In the world of machinery and equipment, having a clear visual representation of individual elements is essential for effective maintenance and assembly. This overview serves to illustrate the various sections and components involved in a specific device, allowing users to familiarize themselves with its structure and functionality.

By examining the arrangement and relationships between different units, operators can enhance their understanding of how the system works. This knowledge not only aids in troubleshooting but also contributes to more efficient repairs and upgrades, ultimately prolonging the lifespan of the equipment.

Whether you are a technician or an enthusiast, grasping the intricacies of component layout empowers you to approach tasks with confidence. Such insights pave the way for informed decisions and precise actions, fostering a deeper appreciation for the mechanics at play.

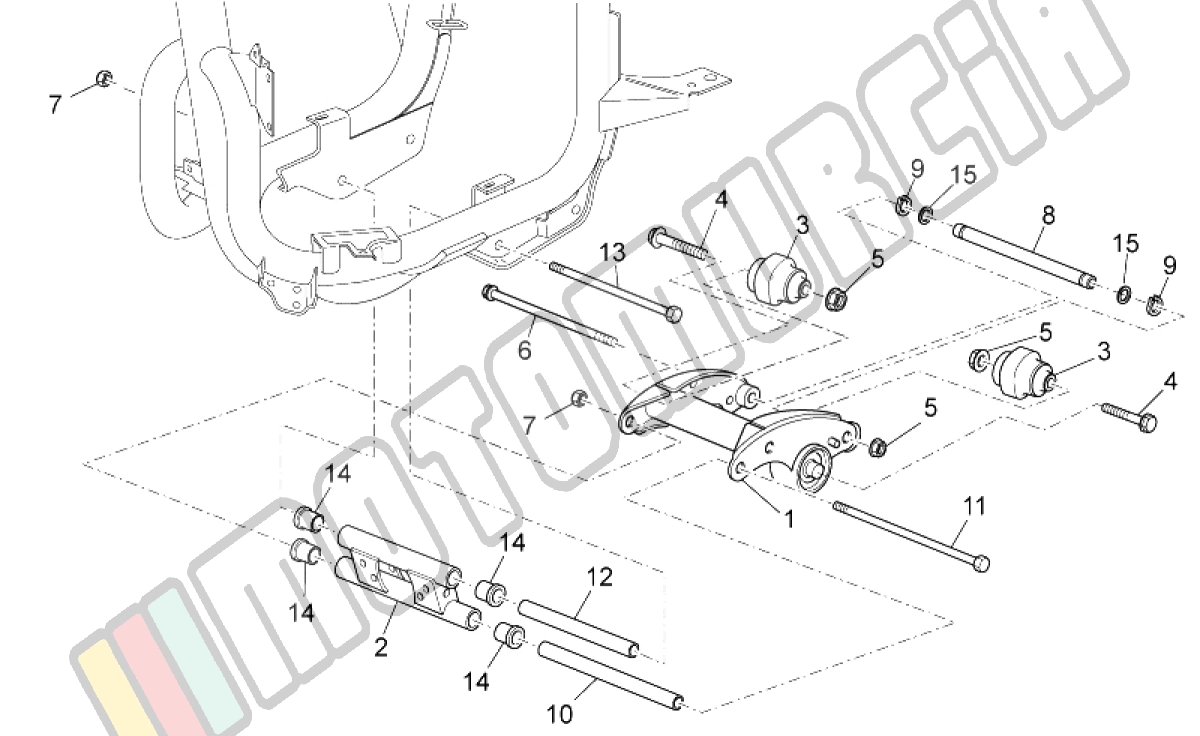

Understanding the FS75 Components

The intricate assembly of the machinery encompasses various elements, each playing a crucial role in its functionality. Recognizing these components enhances one’s ability to maintain and troubleshoot effectively.

Each element is designed to fulfill specific tasks, contributing to the overall performance of the system. Familiarity with their functions aids in ensuring optimal operation and longevity.

By examining the individual parts, one can identify potential issues and implement timely interventions. This understanding is vital for anyone involved in the upkeep and management of the equipment.

