When dealing with complex home appliances, it is essential to have a clear understanding of the internal structure and how each element interacts with the system. A thorough breakdown of various elements can provide valuable insights into the maintenance and repair process. By exploring the roles and features of these individual elements, users can ensure their equipment remains in top working condition.

In this guide, we will explore a detailed map of all critical mechanisms involved. Each component plays a unique role, contributing to the overall functionality and performance. Understanding these mechanisms is not only beneficial for resolving common issues but also helps extend the lifespan of the equipment.

Whether you’re performing routine maintenance or tackling more complex repairs, having a well-documented outline of the internal structure is crucial. Let’s dive into the specific features and the importance of each section within the machine, ensuring you have a solid grasp of the setup and its

Understanding the Components of Dyson UP20

To get the most out of your vacuum cleaner, it’s essential to familiarize yourself with its key components. Each element plays a crucial role in ensuring the device operates efficiently and effectively. By knowing how these parts interact and what functions they perform, you can maintain and troubleshoot the machine more easily.

- Motor Unit: This is the powerhouse of the machine, responsible for generating the suction required to pick up dirt and debris.

- Filtration System: Designed to capture fine dust and allergens, this part ensures clean air is expelled back into your environment.

- Brush Roll: A rotating element located at the base, it agitates the carpet fibers to dislodge dirt for easier

Main Structural Elements of Dyson UP20

The primary components of this advanced cleaning device are carefully engineered to ensure optimal performance and durability. Each part plays a crucial role in maintaining efficiency and ease of use, contributing to its powerful cleaning capabilities.

Core Components

- Body Frame: The foundation that holds all other elements together, providing strength and stability during operation.

- Dust Collection Unit: Responsible for capturing and storing debris, featuring a high-capacity container for extended cleaning sessions.

- Filtration System: Designed to trap fine particles, ensuring that only clean air is released back into the environment.

Functional Elements

- Motor Assembly: Powers the suction mechanism, delivering strong airflow for effective dirt removal.

- Brush Roll: Rotates to

Motor and Its Functions in the Vacuum

The motor plays a pivotal role in ensuring the efficient operation of any vacuum cleaner. It is responsible for generating the necessary power to create suction, which allows the device to remove dirt and debris from various surfaces. The performance and longevity of a vacuum largely depend on the quality and functioning of its motor.

How the Motor Works

The motor drives a fan that creates a powerful stream of air. This airflow creates the suction needed to pick up particles from the floor and other surfaces. When the motor spins the fan, it generates a low-pressure zone inside the vacuum, which pulls air and dirt into the machine. The process ensures effective cleaning by capturing small particles and large debris alike.

Components and Functions

The motor consists of several key parts, each contributing to its overall performance. Below is a table outlining the main components and their respective functions:

Component Function Filter System and Maintenance Tips

Proper care and regular upkeep of the filtration unit ensure optimal performance and longevity of your device. This section will provide guidance on maintaining the filter, including cleaning practices and general care tips to enhance efficiency and prolong the lifespan of your equipment.

- Inspect the filter regularly for any build-up of dust or debris.

- Clean the filter under cold water to remove any particles trapped inside. Avoid using detergents or hot water as these can damage the filtration material.

- Let the filter dry completely before reinstalling it to prevent moisture from damaging the internal components.

- Replace the filter periodically as recommended in the user manual, as filters wear out over time and lose effectiveness.

- Ensure proper airflow by keeping the surrounding areas free of obstructions that could impede the device’s ventilation.

By following these maintenance steps, you can help your machine maintain its efficiency and ensure it continues running smoothly for years to come.

Brush Roll Mechanism in Dyson UP20

The brush roll mechanism plays a crucial role in maintaining optimal cleaning performance, especially on carpets and rugs. This component is designed to agitate dirt and debris, allowing the vacuum to capture them effectively. Understanding how this mechanism works can help users maintain it for consistent efficiency.

The system consists of various moving parts that require proper alignment and occasional maintenance. Below is a breakdown of its key features and their functions:

- Rotating Brush: This element spins rapidly, agitating dirt particles trapped in carpet fibers, loosening them for easier suction.

- Belt Drive: A belt connects the motor to the brush, transferring power to ensure continuous rotation.

