In the realm of machinery and equipment, having a clear visualization of individual elements is essential for effective maintenance and repair. This section delves into the organization and relationship of various components, providing insights that can significantly enhance troubleshooting efforts. Recognizing how each piece fits into the overall system is crucial for both novice and experienced users alike.

By examining the arrangement of these elements, users can gain a deeper understanding of functionality and performance. Such clarity not only aids in identifying issues but also streamlines the repair process. This knowledge serves as a valuable resource for those looking to maximize the longevity and efficiency of their equipment.

Overall, mastering the structure of these components equips users with the tools needed to make informed decisions. This understanding ultimately leads to better care, improved performance, and an enhanced ability to tackle any challenges that may arise during operation.

This section provides a comprehensive overview of how to interpret and utilize visual representations that detail components and their arrangements in various equipment. Such illustrations are essential for understanding the functionality and maintenance of machinery.

Key aspects to consider when exploring these visual layouts include:

- Purpose of Illustrations: Grasp the significance of these representations in simplifying complex mechanical structures.

- Common Symbols: Familiarize yourself with frequently used symbols and their meanings to enhance comprehension.

- Component Identification: Learn how to locate and identify different elements within the schematic.

- Practical Applications: Understand how these visuals can aid in troubleshooting and repair processes.

- Resources for Further Learning: Explore additional materials and references that provide deeper insights into these visual aids.

By mastering these elements, individuals can enhance their technical skills and efficiently engage with machinery maintenance and repair.

Importance of Accurate Diagrams

Precise illustrations are crucial for understanding the complex interrelations within a system. They serve as visual guides that simplify intricate details, enabling users to grasp essential components and their functions quickly. When designed correctly, these representations facilitate efficient assembly, maintenance, and troubleshooting processes.

Enhancing Clarity and Communication

Clear visual representations enhance communication among technicians, engineers, and users. By providing an organized view of various elements, these images help eliminate misunderstandings, ensuring that all parties are aligned in their understanding of the system’s structure and functionality.

Facilitating Efficient Maintenance

Accurate illustrations significantly aid in the maintenance and repair of equipment. They allow users to identify specific areas requiring attention and streamline the process of locating necessary components. This efficiency reduces downtime and prolongs the lifespan of the system.

Components Overview of Columbia Models

This section provides a comprehensive examination of the various elements that make up the different models in the series. Understanding these components is crucial for both operation and maintenance, ensuring optimal performance and longevity of the equipment. Each model incorporates specific features designed to enhance functionality and user experience.

Key Functional Elements

Each unit is equipped with essential functional elements that serve distinct purposes. These components work in harmony to facilitate smooth operation and efficiency. Below is a table summarizing the primary features of each model, along with their respective functions.

| Model | Main Components | Functionality |

|---|---|---|

| Model A | Engine, Transmission, Chassis | Provides power and mobility, ensuring reliable performance. |

| Model B | Hydraulic System, Control Panel, Frame | Enables precise control and operational flexibility. |

| Model C | Power Supply, User Interface, Safety Features | Ensures energy efficiency and user safety. |

Maintenance Considerations

Regular inspection and maintenance of these critical components are vital for preventing breakdowns and extending the life of the equipment. Adhering to recommended service intervals and using quality replacement parts will ensure consistent performance across all models.

