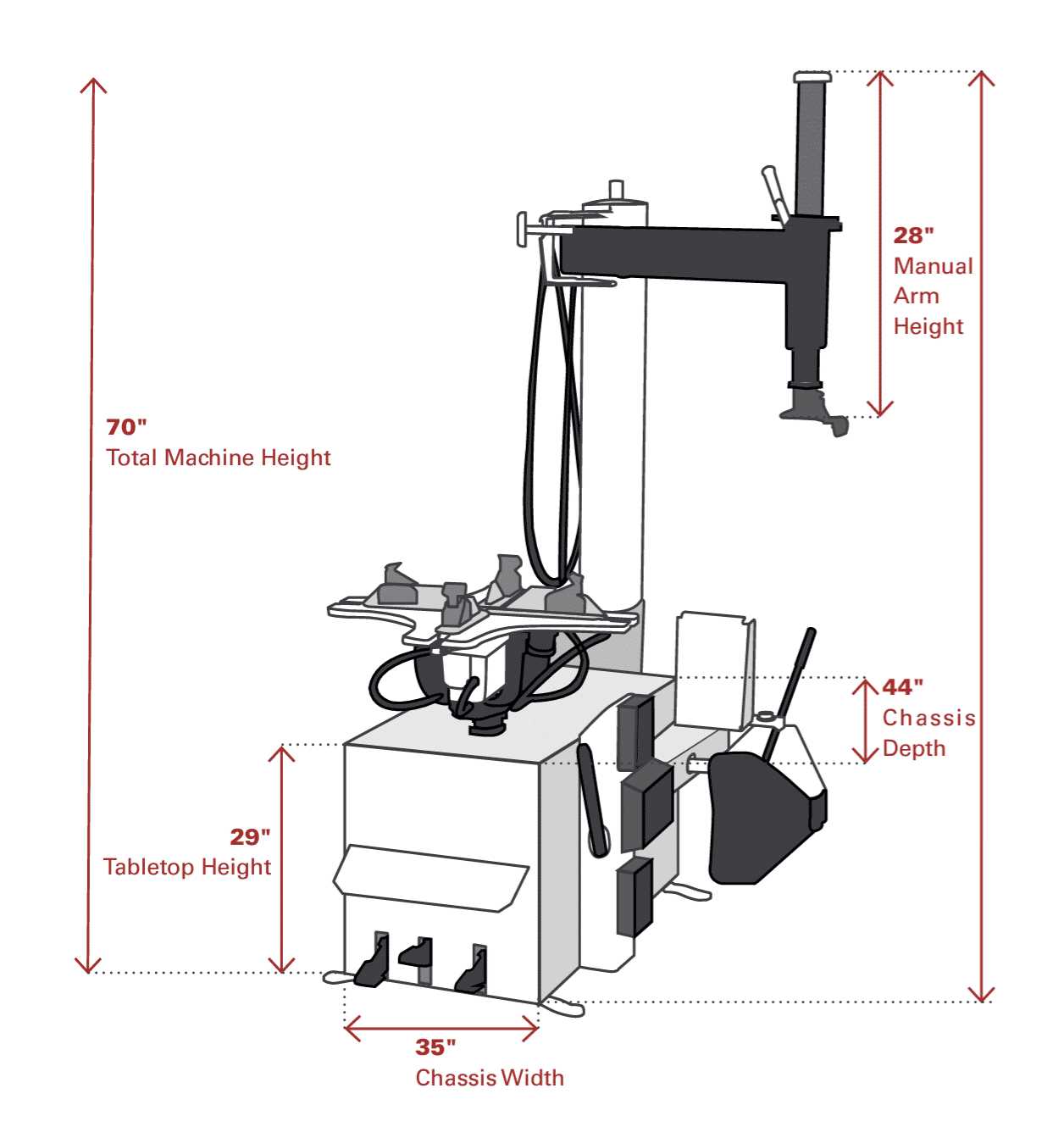

In the realm of tire maintenance, having a clear understanding of the various elements involved in machinery is crucial for efficiency and safety. Each unit consists of multiple components that work in harmony to ensure optimal performance. Knowing the intricacies of these parts can significantly enhance the service process and prolong the life of the equipment.