- End Caps: These secure the brush roll in place, ensuring smooth operation and reducing wear on

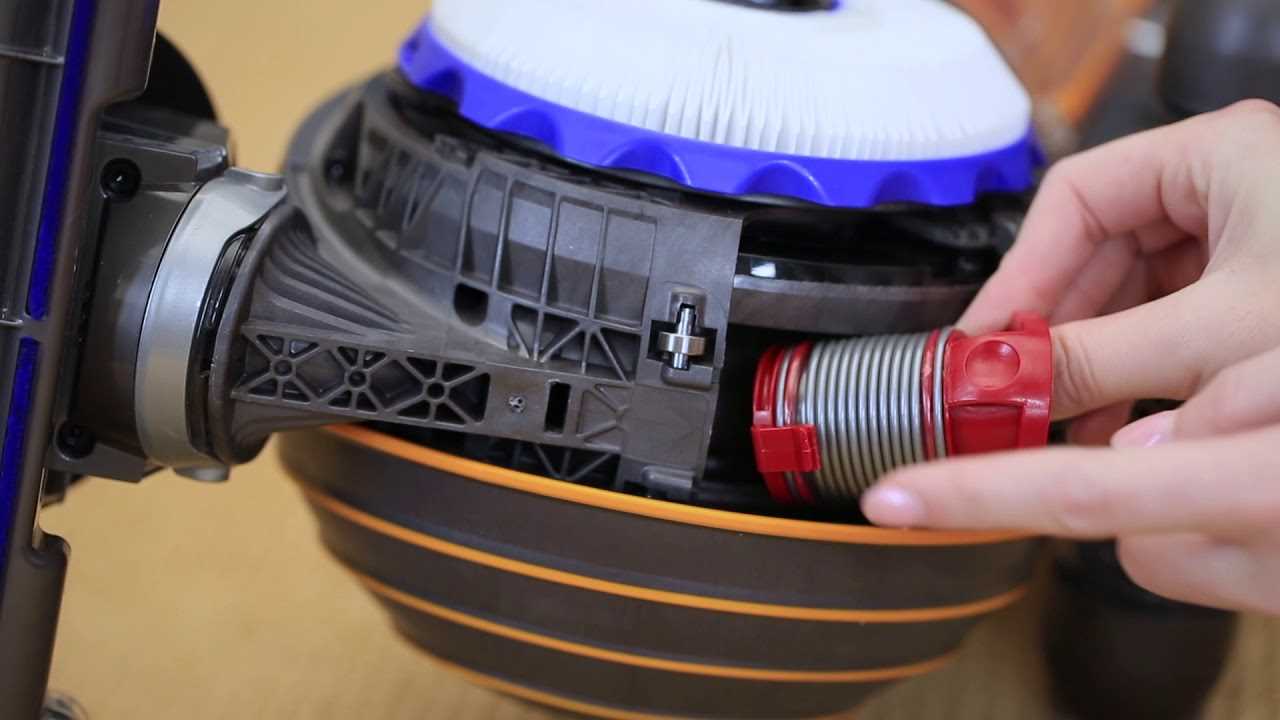

How the Cyclone System Works

The innovative cyclone technology is designed to enhance suction efficiency while minimizing the need for filters. This approach leverages the principles of centrifugal force to separate dust and debris from the airflow, ensuring a powerful cleaning experience without loss of performance.

As air enters the system, it is rapidly spun in a circular motion, creating a vortex that forces larger particles to the outer edges. This process effectively removes dirt from the airflow, allowing cleaner air to pass through the center. The unique design of the cyclone chambers enhances this separation, resulting in a remarkable reduction of particles captured by conventional methods.

In addition to improving airflow, the cyclone system is engineered for easy maintenance. Users can simply detach the collection bin and empty it, ensuring continuous performance without the hassle of replacing filters. This not only saves time but also contributes to the longevity of the device, making it an efficient choice for households.

Overall, the efficiency and functionality of the cyclone mechanism highlight its role in modern cleaning technologies, showcasing how effective engineering can lead to better results in everyday cleaning tasks.

Hose and Wand: Key Features

The flexibility and reach of cleaning equipment are crucial for effective maintenance. The components designed to extend the cleaning range and provide versatility play a significant role in achieving optimal results. Understanding these elements can enhance the overall cleaning experience.

- Length and Flexibility: A longer, flexible hose allows users to navigate around furniture and reach high or low areas without strain.

- Durability: High-quality materials ensure longevity, resisting wear and tear from regular use.

- Connection Mechanism: Secure attachments prevent accidental detachment during operation, enhancing user confidence.

- Weight: Lightweight designs facilitate ease of handling, making it simpler to maneuver during cleaning sessions.

- Storage Options: Compact storage solutions help keep the hose and wand organized, minimizing clutter.

These attributes contribute significantly to the effectiveness and efficiency of cleaning routines, making them essential components of any home maintenance toolkit.

Bin and Dust Container Design

The design of waste receptacles and dust collection units plays a crucial role in enhancing the efficiency of cleaning devices. These components are engineered to optimize the process of collecting and storing debris, ensuring maximum performance and ease of use for the end user.

One of the primary considerations in the design of these containers is their capacity and shape. A well-structured receptacle allows for the efficient accumulation of dirt while minimizing the frequency of emptying. Additionally, the materials used must provide durability and resistance to wear, as they are subjected to constant handling and exposure to various particles.

Another significant aspect is the mechanism for releasing the collected waste. A user-friendly approach that minimizes mess and simplifies disposal is essential. Innovative designs often incorporate features that allow for quick and hygienic emptying, reducing contact with the collected materials.

