In the realm of automotive engineering, a thorough comprehension of the various elements that constitute a vehicle is essential for both maintenance and enhancement. Each individual component plays a pivotal role in ensuring optimal performance and reliability. A well-organized representation of these elements aids technicians and enthusiasts alike in navigating the complexities of modern machinery.

Exploring the intricate arrangements of these vital pieces reveals the interplay between functionality and design. Understanding how each part interacts within the system not only facilitates repairs but also inspires modifications for improved efficiency. This knowledge empowers owners to make informed decisions regarding upgrades and replacements.

By delving into comprehensive schematics, one can uncover the meticulous planning behind every assembly. Such illustrations serve as valuable references, providing insights into the engineering principles at work. Whether for troubleshooting or enhancement, grasping the layout of essential components is key to maintaining a vehicle’s longevity and performance.

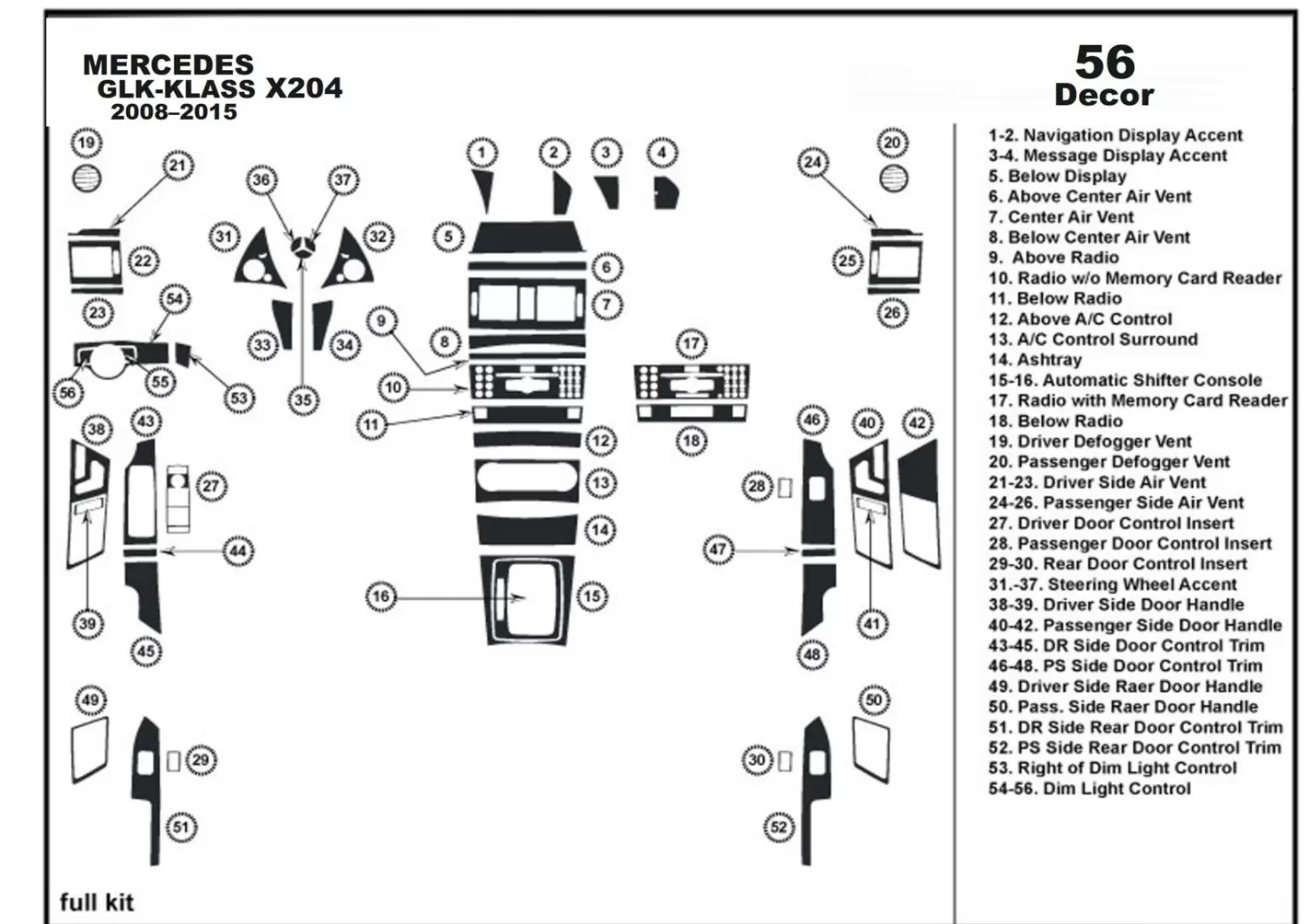

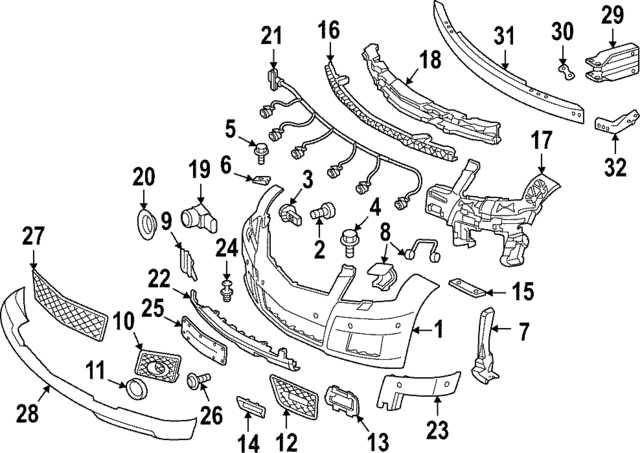

Understanding the GLK 350 Parts Diagram

Comprehending the visual representation of vehicle components is crucial for anyone looking to maintain or repair their automobile. This visual guide serves as a roadmap, showcasing the intricate relationships and placements of various elements within the machinery. By familiarizing oneself with this schematic, owners can make informed decisions regarding maintenance, repairs, and upgrades, ultimately enhancing the performance and longevity of their vehicle.

Key Components Illustrated

The schematic typically highlights essential elements such as the engine, transmission, suspension, and braking systems. Each section is meticulously labeled, allowing for easy identification and understanding of the function of each part. Recognizing these components is the first step toward effective troubleshooting and maintenance.

