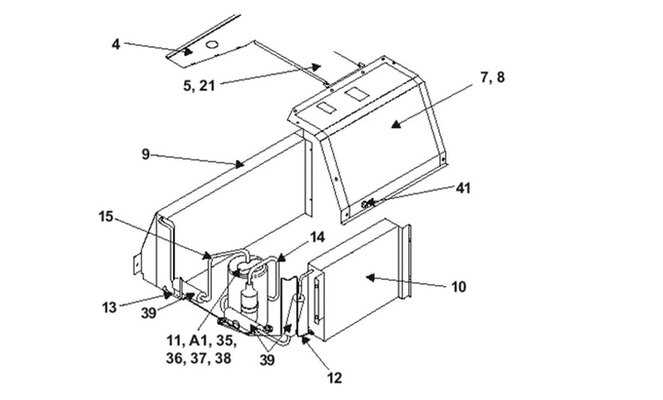

Cooling systems for recreational vehicles are intricate mechanisms designed to ensure a comfortable environment during travel. To maintain these systems efficiently, it’s important to recognize how various elements function together. In this section, we will explore key components that work in harmony to provide temperature regulation.

Whether you’re looking to replace a malfunctioning piece or simply understand how the cooling process operates, gaining insight into the internal structure is essential. By identifying the roles of different elements, you can ensure smooth operation and prevent potential issues during use.

Proper maintenance and timely repairs can extend the lifespan of your cooling unit. In the following sections, we’ll break down the critical parts involved, offering a clear overview of their functions and how they contribute to the system’s overall performance.

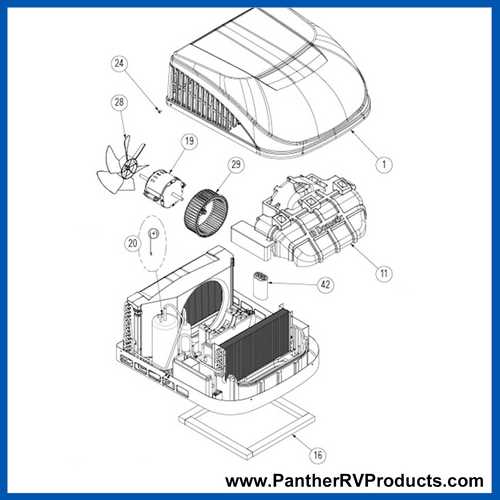

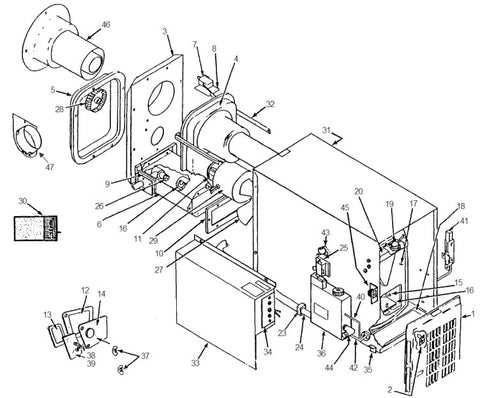

Air Conditioning System Overview

The air conditioning unit provides efficient cooling for vehicles and mobile homes, ensuring a comfortable climate in various weather conditions. It is designed for easy installation and reliable operation, making it a popular choice for long journeys or extended stays. The system is equipped with features that allow for precise temperature control and energy efficiency, which helps maintain a pleasant environment inside the vehicle.

| Feature | Description | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature Control | Allows precise adjustment of the interior climate, ensuring optimal comfort. | |||||||||||||||||||||||||

| Energy Efficiency | Optimized for minimal power consumption while maintaining effective cooling. | |||||||||||||||||||||||||

| Component | Description | Function |

|---|---|---|

| Filter Element | A replaceable medium designed to capture dust, allergens, and other particulates. | Ensures the air entering the system is clean, improving air quality. |

| Housing | The casing that contains the filter and supports installation. | Provides structural integrity and facilitates easy access for maintenance. |

| Seals | Gaskets or rubber components that ensure a tight fit between the housing and filter. | Prevents air leaks, ensuring all air passes through the filter. |

| Mounting Bracket | A support piece that secures the assembly in place within the unit. | Ensures stability during operation and helps in alignment. |

