In the realm of commercial transportation, comprehending the intricate structure of large vehicles is essential for optimal performance and longevity. Each element plays a pivotal role, contributing to the overall functionality and efficiency of the machine.

By examining the various sections and their respective functionalities, one can gain valuable insights into how these vehicles operate. This knowledge is not only beneficial for maintenance but also crucial for ensuring that every journey is smooth and safe.

As we delve into the details, the ultimate aim is to provide a comprehensive overview that aids owners and operators in making informed decisions regarding upkeep and repairs. Understanding the layout of these vital components can significantly enhance operational effectiveness.

Understanding Freightliner M2 Components

Grasping the intricacies of heavy-duty vehicles requires familiarity with their various elements and systems. Each component plays a vital role in ensuring optimal performance and safety, contributing to the overall functionality of the machine. A thorough comprehension of these elements can enhance maintenance efforts and facilitate repairs.

| Component | Description |

|---|---|

| Chassis | The main framework that supports the vehicle’s body and components. |

| Engine | The power source that drives the vehicle, providing the necessary energy for operation. |

| Transmission | System responsible for transferring power from the engine to the wheels. |

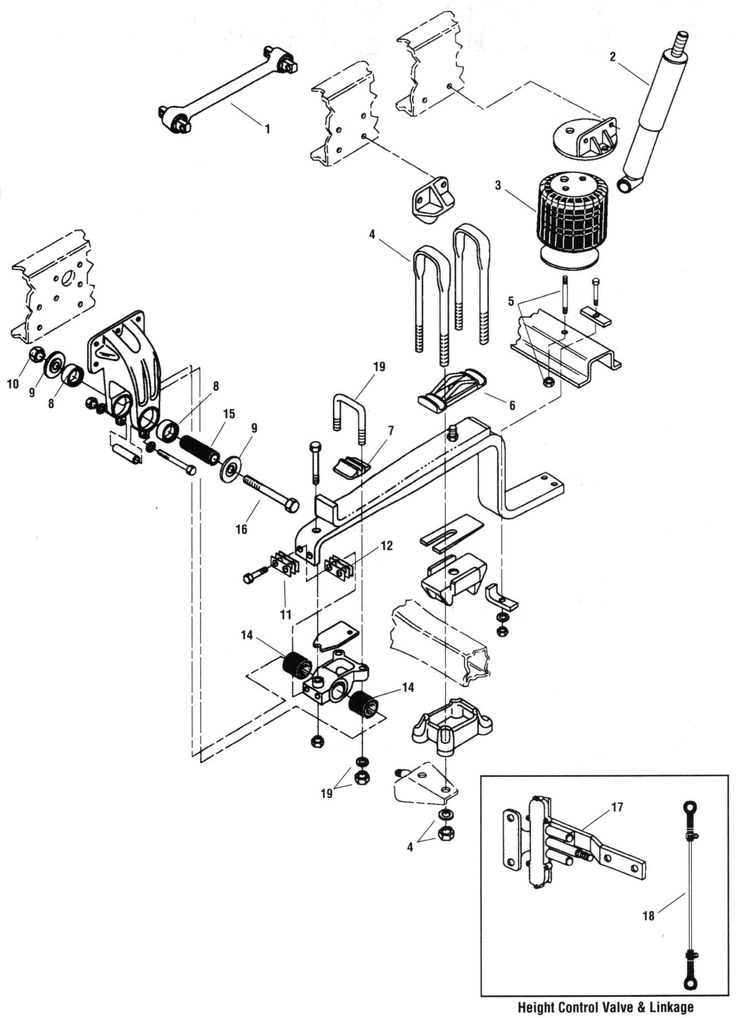

| Suspension | System that absorbs shocks and provides stability while driving. |

| Braking System | Critical for safety, it allows the operator to slow down or stop the vehicle. |