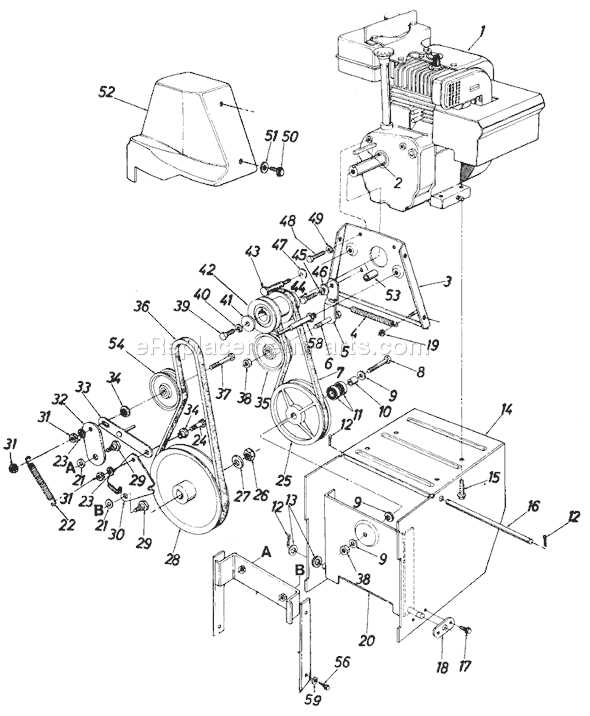

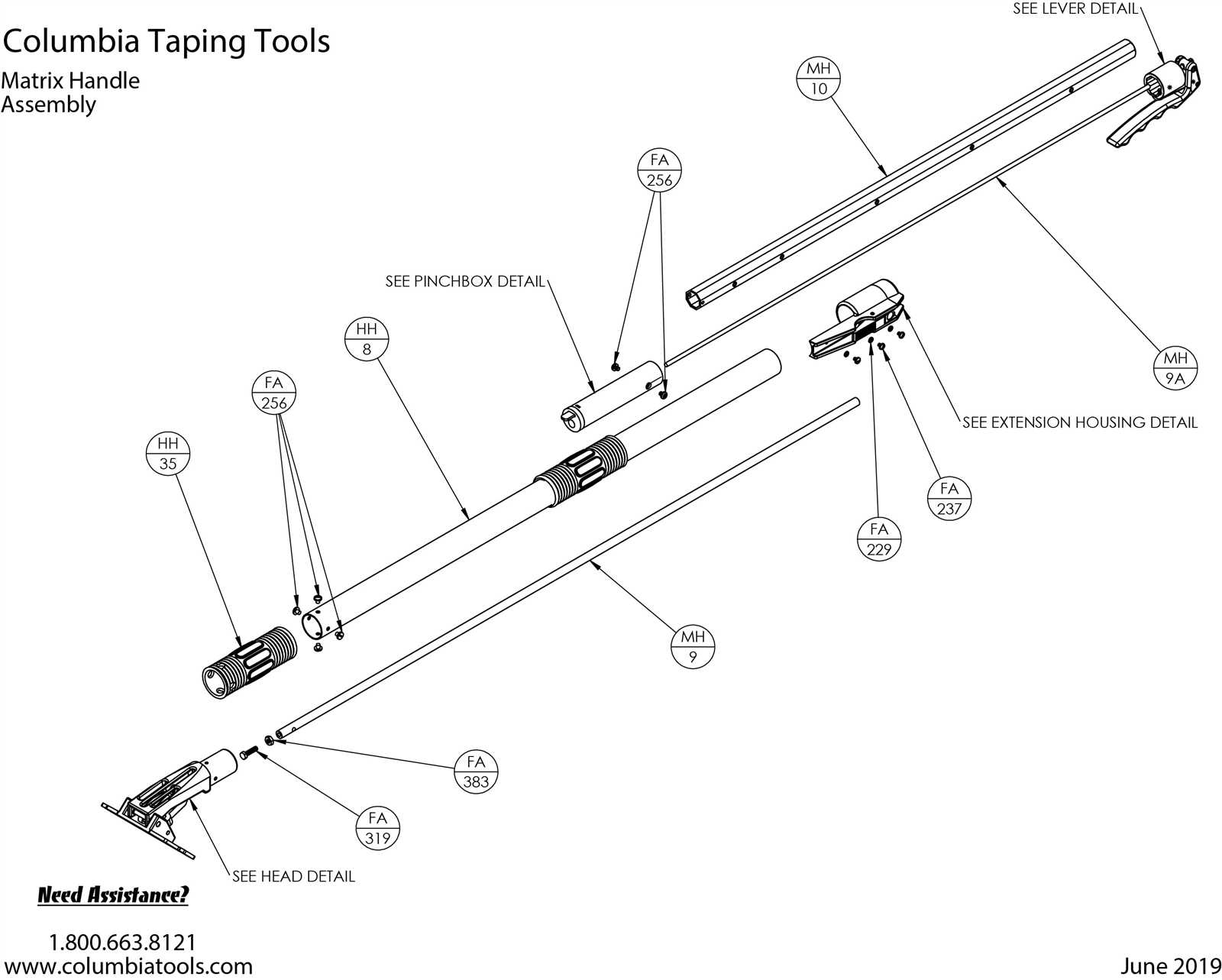

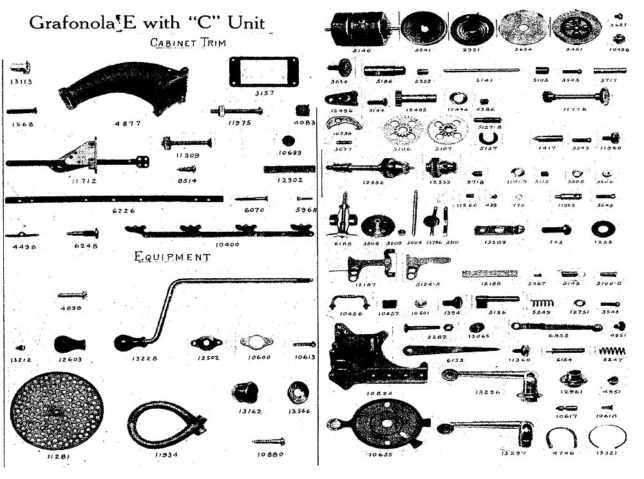

How to Read a Parts Diagram

Understanding an assembly illustration is essential for effective repairs and maintenance. This visual representation serves as a guide to identifying various components and their interconnections within a system. By familiarizing yourself with the layout, you can streamline your troubleshooting process and ensure proper assembly.

To effectively interpret such illustrations, consider the following steps:

- Familiarize Yourself with Symbols: Each illustration often employs specific icons to denote different elements. Learn what each symbol represents.

- Identify the Sections: Most illustrations are divided into sections. Recognize these divisions to locate the relevant parts efficiently.

- Study the Labels: Pay attention to any labels or annotations accompanying the visual. These often provide crucial information about the components.

- Refer to the Legend: Many illustrations include a legend explaining the symbols used. Consult this as needed for clarification.

- Practice with Real Examples: The best way to become proficient is through practice. Work with actual examples to enhance your understanding.

By following these guidelines, you will develop the skills necessary to navigate assembly illustrations confidently, making repairs and maintenance tasks more manageable.

Common Issues in Columbia Parts

When it comes to the components of various equipment, certain challenges frequently arise, affecting performance and longevity. Understanding these typical problems can help users maintain their systems more effectively. Various factors can contribute to these difficulties, including wear and tear, improper installation, and lack of maintenance.

Frequent Malfunctions

One common issue involves components that fail to operate as intended. This may stem from inadequate lubrication, resulting in increased friction and eventual breakdown. Regular inspection and timely lubrication can significantly enhance the reliability of these elements.

Compatibility Concerns

Another prevalent challenge is related to compatibility among different components. Using non-compatible parts can lead to inefficiencies and even damage. It is crucial to ensure that all components work harmoniously together, promoting optimal functionality.

