In many modern devices, a clear understanding of the various internal and external elements can greatly enhance maintenance and troubleshooting efforts. This section aims to provide an insightful overview of the essential elements that make up these systems, focusing on their roles and how they work together to ensure smooth operation.

Detailed component knowledge is crucial for anyone looking to keep equipment in optimal condition. By recognizing each element’s function, one can quickly identify areas needing attention, thereby preventing potential issues from escalating. This guide will cover various crucial elements, their purposes, and tips for maintaining them effectively.

Knowing how different elements interact within the system also allows for more precise adjustments and repairs. Whether you are performing routine maintenance or addressing specific concerns, having a clear picture of the internal structure will support efficient and successful outcomes.

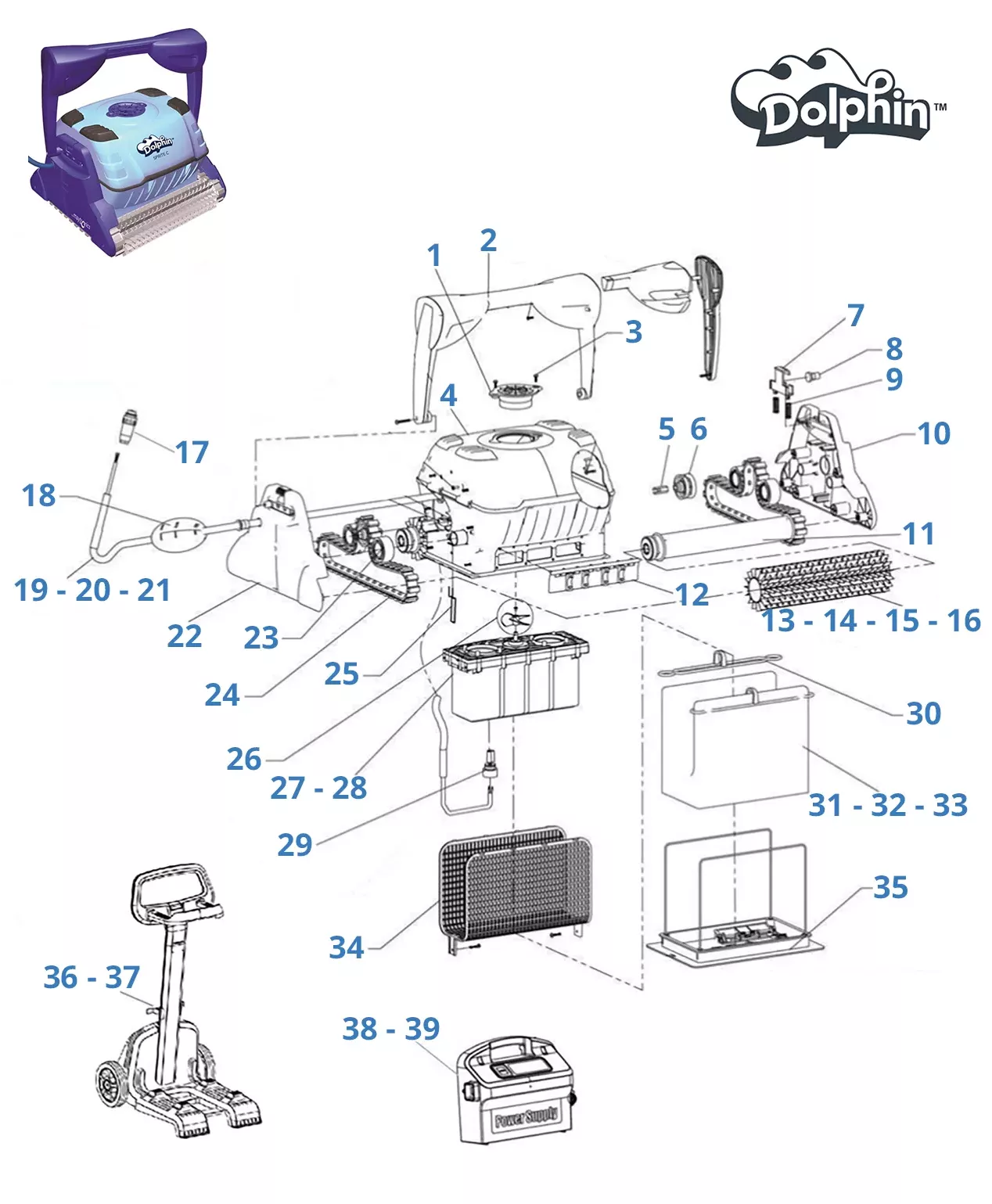

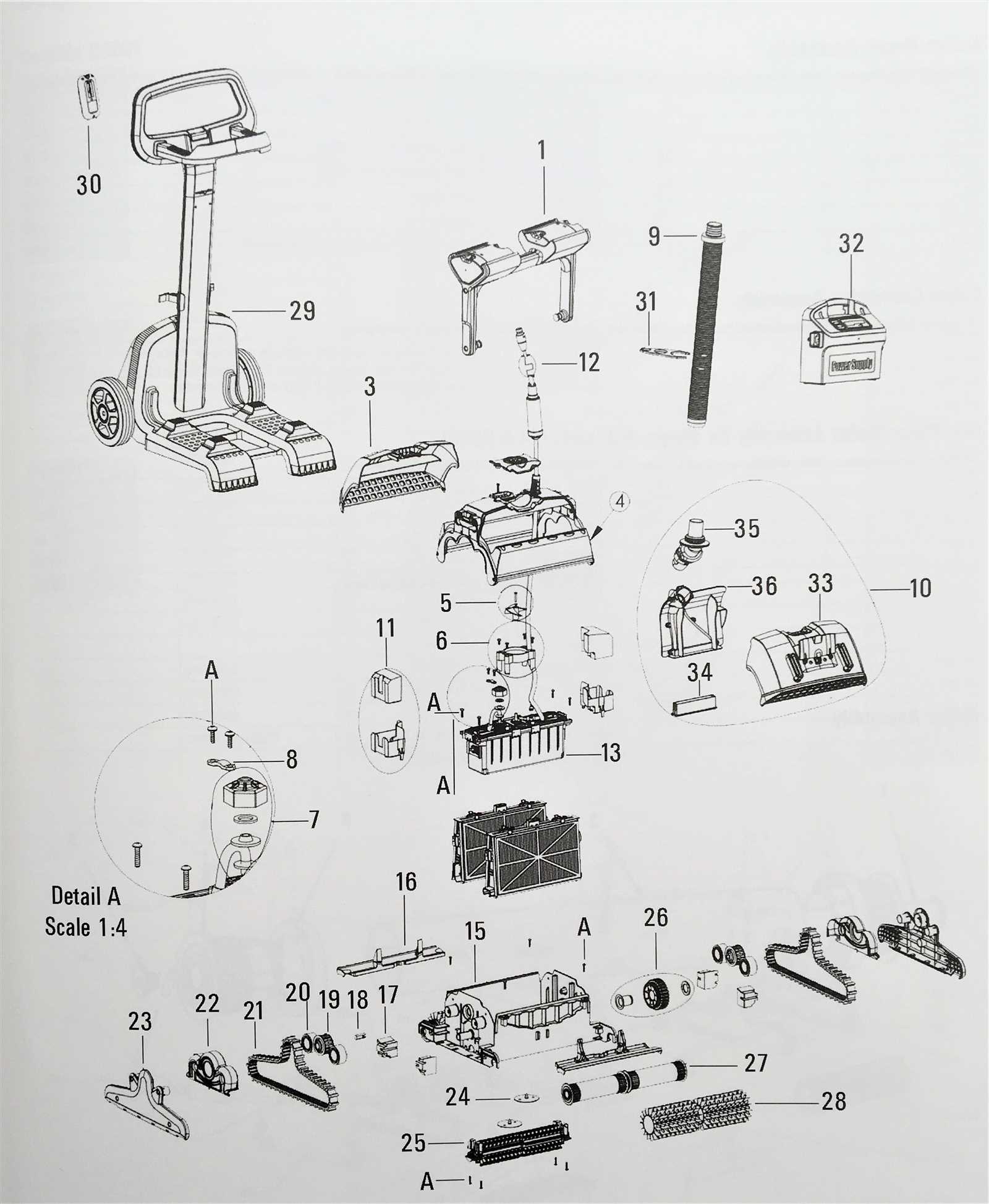

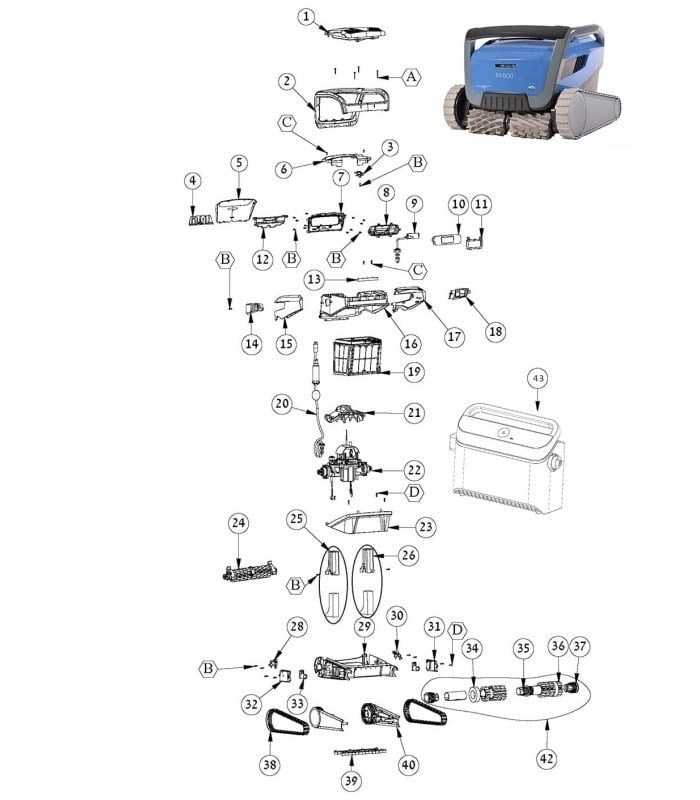

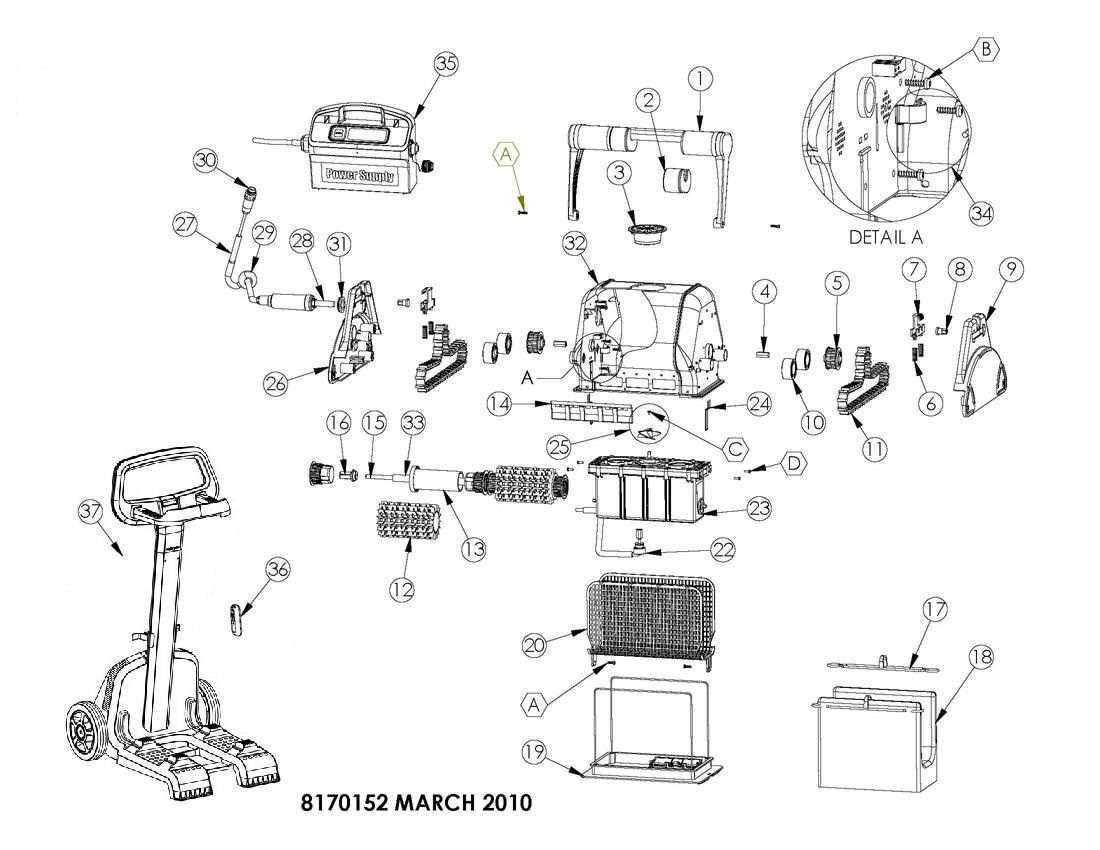

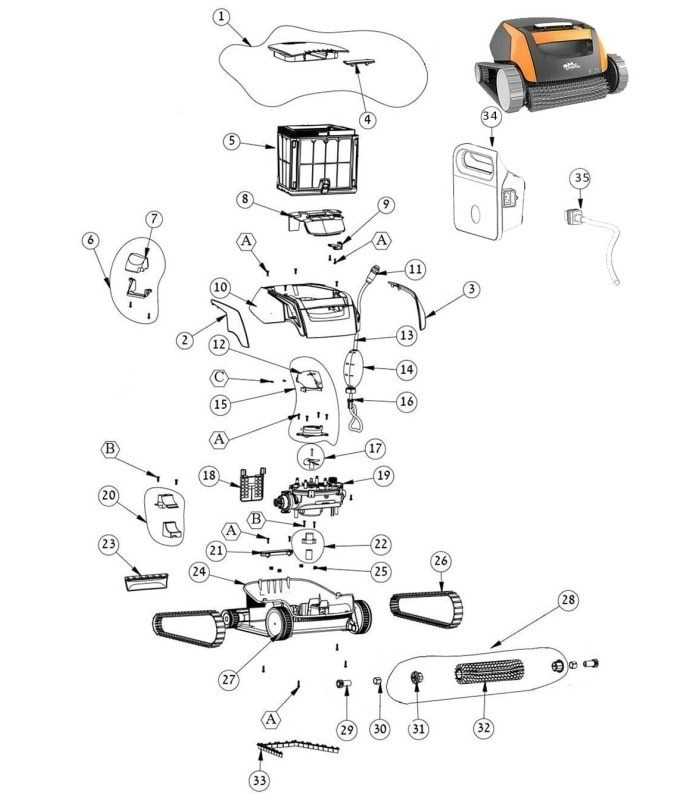

