In the realm of machinery and equipment, comprehending the arrangement and interaction of various elements is crucial for effective maintenance and repair. This section aims to provide insight into the essential components that contribute to the functionality of specific devices, emphasizing their roles and interconnections. By visualizing how each piece fits together, users can enhance their understanding and ensure optimal performance.

The exploration of these configurations not only aids in troubleshooting but also empowers operators to make informed decisions regarding upgrades and replacements. Clear representations of these systems allow for a more intuitive approach to managing technical issues and promote a deeper appreciation for the engineering behind the equipment.

Ultimately, gaining familiarity with the layout of critical components serves as a foundation for improving operational efficiency. Whether for routine maintenance or unexpected repairs, this knowledge equips users with the tools needed to navigate their machinery with confidence and precision.

Identifying Key Components

Understanding the essential elements of a machine is crucial for effective maintenance and operation. Each component plays a vital role in ensuring the overall functionality and efficiency of the equipment. Familiarity with these parts allows users to troubleshoot issues and perform necessary repairs.

Below are some primary elements that are commonly found in similar machinery:

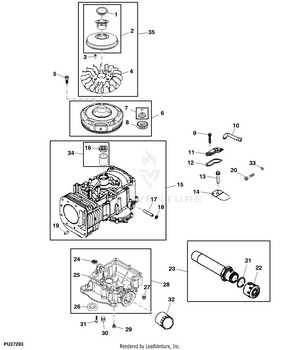

- Engine: The heart of the system, responsible for providing power.

- Transmission: Transfers power from the engine to the wheels, enabling movement.

- Hydraulic System: Essential for operating various functions, including lifting and steering.

- Control Panel: The interface for operators to manage and monitor the machine’s functions.

- Chassis: The framework that supports the machine and houses various components.

Recognizing these key parts will help in understanding the overall structure and performance of the equipment. Regular inspection and awareness of each element’s function can significantly enhance operational efficiency.

Understanding Functionality of Parts

In mechanical systems, each component plays a specific role that ensures the proper functioning of the entire structure. By comprehending how individual elements contribute to the overall performance, users can better maintain and operate their equipment. This section explores how different units interact, ensuring optimal operation and longevity.

| Component | Function |

|---|---|

| Control Mechanism | Manages the direction and speed of movement, ensuring smooth operation. |

| Structural Frame | Provides support and stability, keeping all elements in alignment during operation. |

| Power Source | Supplies the necessary energy for the system to perform its tasks effectively. |

| Transmission Link | Transfers energy from the source to other units, facilitating motion and activity. |

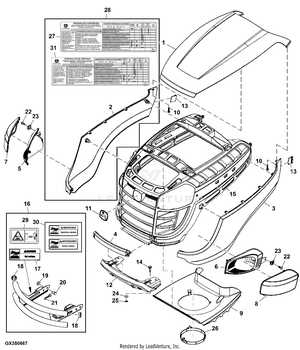

| Protective Shield | Ensures safety by guarding critical sections from external impacts or damage. |

