When it comes to maintaining any mechanical system, having a clear understanding of how individual components are arranged and how they interact is essential. The layout of key elements can offer valuable insights into the overall functionality and performance of the system. Whether you are dealing with an issue or simply aiming to keep everything running smoothly, knowing where each part belongs can make the task much easier.

To ensure longevity and optimal performance, it’s crucial to familiarize yourself with the assembly of the various elements. By examining the structural design and understanding the purpose of each section, you can perform routine maintenance and troubleshoot potential problems with greater accuracy.

Exploring the detailed organization of these mechanical components provides a clear path to efficient repairs, ensuring that everything functions as intended. This knowledge allows you to approach each task with confidence, minimizing the chances of unexpected breakdowns.

Engine Components Overview

The structure of this marine motor is composed of various interconnected elements, each playing a vital role in ensuring smooth and efficient operation. These components work together in harmony to deliver reliable power and performance during use. Understanding the layout and function of these essential parts helps in maintaining the motor and identifying potential issues that may arise over time.

Key elements include the fuel system, which delivers the necessary energy to the motor, and the cooling mechanism, which prevents overheating during extended use. The ignition system ensures a stable start, while other mechanical parts, such as gears and propeller attachments, contribute to the overall functionality of the machine.

Regular inspection and maintenance of these core components are crucial for extending the life of the motor and ensuring optimal operation. Knowing how these pieces fit and function together helps to keep the motor running smoothly and efficiently, ensuring trouble-free performance in various conditions.

Main Features of Evinrude 9.9 Motor

This motor model is known for its reliability and efficiency, providing an excellent balance between power and fuel economy. Its compact design ensures easy handling, making it suitable for various watercraft applications. Whether used for leisure or professional tasks, this engine offers smooth operation and durability over extended periods.

Efficient Fuel Consumption: The motor is designed to maximize fuel efficiency, allowing for longer trips with fewer refueling stops. This makes it ideal for those seeking both performance and cost-effectiveness.

Lightweight and Portable: Thanks to its lightweight build, the motor is easy to transport and install. Its portable nature ensures flexibility for different uses, especially for smaller boats or temporary setups.

Durability and Longevity: Crafted from high-quality materials, this motor is built to withstand various environmental conditions, ensuring long-term reliability. It requires minimal maintenance, which further enhances its lifespan.

Quiet Operation: This engine runs quietly, reducing noise pollution and ensuring a more enjoyable experience on

