Understanding the internal structure of complex cleaning devices can be crucial for maintenance and troubleshooting. A clear layout of the various elements allows users to navigate through the essential components, ensuring better efficiency and functionality.

Each piece within these systems has its own role, contributing to the overall operation. When assembled together, these parts work in harmony, providing optimal performance. Having a detailed view of how these pieces fit together helps in identifying potential issues and facilitates smoother repairs or upgrades.

This section will explore the arrangement of different mechanisms, offering a thorough breakdown of key elements. With a deeper insight into their alignment, users can maintain and enhance the equipment’s effectiveness.

Understanding the Filter Queen Majestic System

The air cleaning system is designed to offer high performance, maintaining cleanliness and improving the quality of the environment. The unit is structured to optimize airflow while effectively capturing dust and other small particles.

This section explains how the different components work together to enhance the cleaning efficiency of the system, ensuring that unwanted elements are collected and stored safely.

- The main chamber houses the motor and fan, which are responsible for generating the suction force required to draw air into the system.

- The airflow path is carefully engineered to ensure that the captured air moves smoothly through the different layers of collection and filtration media.

- The debris containment system securely stores particles, preventing them from being released back into the environment.

Overall, the design is intended to maintain strong suction power while minimizing maintenance needs and ensuring long-term durability.

Key Components of the Vacuum Unit

The vacuum system consists of several essential elements that work together to ensure efficient cleaning performance. These components are designed to provide powerful suction, effective filtration, and ease of use, making the entire unit a reliable tool for maintaining a clean environment.

Suction Motor

The motor serves as the powerhouse of the unit, generating the necessary force to draw in dirt and debris. Its performance directly impacts the vacuum’s efficiency, with more powerful motors providing stronger suction capabilities for thorough cleaning.

Filtration System

The filtration system is a critical component that captures fine dust, allergens, and particles, preventing them from being released back into the air. Multiple layers of filters ensure optimal air quality by trapping various sizes of debris during the cleaning process.

How the Filtration Process Works

The system’s cleaning mechanism operates through a multi-step procedure designed to capture unwanted particles from the surrounding air. Each stage contributes to improving air quality, ensuring a thorough and efficient purification process.

- Initial Capture: The process begins as air is drawn into the system, where large particles like dust and debris are immediately trapped, preventing them from circulating further.

- Particle Separation: As the air moves through subsequent layers, finer elements are extracted, with each layer designed to focus on capturing progressively smaller particles.

- Advanced Purification: At the final stage, any remaining microscopic particles and impurities are removed, resulting in cleaner, breathable air that is free of contaminants.

By utilizing a sequence of distinct stages, the system ensures that air is cleansed efficiently and thoroughly, promoting a healthier indoor environment.

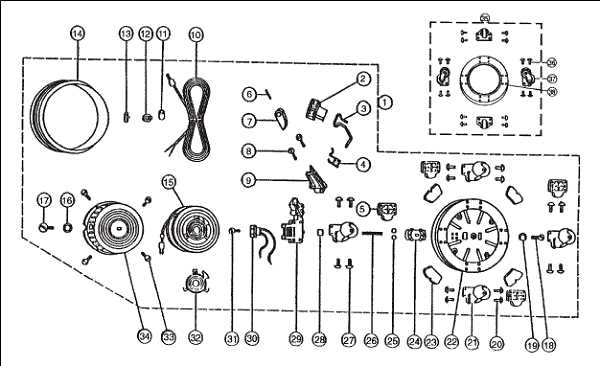

Exploring the Motor Assembly Structure

The motor assembly is a vital component of many devices, responsible for powering the system and ensuring smooth operation. Its design is intricate, consisting of several interconnected elements that work together to convert electrical energy into mechanical motion. Understanding the layout and functionality of these components can help in identifying issues and performing maintenance tasks more effectively.

The core of the motor assembly includes a series of internal mechanisms designed to regulate energy flow and ensure efficient operation. The central drive, rotor, and stator are among the key elements that provide rotational movement. The arrangement of these parts allows the system to run seamlessly, transferring energy where needed.

Supporting elements such as bearings, brushes, and wiring further contribute to the overall performance by minimizing friction and wear while ensuring stable electrical connections. These smaller, yet essential components play a significant role in extending the lifespan of the motor and enhancing its reliability over time.