Importance of Parts Diagrams

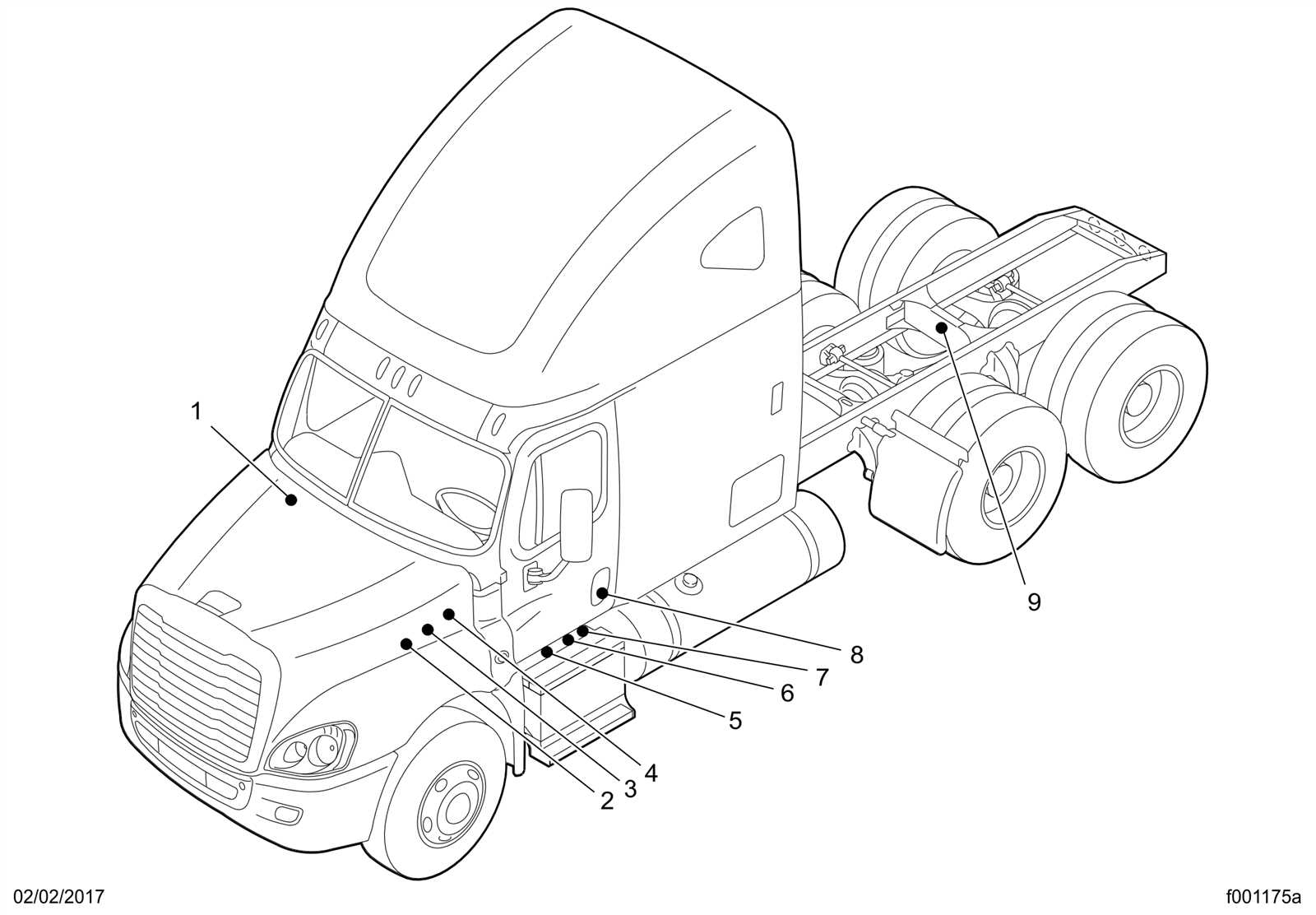

Understanding the components of a vehicle is crucial for effective maintenance and repair. Visual representations that illustrate each element play a significant role in helping technicians and enthusiasts alike grasp the intricate details of machinery. These illustrations not only simplify the identification process but also enhance the overall efficiency of maintenance tasks.

Facilitating Accurate Repairs

Visual guides enable mechanics to pinpoint specific items quickly, ensuring that repairs are carried out with precision. By having a clear view of where each element fits within the system, technicians can avoid mistakes that may lead to further complications or damage.

