In the world of automotive maintenance and repair, effective lifting tools are essential for providing access to various components beneath vehicles. These mechanisms allow technicians to perform a wide range of tasks safely and efficiently, ensuring that both minor and major repairs can be completed with ease. Understanding the internal structure of these tools is crucial for anyone looking to enhance their skills in this area.

Every lifting apparatus consists of several critical components that work in harmony to achieve the desired elevation. Each piece plays a vital role in the overall functionality, and recognizing how they interact can significantly improve maintenance practices. Knowledge of these elements not only aids in troubleshooting but also empowers users to make informed decisions when purchasing or servicing their equipment.

Delving into the intricacies of these systems reveals the importance of proper assembly and care. Familiarity with the various components enhances one’s ability to diagnose issues and implement effective solutions. This understanding fosters greater confidence, ensuring that users can rely on their tools for optimal performance in any situation.

Understanding Floor Jack Components

When working with lifting equipment, it’s essential to grasp the various elements that contribute to its functionality. Each component plays a crucial role in ensuring safety and efficiency during use. Familiarity with these features not only enhances user experience but also promotes better maintenance practices.

Hydraulic System: At the core of this equipment lies a hydraulic mechanism, which utilizes fluid pressure to elevate heavy loads. Understanding how this system operates is vital for effective usage.

Frame Structure: The framework provides stability and support, allowing for safe lifting. A robust structure is essential to withstand significant weight without compromising safety.

Wheels and Rollers: Mobility is facilitated by the wheels, enabling smooth movement across various surfaces. The quality and design of these components affect maneuverability significantly.

Release Valve: This feature allows controlled descent of the lifted load. Mastery of its operation is important to prevent accidents during unloading.

By delving into the intricacies of these elements, users can appreciate the ultimate importance of each part in ensuring safe and effective lifting practices.

Essential Parts of a Floor Jack

Understanding the fundamental components of this lifting device is crucial for effective operation and maintenance. Each element plays a vital role in ensuring safety and efficiency when raising heavy loads. Familiarity with these features helps users diagnose issues and perform necessary repairs.

Main Components

The key features of this lifting apparatus include various mechanisms that work in tandem to achieve optimal performance. Below is a brief overview of these crucial elements.

| Component | Description |

|---|---|

| Chassis | The sturdy frame that supports the entire structure and provides stability during lifting. |

| Hydraulic Cylinder | This part generates the force needed to lift heavy objects by using hydraulic fluid. |

| Pump Mechanism | Responsible for transferring hydraulic fluid to the cylinder, facilitating the lifting action. |

| Release Valve | Allows controlled lowering of the load by regulating hydraulic fluid flow from the cylinder. |

| Wheels | Enable easy maneuverability, allowing the device to be moved to various locations effortlessly. |

Additional Features

In addition to the main components, there are supplementary features designed to enhance usability and safety. Being aware of these can improve the overall experience and effectiveness of the tool.

| Feature | Benefit |

|---|---|

| Safety Lock | Prevents accidental lowering of the load, ensuring user safety. |

| Handle | Provides leverage for pumping and maneuvering, improving user control. |

| Foot Pedal | Allows for hands-free operation, enhancing convenience during lifting. |