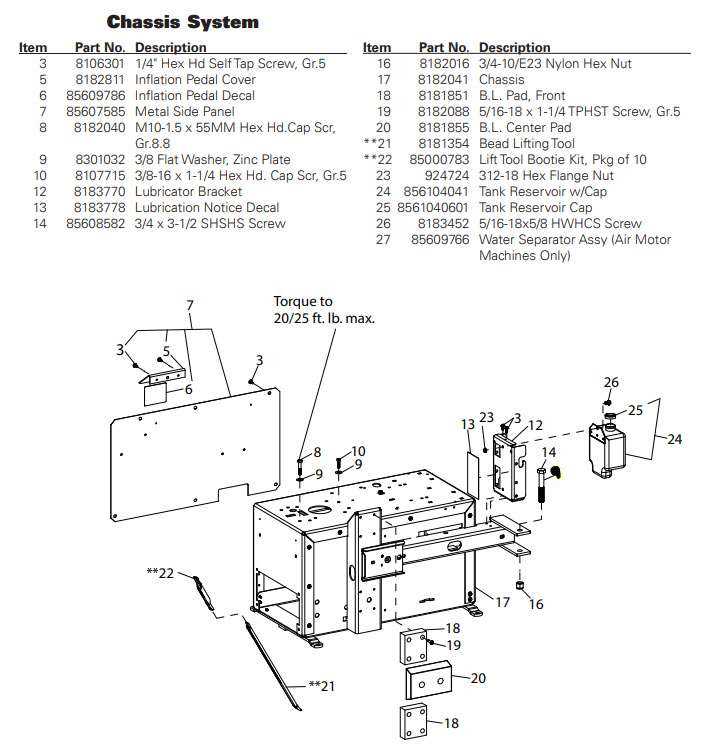

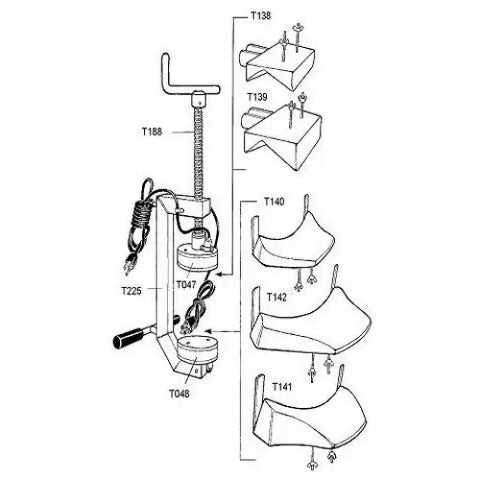

Visual representation of these components can serve as an invaluable resource for technicians and enthusiasts alike. By examining these illustrations, one can quickly identify each section and its function within the larger system. This knowledge not only aids in routine maintenance but also simplifies troubleshooting when issues arise.

Furthermore, being familiar with the layout and relationship between the various elements contributes to a deeper understanding of the mechanics involved. This expertise empowers users to operate the machinery more confidently and effectively, ensuring that tire servicing tasks are carried out with precision and care.

Understanding Coats RC-45 Components

Grasping the intricate elements of a tire changing machine is essential for efficient operation and maintenance. Each component plays a crucial role in ensuring the device functions smoothly and effectively. By familiarizing oneself with these key parts, users can optimize performance and address potential issues more readily.

Among the primary components, one can find various mechanical and electronic elements that work in harmony. Understanding the function of each part not only aids in troubleshooting but also enhances the overall user experience. Below is a table summarizing some vital elements and their respective functions:

| Component | Description |

|---|---|

| Bead Breaker | A tool designed to separate the tire from the rim, facilitating the mounting process. |

| Mounting Arm | This arm assists in placing the tire onto the rim with precision. |

| Spin Plate | A rotating surface that holds the rim securely in place during the tire installation. |

| Control Panel | The interface for operating the machine, allowing users to manage various functions easily. |

| Pressure Gauge | Monitors the air pressure within the tire, ensuring proper inflation. |

By comprehensively understanding these components, operators can ensure their equipment remains in peak condition and can perform tire changes swiftly and safely.

Overview of Coats RC-45 Parts

This section provides a comprehensive insight into the components that constitute a tire changer, highlighting their significance and functionality. Understanding these elements is crucial for effective maintenance and repair, ensuring optimal performance and longevity of the equipment.

The main elements include the mounting head, which plays a pivotal role in tire installation, and the rim clamp, essential for securing the wheel. Additionally, the turntable facilitates rotation, allowing for precise handling during the tire changing process.

Other noteworthy components include the bead breaker, which aids in separating the tire from the rim, and the hydraulic system that powers various functions, ensuring smooth operation. Familiarity with these components enhances overall operational efficiency and safety.

Ultimately, knowledge of these vital components empowers users to make informed decisions regarding repairs and replacements, thereby extending the service life of the equipment.

Importance of Accurate Diagrams

Precision in visual representations is crucial for effective understanding and operation of mechanical systems. Detailed illustrations serve as essential guides, providing users with the information needed to identify components, follow procedures, and ensure proper functionality. This clarity not only facilitates repairs and maintenance but also enhances overall efficiency in various tasks.

