The intricacies of mechanical systems play a crucial role in various applications, from industrial machinery to automotive engineering. A comprehensive understanding of these components is essential for effective maintenance and troubleshooting. Each element within the system contributes to its overall functionality, ensuring smooth operation and reliability.

Visual representations of these assemblies provide valuable insights into their structure and interactions. By examining the arrangement and relationship between different elements, one can better grasp how power is transmitted and transformed. This knowledge not only aids in identifying issues but also enhances the ability to optimize performance.

Exploring the configurations of these mechanical units allows for a deeper appreciation of their engineering design. With a focus on clarity and precision, it becomes easier to navigate the complexities involved. Ultimately, mastering this foundational knowledge equips professionals and enthusiasts alike with the tools needed to excel in their respective fields.

Understanding Gearbox Functionality

Grasping the mechanics behind a transmission system is essential for comprehending how vehicles convert power from the engine to movement. This intricate assembly plays a crucial role in regulating speed and torque, allowing the vehicle to operate efficiently across various conditions. By examining the components and their interactions, one can gain insights into the overall performance and responsiveness of the machine.

At its core, this system consists of a series of interconnected elements designed to facilitate the transfer of energy. Each component serves a specific purpose, whether it’s engaging different ratios or providing smooth shifts. The effectiveness of these mechanisms directly influences the driving experience, impacting acceleration and fuel efficiency.

Understanding the principles behind this assembly also helps in diagnosing issues that may arise during operation. Knowledge of how these elements work together enables technicians to identify faults and carry out effective repairs. Ultimately, a thorough comprehension of this essential system enhances not only maintenance practices but also the overall lifespan of the vehicle.