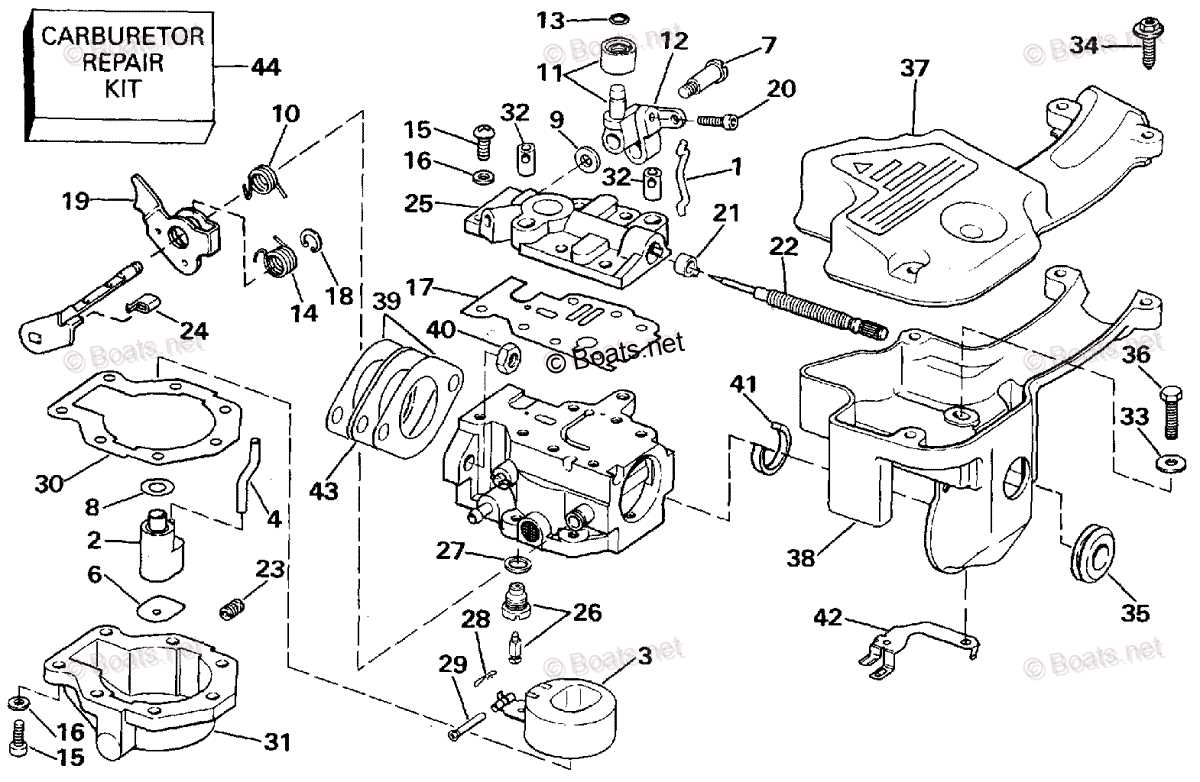

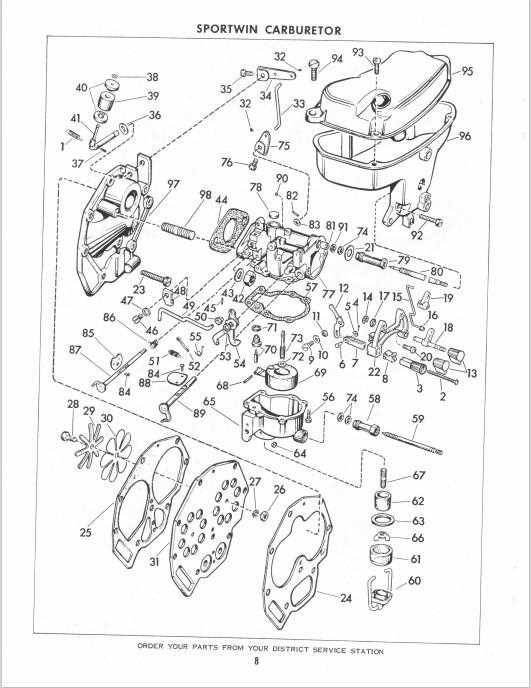

Exploring the Carburetor Assembly Layout

The carburetor is a crucial component of the engine’s fuel system, designed to regulate the mixture of air and fuel to ensure smooth operation. Understanding the layout of this assembly can help in identifying different sections and how they contribute to the overall functioning. The design involves several interconnected elements that work in unison to provide the right balance of air and fuel for optimal performance.

Key Components of the System

In the layout, various elements like valves, jets, and chambers work together to control the flow of air and fuel. Each part has a specific role, from adjusting the fuel intake to fine-tuning the air supply, ensuring efficient combustion. Recognizing the position of these components within the system allows for better maintenance and troubleshooting.