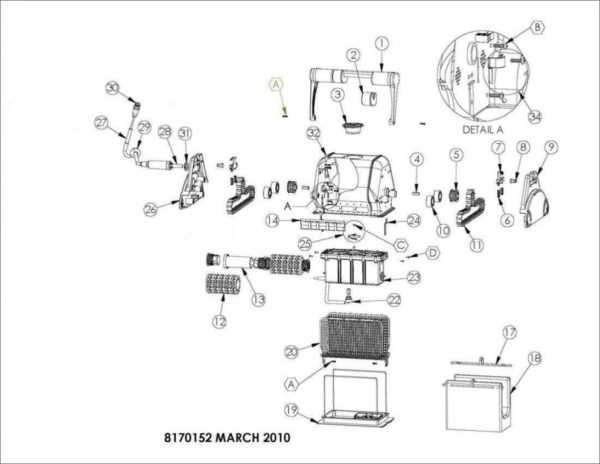

Dolphin M400 Components Overview

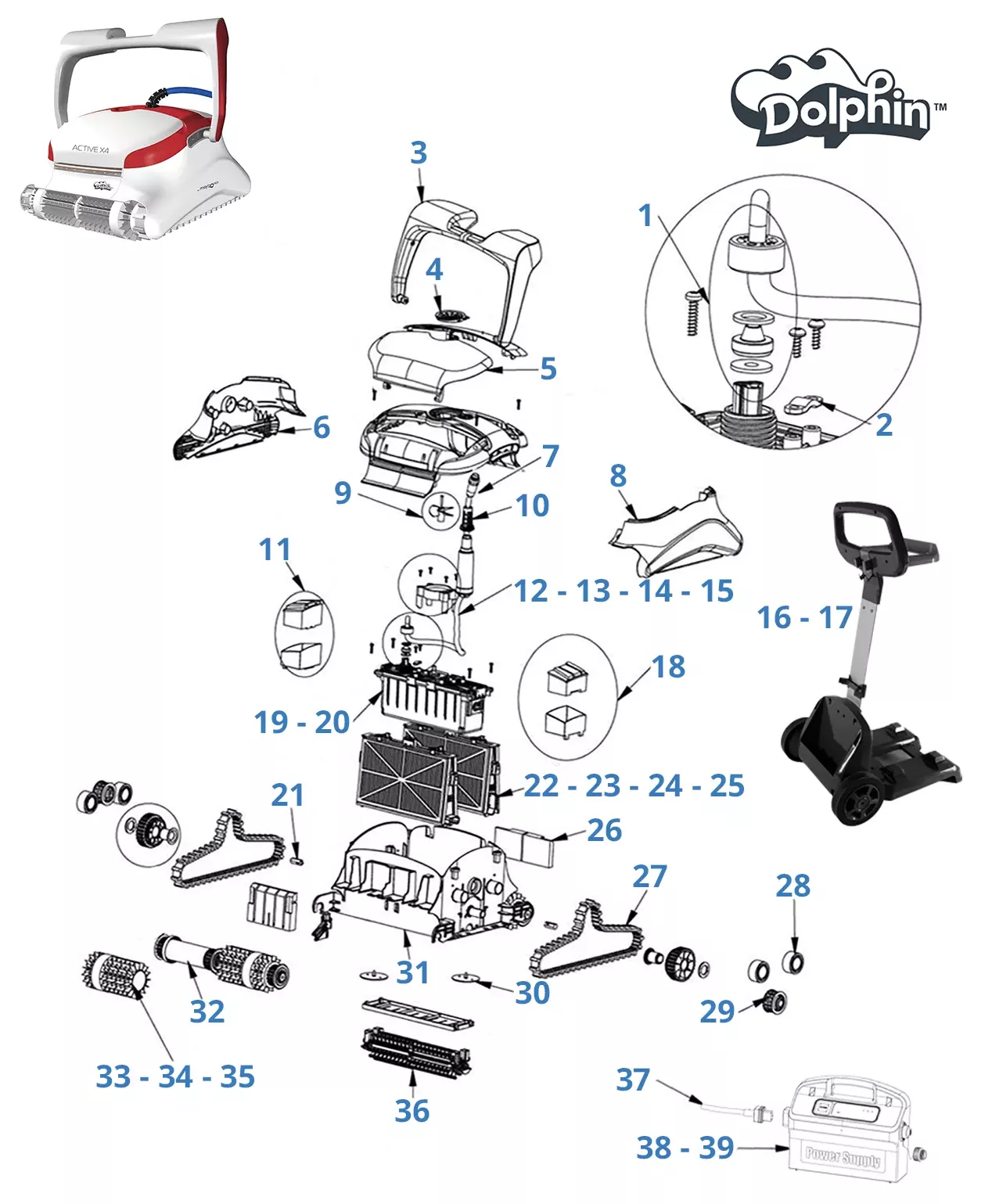

This section provides a detailed look at the various elements that make up a robotic pool cleaner. The discussion focuses on the essential features and structures that contribute to its performance, ensuring efficient cleaning and maintenance.

Main Mechanical Elements

The core mechanical features are designed to optimize movement and scrubbing capabilities. The structure typically includes various components that enable smooth navigation, thorough debris collection, and effective surface coverage.

- Drive system: The propulsion mechanism ensures precise maneuverability, allowing the cleaner to reach all areas of the pool, including walls and steps.

- Brush assembly: Equipped with rotating brushes, the cleaner scrubs surfaces to remove dirt, algae, and other deposits.

- Debris intake system: Positioned near the brushes, it collects particles and transports them to a collection container.

Filtration and Power Components

Filtration elements are crucial for maintaining water clarity, while the power components support

Understanding Key Parts of the M400

The efficient operation of this cleaning machine relies on several essential components working together. Each element plays a vital role in maintaining optimal performance and ensuring thorough cleaning. By familiarizing yourself with these critical components, you can better understand how the machine functions and keep it running smoothly over time.

Filtration System: The filtration setup captures dirt and debris, preventing particles from reentering the water. Regular maintenance of this system is essential to ensure maximum cleaning efficiency and prolong the machine’s life.