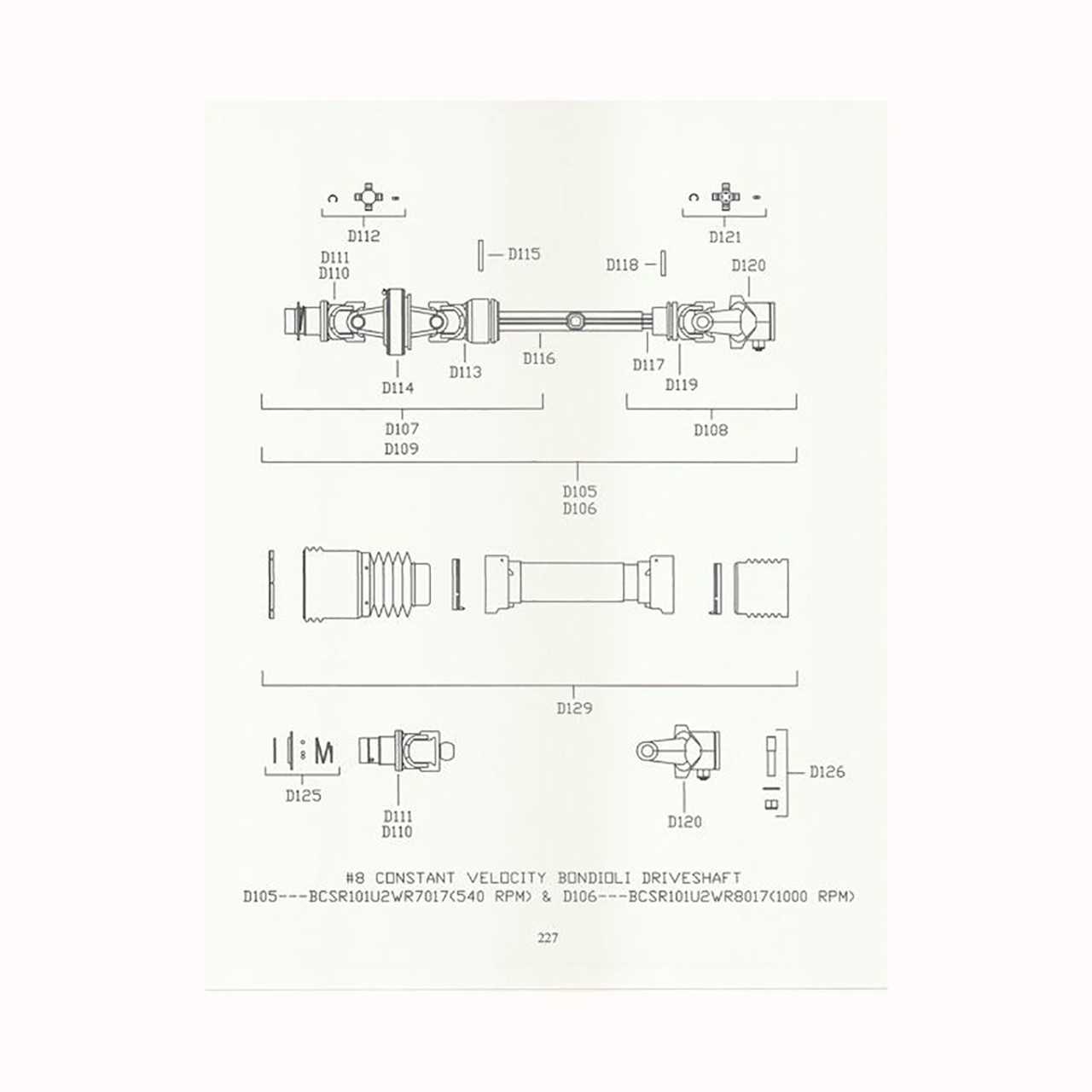

Maintenance Tips for D105 Parts

Proper care and upkeep of mechanical components are essential to ensure longevity and smooth performance. By following a few simple guidelines, you can prevent unnecessary wear and tear, extending the life of your equipment. Regular inspections and timely replacements play a critical role in maintaining functionality over time.

Regular Inspection

To maintain optimal efficiency, it’s important to conduct periodic checks on all moving elements. Look for signs of friction, wear, or looseness. Tightening bolts and lubricating necessary sections can help prevent malfunctions and ensure smooth operation.

Component Cleaning

Keeping all elements free from dust and debris is essential for the machine’s longevity. Use appropriate cleaning tools and solutions to remove grime from surfaces and avoid potential build-up, which can lead to performance issues.

| Task | Recommended Frequency |

|---|---|

| Lubrication of moving elements | Every 3 months |

| Tightening of connections | Every 6 months |

| Cleaning of components | Monthly |

Common Issues and Solutions

Understanding frequent challenges that arise during operation is essential for maintaining performance and avoiding unnecessary downtime. By recognizing potential problems early, you can take preventative measures or apply practical fixes to ensure smooth functioning.