Moreover, the integration of transparent sections can enhance visibility, enabling users to easily monitor fill levels. This design choice not only improves functionality but also contributes to a more satisfying user experience. Ultimately, the effectiveness of any cleaning system heavily relies on the thoughtful design of its waste management components.

Exploring the Power Cord System

The power cord system is a crucial component in the functionality of many modern cleaning devices. This element serves as the primary link between the appliance and the electrical source, ensuring efficient operation. Understanding its design and features can enhance the user experience and maintain the longevity of the device.

Here are some key aspects of the power cord system:

- Length: The length of the cord directly affects maneuverability, allowing users to reach various areas without frequently switching outlets.

- Material: High-quality insulation protects against wear and tear, ensuring safety during use.

- Connector Type: The design of the connector is essential for secure attachment to the device, preventing accidental disconnections.

- Storage Options: Many models include integrated storage solutions, helping to keep the cord neatly coiled when not in use.

In summary, the power cord system is vital for the seamless operation of cleaning equipment. By paying attention to its features, users can ensure a more effective and enjoyable cleaning experience.

Wheels and Maneuverability Components

The functionality and ease of use of any cleaning device significantly rely on the quality of its wheels and related mobility features. These elements play a crucial role in ensuring smooth navigation across various surfaces, allowing for effortless movement and versatility during operation.

High-performance wheels are designed to provide stability and support while enhancing the overall maneuverability of the machine. The construction and arrangement of these components directly influence the ease with which users can pivot and turn the device in tight spaces.

Component Description Functionality Front Wheels Small, swivel wheels located at the front for agile movements. Enable quick directional changes and enhance overall maneuverability. Rear Wheels Larger wheels at the back for stability and balance. Support the weight of the device and provide smooth travel over various terrains. Wheel Housing Protective casing that holds the wheels in place. Ensures durability and prevents damage to the wheels during use. Swivel Mechanism Allows front wheels to rotate freely. Facilitates easy turns and navigation around obstacles. Handle and User Comfort Considerations

When it comes to the design of cleaning devices, the grip and overall user experience play a pivotal role in enhancing efficiency and reducing fatigue during operation. A well-structured handle can significantly influence the ease of maneuvering, allowing users to navigate through different surfaces with minimal effort.

Comfortable grip is essential for prolonged use, ensuring that the user can maintain control without experiencing strain. An ergonomic design, featuring contours that fit the natural shape of the hand, can help in distributing weight evenly, reducing pressure points that may lead to discomfort.

Additionally, materials used in the handle construction can affect the tactile experience. Soft-touch finishes or rubberized surfaces often enhance grip security and contribute to a more pleasant feel during usage. Incorporating features like adjustable height or angle can further cater to a diverse range of users, accommodating varying preferences and physical needs.

Ultimately, investing in thoughtful handle design not only improves the functionality of the equipment but also enriches the overall user experience, making routine tasks more enjoyable and less burdensome.

Understanding the Suction Power Control

The effectiveness of a vacuum cleaner often hinges on its ability to adjust suction strength based on the surface being cleaned. This feature not only enhances cleaning efficiency but also protects delicate materials from damage. Mastering this functionality can lead to optimal cleaning results in various environments.

Effective suction control involves several key components:

- Power Settings: Most models offer multiple power levels, allowing users to select the appropriate suction strength for different tasks.

- Sensor Technology: Advanced models may include sensors that automatically adjust suction based on surface type, ensuring consistent performance.

- User Interface: Intuitive controls enable quick adjustments, making it easier to switch between modes as needed.

Utilizing the suction power control effectively can improve the overall cleaning experience. Here are some tips to maximize its benefits:

- Assess the surface before cleaning and adjust the power accordingly.

- Use lower settings for delicate fabrics to prevent damage.

- Switch to higher settings for carpets or heavily soiled areas for thorough cleaning.

By understanding and utilizing suction control, users can achieve better cleaning outcomes while extending the lifespan of their cleaning devices.

Replacing and Upgrading Dyson UP20 Parts

Maintaining and enhancing your cleaning device can significantly improve its performance and longevity. Whether you’re looking to replace worn components or upgrade to more efficient options, understanding the essential elements is key. This guide will help you navigate the process of ensuring your equipment remains in top condition.

Begin by identifying the specific components that may need attention. Common issues often arise with filters, brushes, and hoses. Upgrading these elements can lead to better suction power and improved filtration, enhancing your overall cleaning experience.

When selecting replacements, consider compatibility and quality. Using original equipment can ensure optimal functionality, while third-party options may offer cost savings. Always check user reviews and product specifications to make informed decisions.

Installation typically involves straightforward steps. Ensure that the device is unplugged before proceeding. Carefully remove the old component and replace it with the new one, following any provided instructions. Regular maintenance checks will help you spot potential issues before they escalate.

Investing time in the upkeep and enhancement of your cleaning appliance will pay off in efficiency and effectiveness. With the right knowledge and tools, you’ll ensure that your machine continues to serve you well for years to come.