Brush Assembly: The brush arrangement helps scrub surfaces to remove grime and algae. These brushes rotate to reach various areas, enhancing the overall cleaning process. Periodic inspection can help detect wear and replace them as needed.

Power Supply Unit: This component provides energy to the cleaning device, allowing it to function autonomously. It also offers control settings for adjusting the cleaning program. Ensuring the power source is in good condition will prevent interruptions during operation.

Understanding these core components and their roles not only aids in troubleshooting but also extends the life of the cleaning device, making it a valuable tool for keeping surfaces pristine.

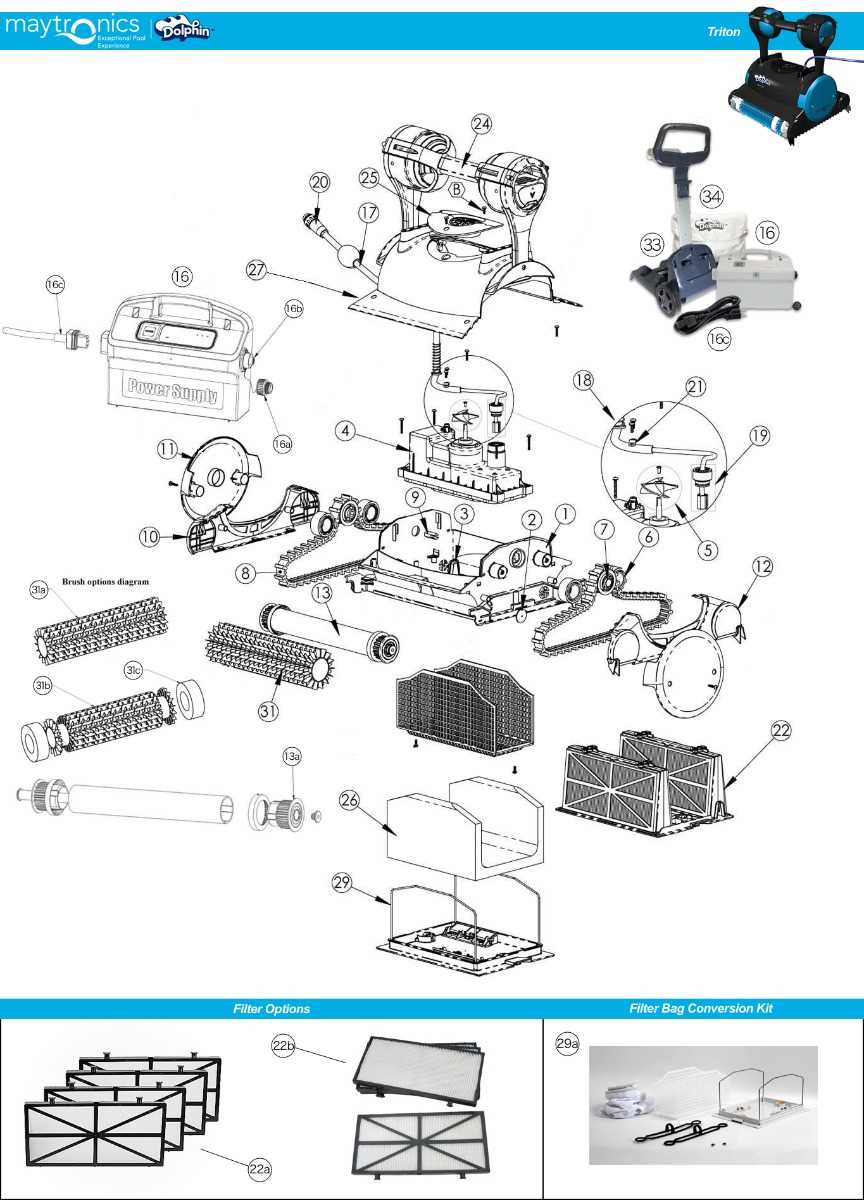

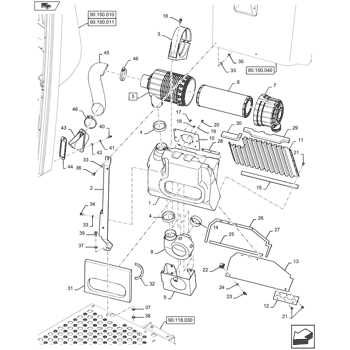

Filter System Details and Maintenance

The filter system plays a crucial role in maintaining optimal performance and ensuring the cleanliness of the device. It functions by capturing debris, fine particles, and contaminants, allowing for clear and hygienic operation. Regular upkeep of the filter mechanism is essential to prevent clogging and to extend the lifespan of the equipment.