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine not starting | Low fuel or battery | Check fuel level and charge the battery |

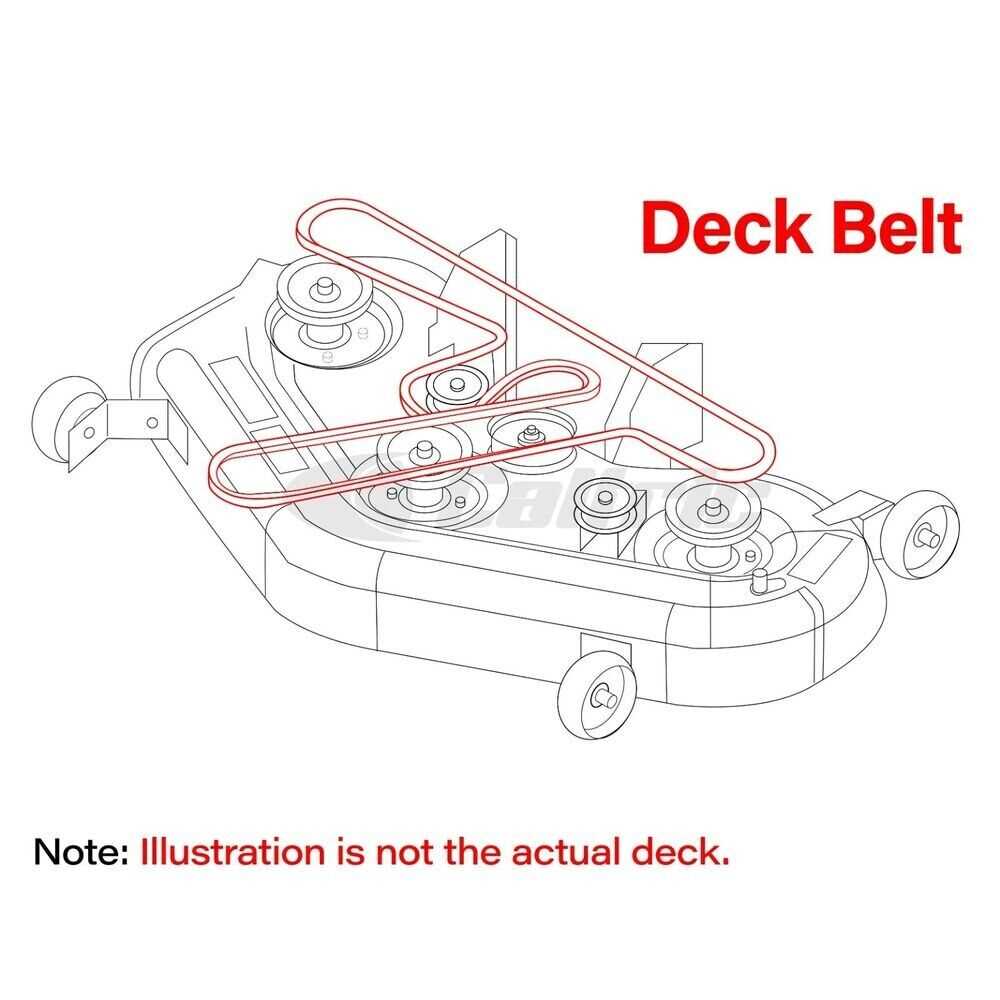

| Poor cutting performance | Blunt or damaged blades | Sharpen or replace blades |

| Overheating during use | Clogged air filters | Clean or replace air filters |

| Uneven operation | Incorrect tire pressure | Check and adjust tire pressure |

Tools Needed for Repairs

When it comes to fixing mechanical equipment, having the right set of instruments is essential for a smooth and efficient process. Each task may require different gear, depending on the complexity and scope of the repair. Proper preparation and access to the necessary tools can significantly reduce the time spent on maintenance and ensure accurate results.

