In the realm of agricultural technology, comprehending the intricate elements of machinery is essential for optimal functionality. A detailed exploration of various components reveals their interconnections and roles in enhancing performance. By analyzing these intricate systems, users can better maintain and operate their equipment efficiently.

Identifying key elements allows operators to troubleshoot issues swiftly, ensuring minimal downtime during critical farming operations. Furthermore, grasping the layout of these mechanisms fosters improved handling and increases the lifespan of the equipment.

Equipped with a thorough understanding of how each component contributes to the overall system, farmers and operators can make informed decisions about repairs and upgrades. This knowledge ultimately leads to a more productive and effective agricultural practice.

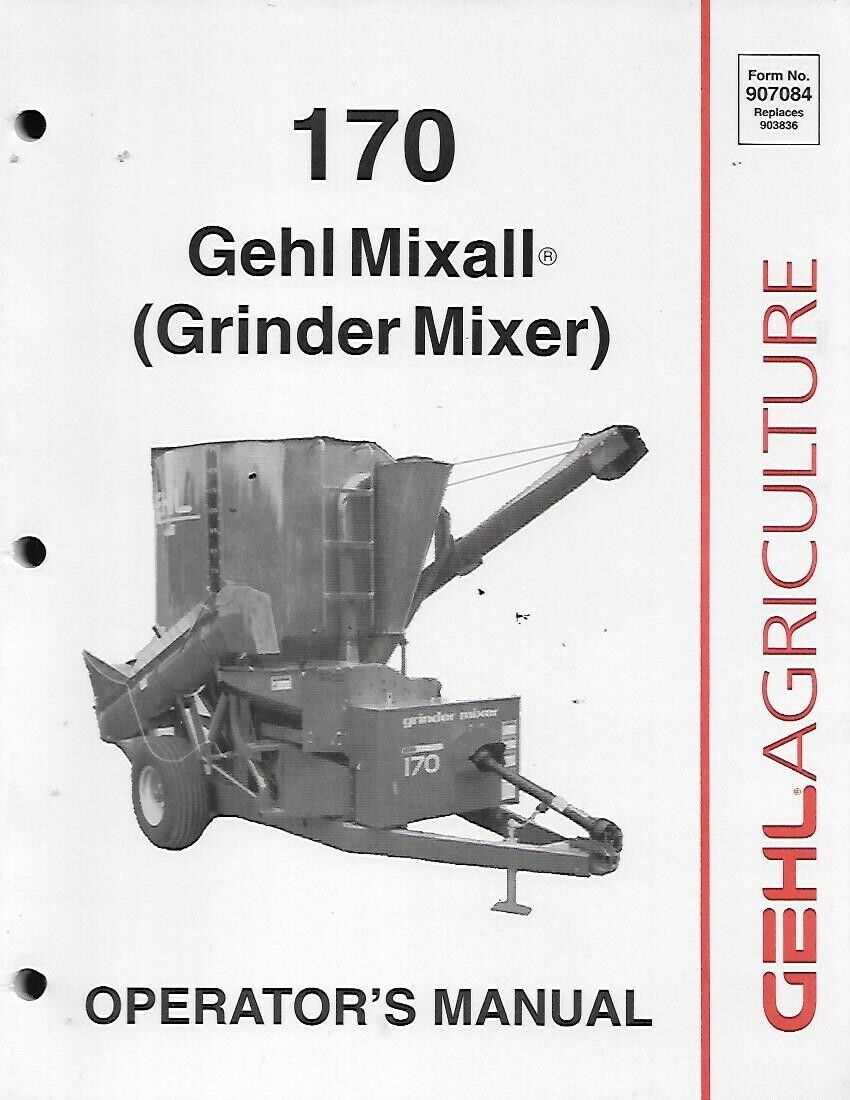

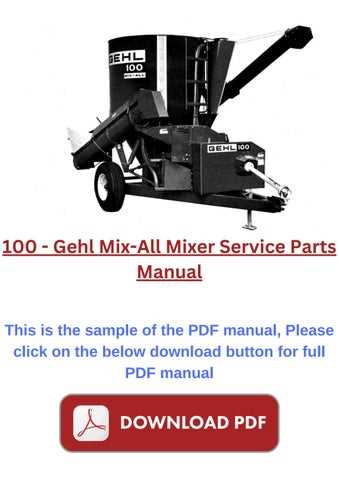

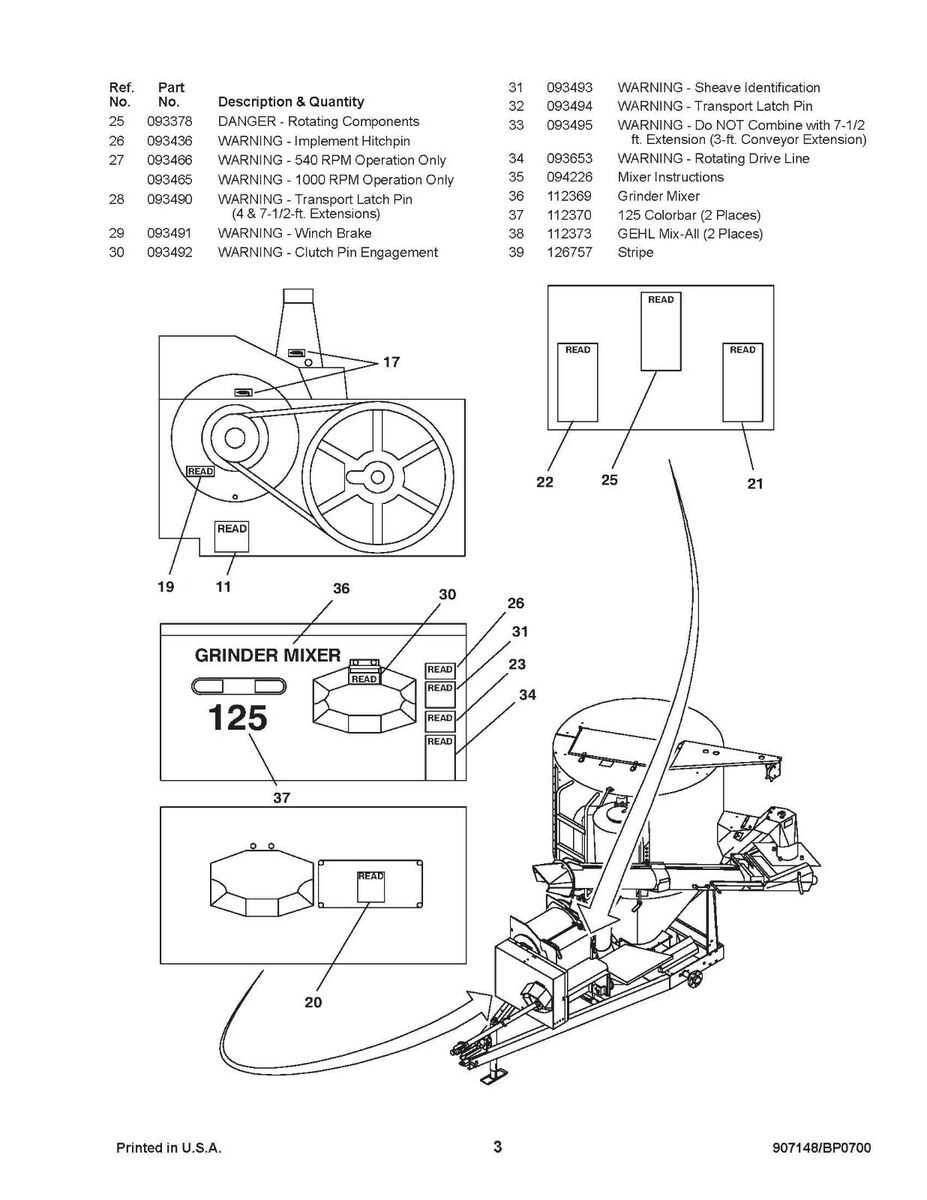

Gehl 100 Grinder Mixer Overview

This section provides a comprehensive examination of a well-known agricultural implement designed for efficient processing of feed materials. Its robust construction ensures durability and reliability, making it a favored choice among farmers. The equipment integrates various functionalities, allowing for seamless mixing and grinding of diverse ingredients, thus enhancing productivity and optimizing feed quality.

