In the intricate world of heavy machinery, having a clear understanding of the various components that make up a powerful engine is essential. Each element plays a crucial role in ensuring optimal performance and longevity of the vehicle. Knowledge of these elements aids in effective maintenance and troubleshooting, enhancing operational efficiency.

In this section, we will explore the essential components that contribute to the engine’s functionality. We will delve into how these parts interact and support one another, forming a cohesive system that drives performance. With a focus on clarity, we aim to provide a comprehensive overview that is accessible to both novices and seasoned professionals.

Ultimately, mastering the layout and function of these components will empower users to make informed decisions regarding repairs and upgrades. Understanding the intricacies of engine parts will not only enhance maintenance practices but also foster a deeper appreciation for engineering excellence.

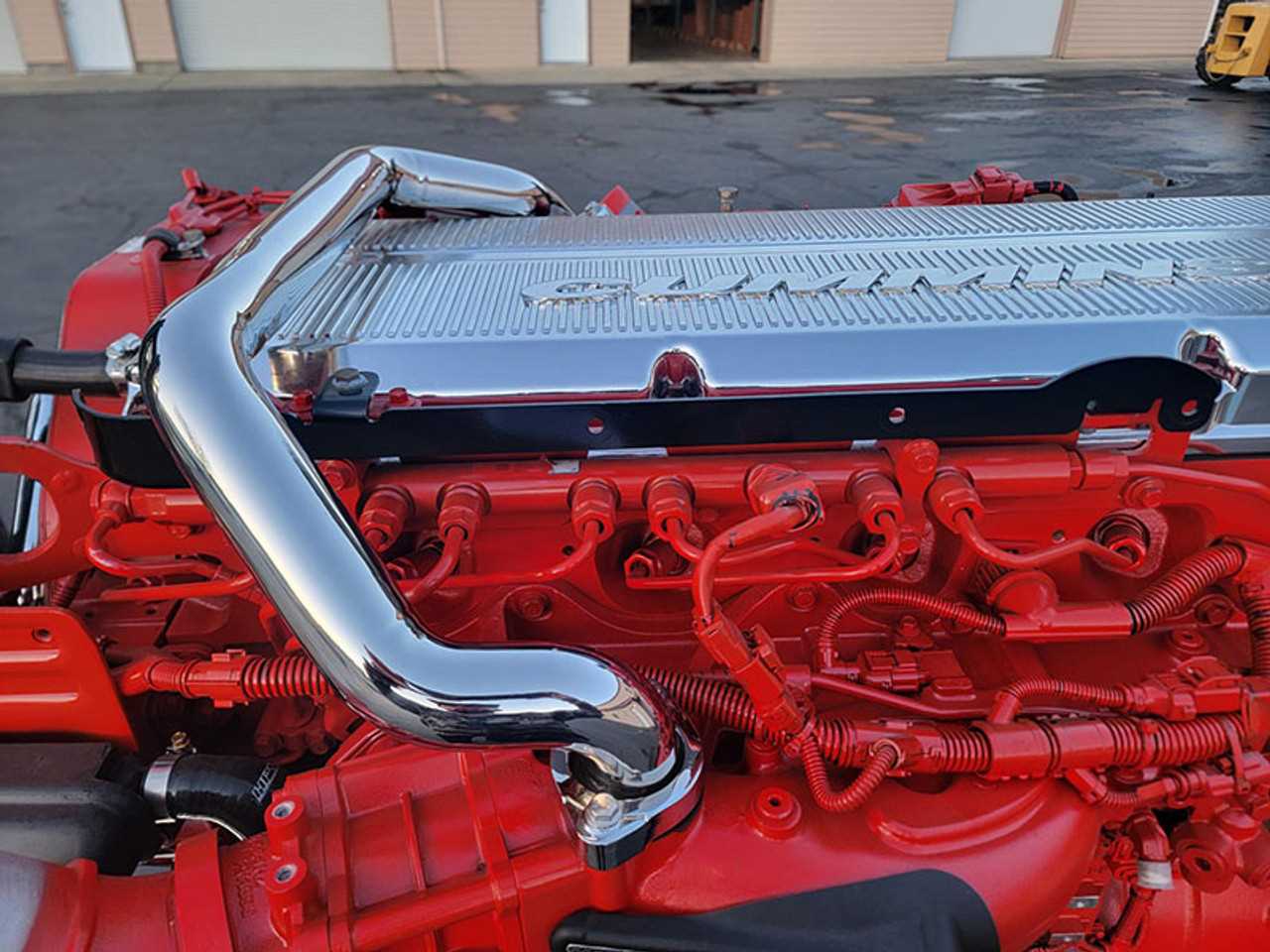

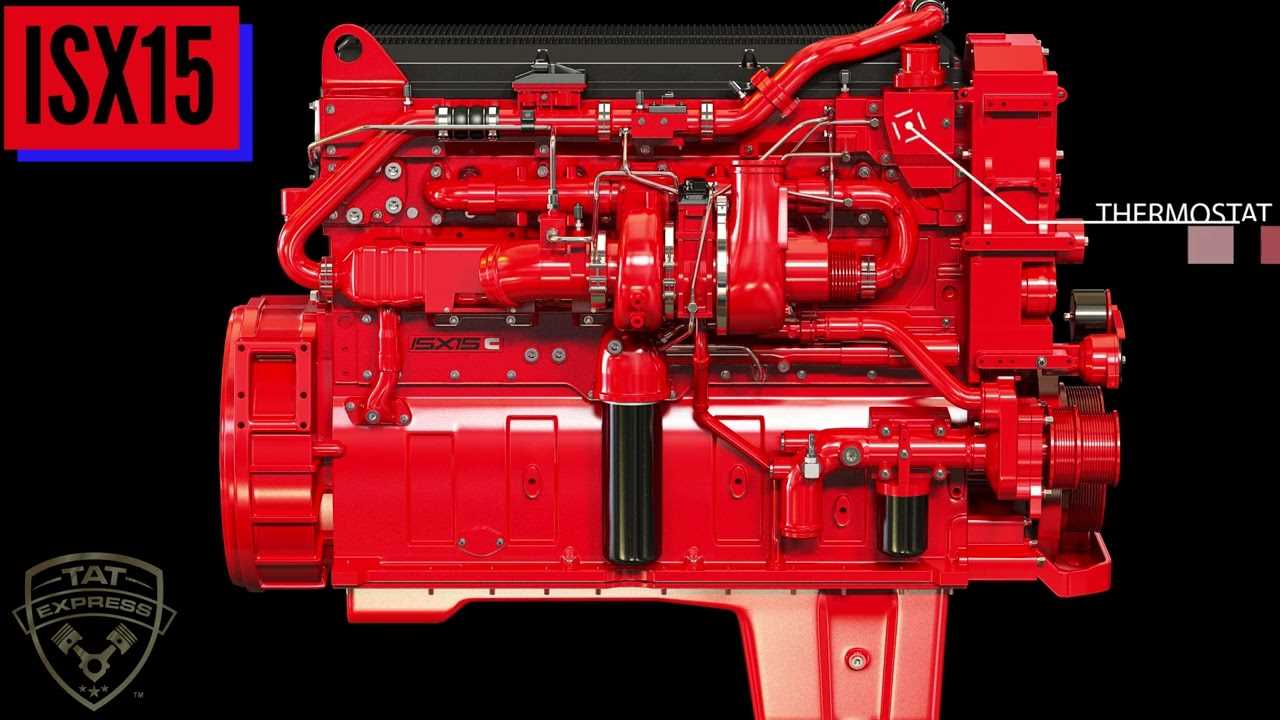

Understanding Cummins X15 Engine Overview

This section aims to provide an insightful exploration of a particular heavy-duty power unit renowned for its efficiency and performance. With advanced technology and robust design, this engine has become a crucial component in various commercial applications, ensuring reliability and longevity.

Key Features: One of the most remarkable aspects of this engine is its ability to balance power output with fuel efficiency. The incorporation of innovative engineering solutions facilitates optimal performance across diverse operating conditions.

Applications: This powerhouse is widely utilized in transportation and industrial settings, showcasing its versatility. Whether in long-haul trucks or construction machinery, it demonstrates unparalleled adaptability to demanding tasks.