| Tool | Function |

|---|---|

| Wrench Set | For loosening or tightening bolts and nuts of various sizes. |

| Screwdrivers | Used for driving or removing screws of different types. |

| Pliers | Ideal for gripping, bending, or cutting wire and small components. |

| Hammer | Used to apply force, often to secure or remove components. |

| Socket Set | For turning fasteners, providing better control over torque. |

| Torque Wrench | Ensures that bolts are tightened to the correct tension. |

| Multimeter | For diagnosing elect

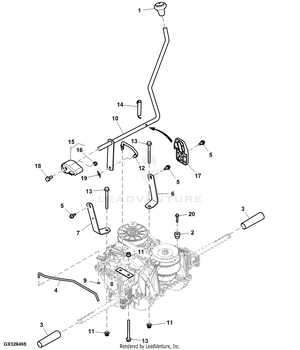

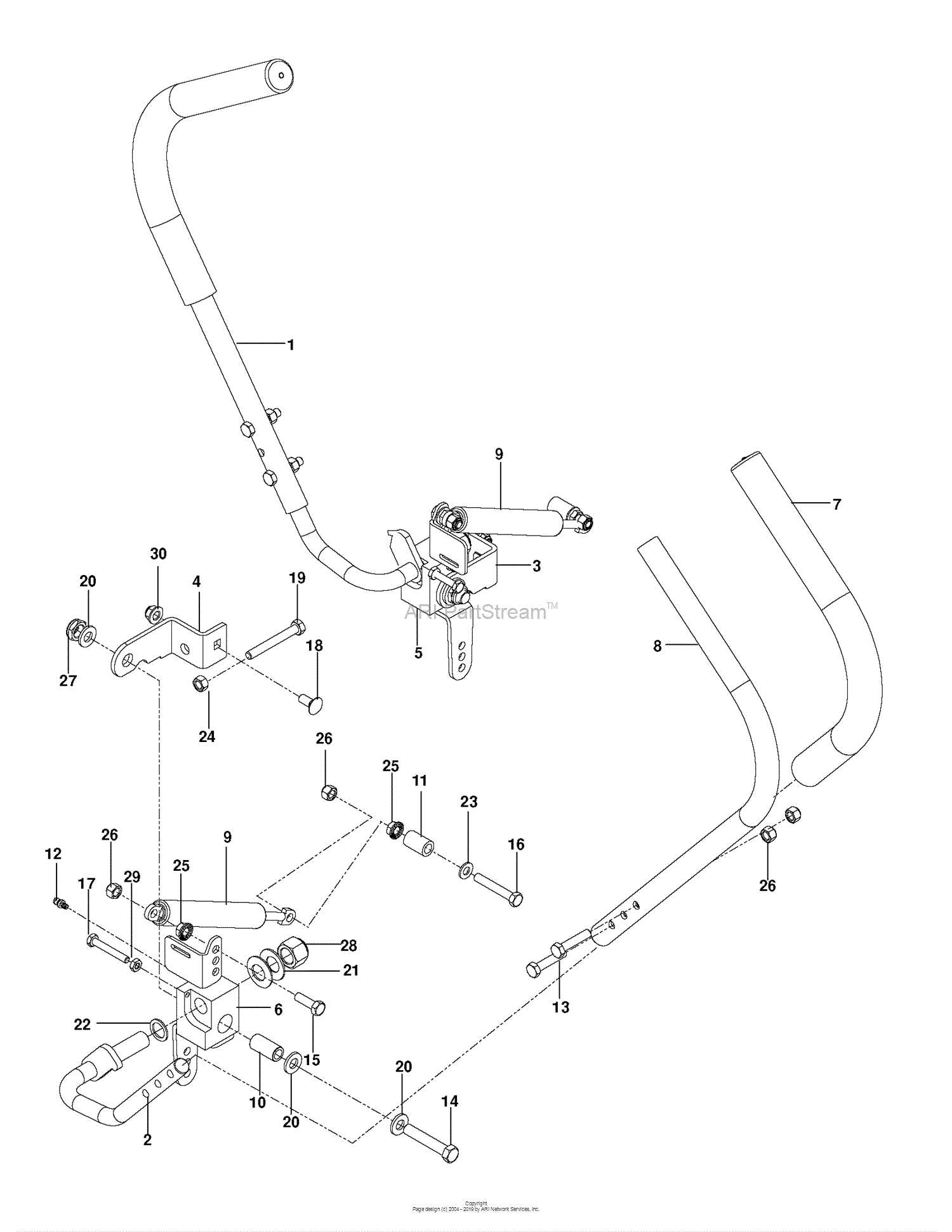

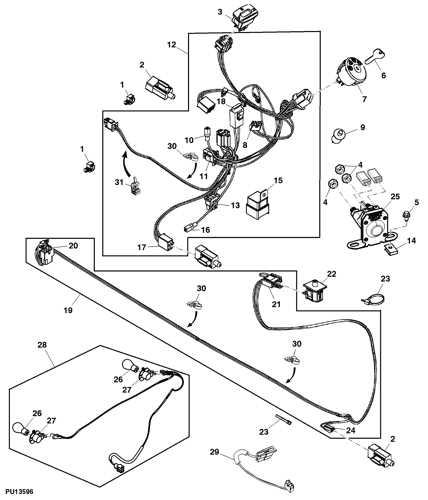

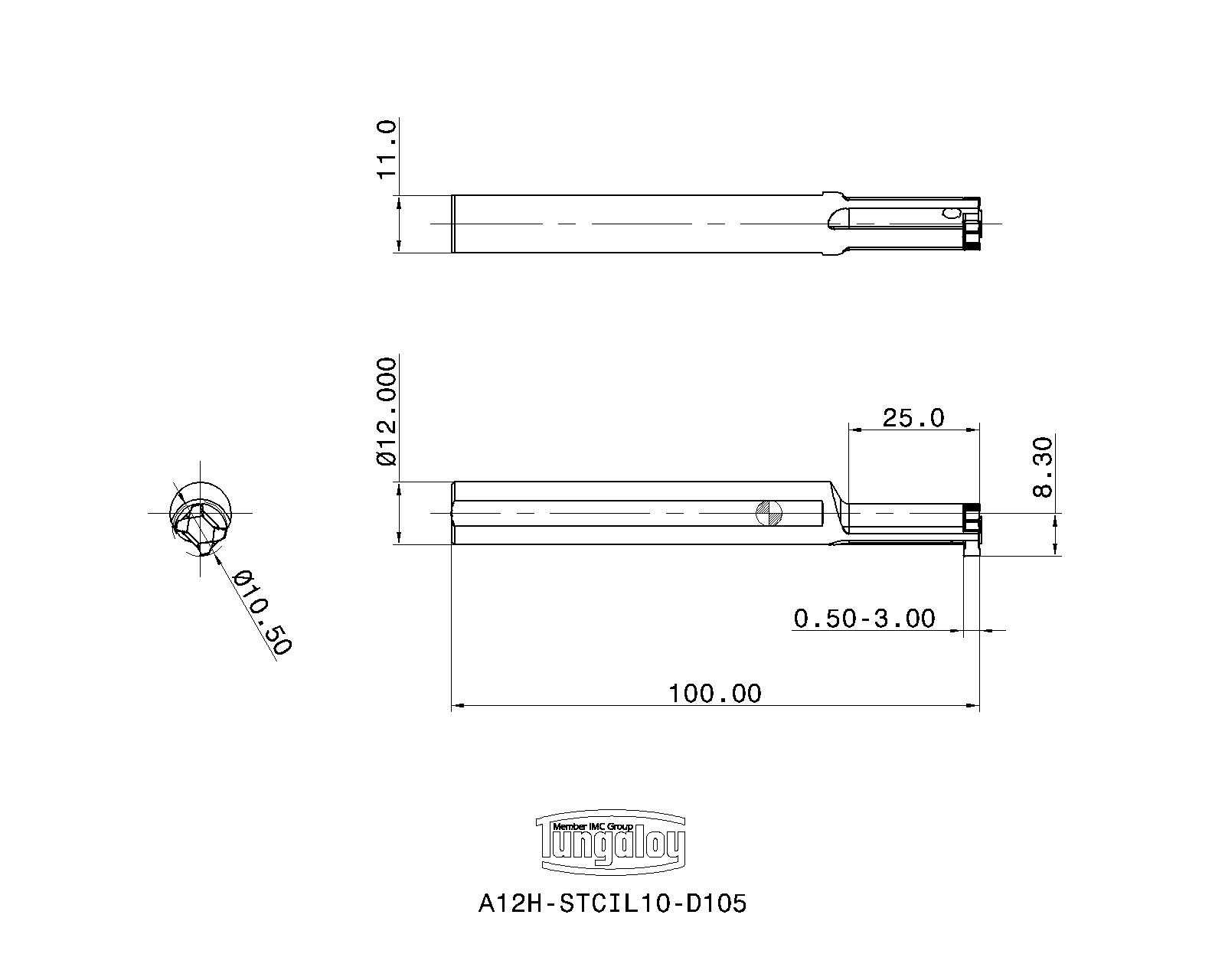

Where to Find Replacement Parts

When it comes to maintaining or repairing your equipment, finding suitable components is essential to ensure long-term functionality. Whether you’re dealing with wear and tear or unexpected issues, sourcing high-quality replacements is crucial for seamless operation. Understanding where to look for these items can save both time and effort, especially if you know the best places to search. You can explore specialized retailers, both online and in physical stores, which often carry a wide range of components tailored to different needs. Additionally, many manufacturers offer official stores or partner distributors that provide original items, ensuring compatibility