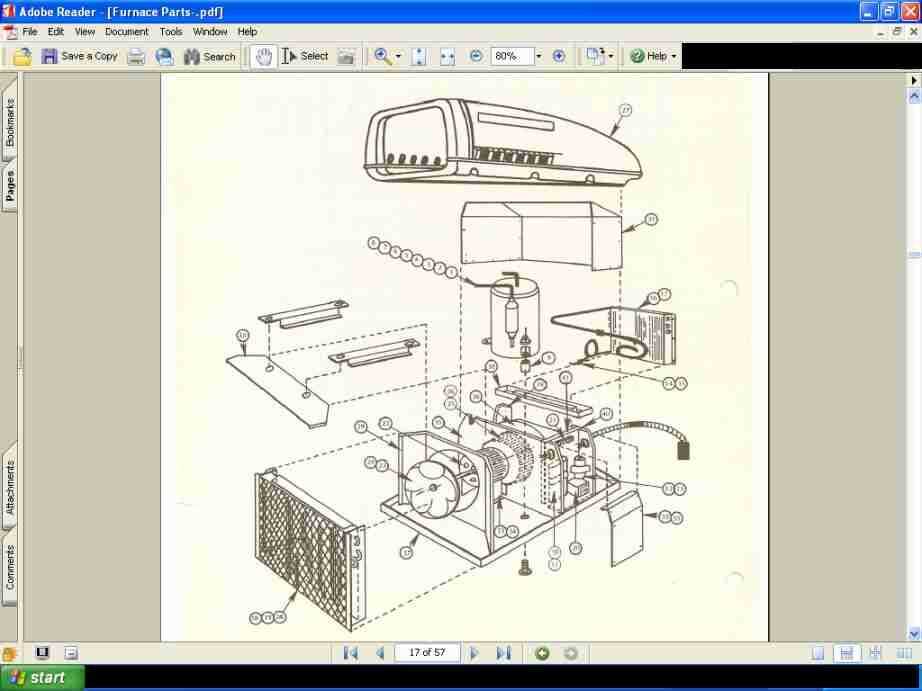

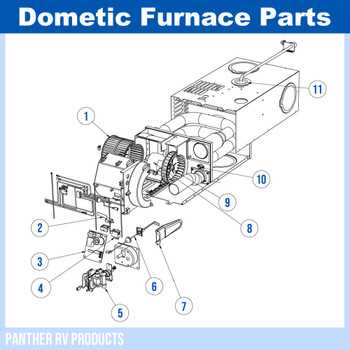

Common Replacement Parts for Maintenance

Regular upkeep of cooling units is essential to ensure their longevity and optimal performance. By identifying and utilizing frequently needed components, users can easily address common issues that may arise during operation. This section outlines the essential elements to consider for maintaining efficient functionality.

Key Components for Efficient Functionality

Among the primary items often replaced are fan motors, which play a crucial role in ensuring proper airflow. Filters are another vital part, as they help maintain air quality and efficiency by trapping dust and debris. Additionally, thermostats are frequently updated to ensure accurate temperature regulation, enhancing the overall effectiveness of the unit.

Importance of Regular Inspections

Routine examinations of the system can help identify worn or damaged parts before they lead to more significant problems. Checking for signs of wear in the electrical connections and seals can prevent costly repairs and extend the life of the equipment. Staying proactive with replacements ensures reliable operation and comfort in any environment.

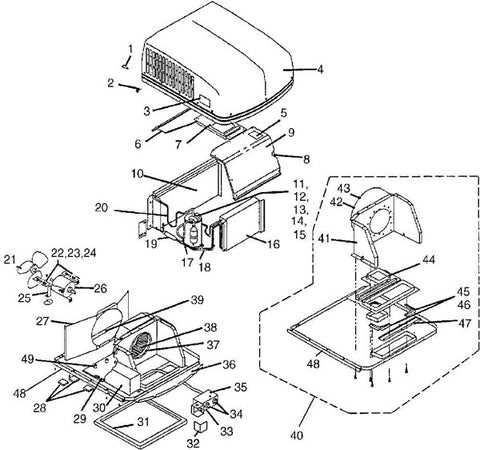

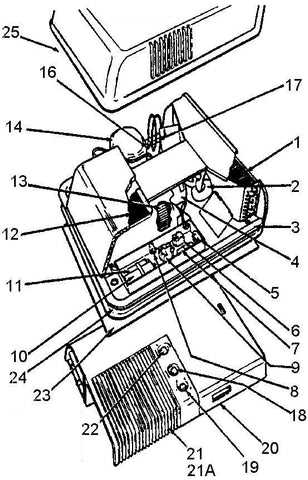

Troubleshooting Based on the Parts Diagram

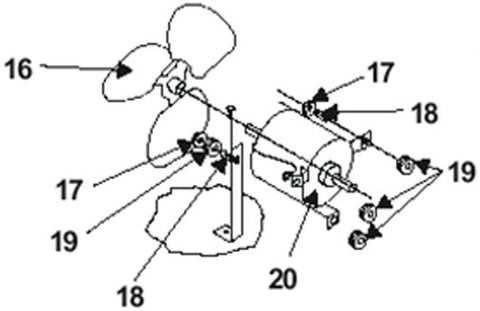

This section aims to provide guidance on resolving common issues by referring to the visual representation of components within the system. Understanding how different elements interact is essential for effective problem-solving, allowing for a systematic approach to maintenance and repair.

Identifying Common Issues

By closely examining the visual layout of the unit, users can identify potential problem areas. Each component is designed to perform specific functions, and recognizing these can help in pinpointing the source of malfunctions. Common issues often relate to electrical connections, cooling performance, or airflow restrictions.

Systematic Approach to Resolution

A structured method for troubleshooting can enhance efficiency. Start by checking the electrical connections and ensuring that all components are securely attached. Next, inspect the cooling system for any obstructions that might affect performance. Lastly, verify that the airflow pathways are clear, as blockages can lead to overheating or inefficient operation.

| Component | Common Issue | Troubleshooting Steps |

|---|---|---|

| Electrical Connections | Loose or damaged wires | Inspect and tighten connections |

| Cooling System | Inefficient cooling | Check for blockages and clean coils |

| Airflow Pathways | Overheating | Clear any obstructions |