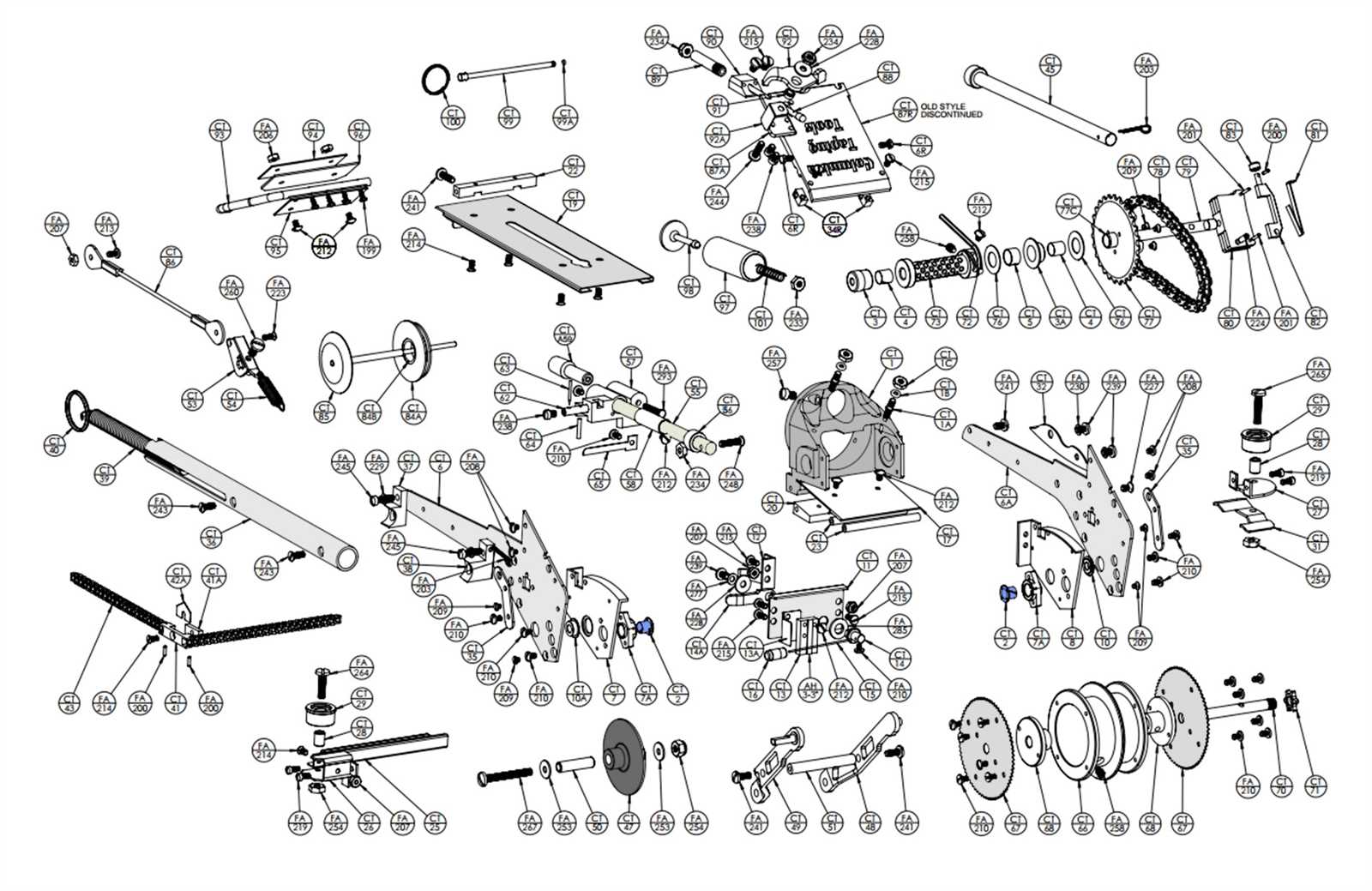

Identifying Replacement Parts Easily

Finding suitable components for machinery can be a straightforward process when you have the right approach. Understanding how to navigate resources and utilize various tools can significantly enhance the efficiency of the identification process. This section provides essential tips for recognizing and sourcing the necessary items without confusion.

