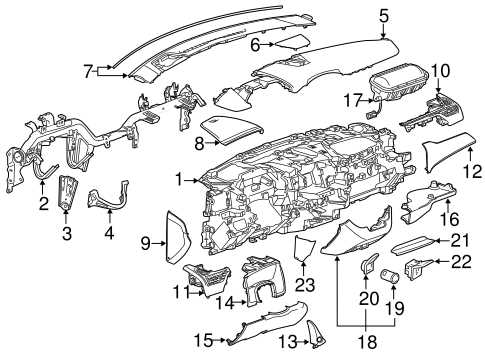

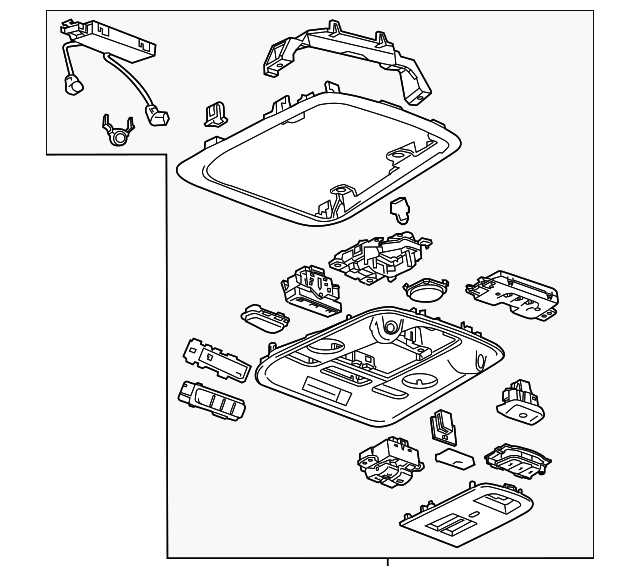

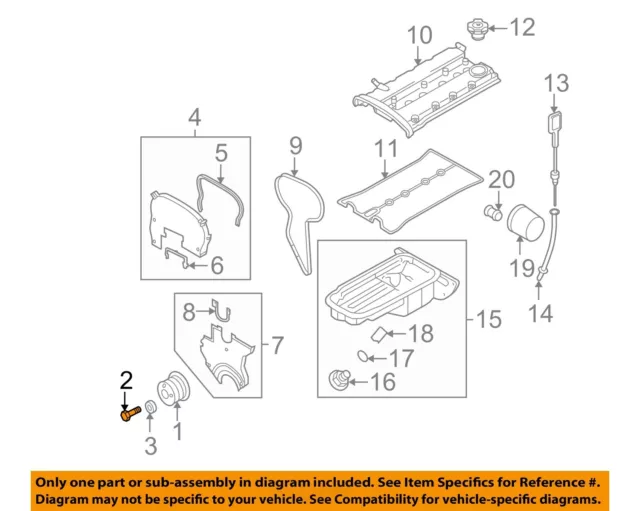

When working on vehicle repairs or upgrades, having a clear understanding of where each component is located and how it interacts with others is crucial. Every part within a car is designed to function together, creating a seamless operation for optimal performance. Knowing the specific areas and mechanisms involved allows for more efficient maintenance and troubleshooting.

Detailed illustrations and placement guides can be invaluable when it comes to understanding these components. They provide insight into the inner workings of the vehicle, showing how various elements are interconnected. This ensures that any adjustments or replacements are carried out correctly, reducing the chances of errors or mal

Understanding GM OEM Parts

When maintaining or repairing vehicles, selecting the correct components is essential for ensuring performance and longevity. For those who own GM vehicles, there are specific items designed to meet factory standards, providing reliability and compatibility. It’s crucial to understand the difference between these and alternative options in the market.

The Importance of Genuine Components

Using components made specifically for your vehicle ensures a perfect fit and optimal function. They are designed to meet the exact requirements set by the manufacturer, which minimizes the risk of issues during installation or operation.

Comparing Alternatives

While there are various alternatives available, choosing components that match factory specifications is often the safest choice. Below is a simple comparison of features between original and aftermarket options.

| Advantages | Description | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Longevity | Original components are made to last longer, reducing the need for frequent replacements. | ||||||||

| Fit and Function | These items are tailored to work perfectly with your vehicle, ensuring smooth operation. | ||||||||

| Warranty Coverage | Why Choose Authentic Parts Over Aftermarket

When it comes to vehicle maintenance, selecting the right components is crucial for ensuring long-lasting performance and reliability. Opting for genuine replacements guarantees that the materials and design align perfectly with your car’s original build, providing a seamless fit and dependable functionality. Durability and Quality AssuranceAuthentic components are manufactured to meet the exact specifications set by the original makers of your vehicle. This level of precision helps avoid unexpected failures and reduces the need for frequent replacements, giving you peace of mind on the road. Preserving Vehicle Integrity