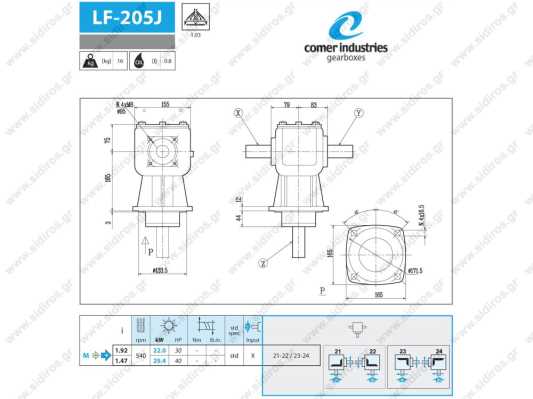

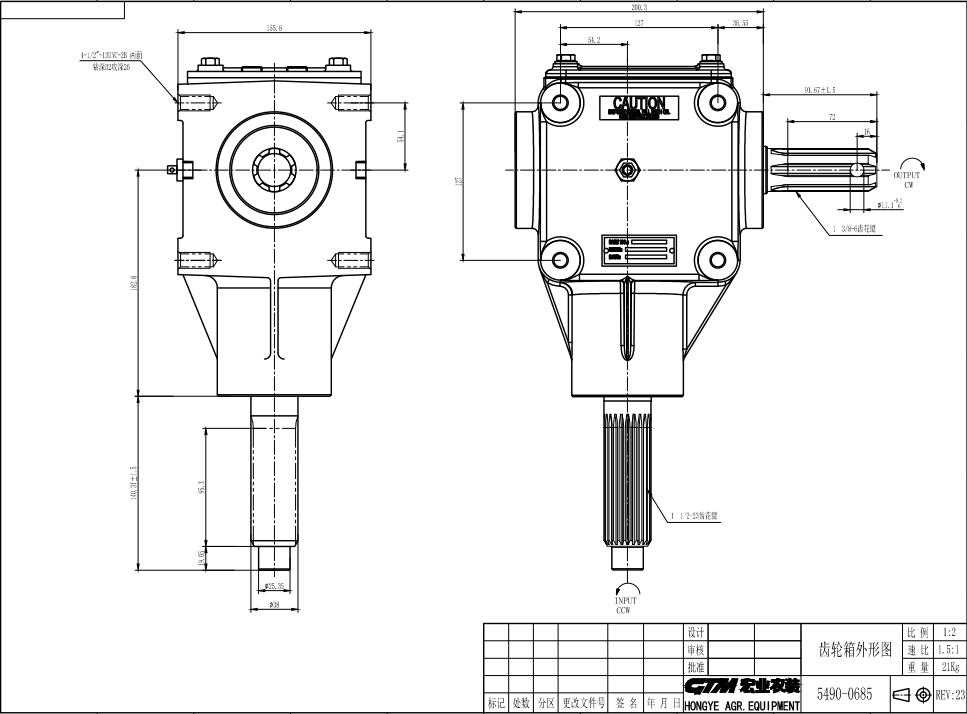

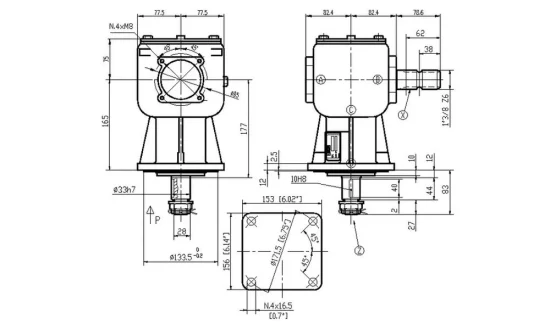

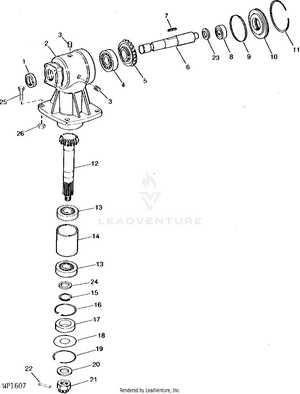

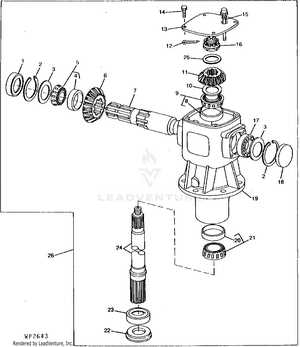

Components of Comer Gearboxes

This section delves into the essential elements that constitute the intricate system responsible for power transmission in machinery. Understanding these components is crucial for optimizing performance and ensuring longevity in various applications.

Main Elements

The primary components play a vital role in the functionality and efficiency of the entire mechanism. Each element contributes to the seamless operation, facilitating the transfer of energy from one part to another.

Supporting Elements

In addition to the main components, several supporting elements enhance stability and reliability. These parts ensure that the system operates smoothly under various conditions, reducing wear and tear over time.

| Component | Function |

|---|---|

| Housing | Protects internal mechanisms and provides structural integrity. |

| Shaft | Transmits torque and rotational energy. |

| Bearings | Support rotating elements and minimize friction. |

| Gears | Engage to alter speed and torque as required. |

| Seals | Prevent contamination and retain lubricants. |

Benefits of Using Genuine Parts

Utilizing authentic components for repairs and replacements brings numerous advantages that enhance the overall performance and longevity of machinery. These elements are designed to meet specific standards and ensure compatibility, ultimately leading to improved efficiency.

Reliability is a significant benefit of choosing original items. They undergo rigorous testing, ensuring they function correctly under various conditions. This reliability translates into less frequent breakdowns and lower maintenance costs over time.

Additionally, using these genuine items can enhance resale value. Equipment equipped with original components often commands a higher price on the market due to the assurance of quality and performance they represent.

Lastly, there’s a peace of mind that comes with using components from reputable manufacturers. Knowing that you’re investing in high-quality, tested elements fosters confidence in your machinery’s performance.

Common Issues in Gearbox Operation

Understanding the frequent challenges encountered in transmission systems is crucial for effective maintenance and optimal performance. These issues can arise from various factors, including wear and tear, lubrication failures, and misalignment.

Noise and Vibration: Unusual sounds and excessive vibrations are often indicators of underlying problems. These can stem from damaged components or insufficient lubrication, which may lead to premature failure.

Overheating: High temperatures can significantly affect functionality. Insufficient cooling or poor fluid conditions can exacerbate this issue, resulting in serious damage if not addressed promptly.

Slipping: A noticeable loss of efficiency can occur when the system fails to engage properly. This can be caused by worn clutches or improper adjustments, affecting overall power transmission.

Leaks: Fluid leaks can compromise the system’s integrity, leading to reduced performance and increased risk of failure. Regular inspections are essential to identify and rectify these issues early.

By recognizing these common pitfalls, operators can take proactive steps to ensure longevity and reliability in their systems.

Maintenance Tips for Gearboxes

Regular upkeep of transmission systems is crucial for ensuring longevity and optimal performance. Proper attention to detail can prevent costly repairs and enhance efficiency. Below are essential practices to consider.

| Tip | Description |

|---|---|

| Regular Inspections | Check for leaks and wear to identify potential issues before they escalate. |

| Fluid Changes | Replace lubricant according to manufacturer recommendations to maintain optimal functioning. |

| Temperature Monitoring | Ensure systems operate within safe temperature ranges to prevent overheating. |

| Vibration Analysis | Monitor vibrations to detect imbalances or misalignments that could indicate problems. |

| Alignment Checks | Ensure proper alignment to reduce stress on components and extend lifespan. |

How to Identify Faulty Components

Recognizing defective elements within mechanical systems is crucial for maintaining optimal performance and longevity. Early detection can prevent further damage and costly repairs. Understanding the signs of wear and malfunction can significantly enhance the troubleshooting process.

Visual Inspection

Start with a thorough visual assessment. Look for signs of discoloration, cracks, or unusual wear patterns. Deformities in structure may indicate underlying issues. Pay close attention to connections and seals, as leaks often signal a need for replacement.

