This section explores the intricate arrangement of essential elements within a specific fluid management system. By examining how these components interact, users can gain a deeper insight into the functionality and efficiency of the unit.

Each part plays a crucial role, contributing to the overall performance and reliability of the mechanism. Familiarizing oneself with this structure is vital for optimal operation and maintenance.

In this guide, we will delve into the various components, highlighting their purposes and interconnections. A clear understanding of this configuration ensures that users can effectively troubleshoot and enhance their system’s performance.

This section explores the operational principles behind various dosing devices used in agricultural and industrial applications. These units are designed to ensure precise and consistent delivery of liquids, enhancing efficiency in a range of processes.

- Proportional Dosing: Automatically adjusts the mixture based on the flow rate of the main fluid.

- Flow Regulation: Maintains a steady output, ensuring uniform distribution of the solution.

- Ease of Use: User-friendly interfaces allow for simple adjustments and monitoring.

Understanding these functionalities can greatly enhance operational effectiveness and resource management.

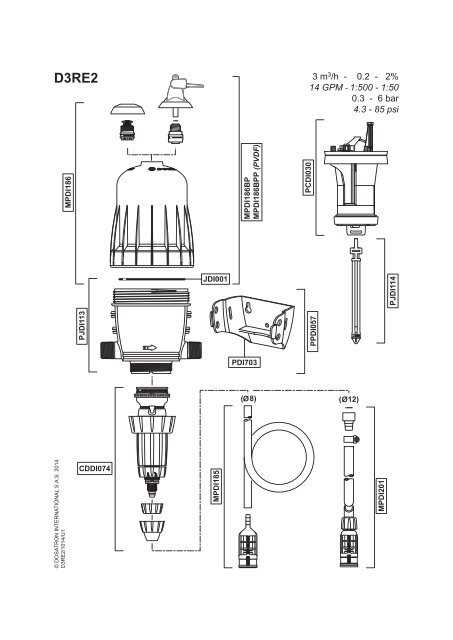

Key Parts in Dosatron Design

This section explores the essential components that contribute to the functionality and efficiency of the liquid dispensing system. Understanding these elements is crucial for grasping how the device operates and delivers precise mixtures.

At the core of this mechanism is a pump, which plays a vital role in drawing the fluid into the system. It ensures consistent flow rates and accurate dosing, adapting to various pressure levels. Additionally, the injector serves as a critical element, enabling the seamless integration of concentrated solutions into the main flow. Its design allows for adjustments to achieve optimal mixing ratios.

Another significant component is the control unit, which regulates the operational parameters and ensures user-friendly adjustments. This unit is often equipped with indicators that provide real-time feedback on the system’s performance. Moreover, the housing protects the internal mechanisms from external elements, contributing to the longevity and reliability of the entire assembly.

Lastly, the valves within the system control the direction and flow of the liquids, playing a crucial role in maintaining the desired operations. Each of these elements works in harmony to ensure the device meets its intended applications efficiently.

Maintenance Tips for Dosatron Systems

Regular upkeep is essential for optimal performance and longevity of dosing systems. Implementing a routine maintenance schedule can prevent issues and ensure consistent operation.

- Check seals and gaskets regularly to prevent leaks.

- Clean all components to avoid buildup of residues.

- Inspect hoses for cracks or wear and replace as needed.

- Test calibration periodically to ensure accurate dosage.

Additionally, consider the following practices:

- Lubricate moving parts to reduce friction and wear.

- Keep the surrounding area clean to avoid contamination.

- Store the system in a dry, temperature-controlled environment when not in use.

By adhering to these guidelines, you can enhance the reliability and efficiency of your dosing equipment.

Identifying Common Dosatron Issues

Understanding typical challenges that arise in fluid dosing systems can significantly enhance maintenance efficiency and system reliability. By recognizing these problems early, operators can implement timely interventions to avoid costly downtimes and ensure optimal performance.

Symptoms of Malfunction

Common indicators of issues may include inconsistent flow rates, unexpected fluctuations in chemical concentration, or unusual noises during operation. Identifying these symptoms promptly can help in diagnosing underlying problems, whether they stem from mechanical wear, blockages, or calibration errors.

Preventative Measures

Regular inspections and maintenance routines are essential in mitigating potential failures. Keeping an eye on critical components, such as seals and fittings, and ensuring proper calibration can prevent many common issues. Furthermore, maintaining a clean system and adhering to recommended operational practices will enhance longevity and reliability.

