This section delves into the intricate assembly of a lifting apparatus, providing insights into its fundamental elements. Each component plays a critical role in the overall functionality and safety of the equipment, making it essential to familiarize oneself with their unique characteristics.

By exploring the various sections of this machinery, readers will gain a deeper appreciation for the engineering and design principles that govern its operation. The terminology used to describe these elements is crucial for effective communication in the industry.

In the following paragraphs, we will highlight the significance of each component, emphasizing how they contribute to the seamless operation of this powerful lifting solution. Understanding these components is the ultimate key to mastering the use of such sophisticated machinery.

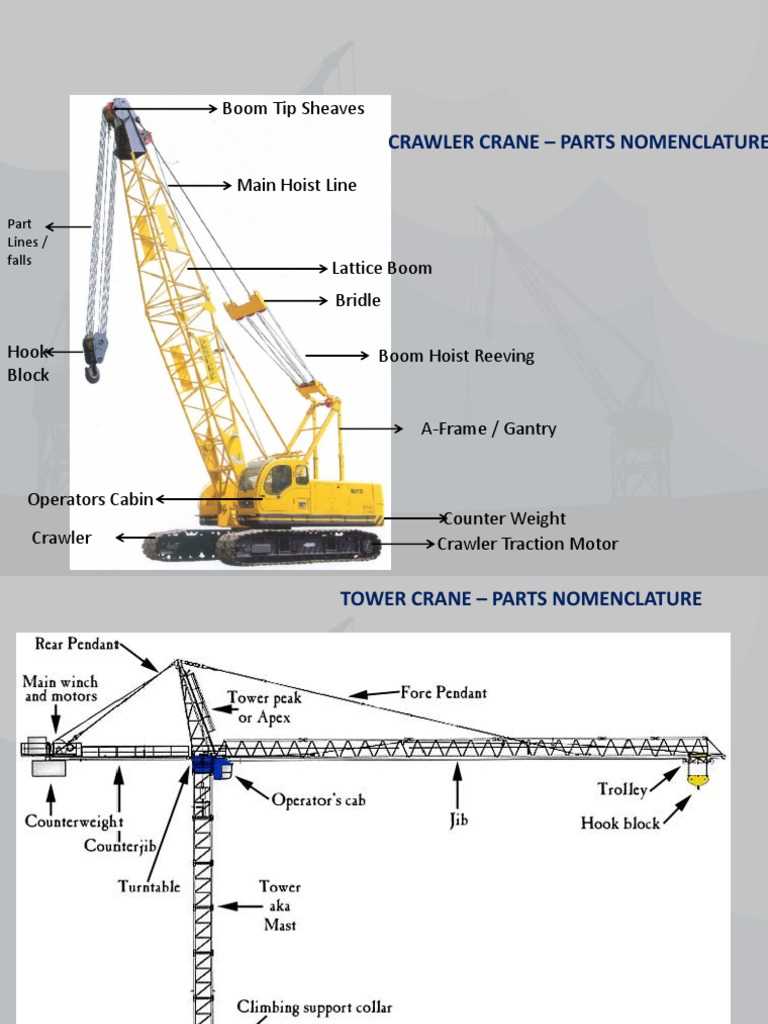

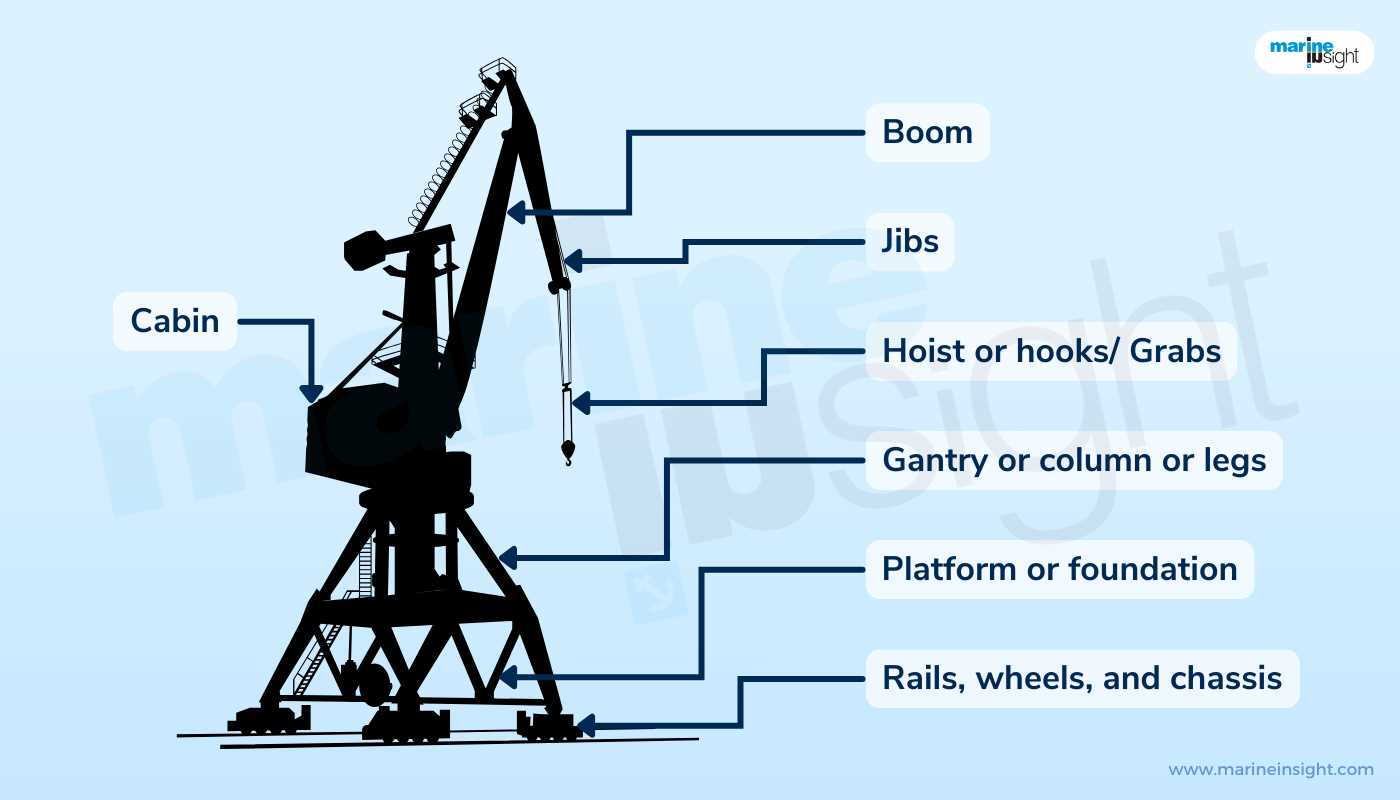

Understanding Mobile Crane Structure

The framework of lifting machinery is complex and essential for various construction and industrial tasks. Each component plays a significant role in ensuring functionality, stability, and safety. A well-designed assembly can enhance performance while minimizing operational risks.

Key elements include the base, which provides stability; the boom, responsible for extending reach; and the rigging systems that secure loads. Understanding these fundamental components is crucial for operators to manage their equipment efficiently.

