In the realm of fluid application technologies, a comprehensive understanding of the various components is essential for optimal functionality. This section delves into the intricacies of a specific type of equipment, providing clarity on its essential elements. Each component plays a critical role in ensuring efficiency and precision in various tasks, from surface finishing to coatings.

Through a detailed examination, readers will gain insights into the configuration and relationship between different segments of the system. Identifying individual elements and their respective functions is crucial for troubleshooting and maintenance. Recognizing how these components interact contributes to a more effective and streamlined operation.

Furthermore, this overview serves as a foundation for those looking to enhance their knowledge or engage in hands-on projects. Whether for professional applications or DIY endeavors, understanding the structure of these systems is invaluable. With a grasp of the key components, users can better navigate repairs, upgrades, or optimizations, leading to improved performance and longevity of the equipment.

Understanding Graco Paint Sprayers

In the realm of efficient coating applications, the technology behind high-performance devices is crucial for achieving flawless results. These machines have transformed how individuals and professionals approach their projects, allowing for quick and uniform application of various substances. Understanding the essential components and their functions can significantly enhance the user experience and effectiveness of the equipment.

Key Features of High-Performance Coating Equipment

- Versatility: Capable of handling a range of substances, from stains to thick coatings.

- Efficiency: Engineered to cover large areas swiftly, reducing time and labor costs.

- Precision: Designed for controlled application, ensuring an even finish without overspray.

- Durability: Constructed with robust materials to withstand frequent use and various environments.

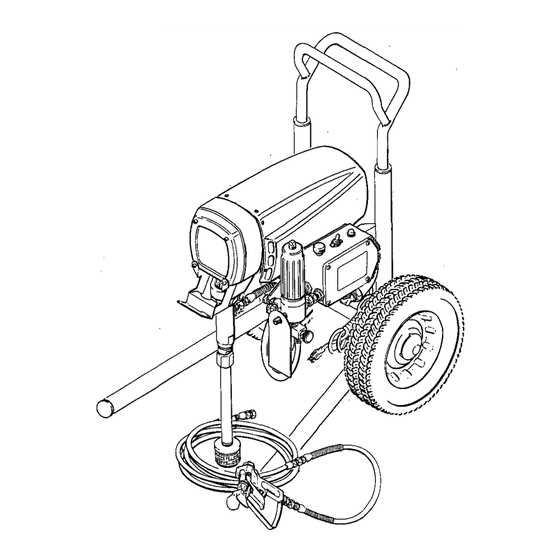

Components of These Devices

- Motor: Powers the entire mechanism, influencing performance and speed.

- Pump: Delivers the material to the nozzle, critical for maintaining consistent flow.

- Nozzle: Determines the spray pattern and width, essential for achieving desired results.

- Hoses: Facilitate the movement of the material from the container to the application area.

- Filters: Ensure that the substance remains free of impurities, preventing clogging and ensuring smooth operation.

Key Components of Graco Models

Understanding the essential elements of these versatile equipment models is crucial for efficient operation and maintenance. Each unit comprises several key components that contribute to its functionality and performance. Familiarity with these parts can enhance user experience and facilitate troubleshooting when issues arise.

The main components typically found in these devices include the following:

| Component | Description |

|---|---|

| Motor | Powers the entire system, enabling movement and pressure generation. |

| Pump | Responsible for drawing liquid from the container and delivering it under pressure. |

| Hose | Connects the pump to the applicator, transporting the material efficiently. |

| Gun | The applicator that delivers the fluid to the surface, allowing for precise control over the application. |

| Nozzle | Determines the spray pattern and size, affecting the coverage and finish quality. |

| Filters | Prevent debris from clogging the system, ensuring smooth operation and consistent output. |

Each of these elements plays a vital role in ensuring that the equipment operates effectively, making it essential for users to understand their functions and interrelationships.