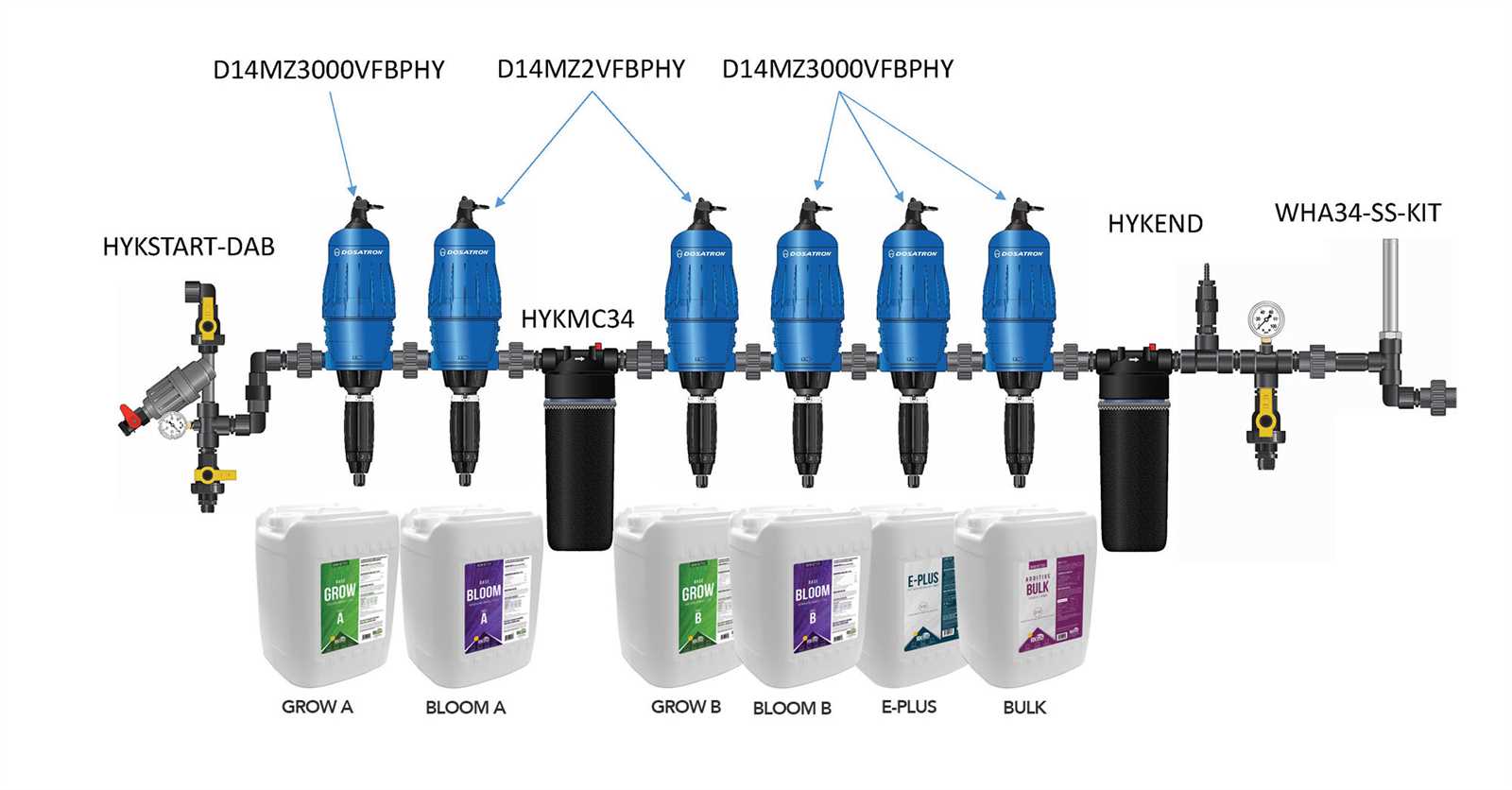

Diagrams and Visual References

This section provides a comprehensive overview of various visual aids and schematics that facilitate the understanding of complex systems. By employing these graphical representations, users can enhance their comprehension of assembly and operational procedures, making it easier to identify components and their functions within the overall structure.

Understanding Component Layouts

Clear visual references allow for a straightforward interpretation of component arrangements. These illustrations serve as valuable tools for both beginners and experienced users, aiding in the recognition of key elements and their placements. By following these guides, users can ensure proper assembly and avoid common errors.