In summary, the exceptional attributes of this heavy-duty engine make it a vital asset for those seeking durability and efficiency in their operations.

Key Components of the X15 Engine

This section highlights the essential elements that contribute to the performance and efficiency of the advanced engine design. Understanding these components provides insights into the mechanics and functionality, ensuring optimal operation and longevity.

Major Parts

| Component | Description |

|---|---|

| Cylinder Head | Encases the combustion chamber, facilitating efficient fuel combustion. |

| Crankshaft | Transforms linear motion into rotational energy, crucial for power delivery. |

| Fuel Injector | Sprays fuel into the combustion chamber for optimal combustion efficiency. |

Supporting Systems

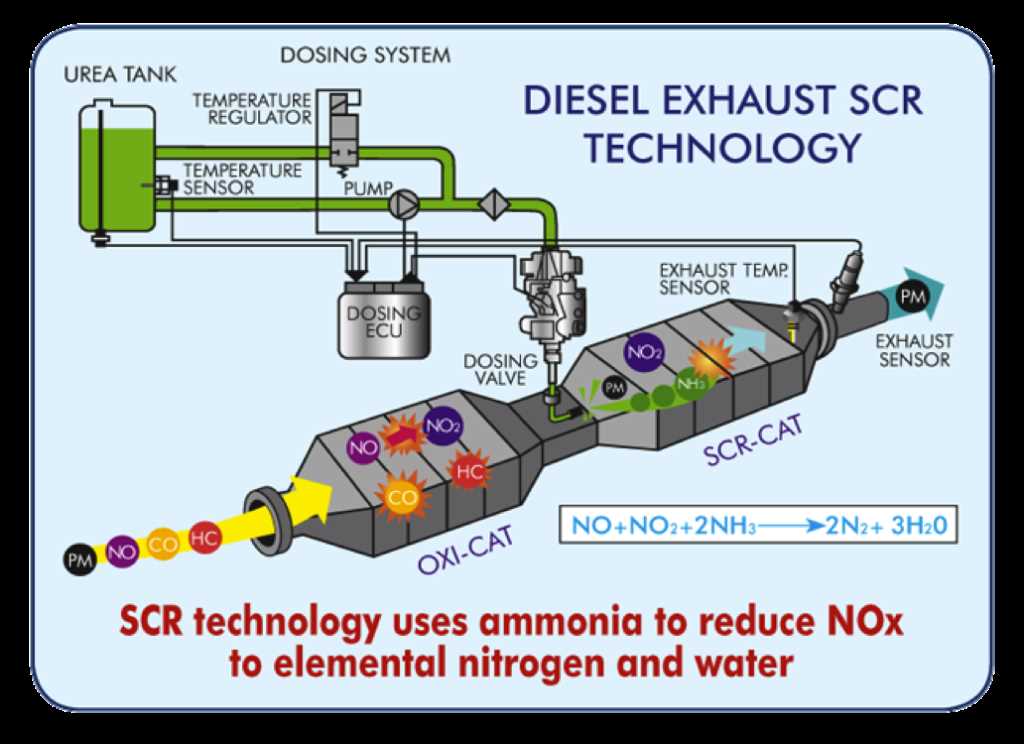

In addition to the core components, various supporting systems enhance overall functionality. These systems include lubrication, cooling, and exhaust management, which work harmoniously to maintain peak performance and minimize emissions.