Streamlining Maintenance Processes

Illustrative materials also aid in organizing regular upkeep tasks. By knowing the exact location and function of various components, vehicle owners can proactively address potential issues before they escalate, thereby prolonging the lifespan of their machinery.

Key Parts of Freightliner M2

This section explores essential components that contribute to the performance and functionality of the vehicle, highlighting their significance in overall operation and maintenance.

Core Elements

- Engine: The powerhouse driving the vehicle.

- Transmission: Responsible for power delivery and speed management.

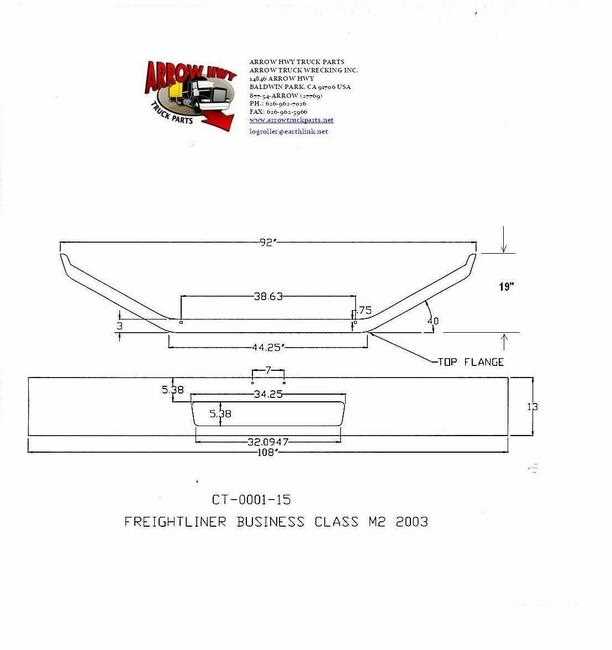

- Chassis: The framework supporting the entire structure.

- Brakes: Crucial for safety and stopping efficiency.

Additional Components

- Suspension: Enhances ride comfort and stability.

- Fuel System: Supplies energy for operation.

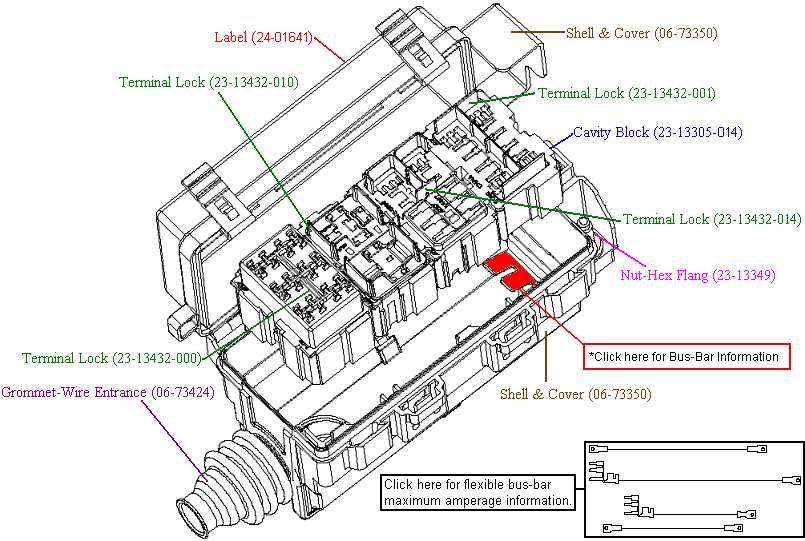

- Electrical System: Powers all electronic features and functionalities.

