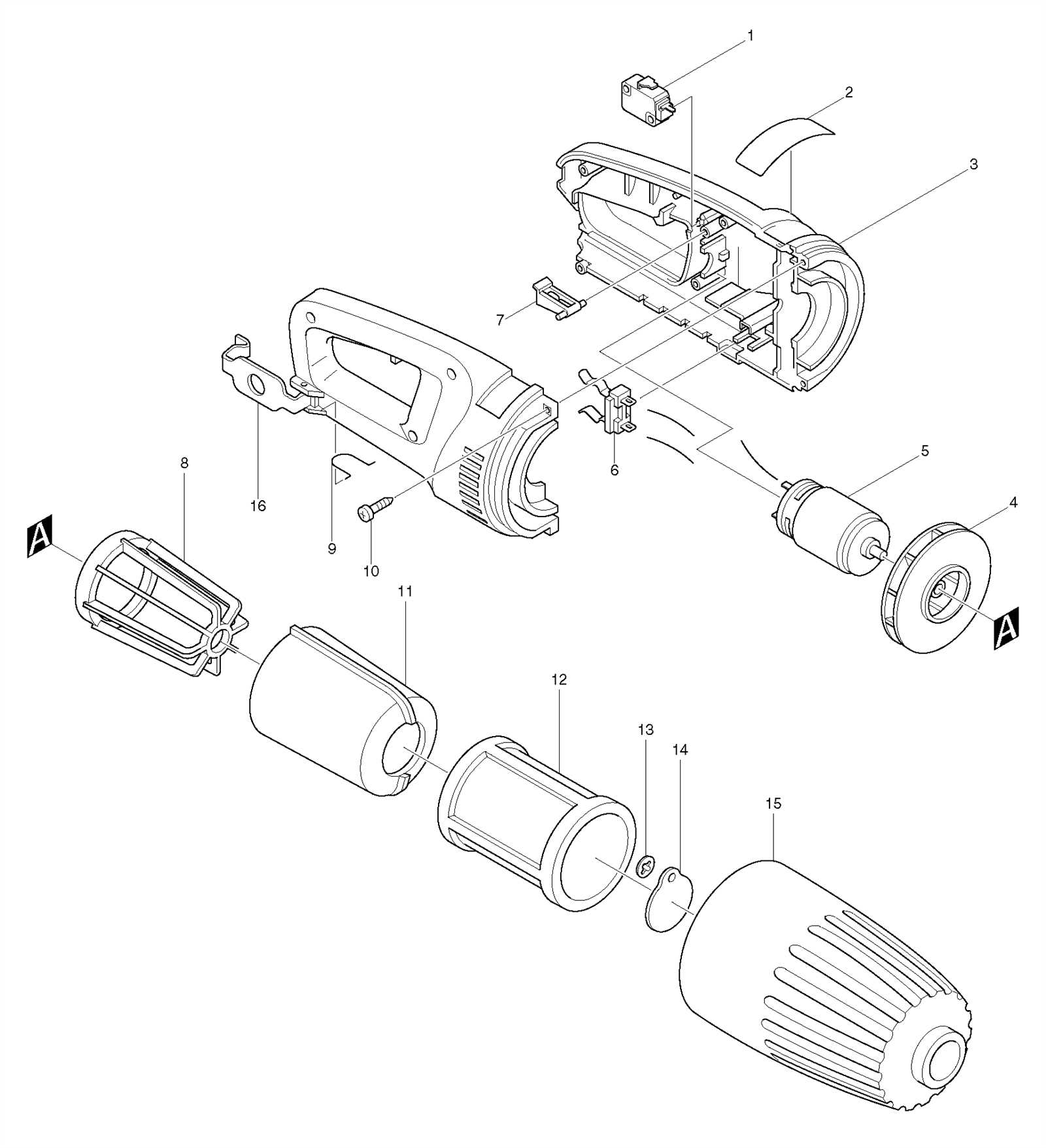

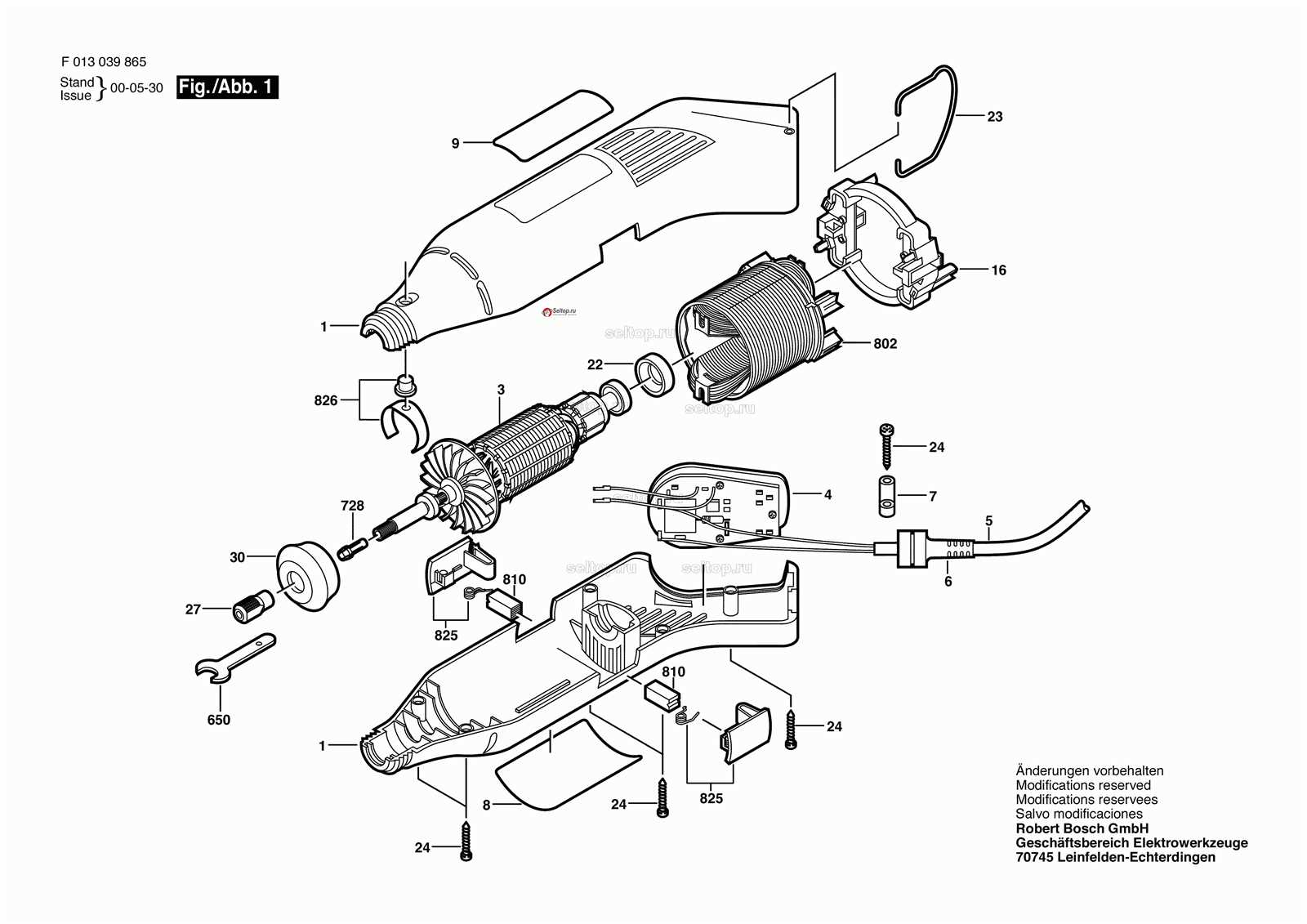

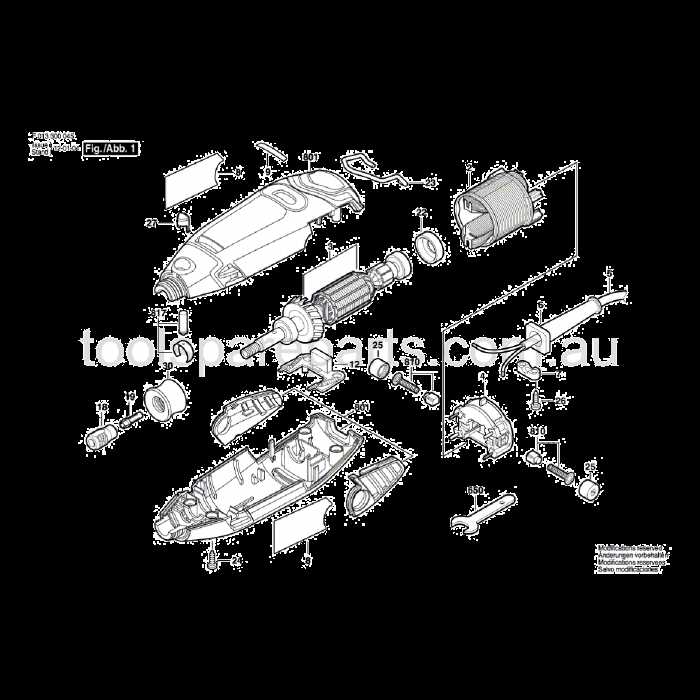

Maintaining and repairing tools often involves knowing the internal structure and how various elements connect to perform their functions. A clear view of these elements and their placement can greatly assist in troubleshooting and part replacements, ensuring that the tool operates smoothly.

Each tool comprises numerous elements, each playing a crucial role in the overall performance. By familiarizing yourself with these key elements, it becomes much easier to identify potential issues and take corrective action. This approach enhances the tool’s longevity and ensures consistent performance over time.