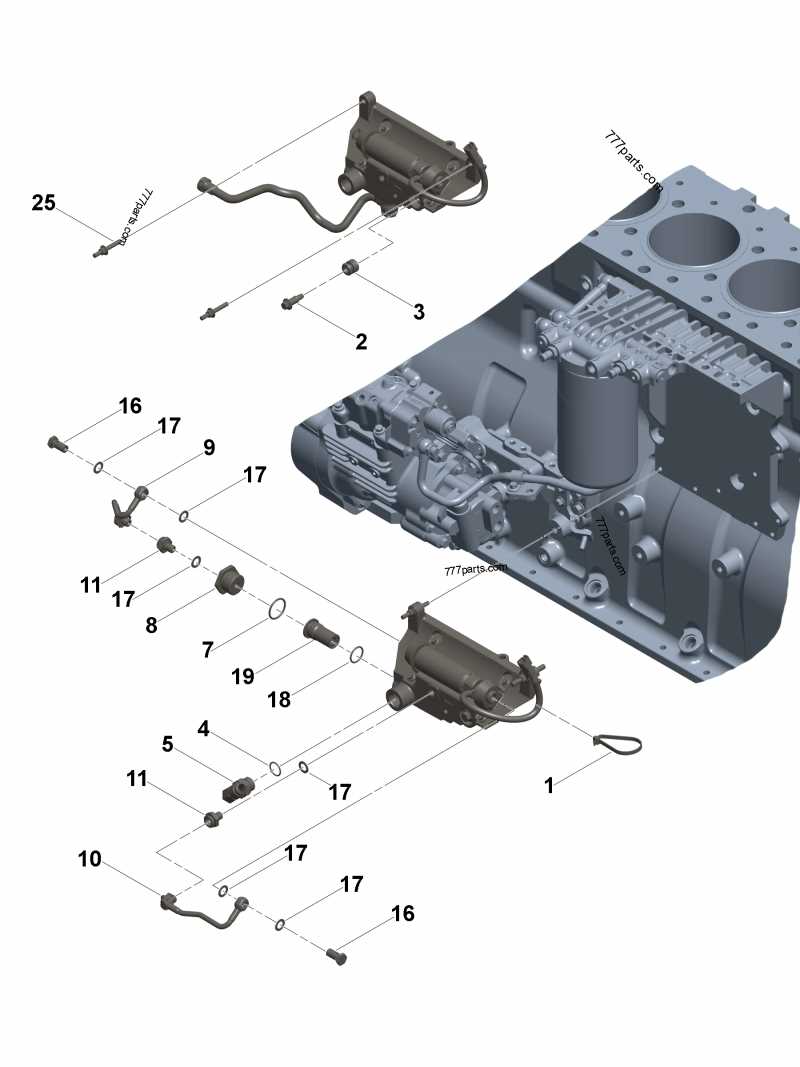

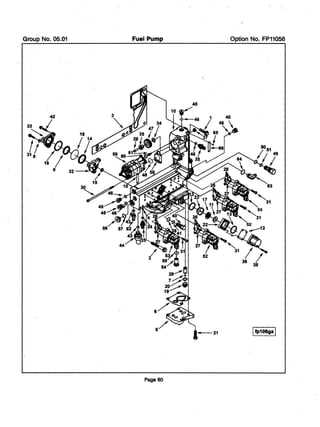

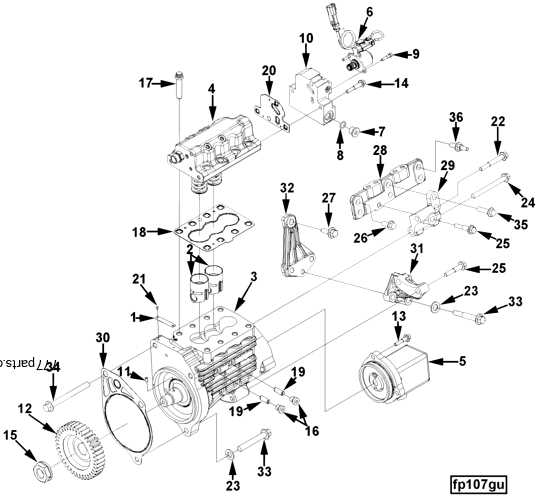

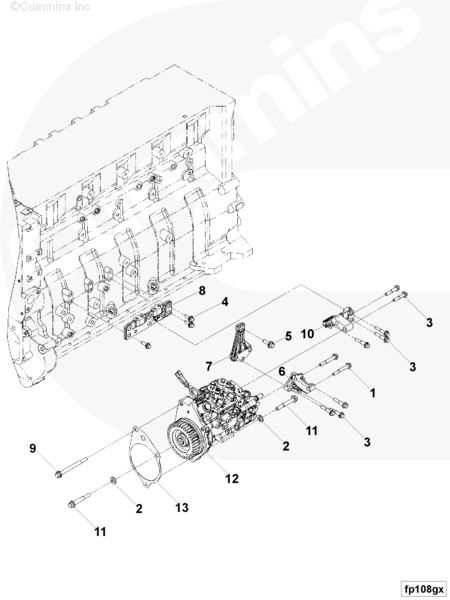

Importance of a Parts Diagram

Understanding the components of any complex system is crucial for efficient maintenance and repair. A visual representation that outlines each element plays a vital role in helping technicians identify, troubleshoot, and replace specific parts accurately. This clarity ensures that every aspect is considered during the servicing process.