Utilizing Visual References

One effective method is to use visual references that clearly outline each component’s function and placement. These illustrations can simplify the search for specific elements, making it easier to match your requirements. By examining these visuals, you can quickly familiarize yourself with the layout and characteristics of the items you need to replace.

Consulting Documentation and Resources

In addition to visual aids, consulting manuals and technical documentation can provide invaluable information. These resources often include detailed descriptions and specifications that can help you pinpoint the correct items for your needs. Utilizing both visual references and written guides ensures a thorough understanding of what is required for replacements.

Maintenance Tips for Columbia Equipment

Proper upkeep of your outdoor gear is essential to ensure longevity and optimal performance. Regular maintenance can prevent issues and enhance the efficiency of your machinery. Implementing a few simple practices can lead to significant improvements in reliability and functionality.

Routine Inspections

Conducting regular inspections is crucial for identifying potential problems before they escalate. Check all components for wear and tear, and ensure that everything is functioning smoothly. Pay close attention to moving parts and connections, as these are often the most vulnerable to damage.

Cleaning and Lubrication

Keeping your equipment clean is vital. Dirt and debris can hinder performance and lead to breakdowns. After each use, clean all surfaces and remove any accumulated grime. Additionally, applying lubricant to moving parts will reduce friction and wear, extending the life of the equipment.

| Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | After Each Use | Check for any visible damage. |

| Cleaning | After Each Use | Remove dirt and debris thoroughly. |

| Lubrication | Weekly | Focus on all moving parts. |

| Professional Servicing | Annually | Have a qualified technician evaluate the equipment. |

Resources for Parts Diagrams

Access to detailed visual representations of components is essential for effective maintenance and repair. These resources provide valuable insights into the structure and organization of equipment, allowing users to understand the relationships between various elements.

Numerous online platforms offer comprehensive catalogs and visual guides that illustrate the intricate layouts of machinery. Utilizing these tools can significantly enhance one’s ability to locate specific elements and make informed decisions regarding replacements and repairs. In addition, many manufacturers provide downloadable manuals that contain exploded views and part numbers, streamlining the identification process.

Community forums and user groups also serve as excellent sources of information, where enthusiasts share their knowledge and experiences. These interactions can lead to discovering alternative solutions and tips for efficient repairs.

For those seeking printed materials, local libraries or technical schools often house reference books that cover a wide range of models and their respective layouts. Engaging with these resources ensures a thorough understanding of the equipment and contributes to successful maintenance endeavors.