Safety features are integrated into the structure to prevent accidents during lifting operations. Regular inspections and maintenance of these elements ensure longevity and reliability in demanding environments.

Key Components of Mobile Cranes

The effectiveness of lifting machinery relies on several essential elements that work in harmony to ensure operational success. Understanding these components is crucial for both operators and engineers, as each element plays a significant role in performance and safety.

Primary Elements

- Boom: The primary arm responsible for extending the reach of the equipment.

- Chassis: The framework that supports the structure and provides mobility.

- Counterweights: Added mass to stabilize the machine during operations.

- Winch: A mechanism for hoisting and lowering loads efficiently.

- Jib: An additional arm that enhances reach and flexibility in lifting.

Supporting Features

- Outriggers: Extendable supports that enhance stability while lifting.

- Control System: Interfaces for operators to manage lifting tasks with precision.

- Hydraulic System: Provides power for various movements and functions.

- Cab: The operator’s compartment, designed for comfort and visibility.

- Suspension System: Ensures smooth movement and minimizes wear during transit.

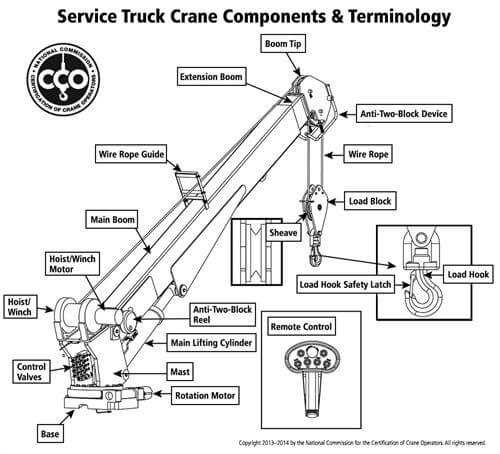

Functions of the Boom Assembly

The boom assembly serves as a crucial component in lifting operations, enabling the manipulation of heavy loads with precision and control. This structure is designed to extend and retract, allowing for versatility in various tasks.

