Exploring the internal setup of advanced hydration units can provide insights into how various elements work together to ensure smooth operation. Each individual component plays a significant role in delivering functionality and efficiency.

Knowing the structure and connections within these systems helps users with troubleshooting and maintaining optimal performance. A well-organized layout is crucial to ensuring that all features, from filtration to cooling, work in harmony.

For those managing maintenance, it’s beneficial to grasp how different elements are linked, making it easier to identify potential issues. This clarity minimizes downtime and ensures a consistent water flow for users.

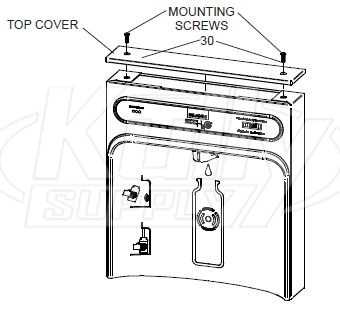

Elkay Ezh2O Parts Diagram Overview

This section provides a structured look at the essential components and connections that ensure smooth operation and efficiency. The goal is to help readers understand how different elements work together to deliver functionality and reliability.

| Component | Description |

|---|---|

| Dispensing Nozzle | Releases water in a controlled manner for convenient access. |

| Filtration Unit | Removes impurities to enhance water quality before delivery. |

| Sensors | Detect user interaction to trigger water flow automatically. |

| Cooling Mechanism | Maintains optimal temperature for refreshing cold water. |

| Control Panel | Allows easy adjustments and displays status indicators. |

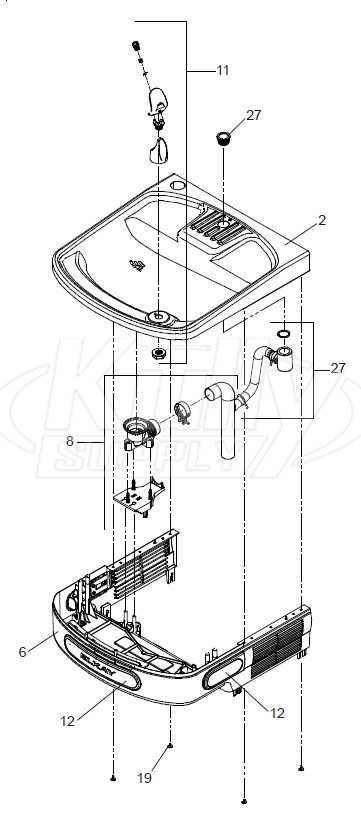

Key Components Inside Elkay Ezh2O Systems

The inner workings of these hydration units consist of multiple essential elements, each contributing to the smooth operation of the system. Designed to ensure efficient water flow and filtration, these components collaborate seamlessly to deliver fresh drinking water while maintaining user convenience and environmental sustainability.

- Filtration Module: Responsible for removing impurities and ensuring the water is safe for consumption, this element enhances the taste and quality.

- Cooling Mechanism: Helps regulate water temperature, ensuring a consistent supply of chilled water, even during continuous usage.

- Sensor System: A hands-free activation feature that minimizes contact, improving hygiene while also conserving water.

- Flow Regulator: Controls the water pressure to ensure steady flow without wastage, enhancing overall efficiency.

- Display Interface: Provides users with relevant information, such as bottle counts and filter status, helping monitor usage and maintenance needs.

Each of these components plays a crucial role in ensuring the system operates smoothly, promoting a sustainable and user-friendly experience for all users.

Understanding the Function of Replacement Filters

Replacement filters play a crucial role in ensuring the consistent quality of water over time. They are designed to maintain optimal performance by removing impurities that accumulate during regular use, preventing issues that can affect both taste and safety.

These components are crafted to capture various contaminants, including sediment and chemical residues, which could otherwise compromise the purity of the water. By intercepting these unwanted particles, the filter helps sustain clarity and ensures the water remains safe for consumption.