Flow and Functionality

The overall layout is designed to guide the air-fuel mixture through a series of stages, with each section contributing to the smooth transition from idle to full throttle. The interaction between the parts ensures that the fuel is properly atomized and mixed with air, allowing

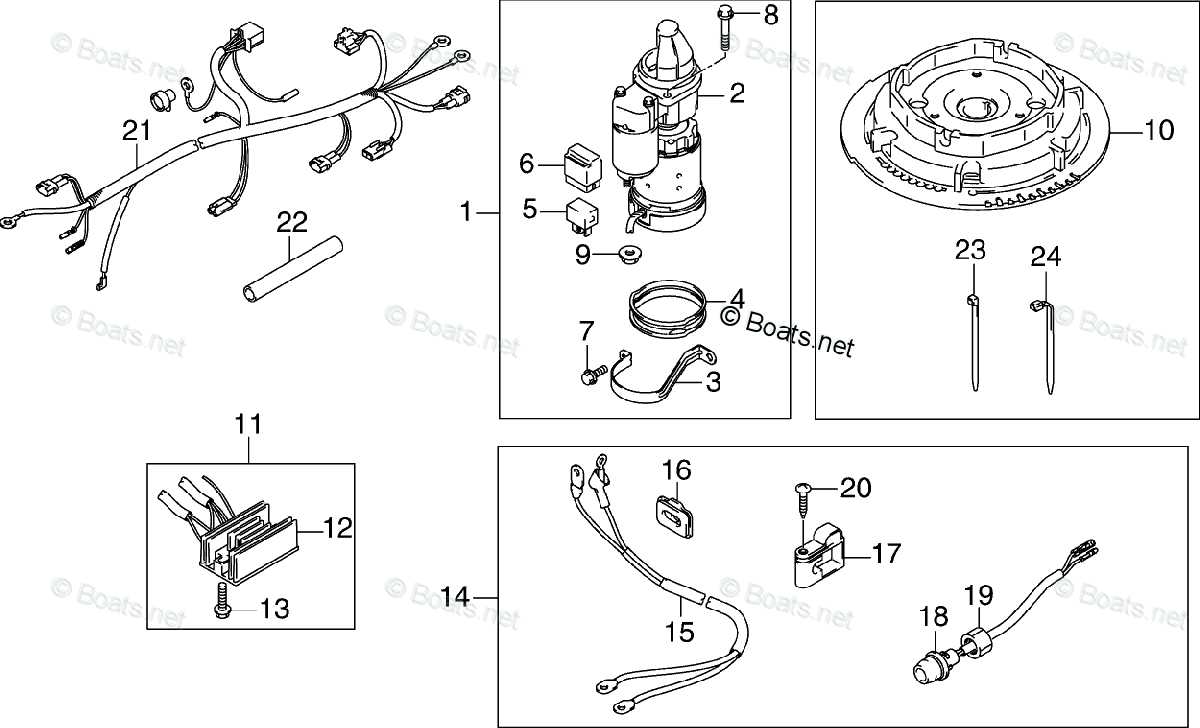

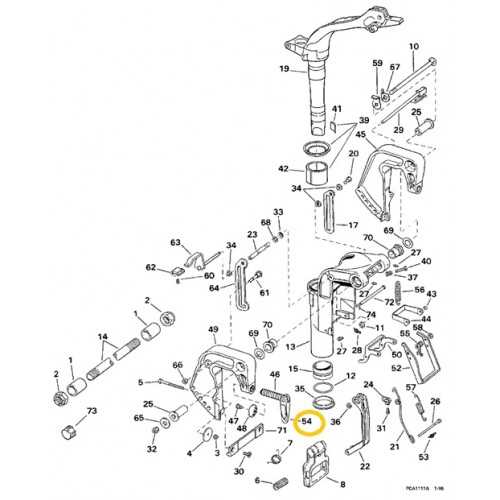

Ignition System Components Breakdown

The ignition system consists of several interconnected elements, each playing a crucial role in ensuring proper engine functionality. Understanding the structure of these components helps maintain the performance and reliability of the machine.

Main Components Overview

- Coil: Converts low voltage into the high voltage needed to ignite the fuel mixture.

- Flywheel: Generates electricity by rotating and triggering the ignition process.

- Spark Plug: Delivers the electric spark to ignite the fuel within the cylinder.