Operational Testing

Conduct operational tests to evaluate functionality. Listen for unusual noises such as grinding or clattering, which may indicate misalignment or damaged elements. Performance inconsistencies during operation can also highlight areas requiring further investigation.

Importance of Proper Lubrication

Effective lubrication is essential for ensuring the longevity and functionality of mechanical systems. It plays a crucial role in minimizing friction and wear, which can lead to failures and costly repairs.

- Reduces heat generation during operation.

- Enhances efficiency by allowing smoother movement.

- Prevents corrosion and rust development.

- Extends the lifespan of components.

To delve deeper, proper lubrication also contributes to:

- Improved performance under varying loads.

- Lower maintenance costs over time.

- Enhanced reliability in demanding conditions.

Ultimately, investing in quality lubrication practices is vital for any mechanical setup aiming for optimal performance and durability.

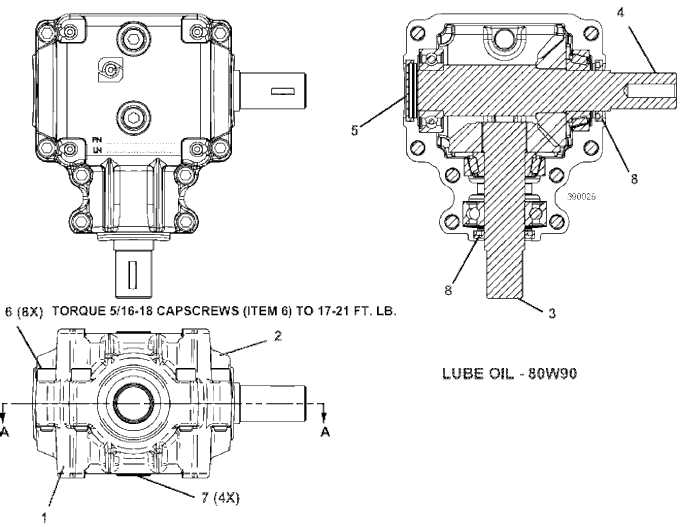

Gearbox Assembly and Disassembly Guide

This section aims to provide a comprehensive overview of the procedures involved in assembling and disassembling the mechanical unit, ensuring optimal performance and longevity. Understanding the sequence of operations is crucial for anyone working with this intricate mechanism.

Preparation Steps

Before starting the process, gather all necessary tools and materials. Ensure a clean workspace to avoid contamination, and familiarize yourself with the components involved. Proper planning minimizes errors and enhances efficiency.

Assembly and Disassembly Procedures

Follow these key steps for effective assembly and disassembly:

| Step | Action |

|---|---|

| 1 | Inspect all components for wear and damage. |

| 2 | Apply lubrication where necessary to ensure smooth operation. |

| 3 | Carefully align components during assembly. |

| 4 | Use appropriate fasteners and tighten them to specified torque settings. |

| 5 | During disassembly, label each component for easier reassembly. |

Choosing the Right Replacement Parts

Selecting the appropriate components for mechanical systems is crucial for ensuring optimal performance and longevity. A careful assessment of quality, compatibility, and reliability can make a significant difference in the overall functionality.

First, evaluate the specifications of the original components. Understanding the dimensions, materials, and operational requirements helps in identifying suitable alternatives. Consulting manufacturer guidelines can provide insights into the best options available.

Additionally, consider sourcing from reputable suppliers. Quality assurance and warranty offerings can indicate the reliability of the replacements. Reading reviews and seeking recommendations can further guide your decision-making process.

Finally, ensure that the selected components are installed correctly. Proper installation not only enhances performance but also minimizes the risk of future issues. Taking the time to choose wisely will ultimately lead to a more efficient and dependable system.

Impact of Gearbox Design on Performance

The configuration and architecture of a transmission system significantly influence its overall efficiency and effectiveness. Various elements, including the arrangement of components and the materials used, play a crucial role in determining how well power is transferred from one part to another. A well-designed system not only enhances operational performance but also contributes to longevity and reliability.

Efficiency is often a key factor in assessing how a system performs under different conditions. Optimal alignment and precision in manufacturing can minimize energy loss, leading to better fuel economy and reduced wear. When the internal layout is thoughtfully crafted, it allows for smoother transitions and minimizes friction, which directly impacts output and responsiveness.

Furthermore, material selection cannot be overlooked. Using advanced materials can reduce weight while maintaining strength, allowing for quicker acceleration and improved handling. This aspect is particularly vital in applications where speed and agility are paramount, as a lighter design can enhance overall agility and performance metrics.

In addition to these factors, maintenance considerations are essential. A thoughtfully constructed system facilitates easier access to critical components, enabling timely servicing that can prevent more significant issues down the line. Regular upkeep becomes simpler, extending the lifespan of the entire assembly and ensuring sustained performance over time.

Ultimately, the interplay between design choices and functional performance is complex. Innovations in engineering continue to push the boundaries, leading to advancements that provide significant benefits across various applications. This evolution highlights the importance of strategic design in achieving superior operational results.