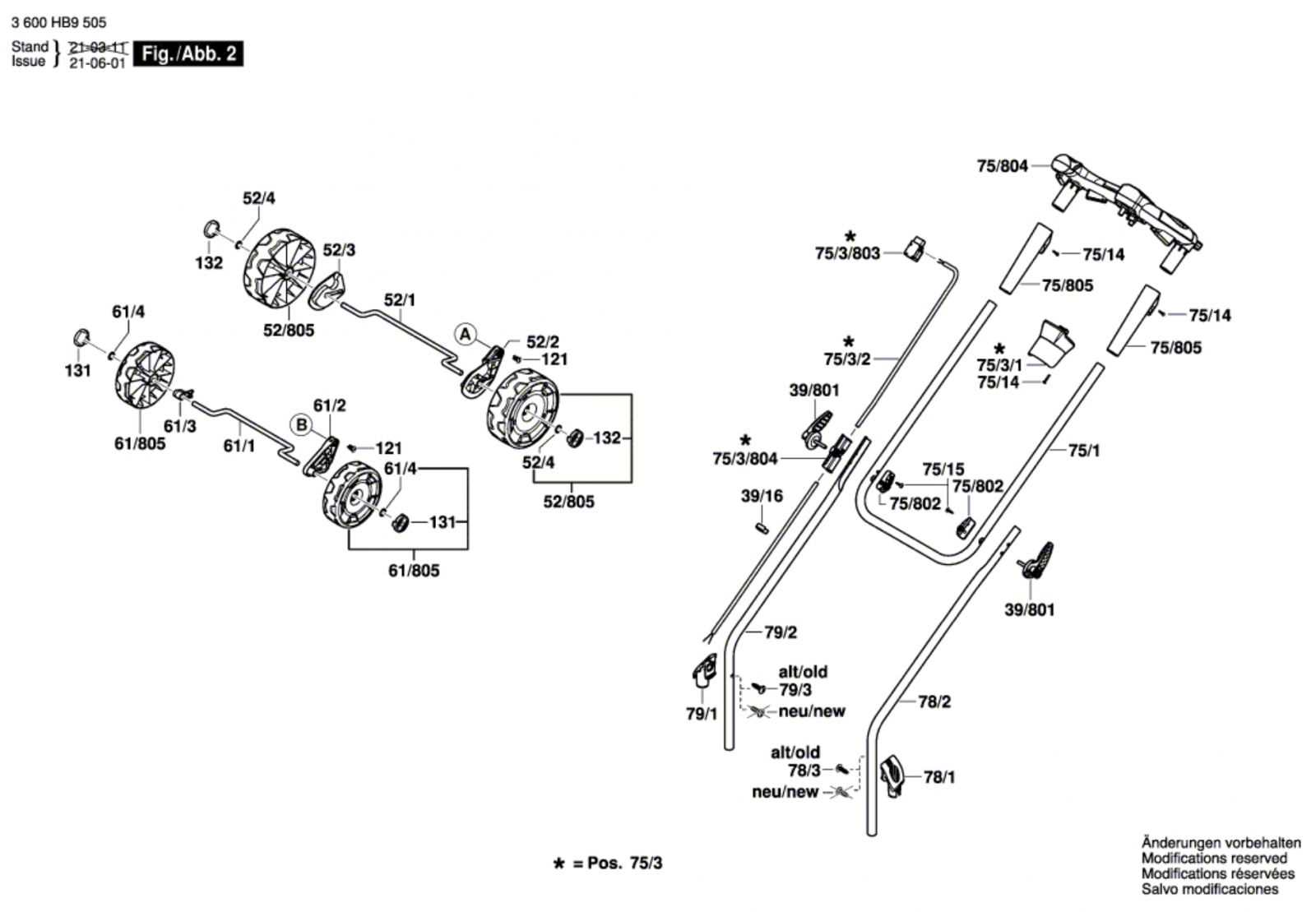

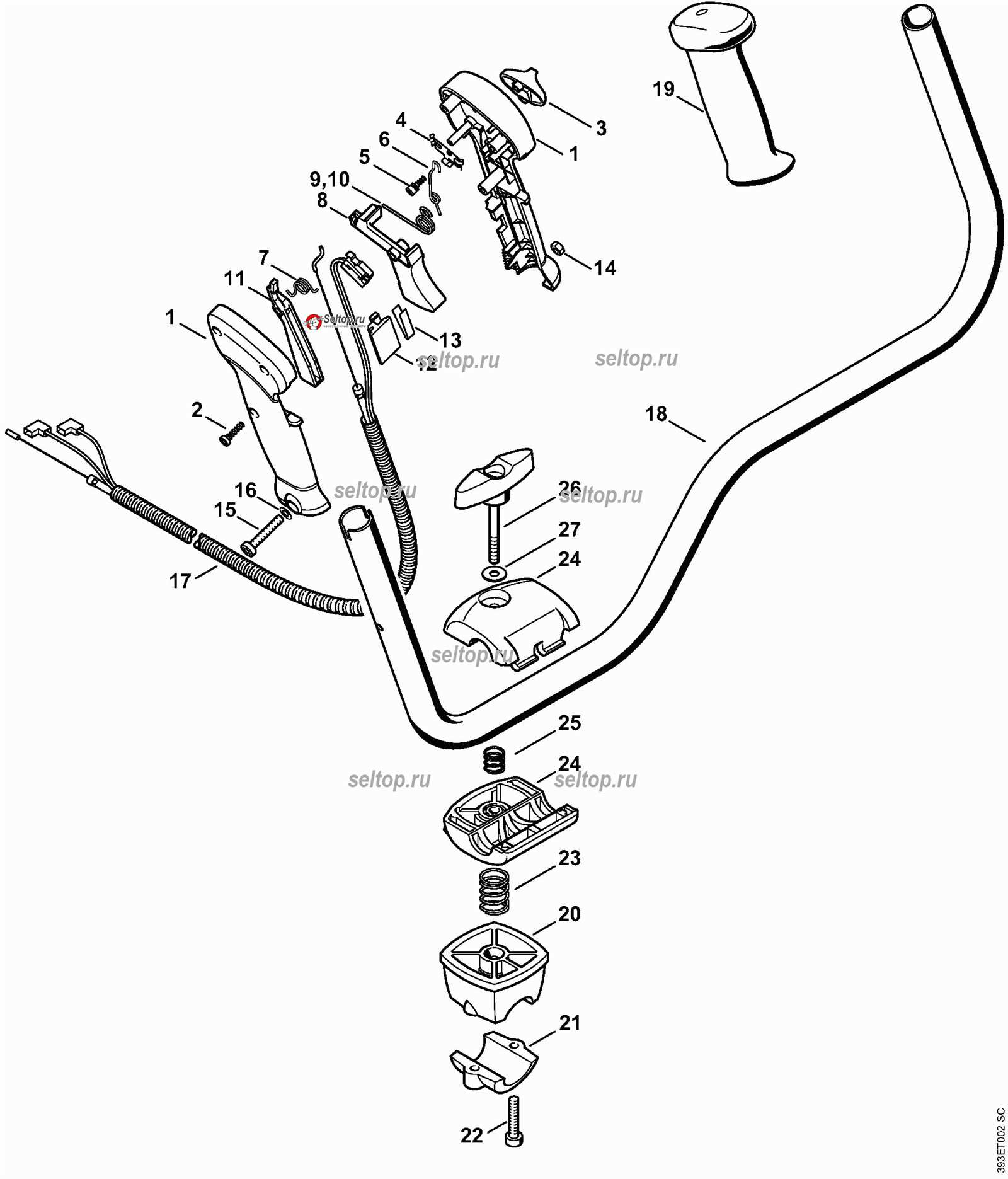

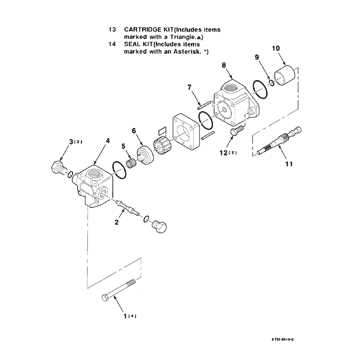

Detailed Overview of Main Parts

This section provides a comprehensive examination of the essential components that constitute the machinery, focusing on their functions and interrelations. Understanding these elements is crucial for effective operation and maintenance.

Key Components and Their Functions

The following table summarizes the primary components along with their respective roles:

| Component | Function |

|---|---|

| Engine | Drives the machinery, converting fuel into mechanical energy. |

| Transmission | Transfers power from the engine to the wheels, enabling movement. |

| Hydraulic System | Facilitates various operations through fluid pressure, enhancing performance. |