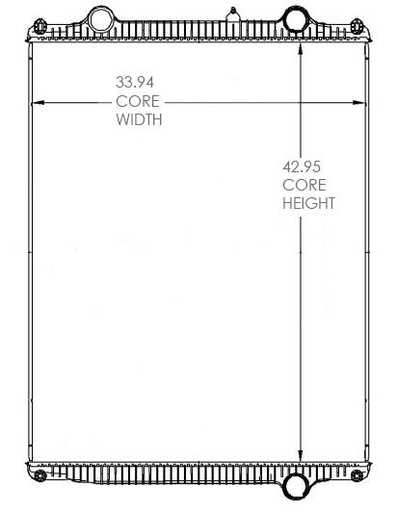

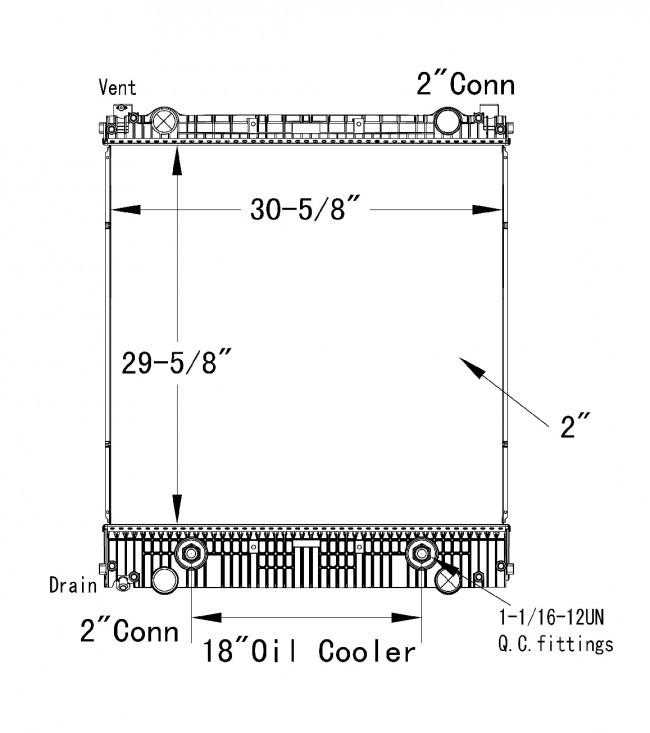

- Cooling System: Maintains optimal engine temperature.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repairs. These illustrations provide valuable information on the layout and relationships between various elements.

Here are some key points to consider when interpreting these visuals:

- Identify Key Symbols: Familiarize yourself with the symbols used in the illustration, as they often represent specific parts or functions.

- Follow Numbering: Components are usually numbered for easy reference. Ensure you follow the sequence to avoid confusion.

- Check Legends: Look for a legend or key that explains the markings and symbols used, providing clarity on the representation.

- Study Connections: Pay attention to how parts are connected. This will help you understand assembly and disassembly processes.

By mastering these aspects, you can effectively navigate the visual layout and enhance your repair skills.