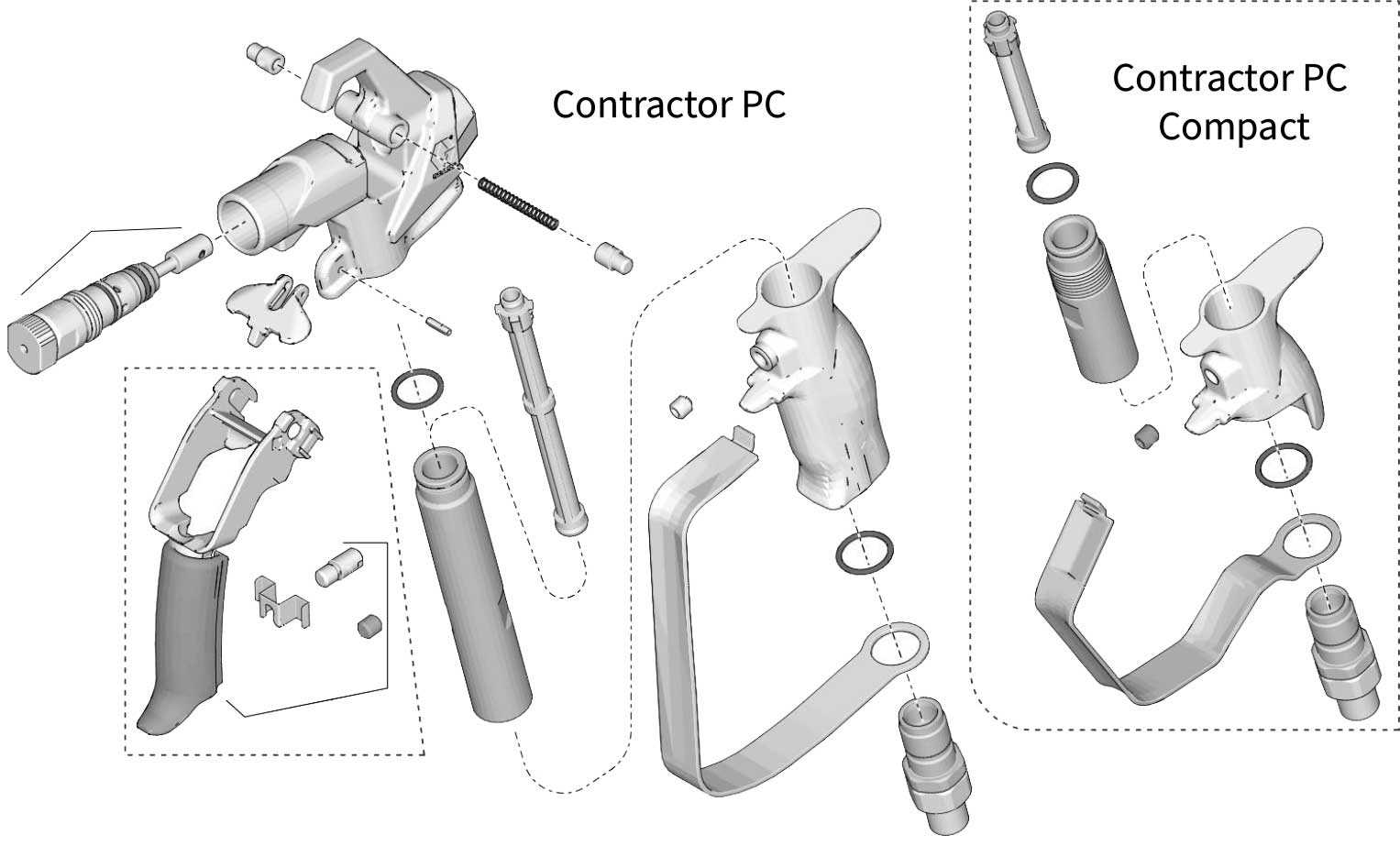

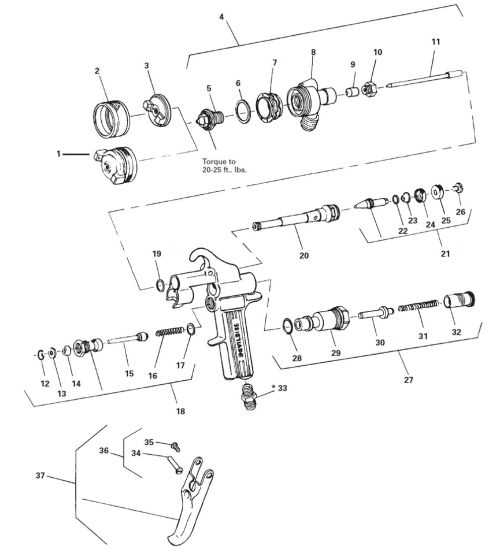

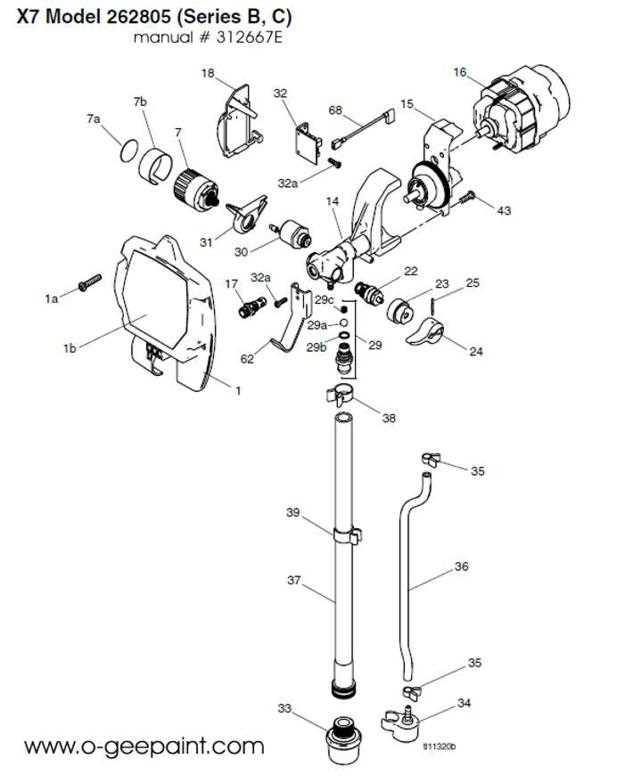

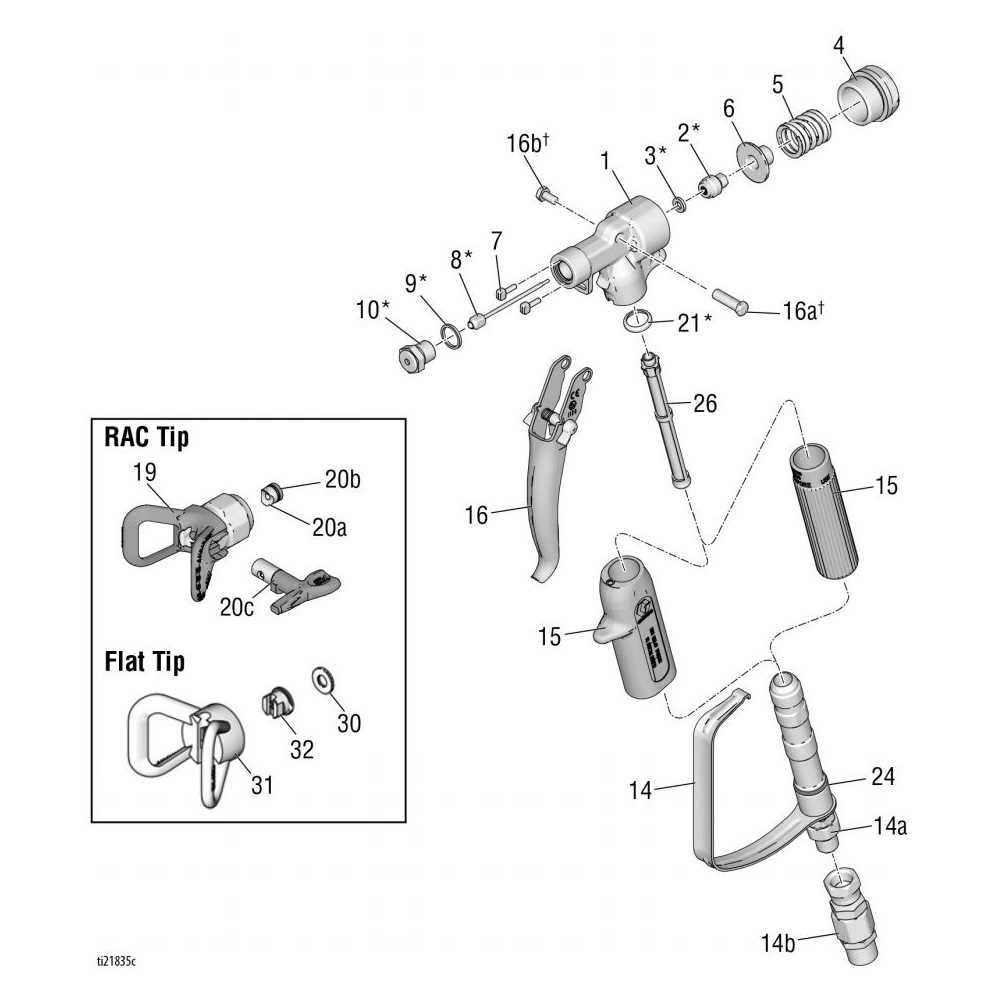

Importance of Parts Diagrams

Understanding the components of a machine is crucial for effective maintenance and repair. A visual representation that outlines the various elements and their relationships aids users in recognizing how each piece functions within the system. This clarity can significantly enhance troubleshooting efficiency and ensure proper assembly after disassembly.

Such illustrations serve as valuable resources for both novices and experienced technicians, providing insights into the configuration of equipment. By referring to these guides, individuals can quickly identify specific elements that may require attention or replacement, thereby streamlining the repair process and minimizing downtime.

Moreover, these visual aids contribute to safety, as they help users to comprehend the intricate workings of the device before undertaking any modifications or repairs. This understanding not only prevents mishaps but also fosters a more thorough knowledge of the overall functionality, empowering users to operate their machinery with confidence.

Common Issues with Paint Sprayers

Many individuals encounter challenges when utilizing spray devices for coating surfaces. Understanding these frequent problems can enhance user experience and ensure better outcomes. This section highlights typical difficulties, their causes, and potential solutions to improve the efficiency of such equipment.

1. Clogging of Nozzle

One prevalent issue is the clogging of the nozzle, which can disrupt the flow of material. This is often caused by dried residues or incompatible substances within the device. Regular cleaning and maintenance can mitigate this problem.

