When working with intricate devices, grasping the layout and functionality of each element is essential for optimal performance and maintenance. A comprehensive visual representation can significantly aid users in identifying and utilizing various components effectively.

In this section, we will explore the essential constituents of a popular rotary instrument. By breaking down its structure, we aim to enhance your familiarity with the tool, ultimately boosting your confidence in its operation.

By delving into the specifics, you will discover how each segment contributes to the overall efficiency of the machine. This knowledge is invaluable for troubleshooting, upgrades, or simple routine care.

Dremel 300 Overview

This section provides a comprehensive insight into a versatile rotary tool known for its precision and adaptability. Designed for a variety of tasks, it excels in both hobbyist projects and professional applications. Understanding its features and capabilities is essential for anyone looking to enhance their craftsmanship.

Key Features

This tool is equipped with a powerful motor, enabling it to handle a range of accessories for cutting, sanding, and engraving. Its ergonomic design ensures comfort during extended use, while the variable speed settings allow for tailored performance based on the task at hand.

Applications

From intricate detailing in woodworking to metalworking and crafting, this device proves invaluable across multiple disciplines. Its ability to effortlessly switch between attachments makes it a favorite among enthusiasts and professionals alike.

Key Features of Dremel 300

This versatile rotary tool is designed to empower users with a wide range of functionalities, making it an essential companion for various projects. Its compact form allows for precision in intricate tasks while offering robust power for heavier applications.

High-Speed Motor: Equipped with a powerful motor, this tool can reach impressive speeds, enabling efficient cutting, grinding, and polishing.

Interchangeable Accessories: A variety of attachments are available, allowing users to tackle numerous tasks–from engraving to sanding–enhancing the tool’s adaptability.

Ergonomic Design: The comfortable grip and lightweight build ensure ease of use, reducing fatigue during extended projects.

Variable Speed Control: Users can adjust the speed settings, providing ultimate control for different materials and techniques.

Durable Construction: Built with high-quality materials, this tool promises longevity and reliability, making it a worthy investment for both amateurs and professionals.