Regularly changing the filter also supports the efficiency of the overall system, reducing the strain on internal mechanisms. A clean filter minimizes blockages and extends the lifespan of the unit, contributing to reliable operation with minimal maintenance needs.

How Sensors Improve Water Dispenser Efficiency

Modern water dispensers have evolved to become more efficient through the use of various sensing technologies. These sensors help conserve resources, minimize waste, and improve user interaction, ensuring the system operates smoothly without unnecessary energy consumption.

Optimizing Water Flow

- Proximity sensors detect when a user approaches, activating the flow only when needed.

- Flow rate sensors ensure precise water delivery, preventing overdispensing and unnecessary spillage.

- Time-based sensors automatically stop the flow after a preset period, promoting water conservation.

Energy Management through Automation

- Temperature sensors monitor ambient conditions, adjusting cooling or heating cycles to save energy.

- Motion sensors detect periods of inactivity, switching the system to energy-saving mode.

- Maintenance alerts are triggered by sensors monitoring usage, reducing downtime and ensuring timely upkeep.

By integrating

Exploring Tubing and Internal Water Channels

The network of tubing and internal water channels plays a vital role in ensuring smooth water flow within hydration systems. These pathways help direct liquid efficiently, maintaining the desired temperature and reducing any potential disruptions along the way. Understanding the arrangement and function of these channels can offer insights into optimizing performance and identifying maintenance needs.

The Role of Tubing in Water Flow

Tubing serves as the primary conduit for transporting water throughout the system. Flexible and durable materials are often used to accommodate continuous usage and prevent leaks. Properly aligned tubing ensures minimal resistance, allowing water to flow smoothly and maintain pressure without interruptions.

Maintaining Internal Water Channels

Internal channels are designed to guide water through complex paths without compromising efficiency. These routes are essential for balancing pressure and ensuring that every section of the system receives an even distribution of water. Regular cleaning and inspection help keep the channels clear of debris, preventing blockages that might affect functionality.

The Role of Cooling Mechanisms in Elkay Units

Efficient temperature regulation is essential in modern water dispensing units. These systems employ various cooling technologies to maintain optimal operating conditions, ensuring a consistent supply of chilled water. Understanding how these mechanisms work can enhance user experience and extend the lifespan of the equipment.

Types of Cooling Technologies

Different methods are utilized to achieve effective cooling. One common approach involves the use of thermoelectric coolers, which leverage the Peltier effect to transfer heat away from the water reservoir. This technology is compact and energy-efficient, making it suitable for various installations. Another method includes traditional refrigerant systems, which circulate a refrigerant through evaporators and condensers to achieve rapid cooling.

Importance of Regular Maintenance

Regular maintenance of cooling components is crucial for optimal performance. Dust and debris accumulation can hinder airflow and reduce efficiency, leading to increased energy consumption and potential system failures. Routine checks and cleaning of these elements can prevent such issues, ensuring that the unit operates smoothly and delivers the desired temperature consistently.

Differences Between Bottle Filling and Fountain Parts

The distinction between components designed for bottle filling and those intended for drinking fountains is essential for understanding their specific functionalities. Each type of assembly serves a unique purpose and caters to different user requirements, leading to variations in design, materials, and mechanisms.

Functional Characteristics

Components for bottle filling units are tailored to efficiently dispense water into various containers, while fountain mechanisms focus on providing a continuous flow for direct drinking. This fundamental difference influences the structure and operation of each assembly.

Design Features

| Feature | Bottle Filling Units | Fountain Mechanisms |

|---|---|---|

| Water Dispensing Method | Controlled stream for precise filling | Constant flow for immediate access |

| Activation Type | Push-button or sensor-activated | Lever or push-button activated |

| Design Focus | Space-efficient for various bottle sizes | Ergonomic height for comfortable drinking |