In this guide, we will explore how individual

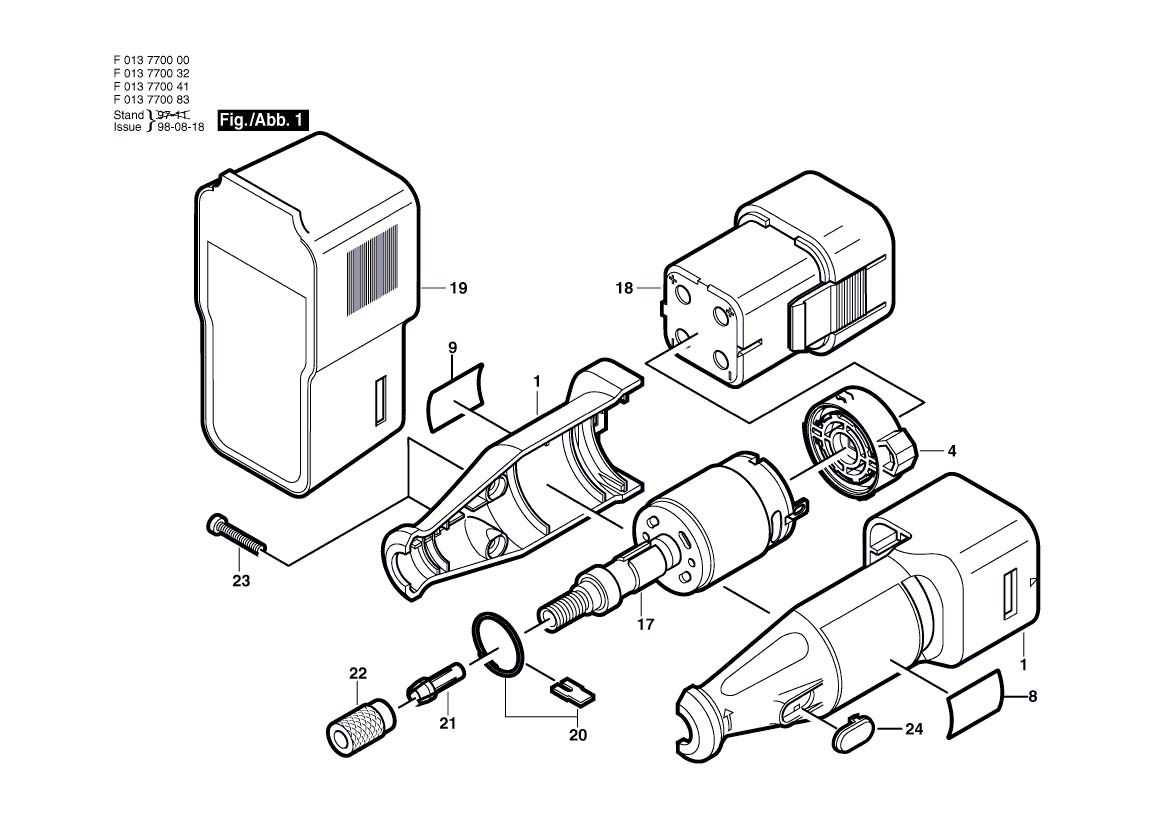

Dremel Tool Components Overview

The versatile handheld tool is composed of various essential elements that allow it to perform multiple functions efficiently. These components work together to ensure precision, flexibility, and ease of use, making the tool suitable for different tasks ranging from cutting to sanding.

| Component | Description |

|---|---|

| Motor | Provides the power needed to rotate attachments at different speeds, allowing for versatility in tasks. |

| Chuck | Secures various accessories and attachments, enabling quick changes between different functions. |

| Speed Control | Allows the user to adjust the rotational speed, offering greater precision for delicate or tough tasks. |

| Attachment Type | Recommended Use |

|---|---|

| High-Speed Cutters | Ideal for shaping and cutting wood, plastic, and soft metals |

| Cut-Off Wheels | Used for slicing through metal rods, bolts, and nails |

Diamond

Rotary Tool Power System BreakdownThe energy system of a rotary device plays a crucial role in determining its overall efficiency and performance. Understanding how the power flows from the source to the motor can help in diagnosing issues and optimizing use. The internal components work together to ensure smooth operation under various conditions, whether running at full speed or handling more delicate tasks. Power Transfer Process

In rotary devices, power is delivered through a combination of wires, connectors, and circuits that channel electricity to the motor. These elements must be in good condition for the tool to perform effectively.