Using factory-approved replacements helps maintain the integrity of your vehicle’s systems, ensuring that all elements work in harmony. This contributes to the overall longevity of the car and can enhance its resale value in Navigating GM OEM Parts DiagramsUnderstanding the layout of vehicle components can be challenging, but knowing where each element fits is key to successful maintenance. With detailed illustrations, you can visualize how various elements interact and connect within a larger system. Understanding Component PlacementEach element within the vehicle’s structure is represented in a way that makes it easy to identify where it belongs. These visual tools allow users to see how different sections align and what steps are necessary for assembly or repair. Locating Specific ComponentsTo locate a specific element, users can rely on clear visuals that provide a step-by-step breakdown of the assembly process. This ensures that every item is easily found, helping to reduce errors Best Practices for Finding Correct PartsWhen it comes to sourcing the right components for your vehicle, following a systematic approach can significantly enhance your experience. Identifying the necessary items can be challenging without a clear strategy, but certain practices can streamline the process. Begin by utilizing official resources. Manufacturer websites often provide extensive information, including specifications and recommendations. Make sure to explore these platforms for guidance on the components suited for your model. Cross-reference with trusted vendors. Compare listings from various suppliers to ensure accuracy. This practice helps in verifying the legitimacy of the items and aids in identifying alternatives if your primary choice is unavailable. Keep detailed records. Maintaining a list of previous purchases, along with their specifications, can prove invaluable. This documentation serves as a reference for future needs and can assist in troubleshooting discrepancies. Engage with online communities. Forums and social media groups focused on automotive discussions can offer insights and recommendations from fellow enthusiasts. Learning from their experiences can guide you towards reputable sources and reliable options. Consult professionals. If you encounter difficulties in finding the right items, do not hesitate to seek help from experienced mechanics or automotive specialists. Their expertise can provide clarity and direction in your search. Common Mistakes in Reading Parts DiagramsUnderstanding visual representations of components can be challenging. Many individuals encounter pitfalls that lead to misinterpretation of essential information. Awareness of these frequent errors is crucial for effective comprehension and utilization of these resources. Neglecting to Review the KeyOne prevalent mistake is overlooking the key or legend accompanying the illustration. This element provides vital context, indicating the meaning of symbols and markings. Failing to consult this section may result in confusion regarding the relationships and functions of various items.

Ignoring Scale and DimensionsAnother common oversight is ignoring the scale and measurements indicated in the visual. Understanding the size relationships between different components is essential for accurate identification and selection. Misjudging dimensions can lead to errors in ordering or installation.

How to Avoid Misinterpretation of SchematicsUnderstanding technical illustrations is essential for effective troubleshooting and repair. Misunderstanding these visuals can lead to errors, increased costs, and unnecessary frustration. To navigate these complexities, one must employ strategies that promote clarity and comprehension. Familiarize Yourself with SymbolsRecognizing common symbols used in technical illustrations can significantly reduce confusion. Each symbol typically represents a specific function or component. Spend time studying the key or legend that accompanies these illustrations to gain insight into their meanings. Cross-Reference with DocumentationAlways consult accompanying documentation when interpreting visuals. These documents often provide context, clarifying the relationship between various components. Taking this extra step helps to ensure accuracy and provides a more comprehensive understanding of the system. GM Parts Numbering System ExplainedThe numbering structure utilized by GM serves as a crucial framework for identifying components and accessories within their range of vehicles. This system not only simplifies the ordering process but also enhances the efficiency of maintaining and servicing vehicles. Understanding the numbering method can greatly benefit both enthusiasts and professionals. Below are key elements that characterize this framework:

When navigating this system, it’s helpful to keep in mind the following components:

By familiarizing oneself with this framework, users can effectively locate and order the necessary components for their vehicles, ensuring optimal performance and longevity. Decoding the Part Numbers for AccuracyUnderstanding the significance of numerical identifiers is essential for ensuring precision when selecting components for your vehicle. These codes serve as a systematic way to categorize and identify various items, aiding in the correct replacement or upgrade process. Importance of Accurate IdentificationAccurate identification of components can prevent issues that may arise from mismatched items. Here are some reasons why precise decoding is crucial:

Steps to Decode the Numerical IdentifiersTo effectively decode these identifiers, follow these guidelines:

By mastering the decoding process, you can make informed decisions and maintain your vehicle’s performance at its peak. Where to Access GM OEM Parts Diagrams

Finding the right resources to view official component illustrations can greatly enhance your understanding of vehicle maintenance and repair. Accessing these visual aids allows users to identify specific elements, ensuring accurate ordering and installation processes. Several reliable platforms provide this essential information for enthusiasts and professionals alike. Online ResourcesNumerous websites offer comprehensive libraries where you can explore a wide range of visual references for various vehicle models. These digital platforms typically include search functionalities, making it easy to locate the required information. Below are some popular options:

Dealerships and WorkshopsLocal dealerships and automotive service centers are valuable sources for obtaining official visual references. These establishments usually have access to proprietary software that includes comprehensive illustrations, allowing for precise identification of vehicle components. Establishing a relationship with local experts can provide additional guidance and support. Online and Offline Resources for DiagramsIn today’s digital age, numerous avenues exist for accessing visual representations related to automotive components. These resources can greatly aid in understanding assembly and repair processes, making them invaluable for enthusiasts and professionals alike. Both internet-based platforms and traditional methods offer unique advantages for locating these valuable references. Online platforms provide a vast array of tools and databases. Websites dedicated to automotive information often feature interactive visuals that allow users to zoom in on specific sections, enhancing clarity and understanding. Many of these sites are updated regularly, ensuring that users have access to the latest information. Additionally, forums and social media groups can serve as great places to share insights and find guidance from experienced individuals. On the other hand, offline resources include printed manuals and guides that offer detailed information. These documents can be particularly beneficial for those who prefer physical copies for easy reference during repairs. Libraries and automotive stores often have a selection of these materials available, allowing users to explore a range of topics related to vehicle maintenance and assembly. While less dynamic than their online counterparts, these resources still provide essential knowledge and can be relied upon when technology is not accessible. Utilizing both online and offline resources can significantly enhance one’s ability to understand and manage vehicle components effectively. Each method complements the other, creating a comprehensive approach to accessing crucial information. Compatibility Checks with GM OEM PartsEnsuring proper fitment is crucial when selecting components for your vehicle. Compatibility checks help guarantee that the selected items will function seamlessly with your specific model, enhancing performance and longevity. Here are key considerations when verifying compatibility:

Utilizing reliable sources and databases can greatly assist in the verification process. By following these steps, you can confidently choose the right components for your vehicle, leading to a smoother driving experience. |