With its user-friendly design, operators can easily access controls and maintenance points. The machinery features a powerful engine that drives the mixing and grinding components, ensuring consistent performance even under heavy loads. Overall, this implement stands out for its effectiveness and ease of use in agricultural settings.

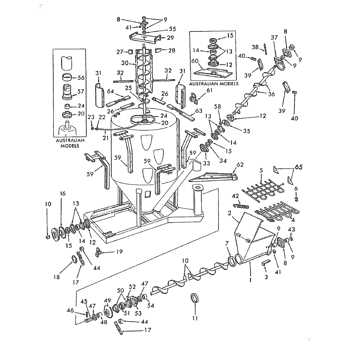

Key Components of the Mixer

This section delves into the essential elements that contribute to the functionality of the mixing apparatus. Understanding these components is crucial for optimizing performance and ensuring longevity.

Mixing Chamber

The mixing chamber serves as the core area where materials are blended. Its design facilitates even distribution and consistent texture, which is vital for achieving the desired outcome.

Power System

The power system drives the entire operation, providing the necessary energy for the machinery to function effectively. A robust power unit enhances efficiency and reliability during use.

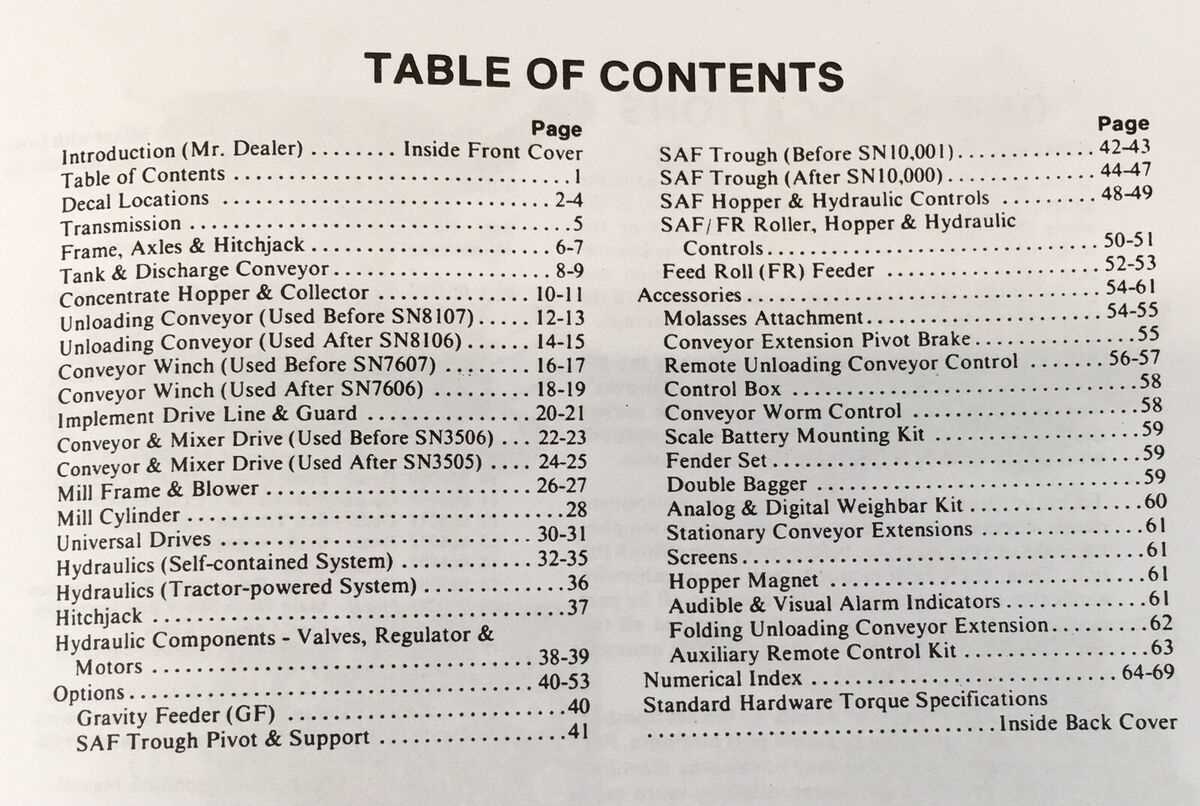

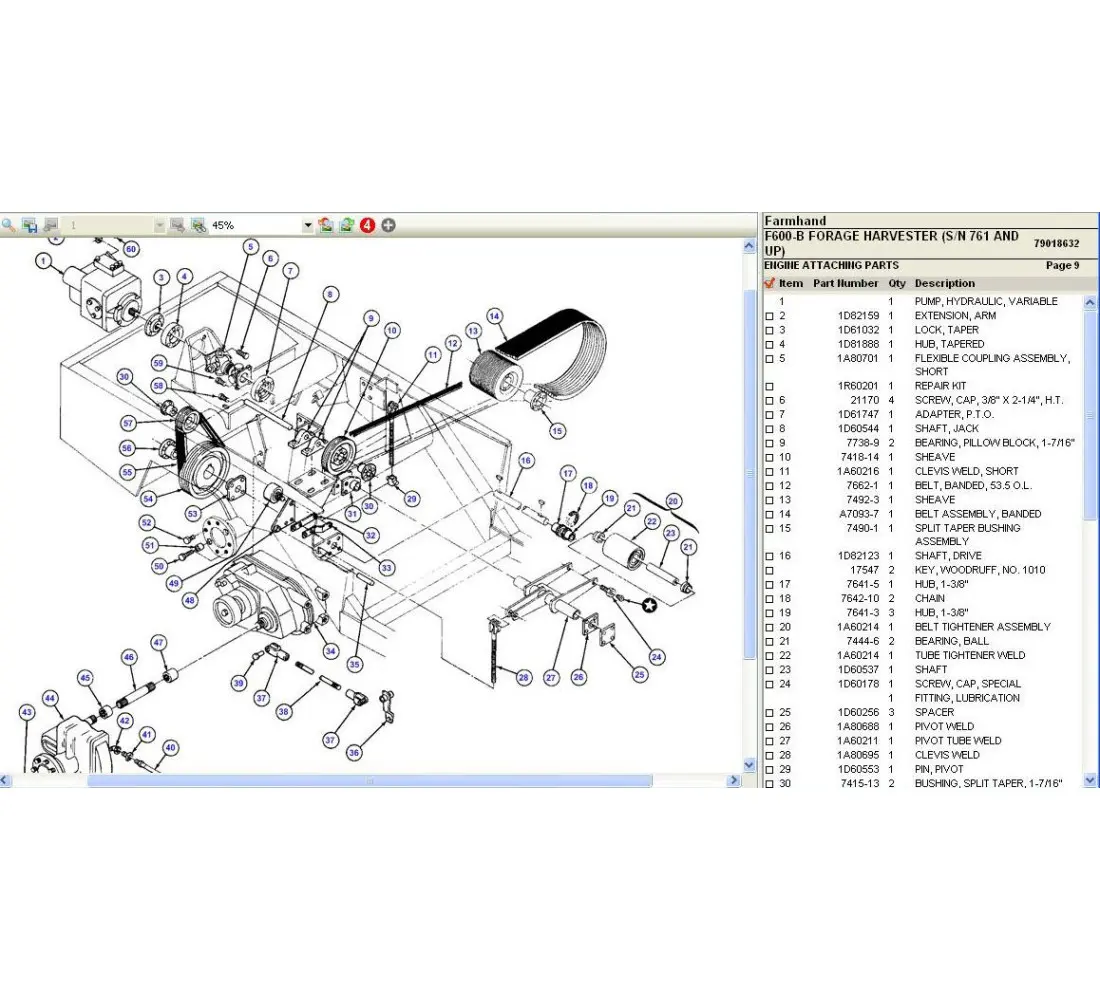

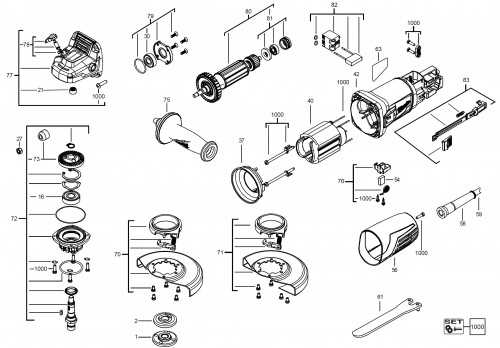

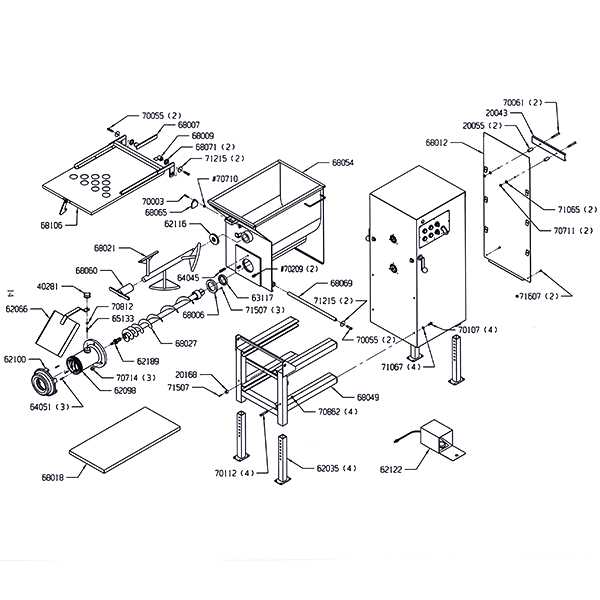

Understanding the Parts Diagram

This section provides an overview of the essential components of a specific agricultural machine. Familiarity with the layout and functionality of these elements is crucial for effective operation and maintenance.