Hose and Attachment Connection Points

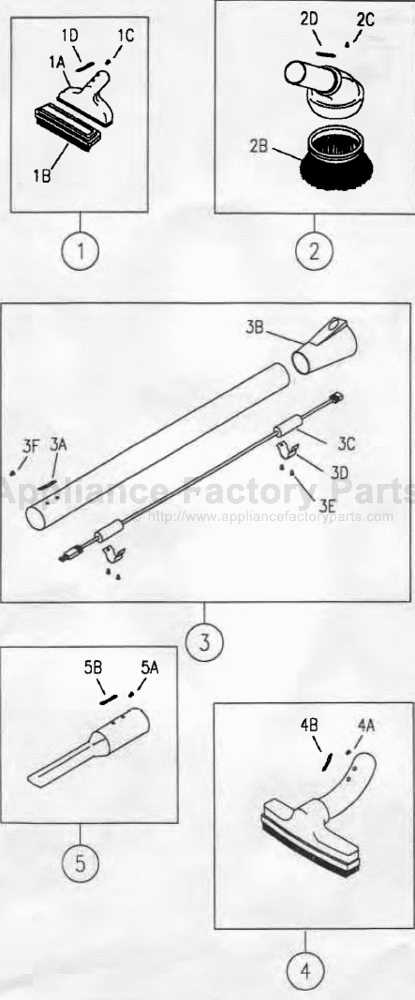

The connection points for the hose and various attachments are essential for ensuring proper functionality and smooth operation. These points allow different cleaning tools to be securely fastened, enabling efficient use of each accessory. A well-designed system simplifies the process of switching between attachments, enhancing overall user experience.

Main Hose Connection

The primary hose attaches directly to the main unit via a secure coupling. This ensures a firm connection, preventing any air leaks or disconnections during use. The locking mechanism is designed for ease of installation, while maintaining a reliable seal.

Accessory Port Connections

Each accessory connects to the hose through dedicated ports that are specifically crafted to match the attachment’s design. These connection points are often equipped with a click or twist system to lock the accessory into place, ensuring stability during cleaning tasks. Proper alignment is crucial for a tight fit.

Maintenance of the Power Nozzle

Proper upkeep of the cleaning head is essential for ensuring optimal performance and longevity. Regular attention not only enhances efficiency but also contributes to the overall cleanliness of your living environment. This section outlines crucial steps to maintain and care for the cleaning attachment effectively.

Routine checks and cleaning can prevent wear and tear, ensuring that the unit functions at peak capacity. It’s advisable to inspect the nozzle for any obstructions or accumulated debris that could impede operation. Here are the key maintenance tasks to consider:

| Task | Frequency | Description |

|---|---|---|

| Visual Inspection | Weekly | Check for cracks, damage, or buildup in the nozzle area. |

| Cleaning | Monthly | Remove and clean the nozzle to eliminate dirt and dust accumulation. |

| Check Brushes | Every 3 Months | Inspect and replace brushes as necessary to maintain effective suction. |

| Inspect Cables | As Needed | Ensure that cables are intact and free from fraying or damage. |

Following these maintenance guidelines will help in prolonging the lifespan of the cleaning head while ensuring it operates efficiently. Keeping the nozzle in prime condition is key to achieving the best cleaning results.

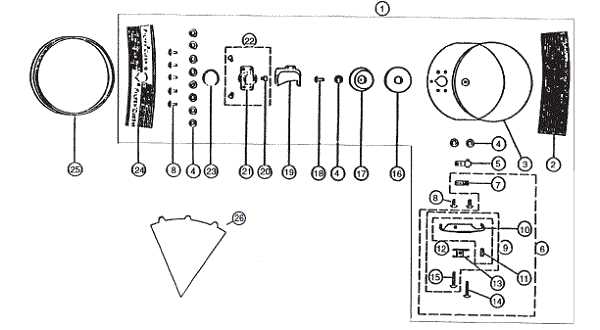

Inspecting the Internal Filter Mechanism

Evaluating the core cleansing system is crucial for maintaining optimal performance. This component plays a vital role in ensuring the efficient operation of the entire apparatus, significantly impacting air quality and overall functionality. Regular assessments can help identify wear, tear, or any obstructions that may hinder performance.

