The intricate structure of high-performance models requires a clear understanding of how each element fits together. In this section, we will explore the various components that make up these systems, providing insight into their placement and functionality. This will help ensure smooth maintenance and optimal performance.

By examining the arrangement of different elements, you can gain a better understanding of their roles in enhancing the overall capabilities. Each section will break down individual elements, explaining their purpose and how they interact within the system to achieve superior results.

Whether you’re looking to upgrade specific elements or simply want to improve your model’s efficiency, understanding this layout is essential. The following guide will provide detailed descriptions and tips to make the process easier and more intuitive.

E Revo Brushless Parts Diagram Overview

Understanding the structure and components of high-performance models is crucial for anyone looking to maintain or upgrade their vehicle. In this section, we’ll explore how different elements come together, ensuring optimal functionality and enhancing durability. A clear grasp of these elements helps in both routine maintenance and more advanced modifications.

Chassis forms the foundation of the vehicle, supporting all essential systems. Each section has its role, contributing to the overall balance and efficiency. Additionally, the suspension system plays a key part in ensuring smooth handling, providing the flexibility needed for challenging terrains.

The motor unit drives the core performance, and paired with a reliable power source, it delivers the required speed and control. Paying attention to how these c

Key Components of E Revo Brushless

The model features a robust structure designed to offer maximum performance and durability. Each element is carefully engineered to ensure smooth operation and long-lasting reliability, working together to deliver speed, precision, and control.

- Motor System: The core of the vehicle’s propulsion, offering powerful acceleration and consistent speed control.

- Suspension Setup: Designed to absorb impacts and provide optimal stability, this system ensures balanced handling on various terrains.

- Drive System: A high-torque mechanism that efficiently transfers power to the wheels, enabling fast response and agility.

- Chassis Design: Built to withstand heavy loads and impacts, this lightweight framework maintains the overall structure and integrity of the model.

Motor and Electronics Layout

The organization of the motor and its electronic components plays a crucial role in ensuring smooth and efficient performance. Understanding the arrangement of these key elements can help in optimizing the overall system, reducing potential issues, and enhancing durability.

Key Components Overview

The motor setup typically involves several integral units that work together harmoniously. These include the power source, the control modules, and various connecting elements that ensure proper function. Each component has a specific role and is strategically placed to maximize efficiency.

Component Placement

In the table below, you’ll find the typical positioning of the main components that contribute to the system’s performance. These elements are arranged in a manner that enhances cooling and minimizes interference, ensuring long-lasting operation.

Component Location Purpose Chassis Structure and Material Breakdown

The frame of the vehicle is built to provide durability and performance under various conditions. Understanding the composition of the structure helps in maintaining stability, distributing forces efficiently, and ensuring longevity during operation.

Key elements of the chassis include components designed to balance strength with weight reduction. Each part of the frame serves a distinct role in reinforcing the overall build.

- Main Frame: The central section, often designed for optimal weight distribution, combines rigidity with flexibility.

- Support Beams: Critical sections that offer additional structural integrity, ensuring the vehicle can withstand impact and stress.

- Protective Elements: These include guards and covers, which protect internal components from d

Suspension System: Diagram and Explanation

The suspension system plays a crucial role in ensuring a smooth and stable ride by absorbing shocks and maintaining optimal contact between the vehicle’s wheels and the ground. This section will provide an overview of its key components and how they work together to enhance handling and performance.

Main Components of the Suspension

- Springs: These are responsible for supporting the vehicle’s weight and absorbing bumps in the road, providing a balanced ride.

- Shock Absorbers: Also known as dampers, these control the movement of the springs, preventing excessive bouncing after an impact.

- Control Arms: These arms connect the wheels to the vehicle’s frame, allowing for smooth

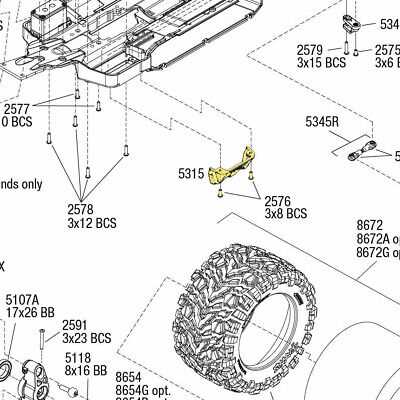

Tire and Wheel Assembly Details

The assembly of tires and wheels is a crucial component in ensuring optimal performance and stability of any vehicle. Understanding the intricacies of this assembly can significantly enhance handling and responsiveness during operation.

Key elements to consider in the assembly include:

- Tire Specifications: Selecting the appropriate tire type and size is essential for compatibility with the vehicle’s frame and intended use.

- Wheel Design: The wheel’s material, shape, and construction play a significant role in durability and weight distribution.

- Mounting Process: Proper techniques for mounting tires on wheels can prevent issues such as imbalance and premature wear.

Moreover, regular maintenance and inspections are vital to ensure the integrity of the tire and wheel assembly. Consider the following maintenance practices:

- Check tire pressure regularly to maintain optimal performance.

- Inspect for signs of wear or damage that could affect safety.