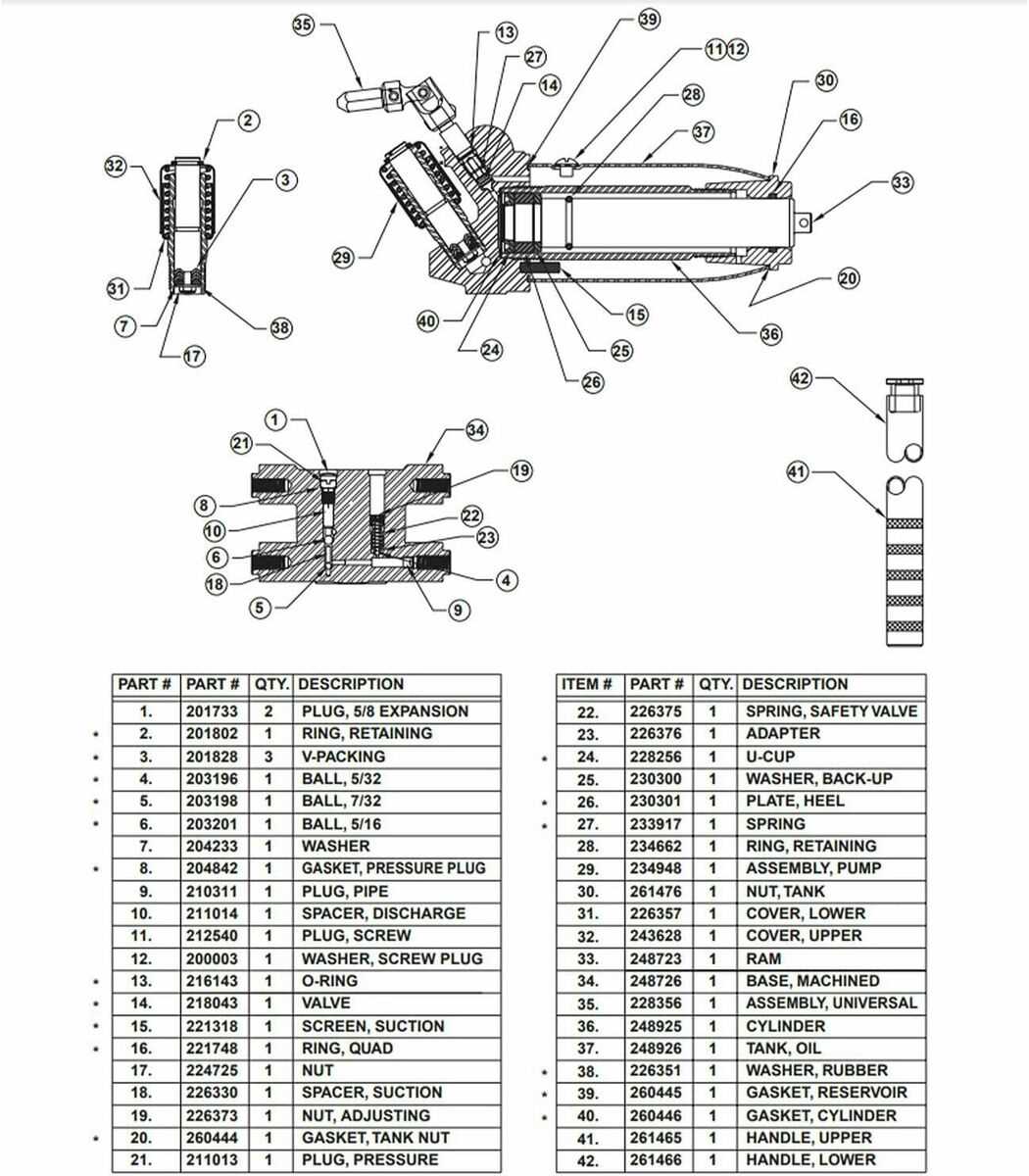

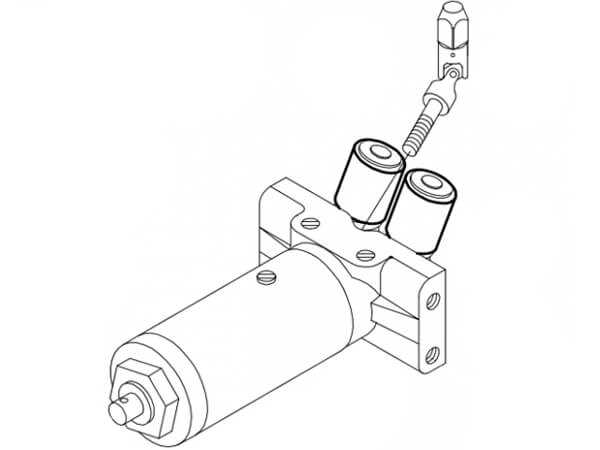

How a Hydraulic System Works

A hydraulic system is a remarkable technology that harnesses the power of fluid under pressure to generate force and motion. This mechanism operates on fundamental principles, allowing for the efficient transfer of energy through liquid. Understanding how this system functions provides insight into its applications in various industries.