Enhancing User Knowledge

Clear and precise visuals empower users by enhancing their comprehension of complex mechanisms. When individuals can easily interpret these images, they gain confidence in their ability to troubleshoot issues, perform maintenance, and execute repairs accurately. This understanding reduces the likelihood of errors, ultimately leading to more successful outcomes in technical endeavors.

Streamlining Maintenance and Repair Processes

Accurate illustrations play a pivotal role in streamlining maintenance and repair processes. By providing step-by-step guidance, these resources minimize downtime and optimize performance. Technicians can quickly locate the necessary elements, follow the correct sequences, and apply the appropriate techniques, making the overall workflow more efficient and effective.

Key Features of the RC-45 Model

This model stands out in its category due to a combination of innovative design and advanced functionality. Users can expect enhanced performance, reliability, and user-friendly operation, making it an ultimate choice for various applications.

Advanced Technology

The incorporation of cutting-edge technology ensures optimal efficiency and precision. This model features an intuitive interface, allowing operators to easily navigate through various functions, streamlining the workflow.

Durability and Reliability

Built with high-quality materials, this equipment promises longevity and consistent performance. Its robust construction minimizes maintenance needs, ensuring that users can rely on it for demanding tasks without frequent interruptions.

Common Issues with RC-45 Parts

When dealing with machinery components, various challenges may arise that can hinder performance and efficiency. Understanding these prevalent concerns is crucial for ensuring optimal functionality and longevity of the equipment.

One frequent issue involves wear and tear on specific elements, which can lead to decreased effectiveness over time. This degradation may result from consistent use, environmental factors, or inadequate maintenance practices.

Another common problem is misalignment of certain components, which can cause operational disruptions. Ensuring that all parts are correctly positioned is essential for smooth operation and minimizing stress on the system.

Additionally, improper lubrication can contribute to friction and overheating, ultimately impacting the machinery’s performance. Regular checks and appropriate maintenance schedules are vital to prevent these issues.

Finally, sourcing quality replacements can be a challenge, as subpar components may not fit correctly or meet performance standards, leading to further complications down the line. Investing in reliable suppliers can mitigate these risks significantly.

How to Source Replacement Parts

Finding suitable components for machinery is essential for maintaining functionality and efficiency. This process can involve various strategies, from consulting manufacturers to exploring aftermarket options. Here’s a structured approach to ensure you acquire the right items.

Identify Your Requirements

Before searching for components, it’s crucial to determine exactly what you need. Gather information about the specifications and compatibility to avoid any mismatches.

Where to Look

There are several avenues to explore when searching for components:

| Source | Description |

|---|---|

| Manufacturer | Directly contact the original equipment producer for genuine components. |

| Distributors | Authorized distributors often carry a wide range of compatible items. |

| Online Marketplaces | Websites like eBay or Amazon may offer new and used components. |

| Local Shops | Visit local repair shops that specialize in your equipment type. |

| Forums | Online communities can provide insights and recommendations for sourcing. |

By systematically assessing your needs and utilizing various sources, you can effectively obtain the necessary components to keep your equipment in optimal condition.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires consistent care and attention. By following a few essential practices, you can minimize wear and tear, reduce the need for repairs, and keep your machinery operating at peak performance. This guide will provide practical advice to help maintain your equipment effectively.

Regular Inspections

Conducting routine checks is crucial for identifying potential issues before they escalate. Examine key components for signs of wear, leaks, or misalignment. Schedule inspections at regular intervals to maintain optimal functionality and prevent unexpected breakdowns.

Proper Cleaning

Keeping your machinery clean is vital for its longevity. Accumulated dirt and debris can cause overheating and hinder performance. Use appropriate cleaning agents and techniques to ensure that all surfaces, especially critical areas, are free from contaminants.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to effectively address common issues encountered in machinery. By following these detailed steps, you can enhance your understanding of the device’s components and ensure a successful repair process.

1. Preparation: Before starting any repair, gather all necessary tools and materials. Ensure you have a clean workspace and good lighting to facilitate your work.

2. Disassembly: Carefully take apart the machine, keeping track of each component. It’s advisable to label parts and take notes, which will help during reassembly.

3. Inspection: Examine each piece for wear and damage. Look for cracks, rust, or any signs of malfunction. Identifying issues early can prevent further complications.

4. Cleaning: Clean all components using appropriate solvents. Removing dirt and grime can improve performance and longevity.

5. Replacement: If any parts are worn out, replace them with new ones. Ensure that replacements match the specifications required for optimal function.

6. Reassembly: Carefully reassemble the machine, referring to your notes and labels. Double-check that all components are correctly positioned and secured.