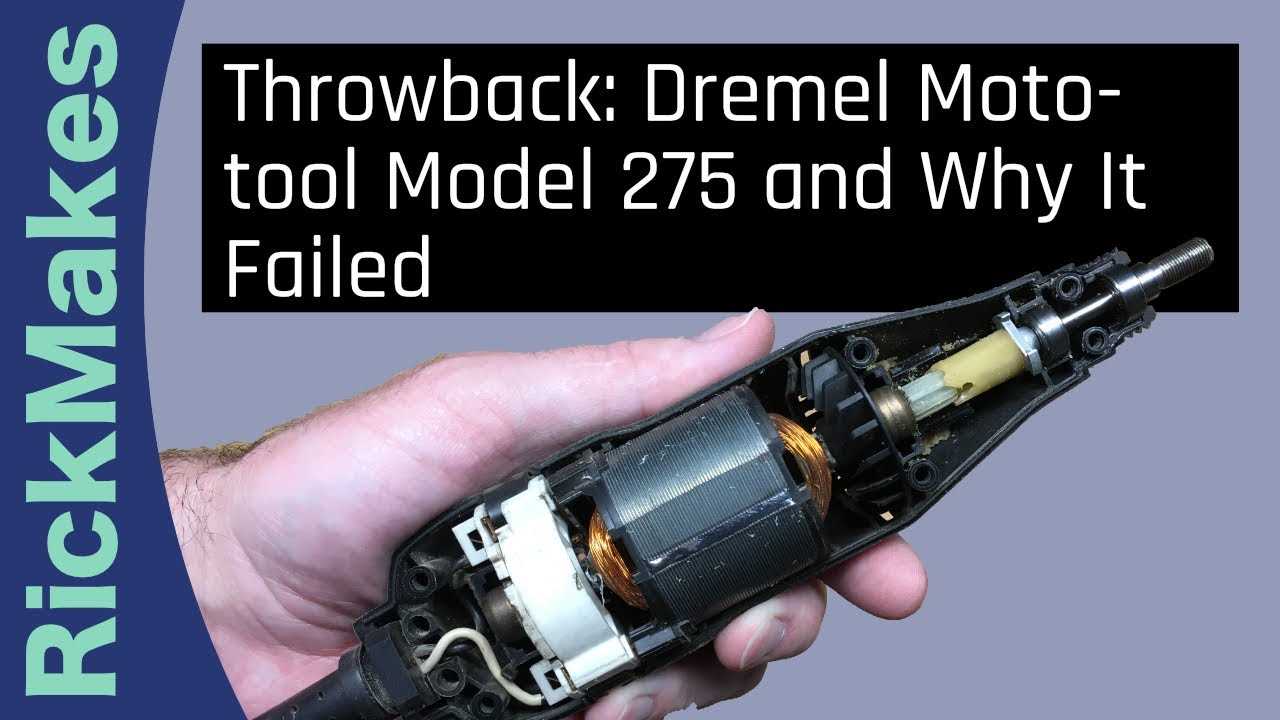

Motor and Speed ControlThe motor is the heart of the rotary tool Key Differences in Motor PartsUnderstanding the variations in motor components is crucial for optimal performance and maintenance. Each element serves a distinct function, contributing to the overall efficiency and longevity of the device. Recognizing these differences can help users select the right components for their specific needs.

By examining these key distinctions, users can better understand the capabilities and limitations of their motor units, ensuring effective and efficient usage. Inspecting Dremel Bearings and ShaftsRegular examination of rotational components is crucial for maintaining optimal performance in power tools. Ensuring that the supporting elements are in good condition can prevent operational failures and prolong the lifespan of the equipment. This section will guide you through the process of inspecting these essential components. Key Indicators of WearWhen assessing the condition of the supporting elements, look for the following signs of wear:

Inspection Steps

To conduct a thorough inspection, follow these steps:

Accessories for Sanding and PolishingWhen it comes to achieving a smooth finish on various materials, utilizing the right accessories can significantly enhance the quality of your work. These tools are designed to simplify the sanding and polishing processes, allowing for greater precision and efficiency. Here are some essential accessories that can be beneficial for sanding and polishing tasks:

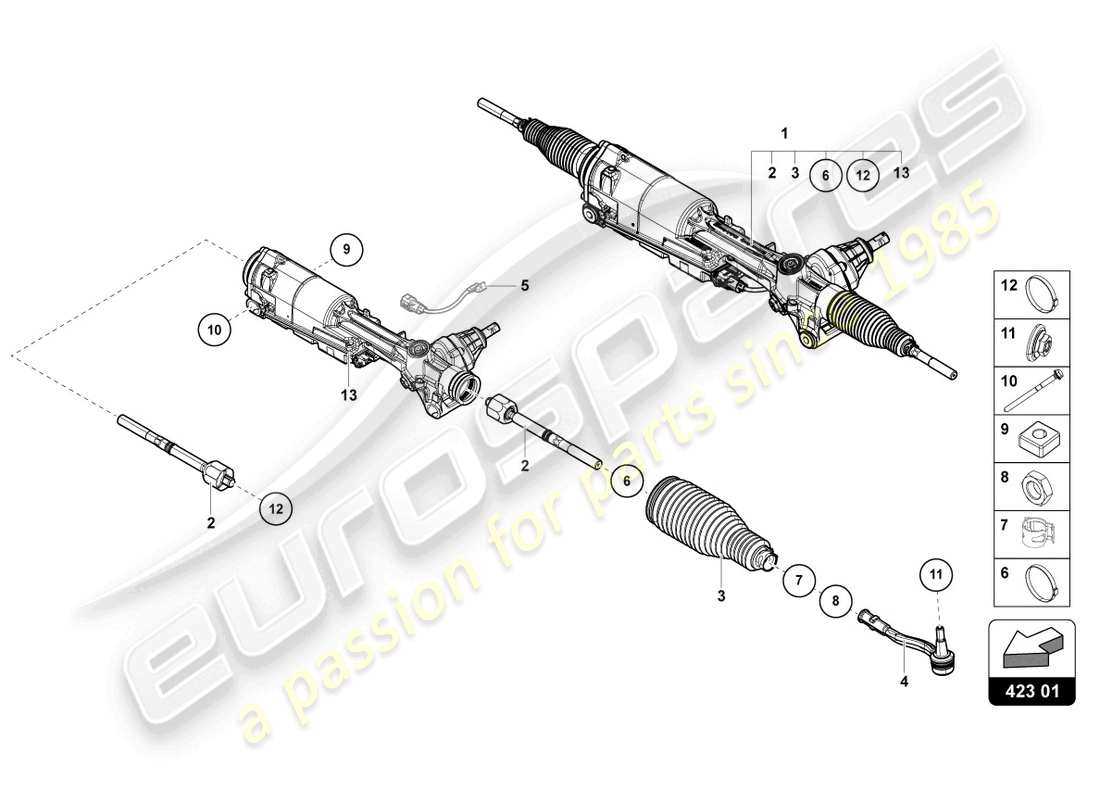

By selecting the appropriate accessories, users can enhance their craftsmanship and achieve professional results in sanding and polishing projects. Replacement Guide for Worn PartsMaintaining tools in optimal condition is essential for their longevity and performance. Over time, certain components may experience wear and tear, requiring timely replacements to ensure continued efficiency. This section provides guidance on identifying and replacing these components, enhancing the functionality of your equipment. Identifying Worn ComponentsRecognizing signs of deterioration is crucial for effective maintenance. Common indicators include unusual noises, decreased performance, or visible damage. Regular inspections can help in detecting these issues early, preventing further complications. Replacement ProcessOnce worn components are identified, replacing them can be straightforward. Begin by referring to the user manual for specific instructions tailored to your model. Ensure you have the correct tools and replacement items ready before starting. Carefully disassemble the necessary parts, replace the damaged components, and reassemble everything securely. Following these steps will restore functionality and extend the life of your equipment. Common Issues with Dremel ComponentsWhen utilizing rotary tools, users may encounter a variety of challenges related to their essential elements. Understanding these common problems can enhance the longevity and performance of the equipment, ensuring smoother operation and effective results. Frequent Problems

Troubleshooting Tips

How to Identify Model-Specific PartsIdentifying components that are unique to specific models can significantly enhance the effectiveness of maintenance and repair tasks. Understanding the nuances between various versions of equipment is crucial for ensuring compatibility and optimal performance. This section will guide you through effective