Benefits of Familiarity

Being well-acquainted with the layout of your vehicle’s components can lead to more efficient service practices. It empowers owners to communicate effectively with mechanics and ensures that they are well-informed about potential issues. This knowledge can save both time and money in the long run, making it a valuable asset for any car enthusiast or everyday driver.

Importance of Accurate Parts Identification

Correct identification of components is crucial in maintaining the efficiency and longevity of any vehicle. Misidentifying a single element can lead to improper installation, diminished performance, and potentially costly repairs. Ensuring each component is precisely recognized enhances reliability and safety on the road.

Impact on Maintenance

Routine upkeep becomes significantly easier when all elements are accurately identified. Technicians can quickly locate the necessary items, reducing downtime and ensuring that replacements or repairs are executed with precision. This ultimately contributes to the vehicle’s overall health and functionality.

Cost Efficiency

Investing time in proper identification can save money in the long run. Avoiding errors related to mismatched components helps in preventing unnecessary expenses associated with repeated repairs or replacements. Thorough knowledge of each element fosters better decision-making regarding maintenance and upgrades, promoting a more economical ownership experience.

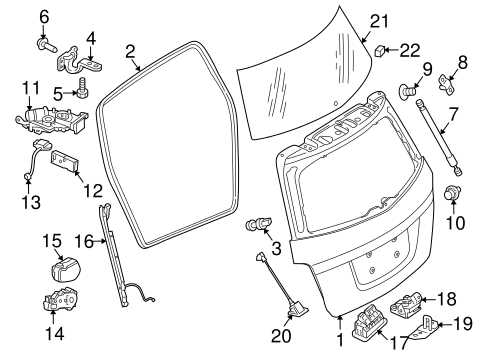

Common Issues with GLK 350 Components

When it comes to vehicles, understanding the frequent challenges associated with various elements can significantly enhance maintenance efforts. Owners often encounter recurring problems that can affect performance, safety, and longevity. Recognizing these common issues is essential for ensuring a smooth driving experience and prolonging the lifespan of the vehicle.

