In the realm of hydraulic systems, having a clear visual representation of the various elements is crucial for both maintenance and optimization. A comprehensive layout not only enhances comprehension but also streamlines troubleshooting processes, enabling operators to effectively manage equipment.

By examining detailed schematics, users can identify the intricate relationships between components, ensuring that each part functions harmoniously within the larger assembly. This insight empowers technicians to delve deeper into their understanding of the system’s mechanics.

Ultimately, a well-structured illustration serves as an invaluable resource, guiding users through the complexities of hydraulic machinery and promoting informed decision-making for repairs and enhancements. Such knowledge is essential for achieving optimal performance and longevity of the equipment.

Understanding Enerpac Turbo 2 Components

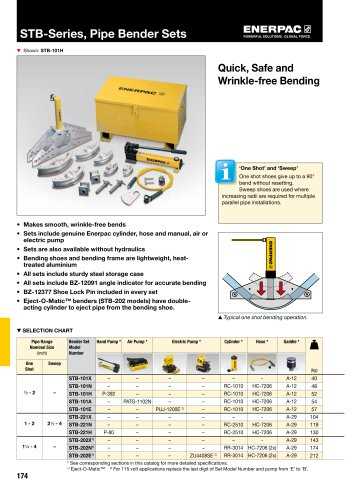

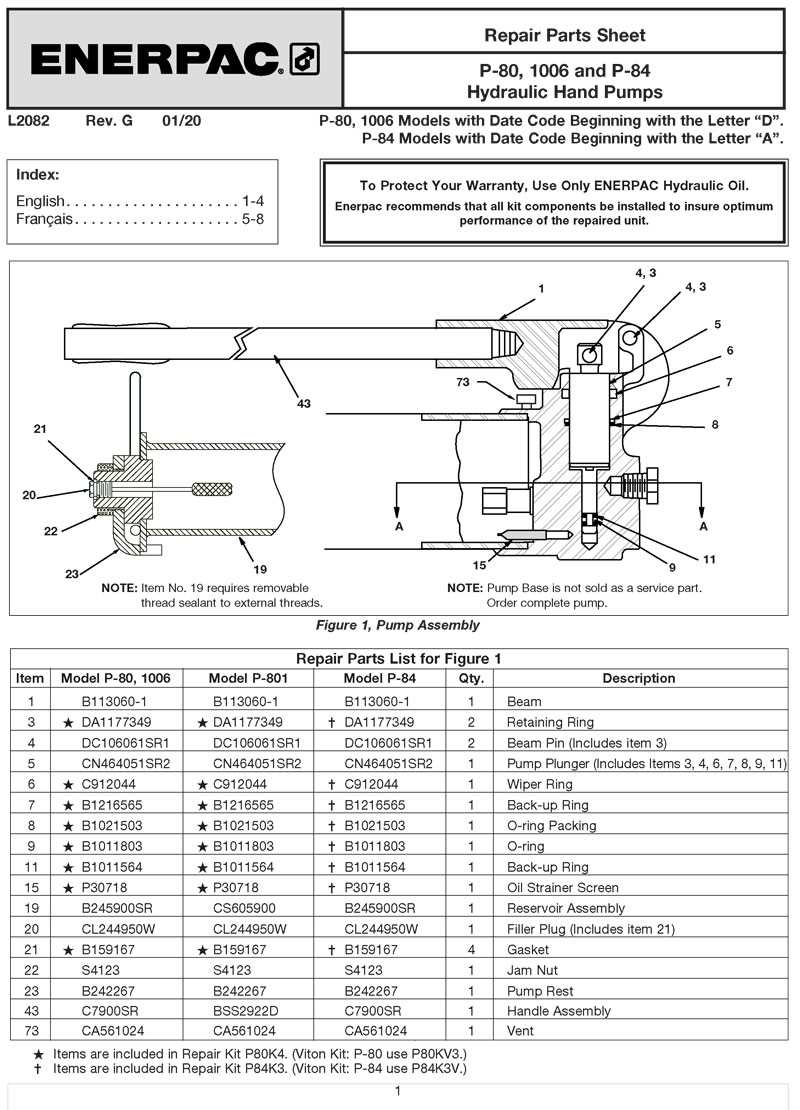

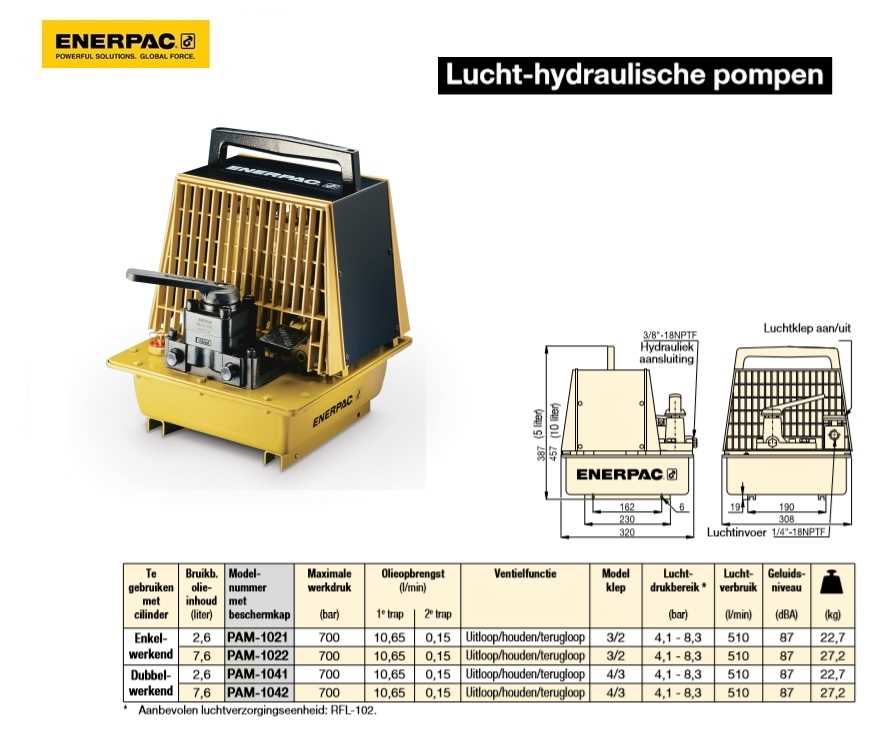

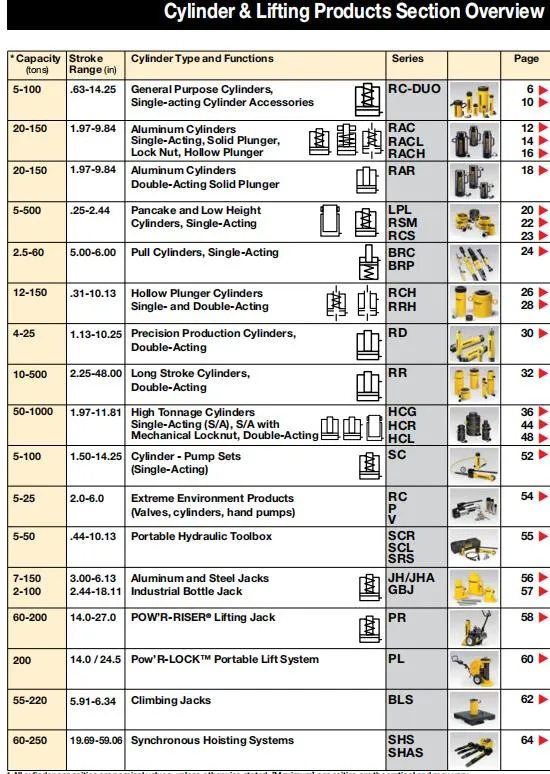

This section explores the essential elements that make up a powerful hydraulic system, focusing on their functions and interconnections. Each component plays a critical role in ensuring efficiency and reliability during operation. By examining these individual parts, one can appreciate the intricate design and engineering that contribute to overall performance.

The core mechanism includes a reservoir that stores fluid, a pump responsible for generating pressure, and various valves that control the flow. Additionally, cylinders are vital for translating hydraulic pressure into mechanical motion, while hoses and fittings facilitate the transfer of fluid between components. Understanding these elements is key to mastering the system’s functionality.

Maintenance and troubleshooting are greatly enhanced by familiarizing oneself with these components. Identifying each part and its purpose allows for more effective diagnosis and repairs, ensuring optimal operation over time. Ultimately, a comprehensive grasp of these elements leads to improved efficiency and longevity of the entire system.