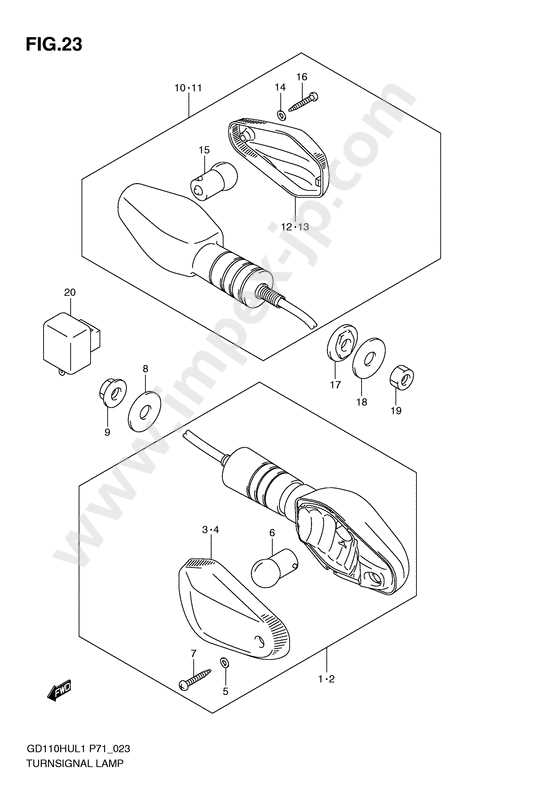

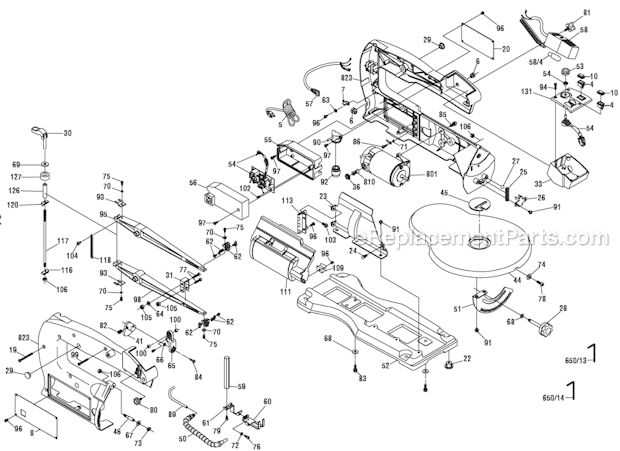

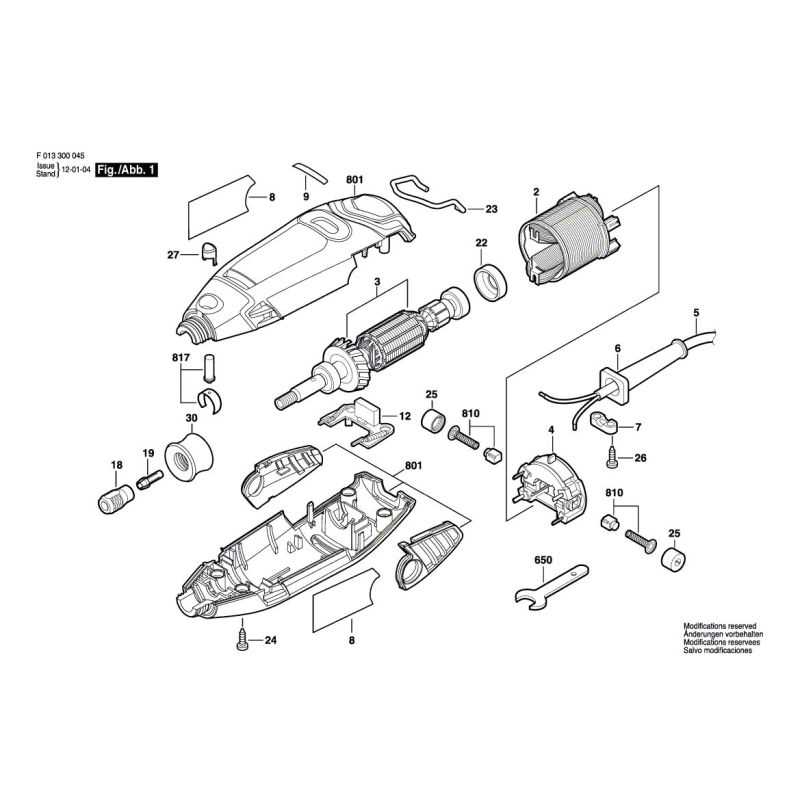

Understanding the Parts Diagram

Comprehending the schematic representation of a tool’s components is essential for effective maintenance and repair. This visual guide aids users in identifying various elements, enhancing their familiarity with the equipment.

Key Components

- Motor Assembly

- Housing

- Collet

- Speed Control

- Power Supply

Benefits of Familiarity

- Improved troubleshooting capabilities.

- Enhanced ability to replace or upgrade components.

- Increased efficiency in project execution.

Essential Components of Dremel 300

The effective functionality of a versatile rotary tool relies heavily on its key elements. Understanding these critical components enhances both performance and user experience. Each part plays a significant role, contributing to the overall efficiency and adaptability of the device.

Motor: At the core of the tool lies a powerful motor, which is responsible for driving the rotational movement. Its strength determines the tool’s capacity to handle various tasks, from intricate detailing to heavier grinding.

Collet: The collet serves as a holder for the accessories, ensuring a secure fit while enabling quick changes. A reliable collet minimizes vibrations and enhances precision during operation.

Housing: The outer casing protects the internal components while providing a comfortable grip for the user. Its ergonomic design facilitates prolonged use without discomfort.

Speed Control: An adjustable speed feature allows users to customize the tool’s performance according to the material being worked on. This adaptability is essential for achieving optimal results across different applications.

Ventilation System: An efficient airflow design prevents overheating during extended use. Proper ventilation ensures that the tool maintains its performance and longevity, making it a reliable companion for various projects.

By familiarizing oneself with these essential components, users can maximize their experience and effectively tackle a wide range of creative endeavors.

How to Identify Parts Easily

Recognizing components in your toolkit can enhance your efficiency and understanding of your equipment. This guide will streamline the identification process, enabling you to quickly locate and differentiate between various elements, thereby improving your overall experience.

Utilize Reference Manuals

Consulting reference manuals or user guides can provide valuable insights into the functionality and appearance of individual components. These resources often include labeled illustrations and descriptions, helping you familiarize yourself with each piece.

Online Resources and Communities

Leverage online forums and communities dedicated to your tools. Engaging with fellow enthusiasts can uncover tips and tricks for recognizing parts, as well as sharing personal experiences and solutions to common challenges.

Common Issues and Solutions

In the realm of rotary tools, users may encounter various challenges that can hinder performance and efficiency. Understanding these common problems and their corresponding remedies can enhance the overall experience and extend the lifespan of the equipment.

| Issue | Possible Cause | Solution |

|---|---|---|

| Tool not starting | Power source issues | Check the power cord and outlet; replace or repair if necessary. |

| Excessive vibration | Imbalanced accessory | Ensure the attachment is securely fastened and not damaged. |

| Overheating | Continuous use without breaks | Allow the tool to cool down periodically during extended use. |

| Inconsistent speed | Worn motor components | Inspect and replace worn parts as needed to restore functionality. |

| Noise during operation | Loose or damaged parts | Tighten any loose components and replace damaged ones. |

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring that your tool remains efficient and serves you well over time. By following a few simple guidelines, you can significantly extend the lifespan and performance of your equipment.