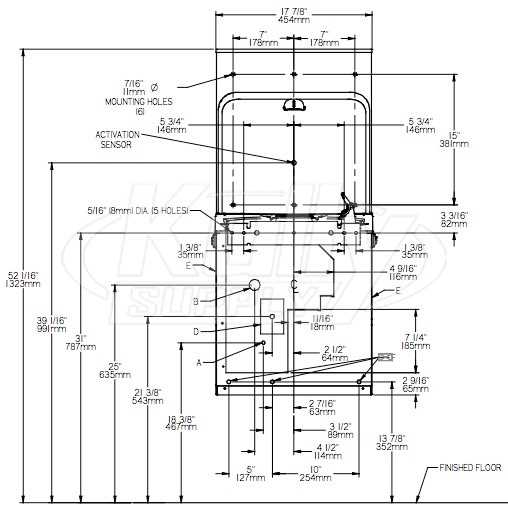

Maintenance Tips for Ezh2O System Components

Proper upkeep of your hydration station’s elements is essential for optimal performance and longevity. Regular maintenance ensures that all components function effectively, providing clean and safe drinking water. Here are some tips to keep your system running smoothly.

Routine Inspections

Conduct regular examinations of all system elements to identify any signs of wear or damage. Check for leaks, corrosion, or unusual noises. Promptly addressing minor issues can prevent more significant problems in the future.

Cleaning and Sanitization

Maintaining cleanliness is crucial for the functionality of your unit. Periodically clean surfaces and components with suitable cleaning agents to remove dirt and bacteria. Ensure that the filtration system is replaced or cleaned according to the manufacturer’s recommendations to maintain water quality.

Electronic Boards and Circuit Integration Explained

The world of electronic components is intricate, encompassing various elements that work harmoniously to perform desired functions. At the heart of many devices lies a network of printed circuit boards that serve as the backbone for connections between different parts. This section delves into the essential role of these boards and how they facilitate seamless integration within various systems.

Understanding Circuit Boards

These boards are designed to provide support and electrical connections for components like resistors, capacitors, and integrated circuits. The layout is meticulously planned, ensuring that each connection is precise, enabling effective communication between the elements. A well-designed board enhances the overall performance, reducing issues related to interference and ensuring a reliable flow of current.

Integration Techniques

Integrating circuits involves several strategies that improve functionality and efficiency. Techniques such as surface-mount technology (SMT) allow for compact designs, while through-hole methods provide robustness for larger components. By understanding these integration approaches, engineers can optimize performance and create innovative solutions tailored to specific applications.

Identifying Common Wear-and-Tear Parts

Understanding the components that may require attention over time is essential for maintaining optimal functionality. Various elements in any system experience wear due to regular usage, leading to potential issues if not addressed promptly. Recognizing these components allows users to plan for maintenance effectively.

The following table outlines typical components that may show signs of wear, along with their functions and replacement suggestions:

| Component | Function | Replacement Tips |

|---|---|---|

| Filter | Cleans water to remove impurities | Replace regularly, depending on usage |

| Faucet Cartridge | Controls water flow and temperature | Inspect for leaks and replace if necessary |

| Seal Gasket | Prevents leaks at joints | Check for cracks or wear; replace when damaged |

| Push Button | Activates water flow | Test for responsiveness and replace if sticky |

Step-by-Step Repair with Part References

This section provides a comprehensive guide for conducting repairs effectively. It emphasizes the importance of understanding the components involved, ensuring that each part is identified correctly for a successful restoration. By following a structured approach, one can streamline the repair process and enhance overall efficiency.

The first step involves assessing the situation to identify any visible issues. Carefully examine the unit for signs of wear, damage, or malfunction. Make notes of the affected areas, as this will guide you in selecting the appropriate components needed for the fix.

Next, gather the necessary tools and resources. Refer to the inventory list to ensure you have all required items at hand. Utilizing the correct instruments is crucial for avoiding further damage during the repair.

Once you have identified the problematic components, it’s time to replace them. Follow the established procedures for disassembling the unit, taking care to keep track of each piece as you go. Ensure that you are using compatible replacements to maintain functionality.

After installing the new components, conduct a thorough test to verify that everything operates as expected. This final step is vital in confirming the success of your repair efforts and ensuring the longevity of the unit.