Importance of Accurate Diagrams

Precise visual representations are essential in various technical fields, as they facilitate understanding and effective communication. When components are depicted correctly, it significantly enhances the ability to assemble, repair, or troubleshoot complex systems.

Enhancing Efficiency

Clear illustrations streamline processes, reducing the likelihood of errors during assembly or maintenance. This efficiency not only saves time but also minimizes resource wastage, leading to overall cost-effectiveness.

Supporting Safety

Accurate representations contribute to safety by ensuring that users can identify potential hazards and understand operational procedures. With reliable visuals, operators can navigate intricate systems confidently, ultimately safeguarding both personnel and equipment.

Common Issues with Turbo 2 Parts

When working with hydraulic equipment, users often encounter various challenges that can impact performance and efficiency. Understanding these common problems is essential for maintaining optimal functionality and ensuring a smooth operation. This section will delve into frequent complications that arise during the use of hydraulic tools and how they can affect overall performance.

Leakage Problems

One of the most prevalent issues involves fluid leakage, which can lead to significant operational disruptions. Leaks may occur due to worn seals or improperly connected components. Identifying the source of the leak promptly is crucial to prevent loss of pressure and potential damage to the machinery.

Pressure Fluctuations

Pressure inconsistencies are another common concern that can hinder the effectiveness of hydraulic systems. These fluctuations may stem from blockages within the system, faulty valves, or incorrect fluid levels. Regular maintenance and monitoring are essential to ensure stable pressure and avoid performance issues.