One of the primary roles of the boom assembly is to provide the necessary reach and height required for lifting. By adjusting its angle and length, it optimizes the lifting capacity, ensuring that materials can be placed accurately in desired locations. This adaptability is essential in construction and industrial settings where space constraints and load specifications vary.

Furthermore, the boom assembly contributes to stability during lifting operations. Its design incorporates elements that help distribute weight evenly, minimizing the risk of tipping or imbalance. This stability is vital for maintaining safety standards and protecting both operators and surrounding personnel.

In addition to these functions, the boom assembly often features mechanisms for attaching various tools and attachments. This allows for a range of applications, from hoisting materials to executing specific tasks such as drilling or excavation. The versatility provided by the boom enhances productivity and efficiency on job sites.

Overall, the boom assembly is integral to effective lifting solutions, combining reach, stability, and adaptability to meet the demands of diverse operational environments.

Role of the Counterweights Explained

Counterweights are crucial components that significantly enhance the stability and performance of lifting machines. By balancing the load, they ensure safe operation during lifting tasks, preventing tipping and enhancing overall safety. Understanding their function is essential for effective equipment management and operational efficiency.

Importance of Stability

The primary purpose of counterweights is to provide stability. When heavy loads are lifted, the center of gravity shifts, which can lead to instability. Counterweights counteract this shift, allowing the machinery to operate safely and effectively. They distribute weight evenly, maintaining balance and preventing accidents.

Types of Counterweights

Different types of counterweights are used depending on the specific application and design of the equipment. They can vary in size, shape, and material. Here is a comparison of common types:

| Type | Material | Application |

|---|---|---|

| Fixed Counterweight | Steel | Standard lifting operations |

| Adjustable Counterweight | Concrete | Dynamic lifting scenarios |

| Modular Counterweight | Iron | Heavy-duty applications |

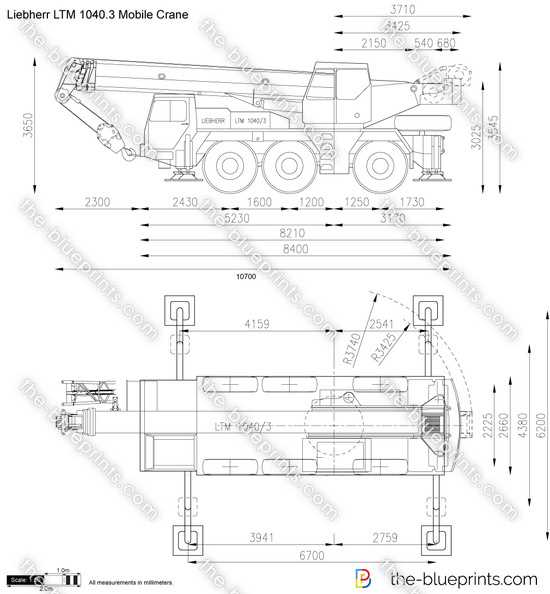

Importance of the Chassis Design

The foundation of any lifting machinery plays a crucial role in its overall performance and safety. A well-thought-out base structure ensures stability, maneuverability, and durability under various operational conditions.

Key aspects to consider in chassis design include:

- Stability: A robust framework prevents tipping and maintains balance during lifting tasks.

- Weight Distribution: Proper layout of components optimizes load handling and reduces stress on the chassis.

- Durability: High-quality materials and engineering enhance longevity, minimizing maintenance needs.

- Maneuverability: An efficient design allows for easier navigation in confined spaces and enhances overall operational efficiency.

In summary, the chassis is not merely a support structure; it is integral to the effectiveness and safety of lifting operations. Investing in superior chassis design is essential for maximizing productivity and ensuring operator safety.