- Ensure wheel alignment is correctly set to avoid uneven tire wear.

By paying attention to these details, operators can ensure a safe and efficient experience during operation.

Drivetrain Components and Configuration

The drivetrain plays a crucial role in the overall performance and efficiency of any electric vehicle. It encompasses various elements that work in harmony to transmit power from the motor to the wheels. Understanding these components and their configuration is essential for optimizing functionality and enhancing the driving experience.

Key Elements of the Drivetrain

- Motor: The power source that drives the entire system, converting electrical energy into mechanical force.

- Transmission: A mechanism that adjusts the torque and speed, ensuring smooth operation across different terrains.

- Differential: This component allows for the distribution of power between the wheels, enabling smooth turns and better traction.

- Drive Shafts: These shafts connect various components and transmit power effectively, playing a vital role in the overall system.

- Wheel Hubs: The points where the wheels attach to the vehicle, providing stability and facilitating movement.

Configuration Considerations

When configuring the drivetrain, several factors must be considered to achieve optimal performance:

- Gear Ratios: Selecting appropriate gear ratios can enhance acceleration and top speed based on the intended use.

- Weight Distribution: Ensuring balanced weight distribution improves handling and stability during operation.

- Component Quality: Utilizing high-quality materials and designs can increase durability and reliability over time.

- Tuning: Fine-tuning various elements can help achieve desired performance characteristics, tailoring the vehicle to specific needs.

Body and Mounting Parts Layout

This section provides an overview of the structural components and their arrangement, focusing on how these elements contribute to the overall functionality and stability of the model. Understanding the layout of these components is crucial for effective assembly and maintenance, ensuring optimal performance during operation.

Structural Composition

The main body serves as the foundation for the assembly, providing a sturdy framework that supports various elements. It is designed to accommodate additional components, allowing for seamless integration and enhancing the vehicle’s durability. Proper alignment and secure mounting of these structural elements are essential for achieving the desired performance.

Attachment Mechanisms

Mounting features are strategically positioned to facilitate the attachment of different components. These mechanisms ensure that each part is securely fastened, minimizing vibrations and potential damage during operation. Utilizing reliable fastening methods is vital for maintaining structural integrity and achieving efficient functionality.

Battery Compartment and Wiring Diagram

This section provides an overview of the power storage area and the associated wiring for efficient connectivity. Understanding the layout and electrical paths is essential for maintaining optimal performance and ensuring safe operations.

The power storage compartment is a critical component that houses the energy source required for the system’s functionality. Proper management of this area enhances the overall efficiency and reliability of the device. Key aspects include:

- Location of the energy source.

- Access points for replacement and maintenance.

- Integration with the overall structure.

The wiring connections play a vital role in the seamless operation of the system. A clear understanding of the electrical pathways can assist in troubleshooting and enhancements. Key points to consider include:

- Identification of positive and negative terminals.

- Connection types and their functions.

- Safety measures to prevent short circuits.

Overall, mastering the layout of the power storage area and the electrical connections ensures that users can maintain and optimize their devices effectively.

Steering Mechanism and Servo Placement

The steering system plays a crucial role in the overall performance and maneuverability of a vehicle. Proper placement of the control components significantly impacts handling, responsiveness, and precision during operation. This section will delve into the essential aspects of steering configurations and the optimal positioning of servos to achieve a balanced and efficient setup.

Understanding the Steering Mechanism

The steering mechanism is responsible for directing the movement of the vehicle. Its design can vary based on the type of vehicle and intended usage. Key considerations include:

- Type of Steering: Various systems exist, such as rack-and-pinion or servo-assisted steering.

- Response Time: The quicker the response, the better the control during navigation.

- Adjustment Options: Ability to fine-tune settings for different driving conditions.

Servo Placement Considerations

Positioning the servos correctly is vital for optimal control. Here are some factors to consider:

- Weight Distribution: Balance the weight to enhance stability and reduce strain on the components.

- Accessibility: Ensure servos are easily reachable for maintenance and adjustments.

- Angle of Operation: Position servos at angles that maximize their effectiveness during steering movements.

Maintaining and Upgrading E Revo Parts

Ensuring the longevity and performance of your remote-controlled vehicle requires regular upkeep and thoughtful enhancements. This section outlines key practices for preserving its functionality while exploring potential improvements. By following these guidelines, enthusiasts can optimize their vehicle’s performance and enhance the overall experience.

Regular maintenance involves inspecting critical components for wear and tear, ensuring that all systems operate efficiently. Common tasks include cleaning, lubrication, and replacing worn-out elements. Additionally, upgrading specific features can lead to significant performance gains, whether through enhanced power systems or improved suspension settings.

Maintenance Task Frequency Benefits Cleaning chassis and components After each use Prevents buildup of dirt and debris Lubricating moving parts Monthly Reduces friction and wear Checking battery condition Before each run Ensures optimal power delivery Upgrading electronics As needed Improves speed and efficiency By prioritizing these maintenance tasks and considering strategic upgrades, users can significantly enhance the reliability and performance of their remote-controlled vehicle, leading to a more enjoyable and rewarding experience.