7. Testing: Once reassembled, conduct a thorough test to ensure everything operates smoothly. Monitor for any unusual sounds or behaviors that may indicate further adjustments are needed.

8. Final Checks: Perform a final inspection of the entire unit. Make sure all fasteners are tight, and that there are no leftover parts. This step is crucial for safety and efficiency.

By adhering to these steps, you can effectively troubleshoot and restore functionality to your equipment, ensuring it operates at its best.

Identifying Worn Components

Understanding the signs of deterioration in machinery is essential for maintaining optimal performance and prolonging lifespan. Regular inspection can help identify elements that require attention, ensuring that operations remain smooth and efficient.

Key indicators of wear include visual abnormalities, unusual noises, and operational inconsistencies. By recognizing these symptoms, users can take proactive steps to replace or repair components before they lead to more significant issues.

| Indicator | Description | Action Required |

|---|---|---|

| Visual Damage | Cracks, fraying, or discoloration on surfaces. | Inspect and replace if necessary. |

| Noises | Unusual grinding or squeaking sounds during operation. | Investigate and assess for potential replacements. |

| Performance Issues | Decreased efficiency or failure to operate at expected levels. | Conduct thorough diagnostics and consider component evaluation. |

By staying vigilant and addressing these warning signs promptly, operators can ensure that their equipment remains in peak condition, thereby reducing downtime and enhancing productivity.

Tools Needed for Repairs

When it comes to performing maintenance or fixes on machinery, having the right instruments is crucial for ensuring efficiency and effectiveness. A well-equipped toolbox not only speeds up the repair process but also enhances the overall quality of the work done. Below is a list of essential tools that are commonly required for various tasks related to equipment restoration.

| Tool | Purpose |

|---|---|

| Socket Set | Used for loosening and tightening nuts and bolts. |

| Screwdrivers | Essential for removing and securing screws in various components. |

| Wrenches | Helpful for turning fasteners and adjusting parts. |

| Pliers | Ideal for gripping, twisting, and cutting wires or small parts. |

| Torque Wrench | Ensures that fasteners are tightened to the correct specifications. |

| Multimeter | Used for testing electrical connections and diagnosing issues. |

| Work Gloves | Protects hands while handling tools and components. |

Equipping yourself with these tools will facilitate a smoother repair experience, allowing for timely and high-quality results.

Upgrading RC-45 Features

Enhancing the capabilities of your equipment can lead to improved performance and efficiency. By focusing on modern upgrades, users can significantly enhance functionality and user experience. This not only extends the life of the machinery but also boosts productivity in various tasks.

Consider investing in advanced technology, such as digital controls or automated systems, which provide greater precision and ease of use. Integrating new components can lead to smoother operations and reduced manual input, ultimately elevating your overall workflow.

Another key aspect is improving safety features. Upgrading to the latest safety protocols and systems can prevent accidents and ensure a safer working environment. Incorporating enhanced monitoring tools can provide real-time feedback, allowing for timely interventions.

Finally, regular maintenance and software updates are essential. Staying current with advancements can help in maximizing efficiency and minimizing downtime, ensuring that your machinery operates at its best.

Frequently Asked Questions

This section addresses common inquiries related to the assembly and components of specialized machinery. It aims to provide clarity and assist users in navigating their concerns effectively.

General Inquiries

Many users have questions regarding the functionality and maintenance of their equipment. Understanding these aspects can enhance performance and longevity.

Common Issues

Users often encounter similar challenges when dealing with their devices. Below is a table summarizing typical problems and their solutions.

| Issue | Solution |

|---|---|

| Inconsistent operation | Check for loose connections and ensure all components are properly aligned. |

| Unusual noise | Inspect for worn parts and lubricate moving components as needed. |

| Difficulty in functionality | Refer to the user manual for troubleshooting steps and component checks. |

Community Resources and Forums

Engaging with fellow enthusiasts and professionals can significantly enhance your understanding and access to valuable information. Community resources and online discussion platforms provide a space for individuals to share knowledge, ask questions, and exchange ideas related to maintenance and repair tools. These environments foster collaboration and support, making them invaluable for anyone looking to deepen their expertise.

Online Discussion Boards

Participating in specialized discussion boards allows users to connect with others who have similar interests. Members often share their experiences, troubleshooting tips, and recommendations for reliable resources. These platforms can serve as a treasure trove of information, where both novices and seasoned veterans can find guidance and solutions to their queries.

Social Media Groups

Social media platforms have become popular venues for forming groups centered around specific topics. Within these communities, users can post questions, share insights, and connect with experts in the field. Engaging with these groups not only provides quick access to helpful information but also creates opportunities for networking and building lasting relationships with others who share your passion.