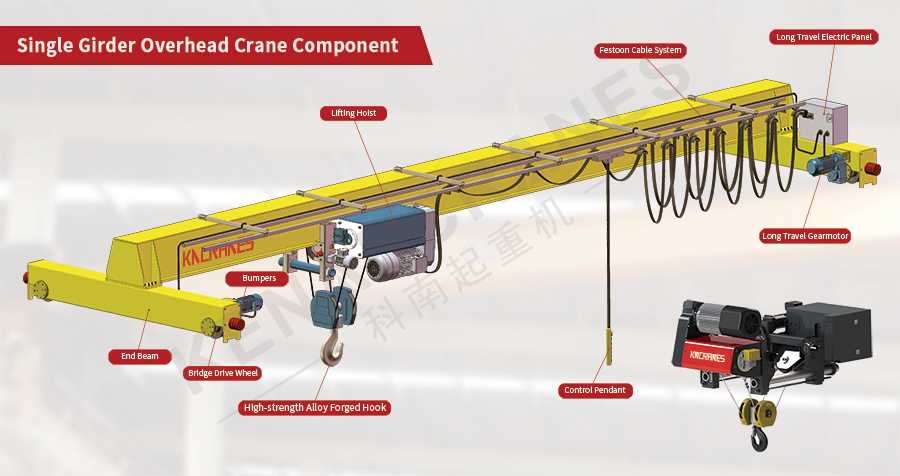

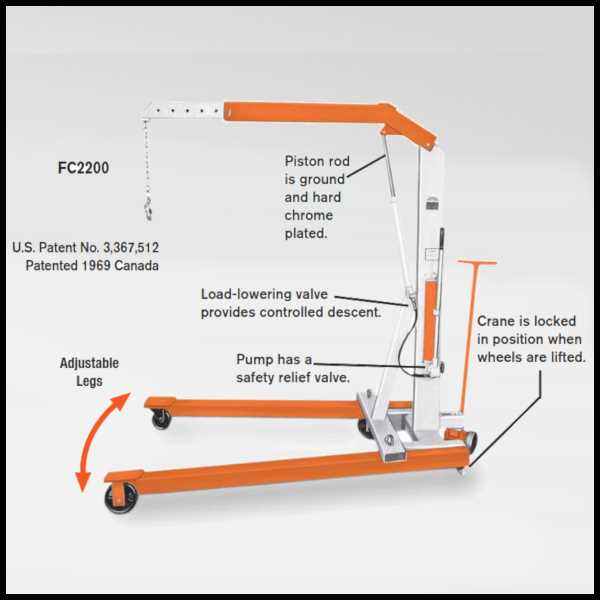

Hydraulic System in Mobile Cranes

The hydraulic system is a crucial component that enables powerful lifting capabilities and smooth operations in heavy machinery. This system utilizes fluid mechanics to transmit force, allowing for precise movements and enhanced performance. The efficiency of hydraulic systems significantly influences the overall functionality of lifting equipment.

Typically, the hydraulic system consists of several key elements, including a pump, cylinders, valves, and fluid reservoirs. The pump generates pressure, which is essential for moving hydraulic fluid through the system. Cylinders convert hydraulic energy into mechanical force, enabling the lifting or lowering of loads. Additionally, valves regulate the flow and pressure of the fluid, ensuring safe and effective operation.

Regular maintenance of the hydraulic system is vital to ensure reliability and longevity. Issues such as leaks, low fluid levels, and contamination can lead to decreased performance and potential failure. Thus, understanding and maintaining this intricate system is essential for operators and technicians alike.

Operator’s Cabin Features and Safety

The operator’s cabin serves as the central command center for controlling heavy machinery, providing both functionality and comfort. It is designed to ensure that the user can operate the equipment efficiently while maintaining a high level of safety. Various features contribute to an optimal working environment, enabling operators to perform their tasks with precision.

Key attributes of the cabin include ergonomic seating, advanced controls, and comprehensive visibility. Safety mechanisms are also integrated to protect the operator during operation. Below is a summary of essential features and safety elements commonly found in the operator’s cabin:

| Feature | Description |

|---|---|

| Ergonomic Design | Adjustable seating and control placement for comfort and reduced fatigue. |

| Visibility | Large windows and mirrors to ensure clear sightlines for safer maneuvering. |

| Control Interface | User-friendly controls that facilitate easy operation of the machinery. |

| Safety Systems | Integrated alarms and automatic shutdown features to prevent accidents. |

| Climate Control | Heating and cooling systems for maintaining a comfortable working environment. |

Understanding these features and their importance can significantly enhance the safety and efficiency of operations, ultimately leading to better performance and reduced risks in the workplace.