Efficiency in repairs is enhanced when one can quickly locate and reference various components. With a comprehensive illustration, technicians can save time and reduce errors, ultimately leading to a smoother workflow. This is especially important in environments where downtime can significantly impact productivity.

Moreover, having a detailed layout fosters a deeper comprehension of how each part interacts within the larger assembly. This knowledge not only aids in immediate repairs but also contributes to long-term maintenance strategies, ensuring that equipment operates at peak performance over time.

Common Issues with X15 Parts

Many users encounter recurring challenges when dealing with components of heavy-duty engines. These difficulties often stem from wear and tear, improper maintenance, or manufacturing inconsistencies. Addressing these issues promptly can enhance performance and longevity.

Wear and Tear: Over time, certain elements may degrade, leading to decreased efficiency. Regular inspections can help identify these signs early.

Improper Installation: Incorrect fitting of components can cause significant operational problems. Ensuring that all pieces are installed according to specifications is crucial.

Quality Control: Occasionally, inconsistencies during the manufacturing process can result in defective items. Always sourcing from reliable suppliers can mitigate this risk.

Maintenance Neglect: Skipping scheduled maintenance can exacerbate issues. Adhering to maintenance routines is vital for optimal functioning.

How to Read the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repair. This guide will help you navigate through the intricate illustrations, allowing you to identify and locate various elements efficiently.

Follow these steps to interpret the illustration accurately:

- Familiarize Yourself with the Layout: Examine the overall structure. Components are often grouped logically, making it easier to find related parts.

- Identify Labels and Numbers: Each item usually has a corresponding label or number. Take note of these identifiers, as they will be crucial for ordering replacements.

- Color Coding: Many illustrations use color coding to distinguish between different categories or types of components. Pay attention to these colors as they can provide quick insights.

- Refer to the Legend: Most visual guides include a legend or key. This section clarifies symbols and notations used in the representation, enhancing your understanding.

By mastering these elements, you will be better equipped to work with the visual aids and improve your efficiency in identifying and sourcing necessary components.

Maintaining Your Cummins X15

Regular upkeep of your engine is crucial for ensuring optimal performance and longevity. A well-maintained unit not only enhances efficiency but also reduces the risk of unexpected failures.

- Check fluid levels frequently, including oil, coolant, and fuel.

- Inspect filters regularly and replace them as needed.

- Monitor engine performance and listen for unusual sounds.

Following a consistent maintenance schedule can help you avoid costly repairs and extend the lifespan of your machinery.

- Perform routine oil changes based on manufacturer recommendations.

- Clean or replace air filters to ensure proper airflow.

- Examine belts and hoses for wear or damage.

By committing to these practices, you can delve deeper into the workings of your engine and ensure its ultimate reliability.

Replacement Parts for Optimal Performance

Ensuring your engine operates at peak efficiency often requires timely upgrades and substitutions of its components. This practice not only enhances longevity but also maximizes productivity. Below are essential considerations for maintaining your system’s functionality.

- Regular assessment of worn-out elements to prevent failures.

- Utilizing high-quality replacements that meet or exceed original specifications.

- Investing in genuine components for compatibility and reliability.

When selecting substitutes, keep the following aspects in mind:

- Performance characteristics specific to your application.

- Manufacturer recommendations to ensure optimal integration.

- Cost-effectiveness without compromising quality.

By focusing on these key areas, you can significantly enhance your engine’s operational capabilities and achieve the ultimate efficiency.

Supplier Options for X15 Parts

When seeking components for advanced engines, it’s crucial to explore various avenues to ensure quality and reliability. Different providers offer a range of choices, from original equipment manufacturers to aftermarket alternatives, each with unique benefits. This section aims to guide you through the available options for sourcing essential elements, helping you make informed decisions tailored to your needs.