The core components of a hydraulic system include:

- Fluid Reservoir: Stores the hydraulic fluid that powers the system.

- Pump: Converts mechanical energy into hydraulic energy by moving the fluid through the system.

- Actuator: Transforms the hydraulic energy back into mechanical energy to perform work.

- Valves: Control the flow and direction of the hydraulic fluid, ensuring precise movement.

The operation of a hydraulic system can be summarized in several key steps:

- The pump draws hydraulic fluid from the reservoir and pressurizes it.

- Pressurized fluid is directed through valves to the actuator.

- The actuator receives the fluid, causing it to move and perform the intended task.

- The fluid then returns to the reservoir, completing the cycle.

This efficient use of liquid under pressure allows hydraulic systems to lift heavy loads and perform complex tasks with ease, making them invaluable in construction, manufacturing, and automotive industries.

Types of Floor Jack Designs

Understanding the various configurations of lifting devices is essential for selecting the right one for specific needs. Each design serves unique purposes and offers distinct features that cater to different scenarios, from automotive repair to heavy machinery lifting.

The most common types include hydraulic, screw, and pneumatic models. Hydraulic versions utilize fluid pressure for enhanced lifting capacity, making them ideal for heavier loads. Screw designs rely on mechanical advantage, offering simplicity and portability for lighter tasks. Pneumatic options harness air pressure, providing rapid lifting in professional settings.

Another noteworthy design is the low-profile variant, engineered to fit under vehicles with minimal clearance. In contrast, high-lift models are perfect for larger applications, enabling access to elevated areas. Understanding these variations allows users to make informed choices based on their requirements.

Identifying Common Jack Failures

Understanding the typical issues that can arise with lifting devices is crucial for maintaining their effectiveness and safety. Recognizing the signs of malfunction can help prevent accidents and prolong the lifespan of the equipment. This section will explore the most frequent failures encountered, allowing users to address problems promptly.

Hydraulic Leaks: One of the most common failures involves fluid escaping from the system. This can lead to reduced lifting capability and requires immediate attention.

Failure to Lift: Devices may struggle or completely fail to elevate loads, often due to internal component wear or insufficient hydraulic pressure.

Unstable Lifting: If a device wobbles or shifts during operation, it may indicate worn-out wheels or structural instability, posing a serious safety risk.

Excessive Noise: Unusual sounds during operation can signal mechanical issues, such as damaged gears or bearings, which should be investigated without delay.

Corrosion and Rust: Exposure to moisture can lead to deterioration of metal components, compromising strength and functionality. Regular inspections can help mitigate this risk.

By delving into these common failures, users can ensure their lifting equipment remains safe and reliable for all tasks.

Maintenance Tips for Longevity

Proper care is essential for ensuring the durability and optimal performance of your lifting equipment. Regular maintenance not only enhances efficiency but also prevents unexpected breakdowns, prolonging its lifespan significantly.

Regular Inspection

- Check for any signs of wear and tear.

- Inspect hydraulic fluid levels and look for leaks.

- Ensure all moving parts operate smoothly.

Proper Storage

- Store in a dry, clean area to avoid corrosion.

- Avoid exposure to extreme temperatures.

- Use protective covers when not in use.

By incorporating these practices into your routine, you can ultimately ensure that your equipment remains reliable and efficient for years to come.

Safety Features in Floor Jacks

Ensuring the well-being of users during lifting operations is paramount in the design of any mechanical tool. A range of innovative elements is incorporated to enhance security, preventing accidents and ensuring that the equipment operates safely under various conditions.

Critical Components for Enhanced Security

Several key features are essential for the safe operation of lifting devices. These components work together to minimize risks and provide users with peace of mind.

| Feature | Description |

|---|---|

| Safety Valve | Prevents overloading by releasing pressure, ensuring stability during use. |

| Locking Mechanism | Secures the lifting platform in place, preventing accidental descent. |

| Sturdy Base | Provides a stable foundation to reduce the risk of tipping during lifting operations. |

Importance of Regular Maintenance

Routine inspections and upkeep are vital for maintaining safety features. Ensuring that all components function correctly helps prevent potential failures that could lead to hazardous situations.