How Outriggers Enhance Stability

Outriggers play a crucial role in providing support and balance to heavy lifting equipment. By extending the base of the machine, they create a wider footprint, which is essential for maintaining equilibrium during operation. This design feature is vital, especially when handling substantial loads, as it minimizes the risk of tipping or swaying.

When deployed, these stabilizing extensions distribute the weight more evenly across the ground, thereby enhancing the overall stability of the apparatus. By increasing the surface area in contact with the ground, outriggers significantly reduce the pressure exerted on any single point. This not only protects the underlying surface but also prevents potential accidents caused by shifting weight distribution.

Moreover, the effective use of outriggers allows operators to work in various environments, including uneven terrain. With the ability to adjust each extension independently, operators can tailor the stability settings to suit the specific conditions of the job site, ensuring a safe and efficient working environment. Overall, outriggers are indispensable for achieving optimal safety and performance in heavy lifting tasks.

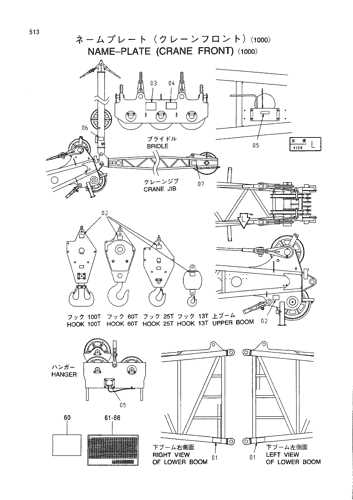

Types of Hooks Used in Cranes

Hooks are essential components in lifting and rigging operations, serving as the interface between the load and the lifting apparatus. Various designs cater to different applications and load types, ensuring safety and efficiency during operations.

- Standard Hook: A versatile option commonly used for general lifting tasks. It features a simple design, allowing easy attachment and detachment.

- Safety Hook: This type incorporates mechanisms to prevent accidental disengagement of the load, enhancing operational safety. Often used in high-risk environments.

- Swivel Hook: Allows for rotation without twisting the rigging line, providing greater maneuverability when positioning loads.

- Triple Action Hook: Designed for heavy lifting, this hook features three locking mechanisms, ensuring secure handling of substantial weights.

- Electromagnetic Hook: Utilizes magnetic force to lift ferrous materials, making it ideal for industrial applications involving metal components.

Understanding the different types of hooks is crucial for selecting the right one for specific tasks, ensuring both efficiency and safety in lifting operations.

Load Charts: Reading and Importance

Understanding the specifications and limitations of lifting equipment is essential for safe and efficient operation. Load charts provide crucial information that helps operators determine the maximum load that can be lifted at various configurations and conditions. These charts play a vital role in ensuring safety and compliance with industry standards.

How to Read Load Charts

To effectively interpret load charts, one must familiarize themselves with key elements such as the lift radius, load capacities at different angles, and various configurations. Here are some common components found in these charts:

| Component | Description |

|---|---|

| Lift Radius | The distance from the center of rotation to the load, affecting capacity. |

| Load Capacity | The maximum weight that can be lifted at a given radius and angle. |

| Configuration | Different setups that influence lifting capabilities, such as boom extension and angle. |

Significance of Load Charts

Proper understanding of load charts is critical for risk management. By adhering to the specifications outlined, operators can avoid overloads, which may lead to equipment failure or accidents. Furthermore, these charts assist in planning and optimizing lifting operations, ensuring that tasks are completed efficiently and safely.

Maintenance Tips for Crane Parts

Proper upkeep is essential for ensuring the longevity and efficiency of lifting equipment. Regular maintenance not only enhances performance but also minimizes the risk of breakdowns, ensuring safety and reliability in operations. Below are some essential practices to keep in mind.

Regular Inspections

Frequent evaluations help identify potential issues before they escalate. Focus on key components and monitor for signs of wear or damage.

Lubrication and Cleaning

Maintaining cleanliness and lubrication of moving elements is crucial. This practice reduces friction and prevents corrosion, ultimately prolonging the life of the machinery.

| Maintenance Activity | Frequency | Purpose |

|---|---|---|

| Visual Inspection | Daily | Identify visible wear and damage |

| Lubrication | Weekly | Reduce friction and wear |

| Full Inspection | Monthly | Comprehensive evaluation of all components |

| Replace Worn Parts | As Needed | Maintain optimal performance |