Electrical System Concerns

The electrical system is a vital component that may experience glitches over time. Symptoms such as flickering lights or unresponsive controls can signal deeper issues. Regular diagnostics are recommended to pinpoint and rectify these malfunctions, preventing further complications.

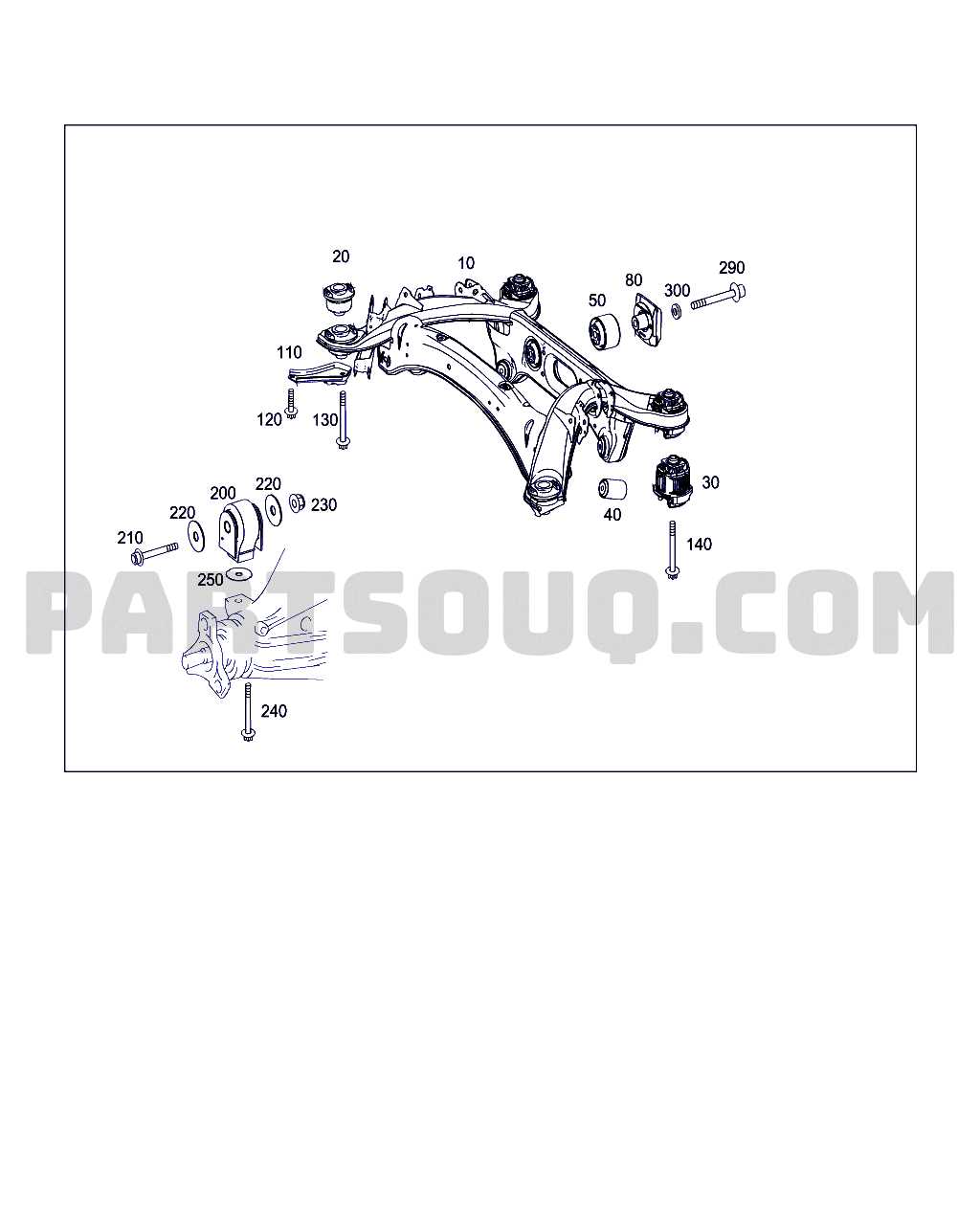

Suspension and Steering Problems

Another area that frequently demands attention is the suspension and steering. Signs like uneven tire wear or unusual noises during turns can indicate potential issues. Addressing these concerns promptly can enhance ride quality and ensure safe handling.