Utilizing Visual Aids for Maintenance

Maintenance becomes significantly more manageable when utilizing schematic representations. These visuals not only depict how components interact but also highlight areas that may require attention. By regularly consulting these references, individuals can maintain optimal performance and longevity of the system.

Upgrading Dosatron Components Effectively

Enhancing the efficiency of your dispensing system involves a careful assessment of its components. Regular upgrades can significantly improve performance and extend the lifespan of the equipment. By focusing on critical elements, users can achieve optimal results while maintaining functionality.

Identifying Key Components for Upgrade

Prioritizing which elements to enhance is essential. Begin by examining performance metrics and identifying any areas lacking efficiency. Components such as pumps and valves often benefit most from modern alternatives that offer better reliability and precision.

Implementation of Upgrades

When integrating new elements, ensure compatibility with existing systems. This may involve consulting with suppliers to confirm specifications. Regular maintenance following upgrades is vital to prevent issues and ensure long-lasting improvements. Investing time in this process will yield substantial benefits in overall performance.

Choosing the Right Replacement Parts

When it comes to maintaining your equipment, selecting the appropriate components is crucial for optimal performance and longevity. Understanding the specific requirements and compatibility of each element will ensure smooth operation and prevent potential issues.

First, identify the specific model and type of your system. Each version may have unique specifications, which will dictate the compatible replacements. Referencing the manufacturer’s guidelines can provide valuable insights into the necessary attributes of the components.

Next, assess the quality of the alternatives available in the market. It’s advisable to opt for reputable brands that guarantee durability and reliability. High-quality components often come with warranties, adding an extra layer of security to your investment.

Finally, consider seeking advice from professionals or experienced users. Their insights can guide you towards the most effective choices based on practical experiences. Making informed decisions will ultimately enhance the efficiency and reliability of your machinery.

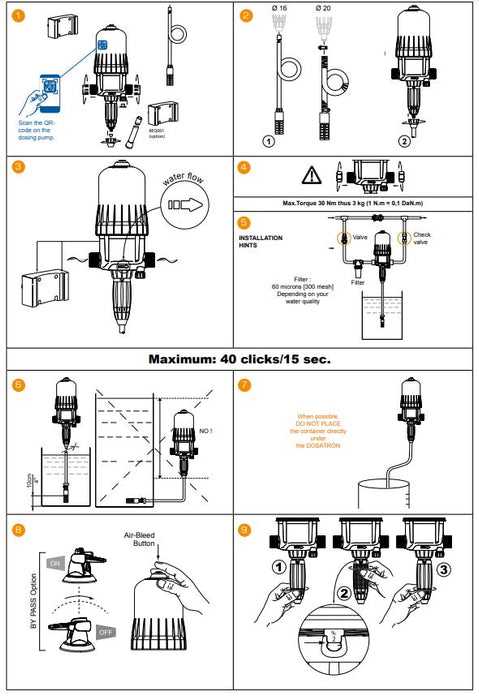

Dosatron Installation Guidelines

Proper installation of the dosing device is essential for optimal performance and longevity. Following a systematic approach ensures that all components are correctly positioned and function effectively within the intended system. Careful attention to detail during the setup process can significantly enhance efficiency and minimize potential issues.

Preparation Before Installation

Before starting the installation, gather all necessary tools and components. Review the manufacturer’s specifications to understand the required setup. Ensure that the installation area is clean and accessible, allowing for easy maneuvering of the unit and connections to the system.

Installation Process

Begin by securely mounting the device according to the provided instructions. Connect the inlet and outlet hoses, ensuring a tight fit to prevent leaks. Adjust the calibration settings as needed to achieve the desired dosing rate. Finally, conduct a thorough test of the system to confirm that everything operates smoothly.

Safety Precautions During Repairs

When undertaking maintenance on mechanical systems, ensuring safety is paramount. Proper precautions not only protect the individual performing the task but also maintain the integrity of the equipment involved.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE), including gloves and goggles.

- Ensure the equipment is powered down and disconnected from any power sources.

- Work in a well-ventilated area to avoid inhaling harmful substances.

Emergency Preparedness

- Keep a first aid kit accessible in case of accidents.

- Be familiar with emergency shutdown procedures for the system being serviced.

- Have a fire extinguisher nearby if flammable materials are involved.