Original Equipment Manufacturers

Engaging with original manufacturers guarantees authenticity and adherence to industry standards. These suppliers provide parts specifically designed for optimal performance, ensuring compatibility and longevity. Investing in these components may come at a higher price, but the reliability and peace of mind often justify the expense.

Aftermarket Alternatives

Aftermarket vendors present a cost-effective solution for those looking to save without compromising on quality. Many of these suppliers offer a variety of components that meet or exceed the original specifications. It’s essential to conduct thorough research and select reputable brands to ensure the durability and efficiency of the replacement items.

Innovative Features of the X15 Model

This advanced engine series incorporates cutting-edge technology and design principles to enhance performance, efficiency, and reliability. The innovations integrated into this model not only elevate its operational capabilities but also set a new standard in the industry.

- Enhanced Fuel Efficiency: The system employs sophisticated algorithms to optimize fuel consumption, resulting in significant savings over time.

- Improved Emissions Control: Advanced filtration and catalytic technologies minimize harmful emissions, aligning with environmental regulations.

- Smart Engine Management: A state-of-the-art management system monitors performance parameters, ensuring optimal operation under varying conditions.

- Robust Durability: The materials and construction techniques used in the design enhance longevity and resilience, even in demanding applications.

- Customizable Performance Settings: Operators can tailor performance characteristics to meet specific operational needs, allowing for greater flexibility.

These innovative attributes contribute to a remarkable balance of power and efficiency, making this engine model a preferred choice for many applications.

Comparing X15 with Other Engines

When evaluating high-performance powertrains, it’s essential to explore how different models stack up against each other. Each engine design offers unique features and specifications that cater to various applications and preferences. Understanding these differences can help in making informed choices for optimal efficiency and performance.

One notable distinction lies in the technology employed in fuel management and combustion processes. Advanced systems can enhance fuel efficiency while reducing emissions, providing a competitive edge. Comparing torque and horsepower ratings also reveals how well each engine can handle specific loads and driving conditions, impacting overall productivity.

Moreover, maintenance requirements and longevity are critical factors to consider. Some engines are designed for extended service intervals, while others might necessitate more frequent upkeep. Evaluating total cost of ownership can further inform decisions, particularly in commercial applications where downtime directly affects profitability.

Tips for Efficient Engine Repair

Ensuring optimal performance during engine repairs requires a combination of proper planning, the right tools, and a systematic approach. Streamlining the process can save time and enhance results, ultimately leading to a more reliable machine.

Here are some strategies to consider:

| Tip | Description |

|---|---|

| Assess Before You Start | Conduct a thorough inspection to identify all potential issues before beginning repairs. |

| Gather Necessary Tools | Ensure you have all required equipment at hand to avoid interruptions during the repair. |

| Follow Manufacturer Guidelines | Adhere to recommended practices and specifications to ensure safety and effectiveness. |

| Document Your Process | Keep detailed notes of each step taken for future reference and to assist in troubleshooting. |

| Test Thoroughly | After repairs, conduct comprehensive tests to confirm that everything is functioning correctly. |

Resources for X15 Technical Support

Accessing reliable assistance and information is crucial for maintaining the efficiency of your engine system. Various platforms and resources offer detailed guidance and troubleshooting support, ensuring that you have the tools needed to address any technical challenges.

Online Portals: Numerous websites provide comprehensive manuals, specifications, and maintenance tips. These digital resources are invaluable for understanding the intricate workings of your engine and for finding solutions to common issues.

Community Forums: Engaging with fellow enthusiasts and professionals in dedicated online communities can yield practical advice and firsthand experiences. These forums are excellent for sharing insights and learning from others who have encountered similar situations.

Technical Support Lines: Many manufacturers and service centers offer dedicated hotlines for technical inquiries. Reaching out to these experts can provide you with personalized assistance tailored to your specific needs.

Workshops and Training: Attending workshops or training sessions can enhance your understanding of engine mechanics and maintenance techniques. These educational opportunities often cover advanced topics, allowing for deeper knowledge and skill development.

Utilizing these resources effectively can significantly improve your ability to manage engine performance and resolve issues efficiently.