Types of Filters and Their Functions

There are typically different filter types available, each designed to handle specific levels of debris. Some filters are better suited for larger debris, while others are designed to capture finer particles, providing a comprehensive cleaning approach. Choosing the appropriate filter for the conditions will improve efficiency and help maintain the system’s longevity.

Steps for Proper Filter Maintenance

To keep the filter in top condition, regular inspection and cleaning are necessary. Rinse the filter under running water to remove trapped particles and allow it to dry completely before reinserting. If there are signs of wear or damage, replace the filter to ensure effective performance. Additionally, check the filter housing for any accumulated debris and clean as needed to support the system’s functionality.

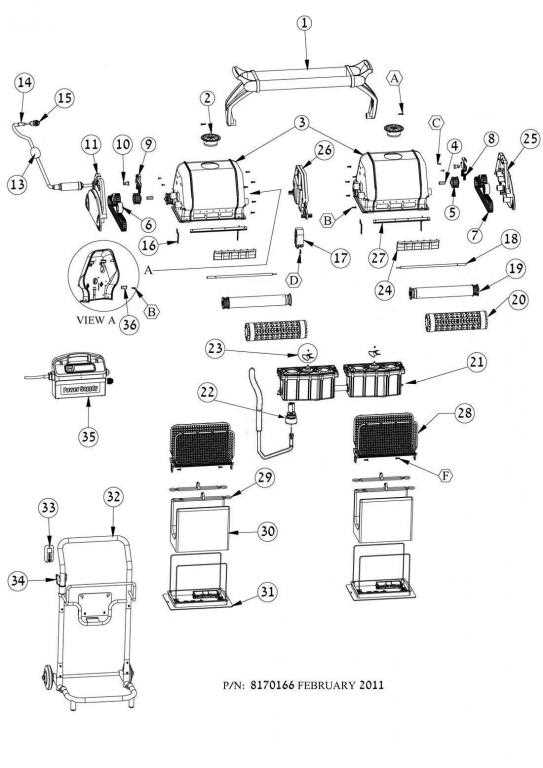

Exploring the Motor Unit Functions

The motor unit plays a crucial role in ensuring the efficient operation of the device, enabling it to perform its tasks with precision and reliability. Understanding how this component works helps in grasping the mechanics behind the device’s movement and overall functionality. In this section, we will examine the key elements and behaviors associated with the motor unit, along with some common factors that may impact its performance.

Key Components of the Motor Unit

The motor unit consists of several interconnected parts that work together to produce movement. Each component serves a specific purpose, contributing to the smooth functioning of the mechanism. Below is an overview of the main elements found within the motor unit:

| Component | Description |

|---|---|

| Drive Motor | Generates

Cleaning Brushes: Types and Uses

Cleaning brushes play a crucial role in maintaining various equipment, offering different functionalities based on their design and materials. Choosing the right brush for a particular task can significantly improve cleaning efficiency, ensuring thorough removal of debris, dirt, and other unwanted particles. Soft Bristle Brushes are ideal for delicate surfaces where gentle scrubbing is necessary. These brushes are often used for light cleaning tasks to avoid scratching or damaging sensitive areas. Hard Bristle Brushes, on the other hand, provide a more aggressive cleaning action, making them suitable for stubborn dirt or tougher surfaces. Their firm bristles can dislodge deeply embedded particles, ensuring a more thorough clean. Another common type is the roller brush, which rotates to cover a larger area quickly. This type is often used for automated cleaning systems, enhancing the efficiency of debris removal over broad surfaces. Additionally, combination brushes merge different bristle types to offer a balance between gentle and rigorous cleaning, making Cable and Power Supply SpecificationsThis section delves into the essential characteristics of the connection cables and power supply units necessary for optimal operation. Understanding these specifications is crucial for ensuring reliable performance and longevity of the equipment. Power Supply Requirements

Power supplies must meet specific criteria to function effectively. The following points highlight the key aspects:

Cable Specifications

Cables play a vital role in establishing a secure connection between components. Important specifications include:

Navigation System: How It Works

The navigation system is a critical component designed to enhance efficiency and precision in aquatic environments. It enables the device to maneuver effectively, ensuring optimal performance during operation. Understanding its functionality is essential for users looking to maximize the capabilities of their equipment. Core Components of the Navigation System

Operational Process

By leveraging these components and processes, the navigation system ensures seamless operation and adaptability in various aquatic settings. This capability is vital for achieving superior results and maintaining operational efficiency. Replacing Worn-Out Parts Effectively

Maintaining the efficiency of any equipment requires timely replacement of deteriorated components. This not only ensures optimal performance but also prolongs the lifespan of the device. Understanding when and how to replace these essential elements is crucial for effective operation. First, it is important to regularly inspect the equipment for signs of wear. Look for visual damage, unusual noises, or decreased functionality. Identifying these issues early can prevent further damage and costly repairs. When a component shows significant signs of fatigue, replacing it promptly will help restore the original functionality. When selecting replacement components, ensure they meet the required specifications for compatibility and quality. Using high-quality replacements enhances overall performance and minimizes future failures. Always consult the manufacturer’s guidelines for recommendations on suitable alternatives and installation procedures. After obtaining the necessary replacements, follow proper procedures for removal and installation. Make sure to power down the device and follow safety protocols to avoid accidents. Take your time during the process; rushing can lead to mistakes that may compromise the equipment’s performance. Lastly, dispose of the old components responsibly. Many manufacturers offer recycling programs, which can be beneficial for the environment. By replacing worn-out elements effectively, you ensure that the equipment remains functional and efficient for years to come. Proper Storage for Extended Lifespan

Ensuring optimal longevity of equipment requires thoughtful storage practices. Proper care not only maintains functionality but also extends the operational life of the device. When equipment is stored correctly, it can prevent damage and deterioration caused by environmental factors. Climate Control: Maintain a stable temperature and humidity level to avoid corrosion and mechanical issues. Extreme temperatures can adversely affect internal components and materials, leading to malfunctions. Cleanliness: Before storage, ensure that the device is free from dirt and debris. Regular cleaning helps prevent contaminants from causing wear or blockages over time. Use appropriate cleaning agents that do not damage sensitive surfaces. Secure Placement: Store the equipment in a dedicated space where it is protected from accidental impacts or falls. Utilize protective coverings to shield against dust and moisture. Ensure that the area is well-ventilated to avoid stagnant air. Regular Checks: Periodically inspect the stored device to identify any potential issues early. This proactive approach allows for timely maintenance and repair, ensuring that it remains in good working condition when needed. Troubleshooting Common Component Issues

When dealing with mechanical devices, encountering problems with individual elements is not uncommon. Understanding how to identify and address these issues can significantly enhance the device’s performance and longevity. Below are some typical challenges that users might face, along with effective solutions.

By systematically checking these components, users can often resolve common issues efficiently. Regular maintenance and prompt troubleshooting are key to optimal performance. Accessories to Enhance M400 Performance

Improving the functionality and efficiency of a cleaning device can significantly enhance its overall performance. By utilizing various supplementary tools and enhancements, users can maximize the effectiveness and longevity of their equipment. This section explores a range of accessories designed to elevate performance levels, ensuring optimal operation and satisfaction. 1. Replacement Brushes are essential for maintaining cleaning efficiency. Over time, the bristles on the brushes may wear down, leading to reduced effectiveness. Upgrading to high-quality replacement brushes can ensure thorough cleaning and better dirt removal. 2. Enhanced Filters play a critical role in capturing debris and ensuring clean output. Investing in advanced filtration systems can greatly improve the cleaning process, allowing for finer particles to be trapped and maintaining cleaner water. 3. Maintenance Kits are invaluable for regular upkeep. These kits typically include essential tools and components that help keep the device functioning optimally. Regular maintenance not only extends the life of the equipment but also enhances performance. 4. Remote Control Options can significantly improve user experience by providing convenient access to settings and functions from a distance. This feature allows for effortless adjustments during operation, adding a layer of control and ease. Incorporating these accessories can lead to a noticeable improvement in performance, ensuring that the cleaning process remains efficient and effective for extended periods. |