How to Use a Parts Diagram

Understanding an illustration that displays components of a system is essential for efficient maintenance and repair. These visual aids provide clarity on the relationship between various elements, helping users identify necessary replacements and ensuring proper assembly.

First, familiarize yourself with the layout of the illustration. Each section typically corresponds to specific assemblies, allowing you to navigate easily. Take note of the labels and numbering, which can guide you in pinpointing individual elements.

Next, cross-reference the visual with a list of components. This practice helps ensure you are selecting the correct item for your task. When dealing with replacements, double-check that the part you choose matches the specifications indicated in the illustration.

Additionally, consult the manufacturer’s manual for any notes or instructions that accompany the visual representation. These details often provide crucial insights about installation procedures or compatibility issues.

Finally, keep the illustration handy during your project. It can serve as a valuable reference point, reducing the likelihood of errors and improving your overall efficiency. By mastering the use of these visuals, you enhance your ability to maintain and repair effectively.

Essential Tools for Maintenance Tasks

Proper maintenance requires a variety of instruments to ensure efficiency and effectiveness. Having the right tools not only simplifies the process but also enhances safety and prolongs the lifespan of components.

- Wrenches: Adjustable and socket wrenches are vital for securing and loosening nuts and bolts.

- Screwdrivers: A set with various sizes and types helps tackle different fasteners.

- Pliers: Needle-nose and slip-joint pliers are essential for gripping and manipulating objects.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications.

- Jack and Jack Stands: Necessary for lifting vehicles safely during inspection and repair.

- Multimeter: Useful for diagnosing electrical issues and checking voltages.

Investing in quality tools can significantly enhance the maintenance experience and lead to successful outcomes.

Identifying Genuine vs. Aftermarket Parts

When it comes to vehicle maintenance, distinguishing between authentic components and their alternative counterparts is crucial for ensuring optimal performance and longevity. Each option comes with its own set of advantages and disadvantages that can impact your driving experience.

| Criteria | Genuine Components | Aftermarket Alternatives |

|---|---|---|

| Quality | Manufactured to original specifications | Varies significantly |

| Price | Typically higher | Often more affordable |

| Warranty | Usually includes a manufacturer’s warranty | May have limited or no warranty |

| Availability | Available through official dealers | Widely available from various suppliers |

Understanding these differences can guide your decision-making process, ensuring that you choose the right components for your vehicle’s needs.

Step-by-Step Repair Guide for GLK 350

This guide provides a detailed approach to tackling repairs for your vehicle, ensuring a comprehensive understanding of each phase of the process. By following these steps, you can enhance your skills and ensure that your automobile remains in optimal condition.

Step 1: Begin by gathering all necessary tools and components. Having everything at hand will streamline the process and prevent unnecessary interruptions.

Step 2: Carefully consult the service manual to identify specific areas needing attention. Familiarizing yourself with the layout will allow you to navigate effectively.

Step 3: Proceed with disassembly, ensuring that each component is handled with care. Documenting your steps can be invaluable when reassembling.

Step 4: Inspect each part for wear or damage. Replace any items that do not meet quality standards to maintain the performance of your vehicle.

Step 5: Reassemble the components in the reverse order of disassembly. Be meticulous to ensure that everything is secured properly.

Step 6: Conduct a thorough test to confirm that all repairs were successful. Address any remaining issues promptly to achieve ultimate reliability.

Where to Find Quality Replacement Parts

Finding top-notch components for your vehicle can significantly enhance its performance and longevity. Whether you’re a DIY enthusiast or prefer professional help, sourcing reliable items is crucial for maintaining optimal function.

- Authorized Dealers: Visit certified dealerships for original equipment manufacturer (OEM) components that ensure compatibility and quality.

- Online Retailers: Explore reputable e-commerce platforms specializing in automotive supplies. Look for customer reviews and ratings.

- Local Auto Shops: Check neighborhood stores that often carry a variety of high-quality alternatives at competitive prices.