Each segment of the illustration serves a distinct role, contributing to the overall efficiency and performance. Recognizing these various sections allows users to troubleshoot issues and perform necessary adjustments seamlessly.

| Component | Description |

|---|---|

| Element A | This part is responsible for the initial processing of materials. |

| Element B | It plays a critical role in ensuring uniformity during operation. |

| Element C | This section aids in the final output and distribution of the processed materials. |

Common Issues with Grinder Mixers

Many operators encounter various challenges when using blending machines. These devices are essential for efficiently processing ingredients, yet they can sometimes exhibit problems that affect performance and output quality.

Mechanical Malfunctions

One of the frequent issues is related to mechanical components. Users should be aware of signs that indicate potential failures.

- Unusual noises during operation

- Frequent overheating of the motor

- Inconsistent blending results

Operational Inefficiencies

Another common concern involves the overall efficiency of the machinery. Addressing these inefficiencies can enhance productivity.

- Improper calibration settings

- Clogs due to residue buildup

- Inadequate maintenance routines

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires consistent care and attention. Implementing a structured maintenance routine can significantly extend the lifespan of machinery and enhance its performance.

Regular Inspections: Conduct frequent checks to identify wear and tear. Pay attention to moving parts, as they are often the first to show signs of fatigue.

Lubrication: Keep all mechanical components well-lubricated to reduce friction and prevent overheating. Use appropriate oils and greases as specified by the manufacturer.

Cleaning: Remove debris and buildup regularly. This practice not only promotes efficiency but also helps in spotting potential issues early on.

Proper Storage: When not in use, store equipment in a dry and clean environment to avoid rust and damage from exposure to the elements.

Timely Repairs: Address any issues immediately to prevent them from escalating. Delaying repairs can lead to more significant problems and costly downtime.

How to Replace Worn Parts

Maintaining machinery in optimal condition is crucial for efficiency and longevity. Replacing outdated components ensures smooth operation and prevents further damage. Here are steps to guide you through the process.

Before starting, gather necessary tools and materials:

- Replacement components

- Wrenches and sockets

- Screwdrivers

- Lubricants

- Safety gear

Follow these essential steps for a successful replacement:

- Turn off the equipment and disconnect it from any power sources.

- Carefully remove any protective coverings to access the worn elements.