| Chassis | Supports all components, providing structural integrity and stability. |

Interconnections Between Components

The effectiveness of the machinery relies heavily on the seamless interaction between these elements. Proper alignment and maintenance are essential to ensure optimal performance and longevity.

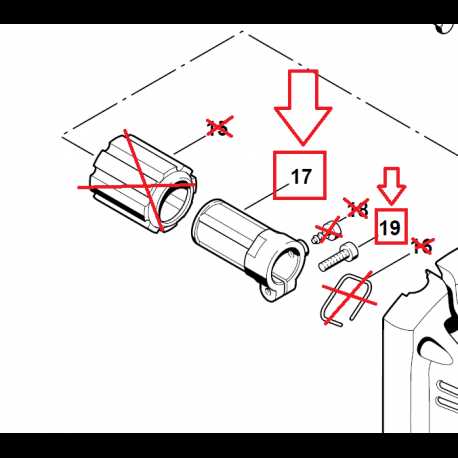

How to Read the Diagram

Understanding technical illustrations is essential for effectively identifying components and their interconnections. This section provides guidance on interpreting these visuals to enhance comprehension of the assembly.

Key Elements to Observe

Focus on the symbols and labels used within the illustration. Each icon typically represents a specific element, while accompanying text provides valuable context regarding its function and positioning.