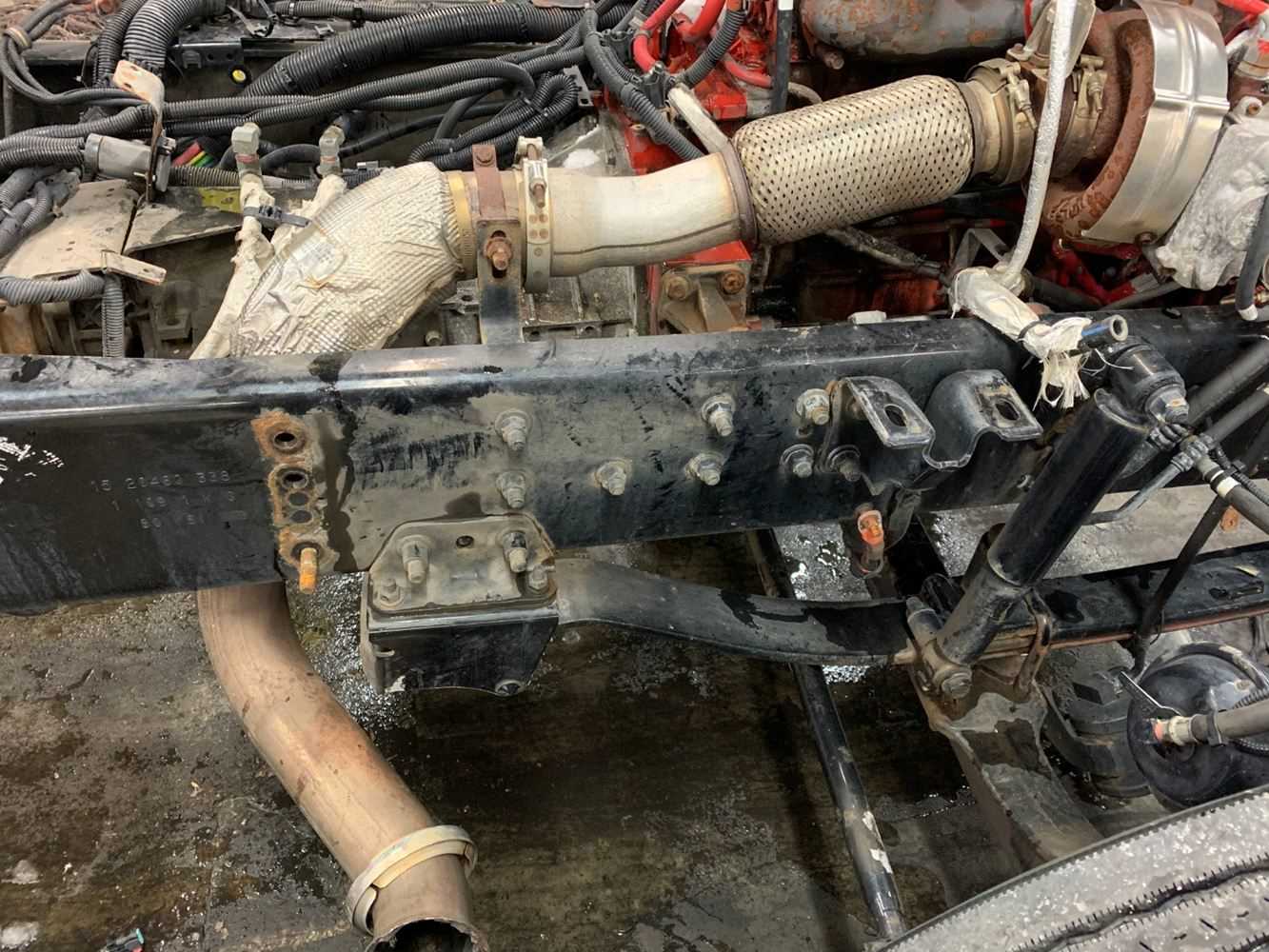

Common Issues with M2 Parts

When it comes to heavy-duty vehicles, understanding the potential challenges associated with their components is crucial for maintaining performance and longevity. Various factors can lead to complications that may affect the overall functionality and reliability of the vehicle.

Some frequent problems that operators may encounter include:

- Wear and tear on essential components due to heavy usage.

- Corrosion caused by exposure to harsh weather conditions.

- Electrical system malfunctions stemming from poor connections or damaged wiring.

- Fluid leaks resulting from deteriorating seals or gaskets.

- Overheating of the engine due to inadequate cooling system efficiency.

Addressing these issues promptly can help prevent further damage and costly repairs. Regular maintenance and inspections play a key role in identifying and resolving these common challenges.

To ensure the vehicle operates smoothly, consider the following maintenance tips:

- Conduct routine checks on fluid levels and quality.

- Inspect electrical connections for signs of wear or corrosion.

- Monitor component wear and replace as necessary.

- Ensure the cooling system is functioning correctly to avoid overheating.

- Schedule regular maintenance with qualified technicians.

By being proactive and attentive to these issues, operators can enhance the performance and lifespan of their heavy-duty vehicles.

Where to Find Replacement Parts

Finding suitable components for your vehicle can be a straightforward process if you know where to look. Numerous resources are available to help you locate quality replacements, whether online or in local stores.

Online Resources

Websites dedicated to automotive supplies offer a wide range of options. Major retailers often provide detailed catalogs, allowing you to explore various components and compare prices easily. Additionally, specialized forums and communities can offer valuable insights and recommendations.

Local Dealers and Salvage Yards

Visiting local dealerships can yield authentic replacements, while salvage yards often have affordable alternatives. Engaging with knowledgeable staff can help you delve into the best options suited for your needs, ensuring you find the ultimate fit for your vehicle.