How to Identify Genuine Parts

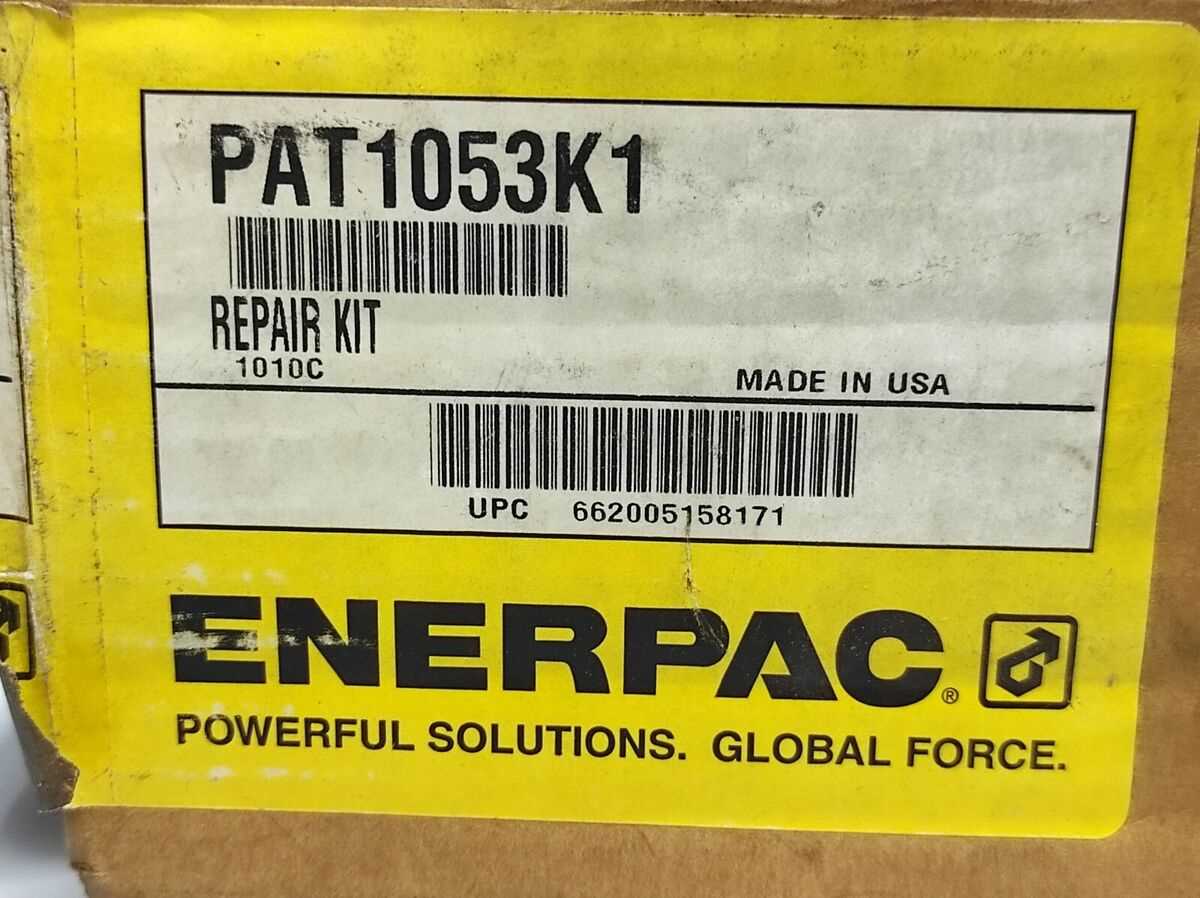

Ensuring the authenticity of components is crucial for maintaining optimal performance and safety in machinery. Counterfeit or inferior items can lead to operational issues and increased costs over time. Understanding how to differentiate between authentic and imitation offerings can save both time and resources.

One effective method is to scrutinize packaging details. Genuine components typically have consistent branding and high-quality finishes, while replicas often display inconsistencies or poor craftsmanship. Additionally, verifying serial numbers or product codes with the manufacturer can confirm authenticity.

It’s also advisable to purchase from authorized distributors or reputable retailers. Researching reviews and feedback can further provide insights into the reliability of the source. Ultimately, investing time in identifying authentic items will ensure longevity and efficiency in your equipment.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your hydraulic equipment requires regular upkeep and attention. By following a few essential practices, you can significantly extend the lifespan of your machinery and maintain its optimal performance.

Regular Inspections: Conduct routine checks on your system to identify any signs of wear or damage. Look for leaks, loose connections, and other potential issues that may require immediate attention.

Proper Lubrication: Keep all moving components well-lubricated. This reduces friction and prevents premature wear, ensuring smoother operation over time.

Cleanliness: Maintain a clean working environment around your machinery. Dust, dirt, and debris can cause blockages and affect performance. Regularly clean surfaces and remove any contaminants.

Use Quality Fluids: Always utilize recommended hydraulic fluids to ensure compatibility and efficiency. Using substandard products can lead to malfunctions and reduce the lifespan of your equipment.

Monitor Operating Conditions: Pay attention to temperature and pressure levels during operation. Keeping these parameters within recommended limits prevents undue stress on components.

Training and Best Practices: Ensure that all operators are properly trained in the use of the equipment. Following manufacturer guidelines and best practices is essential for safe and effective operation.

By implementing these maintenance strategies, you can enhance the reliability and longevity of your hydraulic systems, ultimately saving time and resources in the long run.

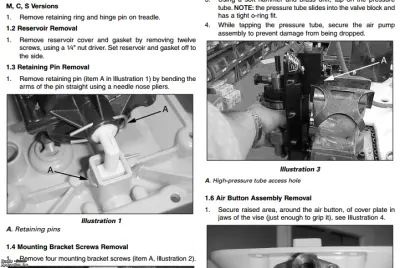

Step-by-Step Assembly Guide

This section provides a clear and concise method for assembling your equipment, ensuring that each component is placed accurately for optimal functionality. Following these steps will facilitate a smooth assembly process and help avoid common pitfalls.

Preparation

Before starting the assembly, gather all necessary tools and components. Having everything ready will streamline the process.

- Check the inventory of parts.

- Ensure all tools are in good condition.

- Review the assembly instructions carefully.

Assembly Steps

- Begin with the base unit. Secure it on a stable surface.

- Attach the primary components, ensuring each fits snugly into place.

- Use the appropriate fasteners to secure each part, following the sequence outlined in your instructions.

- Double-check alignment and tightness of all connections.

- Connect any additional accessories as specified.

- Perform a final inspection to confirm everything is assembled correctly.

Completing these steps will ensure your system is ready for operation. Always refer to the guidelines provided for any specific instructions related to your model.

Benefits of Using Turbo 2 System

The implementation of advanced hydraulic systems can significantly enhance operational efficiency and productivity across various applications. Such systems offer numerous advantages that contribute to better performance and reliability.

- Increased Efficiency: These systems are designed to optimize fluid flow, resulting in faster operation times.