- Salvage Yards: Consider visiting junkyards for gently used items. They can be a cost-effective solution for certain parts.

- Forums and Communities: Engage in online communities where enthusiasts share recommendations and experiences about sourcing reliable components.

Ultimately, the key is to conduct thorough research and choose suppliers with a proven track record to ensure your vehicle remains in top shape.

Understanding Component Interchangeability

Component interchangeability is a vital aspect of vehicle maintenance and repair, focusing on the ability to replace one part with another without compromising functionality. This concept allows for flexibility in sourcing replacements and enhances the efficiency of repair processes, ultimately reducing costs and downtime.

Factors Influencing Interchangeability

Several factors affect the interchangeability of components, including design specifications, manufacturing standards, and material compatibility. Understanding these elements is essential for ensuring that substituted parts perform adequately and meet safety requirements. Compatibility is key; even slight variations in design can lead to performance issues.

Benefits of Interchangeable Components

The ultimate advantage of interchangeable parts lies in the increased availability and accessibility of replacements. This flexibility not only facilitates repairs but also encourages a sustainable approach by allowing the use of refurbished or recycled components. Utilizing interchangeable parts can enhance vehicle longevity while supporting environmental responsibility.

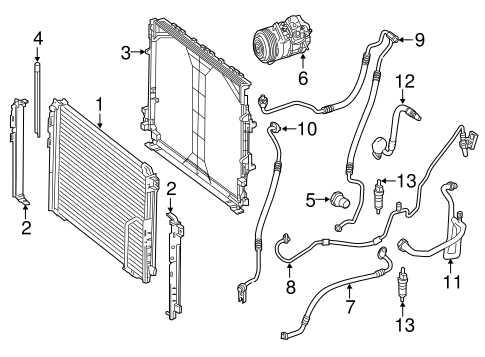

Visualizing the Engine Assembly Layout

Understanding the intricate arrangement of engine components is essential for effective maintenance and performance optimization. This section aims to illustrate the configuration of various elements within the power unit, showcasing how they interact to deliver ultimate efficiency. By grasping the layout, one can better appreciate the complexity and engineering marvel behind modern automotive technology.

Key components such as the cylinder block, crankshaft, and camshaft work in unison, each playing a pivotal role in the overall functionality. Visual aids help to clarify the spatial relationships and connectivity among these parts, enabling a deeper insight into their respective functions.

Furthermore, diagrammatic representations serve as valuable tools for technicians and enthusiasts alike, facilitating troubleshooting and enhancing comprehension of repair processes. Engaging with these visualizations allows for a more profound understanding of the engine’s architecture and operational dynamics.

Tips for Regular Maintenance Checks

Ensuring optimal performance and longevity of your vehicle requires consistent inspections and care. Regular maintenance checks can help identify potential issues before they escalate, ultimately saving time and money. Adopting a proactive approach to vehicle upkeep is essential for all drivers who value reliability and safety.

Here are some essential tips to consider during your routine assessments:

| Component | Check Frequency | Action |

|---|---|---|

| Oil Level | Every month | Top up or change if necessary |

| Brake Pads | Every 6 months | Inspect and replace if worn |

| Tires | Monthly | Check pressure and tread depth |

| Coolant | Every 3 months | Inspect level and top up |

| Battery | Every 6 months | Check terminals and charge |

| Lights | Monthly | Test all lights and replace bulbs |

By staying on top of these checks, you can maintain your vehicle’s efficiency and ensure a smooth driving experience. Regular attention to these details contributes significantly to your safety on the road and can prevent unexpected breakdowns.

Online Resources for GLK 350 Owners

For enthusiasts and owners of this particular vehicle, the internet offers a wealth of information and support. Accessing reliable online platforms can enhance your understanding and maintenance of your automobile, ensuring you stay informed about its performance and care.

Forums and Community Groups

Joining online communities dedicated to your vehicle can provide invaluable insights. These forums often feature discussions on common issues, troubleshooting tips, and recommendations for upgrades, allowing you to connect with fellow owners who share similar experiences.

Official Manufacturer Websites

Official websites are excellent resources for obtaining technical documentation and updates. Here, you can find detailed information regarding specifications, service bulletins, and warranty details that are crucial for maintaining your vehicle in top condition.