Choosing the Right Jack Size

When it comes to selecting the appropriate lifting tool for your needs, understanding dimensions and capacities is crucial. A well-suited device can ensure safety and efficiency while handling various tasks. Whether you are working on a vehicle or other heavy objects, choosing the right size significantly impacts performance and usability.

Understanding Capacity Requirements

Before making a choice, assess the weight of the items you intend to lift. Each tool has a specific load limit, and selecting one that can comfortably support the weight is essential. Overloading can lead to malfunction or accidents, so it’s wise to opt for a model that exceeds the expected load.

Height and Reach Considerations

Another factor to consider is the height and reach of the device. Different tasks may require varying lifting heights. Ensure that the model you select can raise the object to the necessary elevation. Additionally, check the minimum height to ensure it can fit under the load when not elevated. This consideration is key for stability and effectiveness during operation.

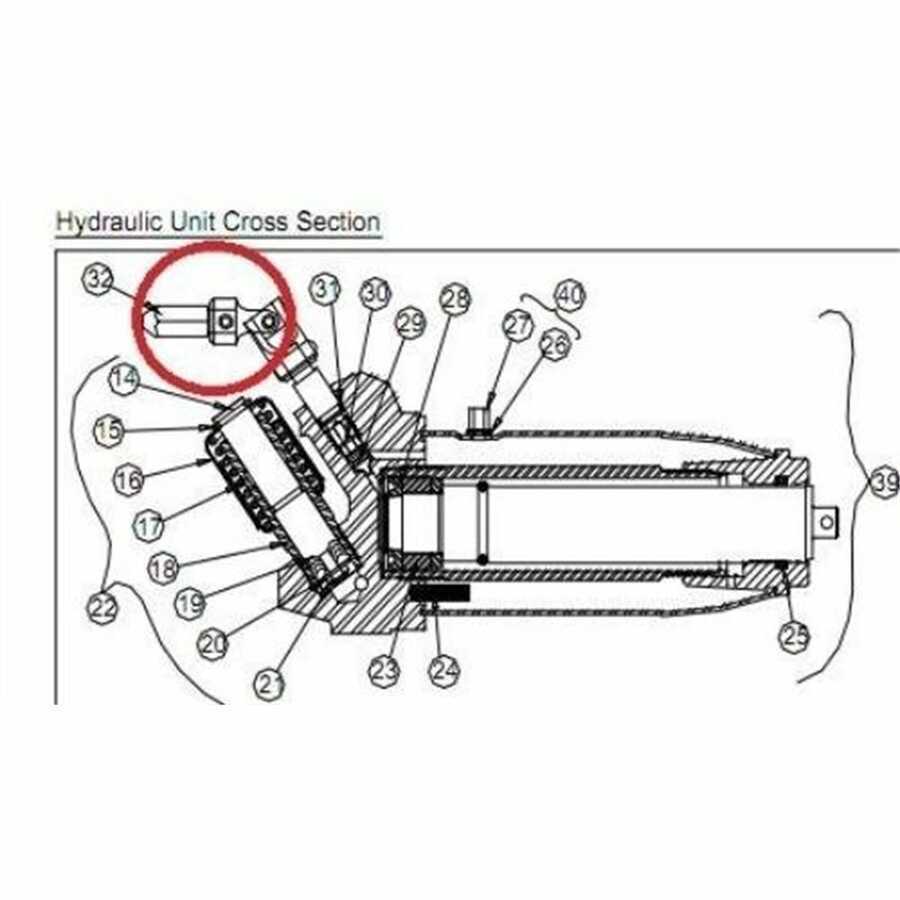

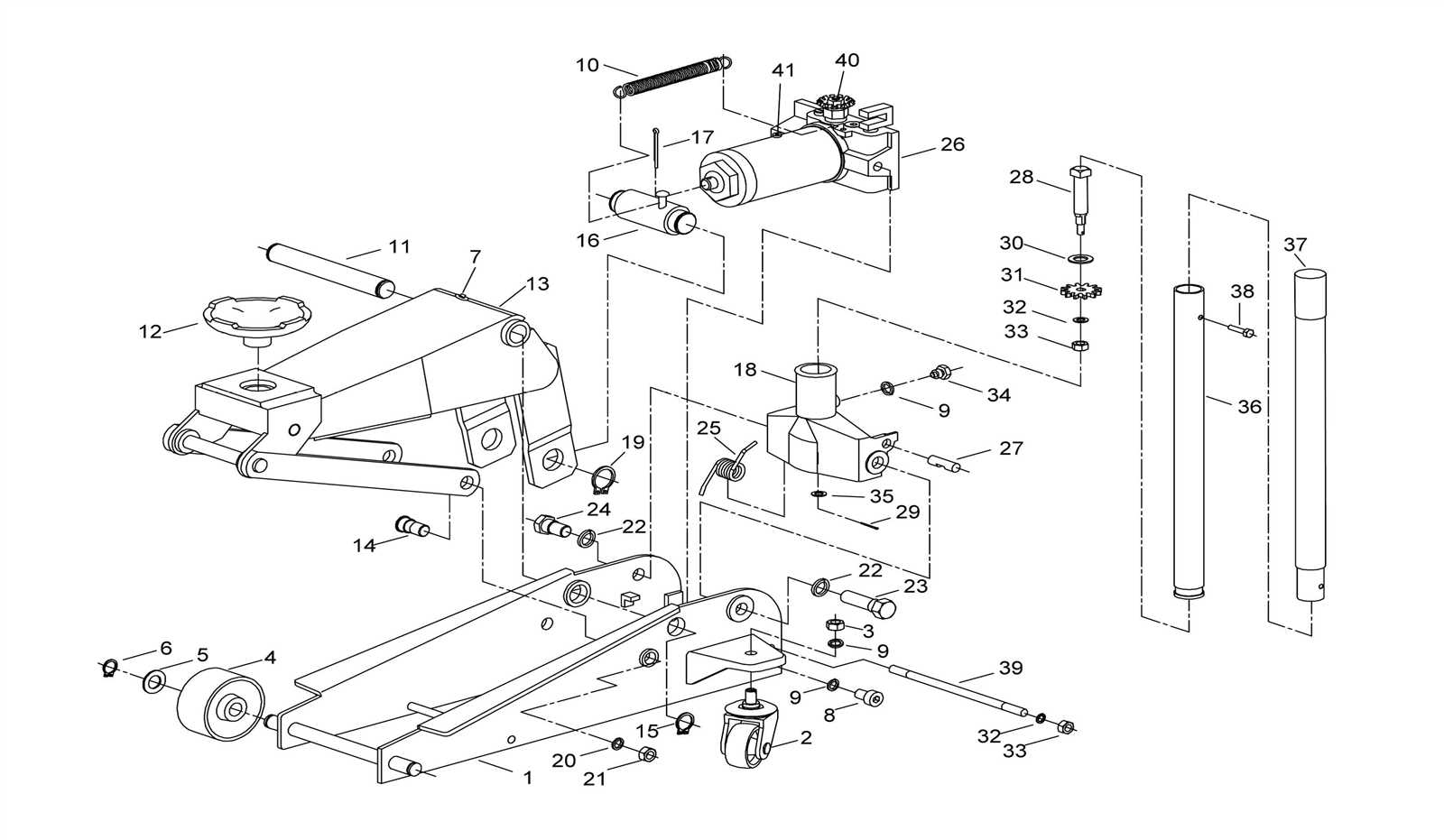

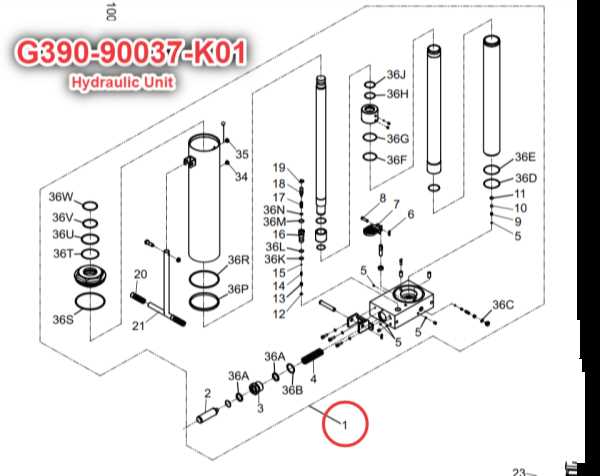

Assembly Diagram Overview

This section provides a comprehensive look at the components involved in the construction and operation of lifting devices. Understanding the arrangement and function of each element is crucial for effective maintenance and troubleshooting.