- Durability: Built with high-quality materials, they ensure longevity and resistance to wear and tear.

- Versatility: Suitable for a range of applications, making them adaptable to different tasks.

- Enhanced Safety: Incorporating advanced safety features minimizes risks associated with hydraulic operations.

- Cost-Effectiveness: Reduced maintenance needs lead to lower operational costs over time.

By exploring these benefits, users can ultimately make informed decisions that lead to improved outcomes in their projects.

Comparative Analysis with Competitors

This section aims to provide a thorough examination of a leading product within its category in relation to its market rivals. By assessing key features, pricing structures, and user satisfaction levels, we can gain insight into the competitive landscape and identify potential advantages or drawbacks.

Feature Comparison

| Feature | Brand A | Brand B | Brand C |

|---|---|---|---|

| Performance | High efficiency | Moderate efficiency | High efficiency |

| Durability | Excellent | Good | Very Good |

| Ease of Use | User-friendly | Complex | User-friendly |

| Price Range | $$$ | $$ | $$$$ |

User Feedback

Feedback from users often highlights the importance of reliability and support. While some brands excel in providing responsive customer service, others may lack in this area. Analyzing reviews and testimonials reveals a trend in user preferences, shedding light on which aspects resonate most with consumers.

Upgrades and Modifications Available

Enhancing performance and functionality is a common goal for many users of hydraulic equipment. Various upgrades and custom modifications can significantly improve efficiency and adaptability to specific tasks. These enhancements can range from simple adjustments to comprehensive overhauls, providing tailored solutions to meet diverse operational needs.

One popular modification involves the integration of advanced control systems that allow for more precise operation and increased automation. This can lead to improved productivity and safety in high-demand environments. Additionally, upgrading seals and hoses can enhance durability and resistance to wear, ensuring longer service life and reduced maintenance costs.

Another area for potential improvement is the incorporation of lightweight materials, which can enhance portability without compromising strength. This is particularly beneficial in applications where mobility is essential. Furthermore, custom mounting solutions can facilitate easier integration with existing machinery, streamlining workflows and enhancing overall efficiency.

Lastly, exploring various power options, such as electric or battery-powered alternatives, can provide greater flexibility in where and how equipment is used. By considering these upgrades and modifications, users can optimize their hydraulic systems to better suit their specific requirements and improve overall performance.

Expert Insights on Troubleshooting

Troubleshooting equipment can often seem daunting, yet understanding common issues and their solutions can greatly simplify the process. This section provides valuable insights that can enhance your diagnostic skills, ensuring efficient resolution of problems that may arise during operation.

Identifying Common Issues

Begin by observing the symptoms of the malfunction. Look for patterns, such as unusual noises or performance inconsistencies. Taking note of these details allows for a more precise diagnosis, leading to quicker fixes. Documentation of previous issues can also serve as a useful reference.

Effective Solutions and Best Practices

Once the issue is identified, consider employing a systematic approach to resolve it. Always consult the manufacturer’s guidelines for specific troubleshooting steps. Utilizing proper tools and techniques is essential; this not only ensures safety but also promotes longevity of the equipment. Remember, patience and careful analysis are key to successful problem-solving.

Resources for Parts Replacement

When it comes to replacing components in hydraulic systems, having access to reliable resources is crucial. Whether you are a technician or a DIY enthusiast, knowing where to find high-quality replacements can significantly enhance the longevity and performance of your equipment. This section highlights various options available for sourcing essential components.

One effective way to ensure you obtain the right items is by consulting manufacturer websites. These platforms typically provide comprehensive information regarding compatible replacements, including specifications and recommended vendors.

| Resource Type | Description | Example |

|---|---|---|

| Manufacturer Documentation | Official manuals and guides detailing compatible components. | Technical manuals available on the manufacturer’s website. |

| Authorized Distributors | Verified sellers that stock original and high-quality alternatives. | Local or online suppliers listed on the manufacturer’s site. |

| Online Marketplaces | Platforms that offer a wide variety of components from different sellers. | Amazon, eBay, and specialized hydraulic component sites. |

| Forums and Community Groups | Online communities where users share experiences and recommendations. | Hydraulic equipment forums and Facebook groups. |

Utilizing these resources can help ensure you find the right components efficiently, leading to improved operational reliability and reduced downtime in your hydraulic systems.