- Regular Cleaning: After each use, remove dust and debris from the tool’s exterior and moving parts. This prevents buildup that can hinder performance.

- Lubrication: Apply appropriate lubricants to the moving components periodically. This reduces friction and wear, keeping the mechanism running smoothly.

- Inspection: Frequently check for any signs of wear or damage. Addressing minor issues early can prevent more significant problems down the line.

- Proper Storage: Store the tool in a dry, cool place. Avoid exposing it to extreme temperatures or moisture, which can lead to corrosion and deterioration.

- Use the Right Accessories: Ensure that you are using compatible attachments and accessories. Using the wrong parts can cause excessive strain and damage.

By incorporating these practices into your routine, you can maintain optimal functionality and extend the operational life of your equipment, ensuring it remains a reliable asset for your projects.

Tools for Dremel 300 Repairs

When it comes to maintaining and fixing precision rotary tools, having the right equipment at hand is essential. A well-equipped toolkit not only streamlines the repair process but also enhances the longevity and performance of your device. Below are some indispensable instruments that will aid in effective troubleshooting and restoration.

1. Screwdrivers: A variety of screwdrivers, including Phillips and flat-head types, are crucial for accessing internal components. The right size will prevent stripping and damage.

2. Pliers: Needle-nose and slip-joint pliers are perfect for gripping and manipulating small parts, ensuring you can handle delicate tasks with precision.

3. Wrenches: A set of adjustable wrenches will allow you to loosen or tighten any fasteners securely, making adjustments easier.

4. Lubricants: Quality lubricants can keep moving parts functioning smoothly and prevent wear over time, essential for optimal operation.

5. Cleaning Supplies: Brushes and cloths help maintain cleanliness, removing debris and dust that could hinder performance.

By assembling these essential tools, you can effectively address any issues and ensure your rotary device operates at its best for years to come.

Replacing Worn-Out Components

Over time, tools can experience wear and tear, affecting their performance and efficiency. Regularly assessing and replacing degraded elements is crucial for maintaining optimal functionality. This section focuses on the essential steps to identify and substitute these parts effectively.

Identifying the Affected Components

Before any replacements, it’s vital to pinpoint which components are underperforming. Look for signs such as unusual noises, decreased power, or physical damage. A thorough inspection will allow you to prioritize replacements and enhance the overall performance of your equipment.

Steps for Replacement

Once you’ve identified the worn parts, gather the necessary tools and follow these steps: disassemble the unit carefully, remove the damaged components, and install the new ones by following the manufacturer’s guidelines. Ensure everything is securely fastened before reassembly, as this will contribute to the longevity of your tool.

Upgrading Your Dremel 300

Enhancing the performance of your rotary tool can significantly improve your projects’ efficiency and quality. By investing in better components and accessories, you can achieve the ultimate results while ensuring longevity and versatility in your work. This section explores various upgrades that can transform your device into a more powerful and reliable tool.

Choosing High-Quality Accessories

One of the most impactful upgrades involves selecting premium attachments and bits. High-quality components not only increase performance but also enhance precision. Look for diamond bits for cutting and grinding, or carbide burrs for shaping materials effectively.

Enhancing Power and Stability

Consider modifications that boost the tool’s power and stability. Installing a more robust motor can provide greater torque and speed, while adding a vibration dampening system can improve control and reduce fatigue during extended use. These enhancements ultimately lead to a smoother and more enjoyable crafting experience.

Accessories to Enhance Functionality

Enhancing the versatility of your rotary tool can significantly improve your projects, making them more efficient and enjoyable. By utilizing various attachments and accessories, you can expand the capabilities of your device, allowing for precision work across a wide range of materials and applications.

Types of Attachments

Different types of attachments serve specific purposes, from cutting and grinding to polishing and engraving. Cutting wheels are essential for slicing through various materials, while grinding bits are perfect for shaping and smoothing surfaces. For detailed work, carving tools provide the finesse needed to achieve intricate designs.

Specialized Accessories

To further elevate your tool’s performance, consider incorporating specialized accessories. Flex shafts allow for greater maneuverability in tight spaces, while router attachments can transform your device into a mini-router for woodworking tasks. Additionally, polishing pads enable you to achieve a high-gloss finish on metals and plastics, enhancing the overall aesthetic of your projects.

Where to Find Replacement Parts

When seeking components for your tool, there are several reliable sources to consider. Online retailers often have extensive inventories, making it easy to find specific items. Additionally, local hardware stores may stock essential pieces, providing a hands-on option for users. Manufacturer websites can also be invaluable, offering direct access to authentic replacements.

For those who prefer community support, forums and groups dedicated to tool enthusiasts can provide recommendations and tips on sourcing rare items. Auction sites and marketplaces might have used or refurbished components, often at a lower cost. Overall, exploring multiple avenues will enhance your chances of finding exactly what you need.