and durability. It’s also worth considering local suppliers for quicker access to what you need. For those looking for more budget-friendly options, second-hand markets or online platforms may offer refurbished or gently used pieces. This can be a cost-effective solution, especially for older models. Always ensure the quality and authenticity of the components to avoid further issues down the line. Diagram Interpretation TechniquesUnderstanding visual representations requires attention to detail and the ability to analyze relationships between different components. By focusing on key elements and identifying how they interact with each other, you can grasp the structure and functionality of complex systems more effectively. Focus on Key Symbols: Begin by identifying the most important symbols and markers in the illustration. These often represent the core elements, and recognizing them early can simplify the entire process of interpretation. Follow Logical Sequences: Many illustrations are designed to guide the viewer through a sequence. It is essential to follow the natural flow from one section to another, ensuring that each step is understood before moving to the next. Contextual Understanding: Always consider the broader context of what is being represented. Rather than focusing solely on individual elements, think about how they contribute to the overall system’s functionality. Look for Repeated Patterns: In many cases, recurring patterns or structures can indicate standard processes or similar functionalities. Identifying these can significantly enhance comprehension and speed up the interpretation process. Mastering these techniques ensures a more efficient and accurate understanding of visual layouts, allowing for a comprehensive analysis of even the most intricate systems. Visualizing Assembly Procedures

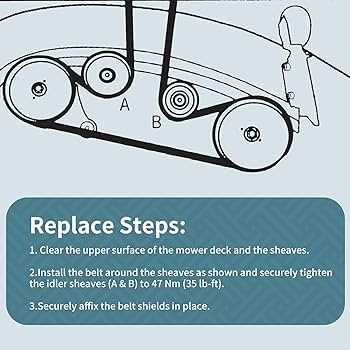

Understanding the steps involved in assembling a complex structure can be greatly enhanced by visual representations. By breaking down the process into clear and logical stages, it becomes easier to follow and execute each step with precision. Visual tools help simplify intricate configurations, allowing for a more intuitive assembly experience. Breaking Down the Process

To ensure smooth assembly, it’s crucial to divide the task into manageable sections. Each part of the procedure should be clearly identified and approached in a step-by-step manner, making sure that every element fits into the overall structure efficiently.

Optimizing the Workflow

Incorporating visuals into the process not only aids in understanding but also improves the overall efficiency of the assembly. Clear illustrations, combined with written instructions, reduce the likelihood of mistakes and ensure a seamless workflow.

|