strategies for recognizing these distinct elements. Check the User ManualThe user manual typically provides a comprehensive overview of the individual components, including their functions and compatibility with different models. Referencing this guide can clarify which pieces are necessary for your specific version and aid in troubleshooting potential issues. Utilize Manufacturer ResourcesMany manufacturers offer online resources, including parts lists and schematics, tailored for each model. These tools can assist in pinpointing the exact items needed for repairs or upgrades, ensuring you select the right ones for your device. Maintaining Your Dremel Tool EfficientlyRegular upkeep of your rotary instrument is essential for optimal performance and longevity. Proper maintenance not only enhances efficiency but also prevents unexpected breakdowns and costly repairs. Understanding the key aspects of care will help ensure that your device operates smoothly and effectively. To begin, always ensure that your tool is clean. Dust and debris can accumulate, hindering functionality. Use a soft brush or compressed air to remove particles from vents and crevices. Additionally, regularly inspect the accessory attachments for wear and tear. Replacing worn components promptly will prevent further damage and maintain cutting precision. Lubrication is another critical factor. Applying a suitable lubricant to moving parts reduces friction and extends the life of your instrument. Follow the manufacturer’s guidelines for recommended products and application frequency. Furthermore, keep the power cord and plug in good condition to ensure safety during operation. Lastly, store your rotary tool in a dry and secure environment. Protect it from extreme temperatures and humidity, which can affect performance. By following these maintenance tips, you can enhance the efficiency of your rotary instrument and ensure it remains a reliable companion for your projects. |