Key components typically include:

- Base: The foundation that supports the entire mechanism.

- Piston: Responsible for creating the lifting force.

- Handle: Used to operate the system, facilitating the lifting and lowering actions.

- Release Valve: Controls the descent of the lifted load.

- Wheels: Allow for mobility and positioning of the unit.

Each of these components plays a vital role in ensuring safety and efficiency. A clear understanding of their layout aids in the assembly process and enhances overall functionality.

- Start with the base to ensure stability.

- Attach the piston securely to facilitate optimal performance.

- Integrate the handle for ease of use.

- Install the release valve to maintain control.

- Affix the wheels for convenient movement.

Reviewing this arrangement will empower users to engage with their equipment confidently and effectively.

Tools Needed for Repairs

When it comes to conducting maintenance or fixing equipment, having the right tools is crucial. These instruments ensure efficiency and precision during the repair process, ultimately leading to successful outcomes. Without proper tools, even simple tasks can become daunting challenges.

Essential Instruments

Among the primary items required are wrenches and screwdrivers, which allow for easy manipulation of various components. Additionally, a sturdy lifting mechanism can facilitate access to hard-to-reach areas, enhancing the overall effectiveness of repairs.

Safety Gear

Equally important is the use of safety gear. Items such as gloves and goggles protect against potential hazards, ensuring a secure working environment. Investing in these essential tools not only safeguards the individual but also promotes a more efficient repair process.

Signs Your Jack Needs Replacement

Recognizing the signs that your lifting device requires replacement is crucial for safety and efficiency. Over time, wear and tear can lead to performance issues that may compromise your tasks.

Common Indicators

Look for specific symptoms that signal it’s time for a new model. These can include visible damage, reduced lifting capacity, and unusual noises during operation.

Assessment Checklist

| Indicator | Description |

|---|---|

| Visible Damage | Cracks or bends in the structure that could affect stability. |

| Fluid Leaks | Any signs of leaking hydraulic fluid indicate potential failure. |

| Poor Lifting Performance | Inability to lift to the expected height or hold weight securely. |

| Unusual Noises | Grinding or hissing sounds can indicate internal issues. |

Comparing Manual vs. Electric Jacks

The choice between manual and electric lifting devices often comes down to efficiency, convenience, and personal preference. Each type offers unique advantages and potential drawbacks, making it essential to consider various factors before making a decision. This comparison highlights key differences that may influence your choice.

| Feature | Manual | Electric |

|---|---|---|

| Operation | Requires physical effort | Powered by electricity |

| Speed | Slower lifting process | Faster lifting capabilities |

| Portability | Lightweight and easy to transport | Heavier, needs a power source |

| Maintenance | Less prone to technical issues | May require more upkeep |

| Cost | Generally more affordable | Typically higher initial investment |

In summary, selecting the appropriate lifting tool hinges on individual needs and circumstances. While manual devices may appeal to those seeking simplicity and cost-effectiveness, electric options provide speed and ease of use for more demanding tasks.

How to Use a Floor Jack Safely

Ensuring safety during the lifting process of vehicles is paramount. Proper techniques and precautions are essential to prevent accidents and ensure a smooth operation. This section outlines the best practices for handling lifting equipment effectively.

Preparation Before Lifting

- Choose a stable and flat surface to work on.

- Inspect the equipment for any signs of wear or damage.

- Make sure the lifting device is rated for the weight of the vehicle.

- Clear the area of any obstacles and ensure adequate lighting.

Safe Lifting Procedures

- Position the lifting device under the vehicle’s designated lift points.

- Slowly raise the vehicle, monitoring for stability.

- Once lifted, securely place jack stands to support the vehicle.

- Never work under a vehicle supported solely by the lifting device.

By following these guidelines, you can help ensure a safer lifting experience and reduce the risk of injury or damage. Always prioritize safety and proceed with caution during every step of the process.