- Unscrew or unbolt the old components, taking note of their arrangement.

- Install the new parts, ensuring they fit snugly and securely.

- Replace any protective coverings and reconnect power sources.

Regular inspections and timely replacements can significantly enhance performance and safety.

Identifying Essential Spare Parts

Understanding the critical components of machinery is vital for maintaining efficiency and performance. Each element plays a specific role, contributing to the overall functionality. Recognizing these integral components ensures timely replacements and helps in avoiding costly downtimes.

Common Components to Monitor

Several key elements should be regularly inspected. These include wear items such as belts and bearings, which often show signs of fatigue over time. Additionally, hydraulic and electrical systems require special attention, as any malfunction can significantly impact operations.

Signs of Wear and Replacement

It is essential to identify early warning signs that indicate a component may need replacement. Unusual noises, vibrations, or decreased performance are all indicators that specific parts may be deteriorating. Regular maintenance checks can help pinpoint issues before they escalate, ensuring smooth operation.

Comparing Gehl 100 with Other Models

When evaluating various agricultural machinery, it is essential to consider the unique features and capabilities that distinguish each model. This section delves into a comparative analysis, highlighting how one specific model stacks up against its competitors in terms of functionality, efficiency, and overall performance.

Performance Metrics

Performance is a crucial factor in determining the effectiveness of any piece of equipment. The model in question demonstrates robust capabilities, offering reliable output and consistent results. When placed alongside alternatives, it often shows superior efficiency, making it a favored choice among users seeking optimal productivity.

Design and Usability

In terms of design, this machine features a user-friendly interface, which enhances its usability. Compared to similar products, it stands out for its intuitive controls and ergonomic design, allowing operators to work with ease and comfort. This attention to detail in design significantly impacts the overall user experience.

Safety Features of the Mixer

Ensuring safety in operational equipment is paramount for optimal performance and user protection. Advanced machines incorporate various mechanisms designed to mitigate risks, safeguarding both the operator and the surroundings. Understanding these features can enhance the overall experience and efficiency of the equipment.

Emergency Shut-Off Mechanisms

One of the primary safety enhancements includes emergency shut-off systems. These allow users to quickly halt operations in case of unforeseen incidents, minimizing potential harm. Responsive controls are crucial for maintaining a safe working environment.

Protective Guards and Shields

Incorporating protective barriers around moving parts is another vital feature. These guards prevent accidental contact with hazardous components, significantly reducing the risk of injury. Regular maintenance and inspections of these features ensure they remain effective and reliable.

Performance Enhancements and Upgrades

Improving the efficiency and functionality of agricultural equipment can lead to significant productivity gains. Upgrading specific components or incorporating advanced features can enhance overall performance and ensure optimal operation.

Several modifications can be implemented to achieve these improvements:

- Engine Upgrades: Increasing horsepower and torque can enhance overall output.

- Hydraulic System Enhancements: Optimizing hydraulic components can improve responsiveness and power.

- Feed Delivery Improvements: Modifying the delivery system can ensure a consistent and efficient process.

- Durable Materials: Utilizing higher quality materials can extend the lifespan of critical components.

- Technology Integration: Adding smart technology for monitoring and control can streamline operations.

Implementing these upgrades can ultimately lead to better performance and efficiency, maximizing the potential of the machinery.

Resources for Parts and Support

When seeking assistance with machinery maintenance and repair, numerous avenues can provide valuable information and resources. Accessing reliable support can enhance the functionality and longevity of your equipment, ensuring optimal performance.

Online Platforms

- Manufacturer’s Website: Visit the official site for access to manuals, troubleshooting guides, and customer service contacts.

- Parts Retailers: Many online stores specialize in offering components for various machines, often featuring schematics and customer reviews.

- Forums and Communities: Engaging with online forums dedicated to machinery can yield practical advice and shared experiences from fellow users.

Local Support Options

- Authorized Dealers: Locate nearby dealerships that can provide expert support and genuine components.

- Repair Shops: Local technicians often have the knowledge to diagnose issues and suggest necessary replacements.

- Workshops and Training: Participating in local workshops can enhance skills related to maintenance and operation.