- Ignition Switch: Initiates the power flow and controls the engine start.

How the System Operates

- The ignition switch is turned on, sending electrical power through the system.

- The flywheel rotates, generating the necessary charge within the coil.

- The coil transforms the charge into high voltage, which is sent to the spark plug.

- The spark plug ign

Fuel Delivery System and Key Parts

The fuel delivery system plays a crucial role in ensuring the engine receives the right amount of fuel for efficient operation. This process involves multiple components that work together to supply fuel from the tank to the engine, ensuring smooth performance and optimal power output.

Key elements within the fuel system are designed to regulate, transport, and prepare the fuel before combustion. These components must function properly to prevent issues like poor fuel efficiency or engine malfunctions.

- Fuel Pump: Moves fuel from the tank to the engine, ensuring a steady flow.

- Fuel Lines: Tubes that transport fuel between various parts of the system, maintaining pressure and preventing leaks.

- Fuel Filter: Removes impurities from the fuel, protecting the engine from debris and contaminants.

- Carburetor: Mixes air and fuel in the proper ratio for combustion, critical for maintaining power and efficiency.

- Primer Bulb: Assists in manually pumping fuel into

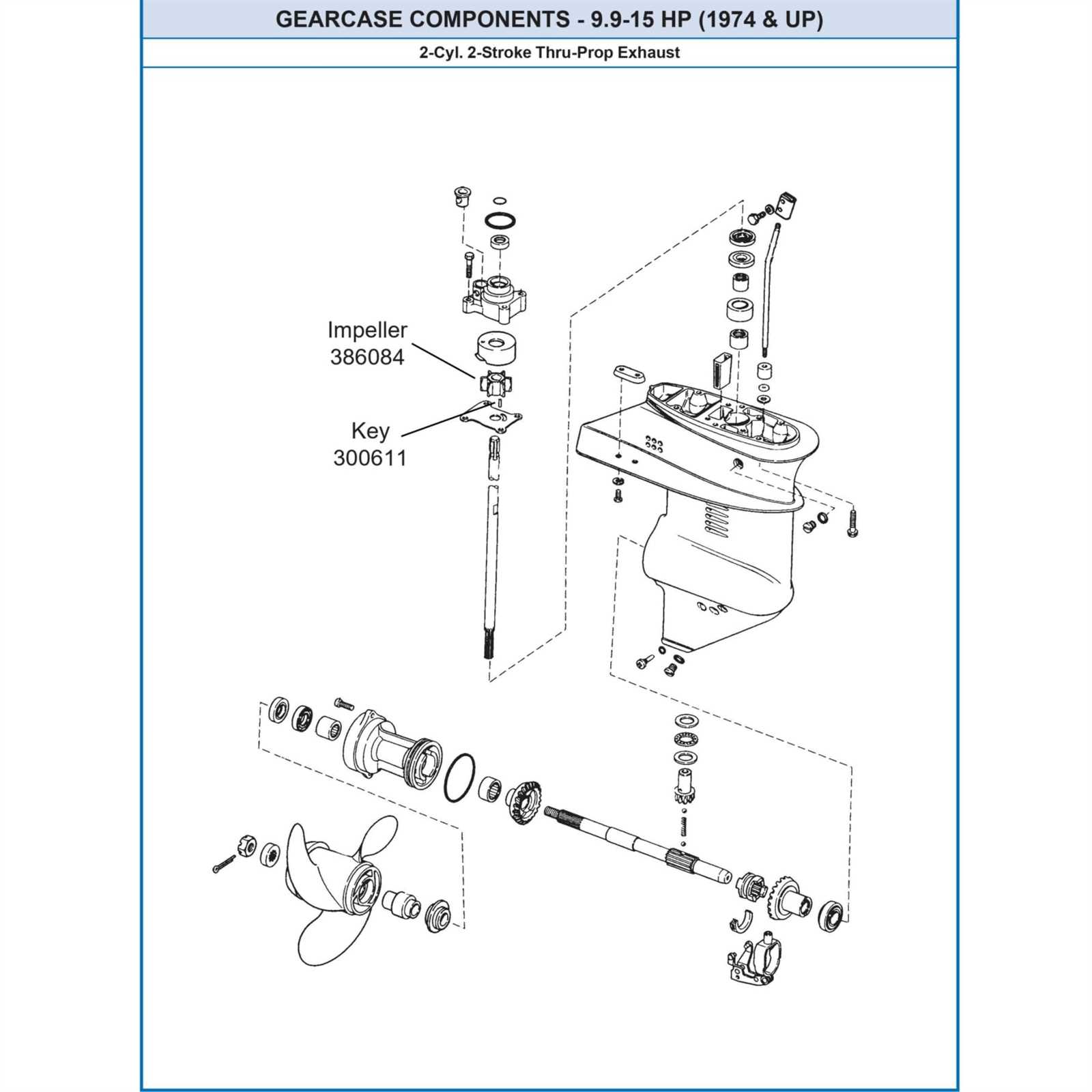

Understanding the Water Pump and Impeller

The water pump and its associated component are vital for the efficient operation of marine engines. These elements play a crucial role in ensuring that the cooling system functions properly, helping to maintain optimal temperatures during use. A reliable water pump facilitates the circulation of water, preventing overheating and ensuring the engine operates smoothly.

The impeller serves as the heart of the water pump, responsible for drawing in water and propelling it through the cooling system. This component is typically made of durable materials that withstand the harsh conditions of marine environments. Over time, however, wear and tear can affect the impeller’s efficiency, making regular inspection and maintenance essential.

Understanding the interaction between the water pump and the impeller is key to ensuring the longevity and performance of any marine engine. By familiarizing oneself with these components, operators can take proactive measures to address potential issues, thereby enhancing the overall reliability of their vessels.

Exhaust System Parts and Functionality