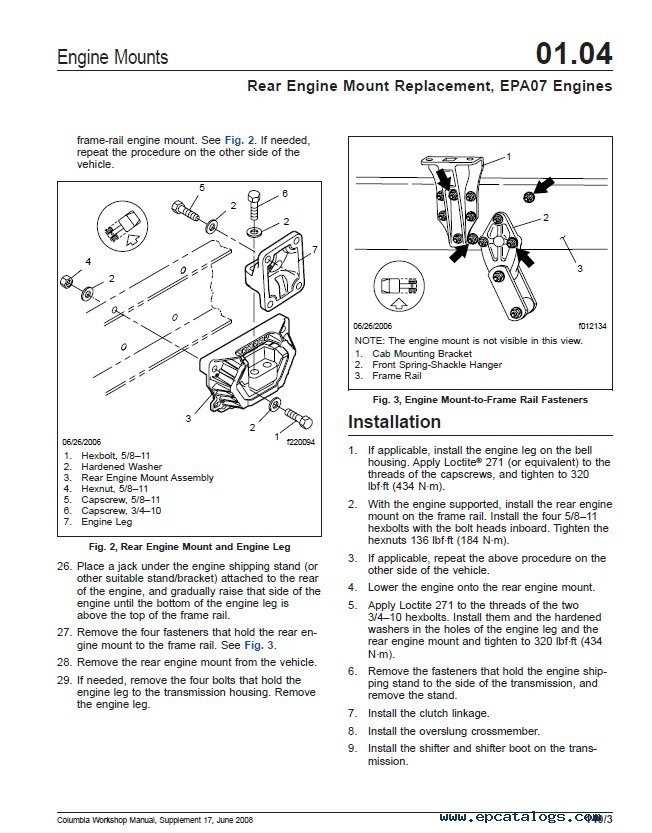

Manufacturer Support and Documentation

The availability of reliable assistance and comprehensive resources is crucial for users seeking to understand and maintain their equipment. Effective guidance can significantly enhance user experience and operational efficiency.

Many manufacturers provide extensive support through various channels, ensuring that users have access to necessary information. This includes online resources, manuals, and customer service contacts, all aimed at facilitating proper usage and maintenance.

Technical documentation plays a vital role in this process, offering detailed instructions and specifications. These resources often encompass installation guidelines, troubleshooting tips, and maintenance schedules, empowering users to resolve issues independently.

In addition, manufacturers frequently update their support materials to reflect new technologies and practices. This commitment to keeping documentation current ensures that users are equipped with the latest knowledge, enhancing the longevity and performance of their equipment.

Comparison of Different Columbia Models

This section provides an overview of various models produced by a well-known manufacturer, focusing on their unique features and specifications. By analyzing the distinctions among these models, users can make informed decisions based on their individual needs and preferences.

Each variant showcases distinct functionalities that cater to specific applications, making it essential to understand the core differences. For instance, some models prioritize durability and strength, while others emphasize efficiency and user-friendliness. Key attributes such as power output, size, and design can significantly impact performance and usability.

Furthermore, advancements in technology have led to innovative enhancements in newer models. Users may find that features like improved ergonomics and energy efficiency are prevalent in the latest offerings. Ultimately, selecting the right model involves considering factors such as intended use, budget, and desired capabilities.

Benefits of Using Original Parts

Utilizing authentic components for your equipment provides numerous advantages that enhance both performance and longevity. Original items are specifically designed to match the precise specifications of your machinery, ensuring optimal compatibility and functionality. This focus on quality translates into a reliable user experience, reducing the likelihood of malfunctions and extending the lifespan of your tools.

Quality Assurance

Authentic components undergo rigorous testing and quality control, which guarantees their effectiveness and durability. Manufacturers prioritize the materials and engineering processes involved, resulting in superior products that can withstand the demands of regular use. This commitment to excellence minimizes the risk of premature wear and tear, ultimately saving time and money in repairs.

Enhanced Performance

By choosing original items, users often experience improved efficiency and performance. These components are engineered to work seamlessly with existing systems, providing reliable functionality. This compatibility not only optimizes the overall performance of the equipment but also enhances safety, ensuring a smoother operation during use.

| Advantage | Description |

|---|---|

| Durability | Original components are built to last, reducing the frequency of replacements. |

| Reliability | Authentic items ensure consistent performance and minimize breakdowns. |

| Safety | Using original components decreases the risk of accidents or failures. |

| Warranty | Many manufacturers offer warranties on their authentic components, providing added peace of mind. |

Finding Local Dealers for Parts

Locating nearby retailers that specialize in components for your equipment can greatly enhance your maintenance experience. These dealers offer a range of solutions, from high-quality replacements to expert advice, ensuring your machinery operates efficiently.

Researching Options

Begin by conducting an online search to identify vendors in your vicinity. Use terms like “authorized retailers” or “component suppliers” to find businesses that align with your needs. Customer reviews and ratings can provide insight into their reliability and product offerings.

Connecting with Professionals

Consider reaching out to local repair shops or service centers. These professionals often have established relationships with suppliers and can recommend trustworthy dealers. Networking within community forums or social media groups dedicated to your equipment can also yield valuable recommendations.