Maintenance Tips for Freightliner M2

Proper upkeep of your vehicle is crucial for ensuring longevity and optimal performance. Regular maintenance not only enhances reliability but also minimizes the risk of costly repairs. Here are some essential tips to keep your truck in peak condition.

- Regular Inspections: Conduct thorough checks on all vital components, including brakes, tires, and fluids.

- Fluid Levels: Monitor and maintain appropriate levels of oil, coolant, and transmission fluid to prevent overheating and wear.

- Brake System Maintenance: Inspect the braking system regularly for wear and tear. Replace pads and rotors as necessary.

- Tire Care: Rotate tires periodically and check for proper inflation to ensure even wear and improved fuel efficiency.

- Battery Check: Inspect battery connections for corrosion and ensure the charge is sufficient for reliable starts.

Implementing these tips can significantly enhance the performance and lifespan of your truck. Always refer to the manufacturer’s guidelines for specific recommendations.

- Keep a Maintenance Log: Documenting services performed helps track maintenance history and schedules.

- Replace Worn Components: Address any signs of wear promptly to avoid further damage or breakdowns.

- Use Quality Parts: When replacements are necessary, opt for high-quality components that meet or exceed specifications.

- Stay Informed: Keep up with any recalls or service bulletins related to your model to address potential issues proactively.

Following these guidelines will ensure your vehicle operates smoothly and efficiently, safeguarding your investment over time.

Upgrading Components for Performance

Enhancing the efficiency and capabilities of your vehicle can lead to significant improvements in its overall performance. By focusing on specific elements, you can achieve better power output, improved fuel economy, and increased durability. This approach not only optimizes your vehicle’s potential but also contributes to a more enjoyable driving experience.

| Component | Benefits | Upgrade Options |

|---|---|---|

| Engine | Increased horsepower and torque | Aftermarket tuners, performance chips |

| Exhaust System | Better airflow and reduced back pressure | High-performance headers, cat-back systems |

| Suspension | Improved handling and stability | Upgraded shocks, performance springs |

| Brakes | Enhanced stopping power and safety | Slotted rotors, performance pads |

Tools Needed for Parts Replacement

When undertaking the task of replacing components in heavy-duty vehicles, having the right instruments at your disposal is essential for efficiency and safety. A well-equipped toolkit not only simplifies the process but also minimizes the risk of damage to surrounding systems. Understanding which tools are necessary ensures that the job can be completed smoothly and effectively.

Basic Hand Tools

To start, a selection of basic hand tools is crucial. These include wrenches, sockets, and screwdrivers. Each tool serves a specific function, enabling you to loosen or tighten bolts and screws with ease. A reliable ratchet set can significantly speed up the work, while an array of pliers can help with gripping and manipulating various components.

Specialized Equipment

In addition to standard tools, certain specialized equipment may be required for more complex tasks. For instance, a torque wrench is essential for ensuring that fasteners are tightened to the manufacturer’s specifications. Furthermore, a multimeter can assist in diagnosing electrical issues, while a hydraulic jack provides the necessary lift for easier access to undercarriage elements. Having these specialized tools on hand can greatly enhance the effectiveness of your maintenance efforts.

Freightliner M2 Parts Suppliers Overview

This section provides an insight into the various sources where components for a specific truck model can be obtained. Understanding the landscape of suppliers is crucial for ensuring quality and availability. Each supplier offers distinct advantages, making it essential to choose wisely based on needs and budget.

Types of Suppliers

- Original Equipment Manufacturers (OEMs): These suppliers provide components that meet the manufacturer’s specifications, ensuring compatibility and reliability.

- Aftermarket Providers: Offering a range of options at competitive prices, these suppliers often focus on performance enhancements and cost-effective alternatives.

- Salvage Yards: A resource for used components, salvage yards can be an economical choice for those looking to repair rather than replace.

Considerations for Choosing a Supplier

- Quality Assurance: Ensure that the components meet industry standards and have a good reputation for durability.

- Pricing: Compare prices among different suppliers to find the best value for your investment.

- Customer Service: A supplier that offers excellent support can make a significant difference in the purchasing experience.

- Availability: Check stock levels and delivery options to minimize downtime during repairs or maintenance.