The exhaust system plays a crucial role in the overall performance of marine engines, facilitating the expulsion of gases produced during combustion. Understanding its components and their functions is essential for maintaining engine efficiency and ensuring smooth operation.

Key elements of this system include the manifold, which collects exhaust gases from the engine; the riser, which directs these gases upward; and the silencer, designed to minimize noise. Each component works in harmony to ensure that harmful emissions are effectively channeled away from the engine while allowing for optimal airflow.

Manifold: This component gathers exhaust fumes directly from the engine cylinders, serving as the initial passage for gases to exit. It is typically made from durable materials to withstand high temperatures.

Riser: Positioned between the manifold and the outlet, this part elevates the exhaust flow, preventing water from entering the engine. Its design is critical for maintaining proper drainage and avoiding potential damage.

Silencer: Often referred to as a muffler, this element reduces engine noise by dissipating sound waves. It is an essential feature for compliance with marine regulations and ensuring a quieter operation on the water.

Overall, the effectiveness of the exhaust system significantly influences the engine’s performance and longevity, highlighting the importance of regular inspections and maintenance of its components.

Throttle Mechanism and Related Components

The throttle mechanism plays a crucial role in regulating the engine’s power output by controlling the airflow and fuel mixture. This system comprises various interconnected elements that work harmoniously to ensure optimal performance and responsiveness of the motor.

Central to this assembly is the throttle lever, which allows the operator to adjust the engine’s speed. This lever connects to a series of linkages that transmit the movement to the throttle plate, enabling precise control over the engine’s operation. Additionally, components such as the governor mechanism help maintain consistent performance by automatically adjusting the throttle position based on load conditions.

Moreover, the proper functioning of the throttle system relies on various supporting parts, including cables, springs, and brackets. Each element contributes to the overall efficiency and reliability of the engine, ensuring smooth acceleration and deceleration. Understanding these components is essential for effective maintenance and troubleshooting.