Step-by-Step Approach

To facilitate understanding, follow these steps:

| Step | Action |

|---|---|

| 1 | Identify the main sections of the illustration. |

| 2 | Review labels and symbols for clarity. |

| 3 | Cross-reference with user manuals for detailed information. |

Common Issues and Solutions

In any mechanical system, users may encounter a variety of challenges that can impact performance. Identifying these common problems and their respective solutions can significantly enhance efficiency and longevity.

Frequent Problems

- Inconsistent functionality

- Excessive noise during operation

- Wear and tear on critical components

Recommended Solutions

- Regular maintenance and lubrication of moving parts.

- Immediate replacement of worn-out components to prevent further damage.

- Consultation with a professional for complex issues to ensure proper diagnosis.

Maintenance Tips for FS75

Proper upkeep of your equipment ensures optimal performance and longevity. Regular attention to key areas can prevent issues and enhance efficiency.

Routine Inspections

Conduct frequent checks on essential components to identify wear or damage early. Look for signs of corrosion or loose fittings that could impact functionality.

Cleaning and Lubrication

Keep surfaces clean and apply suitable lubricants to moving parts. This practice reduces friction and helps maintain smooth operation.

| Task | Frequency |

|---|---|

| Visual inspection | Weekly |

| Deep cleaning | Monthly |

| Lubrication | Every 3 months |

Replacement Parts Availability

Access to suitable components is crucial for maintaining optimal functionality in machinery. Understanding the availability of these elements ensures seamless operation and reduces downtime during repairs.

Sources for Component Acquisition

Numerous suppliers provide access to essential replacements, ranging from official manufacturers to independent retailers. Online platforms often offer a wide range of options, allowing users to compare prices and availability easily.

Considerations for Selection

When choosing replacements, it is important to consider quality and compatibility. Opting for reputable brands can enhance performance and longevity, while checking specifications guarantees a proper fit. Investing in reliable components ultimately leads to better outcomes and sustained efficiency.

Assembly Instructions for FS75

This section provides essential guidance for the assembly process of the equipment, ensuring each component is correctly positioned for optimal functionality. Following these instructions will help streamline the setup and enhance performance.

Preparation Steps

Before beginning, gather all necessary components and tools. Ensure that the workspace is clean and organized to facilitate a smooth assembly experience.

Assembly Procedure

Start by connecting the base unit with the designated sections, following the provided sequence. Secure each part firmly, checking for proper alignment to prevent any operational issues.

Upgrades for Improved Performance

Enhancing the efficiency of machinery can significantly impact overall productivity and longevity. By integrating advanced components and technologies, users can experience a noticeable improvement in operation and reliability. This section explores various enhancements that can elevate performance and functionality.

Component Enhancements

Upgrading specific elements, such as motors and filters, can lead to better energy efficiency and reduced wear. High-quality replacements ensure smoother operation and lower maintenance costs.

Technological Innovations

Incorporating modern control systems and sensors allows for greater precision and responsiveness. These advancements can optimize performance and provide valuable insights into operational conditions, enabling proactive adjustments.

Safety Precautions When Handling Parts

Ensuring safety during the manipulation of components is essential to prevent accidents and injuries. Proper practices help maintain a secure environment while working with various elements.

Here are key considerations to keep in mind:

- Always wear appropriate personal protective equipment (PPE) such as gloves and goggles.

- Ensure the workspace is clean and organized to avoid tripping hazards.

- Be aware of sharp edges and potential pinch points during handling.

- Use tools designed for the specific tasks to minimize risks.

- Follow the manufacturer’s guidelines for safe handling procedures.

By adhering to these precautions, you can significantly reduce the likelihood of mishaps while working with components.

Comparative Analysis with Similar Models

This section explores the distinctions and similarities among various models in the same category, highlighting key features and performance metrics. By examining these alternatives, users can better understand the unique advantages offered by each design, leading to informed decisions when selecting equipment.

In comparing functionality, attention is given to operational efficiency, durability, and user-friendliness. Many models share similar specifications, yet subtle differences can greatly impact overall performance and suitability for specific tasks. Features such as weight, size, and ease of maintenance often set leading products apart in practical applications.

Furthermore, an analysis of customer feedback and expert reviews provides insight into user experiences, shedding light on reliability and serviceability. Such evaluations are crucial for potential buyers aiming to identify the most effective solutions for their needs, ensuring they invest in a model that aligns with their expectations.

Frequently Asked Questions About FS75

This section addresses common inquiries regarding the specific model and its components. Here, you will find clarifications and insights that may assist users in understanding various aspects of the equipment.

What are the main features of this model? This unit is designed with various functionalities that enhance its efficiency and usability.

Where can I find replacement components? Replacement items can typically be sourced from authorized dealers or specialized online platforms.

How do I troubleshoot common issues? Many challenges can be resolved by following standard guidelines provided in the user manual.

Is there a warranty available for this equipment? Most manufacturers offer a warranty, covering specific repairs and replacements within a designated period.