During inspection, it is essential to examine various elements within the mechanism. Checking for blockages and ensuring all components are free from damage can enhance efficiency and prolong the device’s lifespan.

| Component | Purpose | Inspection Tips |

|---|---|---|

| Inner Screen | Traps large particles and debris | Look for tears or significant accumulation |

| Mesh Filter | Filters smaller particles | Ensure it is clean and free from clogs |

| Seal | Prevents air leaks | Check for any cracks or deterioration |

| Fan Assembly | Promotes airflow | Inspect for proper function and noise levels |

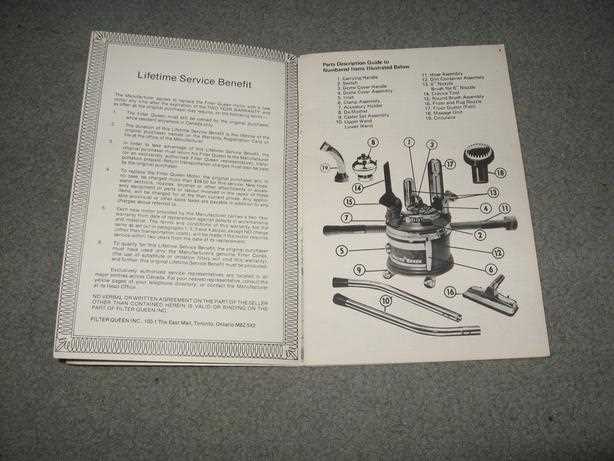

Identifying Essential Replacement Parts

Understanding the key components of your device is crucial for effective maintenance and longevity. Recognizing which elements require attention can help prevent operational issues and ensure optimal performance.

Among the vital components, several play a significant role in the overall functionality. Filters are essential for maintaining cleanliness and efficiency, while motors ensure adequate power for operation. Additionally, housings provide structural integrity and protection for internal mechanisms.

When seeking replacements, it’s important to refer to your model’s specifications. This will help you identify the correct items needed, ensuring compatibility and enhancing your unit’s efficiency. Regularly inspecting these crucial components can lead to timely replacements, preventing potential malfunctions.

Disassembling and Reassembling the Canister

This section provides a comprehensive overview of the process involved in taking apart and putting back together a specific cylindrical container used in various cleaning applications. Proper understanding of the steps ensures optimal performance and longevity of the unit. This guide emphasizes the importance of careful handling to avoid damage to internal components.

Steps for Disassembly

Begin by ensuring that the unit is turned off and unplugged to prevent any accidents. Remove the lid by gently twisting it counterclockwise. Once the top is off, carefully lift out the internal components, taking note of their arrangement. It is advisable to keep track of all elements, including seals and clips, to facilitate easy reassembly.

Reassembly Process

To reassemble, start by placing the internal elements back in the original order. Ensure that all seals are correctly positioned to maintain airtightness. Finally, secure the lid by twisting it clockwise until it clicks into place, indicating that it is properly fastened.

Note: Always consult the user manual for detailed instructions and safety precautions during disassembly and reassembly.

Common Issues with Electrical Components

Electrical systems often face a variety of challenges that can hinder their performance. Understanding these common problems is essential for effective maintenance and troubleshooting.

Here are some prevalent issues that can arise:

- Short Circuits: This occurs when electrical current flows through an unintended path, potentially leading to overheating and component failure.

- Overheating: Excessive heat can damage components, often caused by poor connections or overloading the system.

- Voltage Fluctuations: Variations in voltage levels can affect device operation, leading to malfunctions or reduced lifespan.

- Corrosion: Moisture and contaminants can lead to corrosion, affecting connections and overall electrical flow.

- Loose Connections: Poorly secured connections can result in intermittent failures, disrupting functionality.

Regular inspection and timely repairs can help mitigate these issues, ensuring reliable operation and longevity of the electrical system.

Accessory Functions and Their Benefits

Accessories play a crucial role in enhancing the overall performance and usability of cleaning equipment. By integrating various components, users can significantly improve efficiency, convenience, and effectiveness in their cleaning routines. Understanding the functions of these additional features can help users make informed decisions when optimizing their cleaning processes.

Enhanced Versatility is one of the primary advantages of utilizing accessories. With the right attachments, users can tackle different surfaces and materials with ease. Whether it’s upholstery, hardwood floors, or carpets, these add-ons ensure thorough cleaning across various environments.

Additionally, improved filtration systems contribute to better air quality by capturing dust, allergens, and pollutants. This feature is especially beneficial for individuals with respiratory issues, as it helps create a healthier living space.

Convenience and Ease of Use are also key benefits. Accessories designed for specific tasks reduce the time and effort required for cleaning. For instance, specialized brushes or nozzles allow users to reach tight spaces or effectively clean delicate items without hassle.

Finally, cost-effectiveness is a notable advantage. Investing in accessories can prolong the lifespan of cleaning equipment and reduce the need for frequent replacements. By enhancing the functionality of existing tools, users can maximize their investment and maintain optimal cleaning standards.