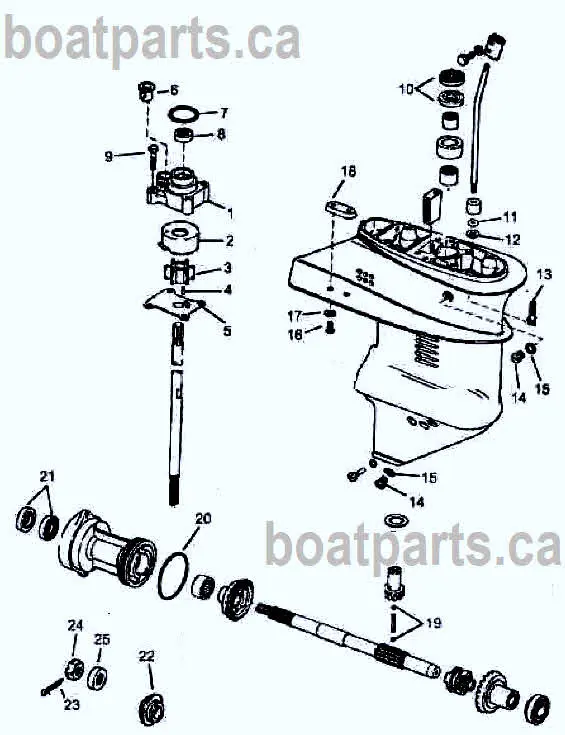

Gearcase and Propeller Parts Diagram

This section provides an overview of the essential components associated with the lower unit and propulsion mechanism of an outboard motor. Understanding these elements is crucial for maintenance and troubleshooting.

The following list outlines key components found within the gearcase and propeller assembly:

- Lower Unit Housing

- Drive Shaft

- Gear Set

- Propeller Nut

- Propeller

- Thrust Washer

- Seal Kit

- Shift Rod

Each of these components plays a vital role in the overall functioning of the motor, contributing to efficient power transmission and thrust generation. Proper knowledge and care of these elements ensure optimal performance and longevity.

Electrical Wiring and Connection Details

This section provides essential information regarding the electrical systems and their interconnections in marine engines. Understanding these aspects is crucial for maintaining optimal performance and ensuring safety during operation.

Proper wiring is vital for the functionality of various components. Here are some key elements to consider:

- Power Supply: Ensure that the power source is correctly connected to prevent voltage fluctuations.

- Ground Connections: Establishing a solid ground is necessary to avoid electrical issues and ensure stable operation.

- Wiring Insulation: Check for any wear or damage on the insulation to prevent short circuits.

- Connector Types: Utilize appropriate connectors for secure and reliable connections.

For effective troubleshooting, follow these guidelines:

- Verify all connections for tightness and proper alignment.

- Use a multimeter to check for continuity in the wiring.

- Inspect for corrosion on terminals and connectors.

- Refer to the manufacturer’s guidelines for specific wiring configurations.

By adhering to these practices, users can enhance the reliability and efficiency of their electrical systems, ultimately leading to improved overall performance.

Maintenance Tips for Evinrude 9.9 Motor

Proper upkeep of a small outboard engine is essential for ensuring optimal performance and longevity. Regular attention to various components not only enhances functionality but also minimizes the risk of breakdowns during use. Here are some practical suggestions to keep your engine running smoothly.

Regular Inspections

Conducting frequent checks on critical parts such as the fuel system, cooling components, and electrical connections can help identify potential issues before they escalate. Look for signs of wear, corrosion, or leaks, and address them promptly to avoid more significant repairs.

Routine Maintenance Practices

Implementing a consistent maintenance schedule is vital. Change the oil and replace the filters regularly to ensure clean operation. Additionally, cleaning or replacing spark plugs can improve ignition efficiency. Make sure to follow the manufacturer’s guidelines for any specific maintenance procedures that apply to your particular model.