2. Uneven Coating

Another common challenge is achieving an inconsistent layer of finish. This can result from improper technique, incorrect pressure settings, or a malfunctioning mechanism. Adjusting the spray pattern and ensuring a steady motion can help attain a uniform application.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Clogged Nozzle | Dried material, incompatible substances | Regular cleaning, using appropriate materials |

| Uneven Coating | Improper technique, incorrect pressure | Adjust settings, maintain steady motion |

| Poor Spray Pattern | Worn parts, air leaks | Inspect and replace worn components |

Maintenance Tips for Graco Sprayers

Proper upkeep is essential for ensuring the longevity and optimal performance of your spraying equipment. Regular maintenance not only enhances efficiency but also minimizes the risk of operational issues, allowing for a smoother application process. Understanding key maintenance practices can significantly improve the reliability of your device.

Firstly, always ensure that the machine is thoroughly cleaned after each use. Residual materials can cause clogs and impair functionality. Use the appropriate cleaning solutions recommended by the manufacturer to dissolve any remaining substances effectively.

Additionally, inspect all components regularly for signs of wear and tear. Replacing damaged parts promptly can prevent further complications and ensure consistent performance. Pay close attention to seals and filters, as these components are crucial for maintaining pressure and preventing leaks.

Another important aspect is to check the fluid levels before each operation. Maintaining the correct fluid levels not only enhances performance but also prevents unnecessary strain on the equipment. If you notice fluctuations in pressure, it may be a sign of a problem that requires immediate attention.

Lastly, storing the equipment in a suitable environment when not in use can prolong its lifespan. Protect it from extreme temperatures and moisture, which can cause significant damage. Following these simple maintenance practices will ensure that your spraying equipment remains in excellent condition for years to come.

Finding Replacement Parts Easily

Locating the necessary components for your equipment can often feel overwhelming. However, with the right approach and resources, you can simplify this process significantly. Understanding where to search and how to identify the right elements is key to maintaining the efficiency of your device.

Utilizing Online Resources

The internet is an invaluable tool for finding replacement components. Various websites offer extensive catalogs that allow users to search by model or specific features. Make use of online marketplaces, manufacturer websites, and specialty retailers to compare options and prices. Customer reviews and ratings can provide insights into the quality and reliability of the components you are considering.

Consulting User Manuals

User manuals often include detailed information about the components needed for your equipment. They can provide part numbers and specifications that are crucial for finding the correct items. Keep a digital or physical copy of the manual for easy reference. Cross-referencing part numbers with available listings can help ensure compatibility and streamline your search.

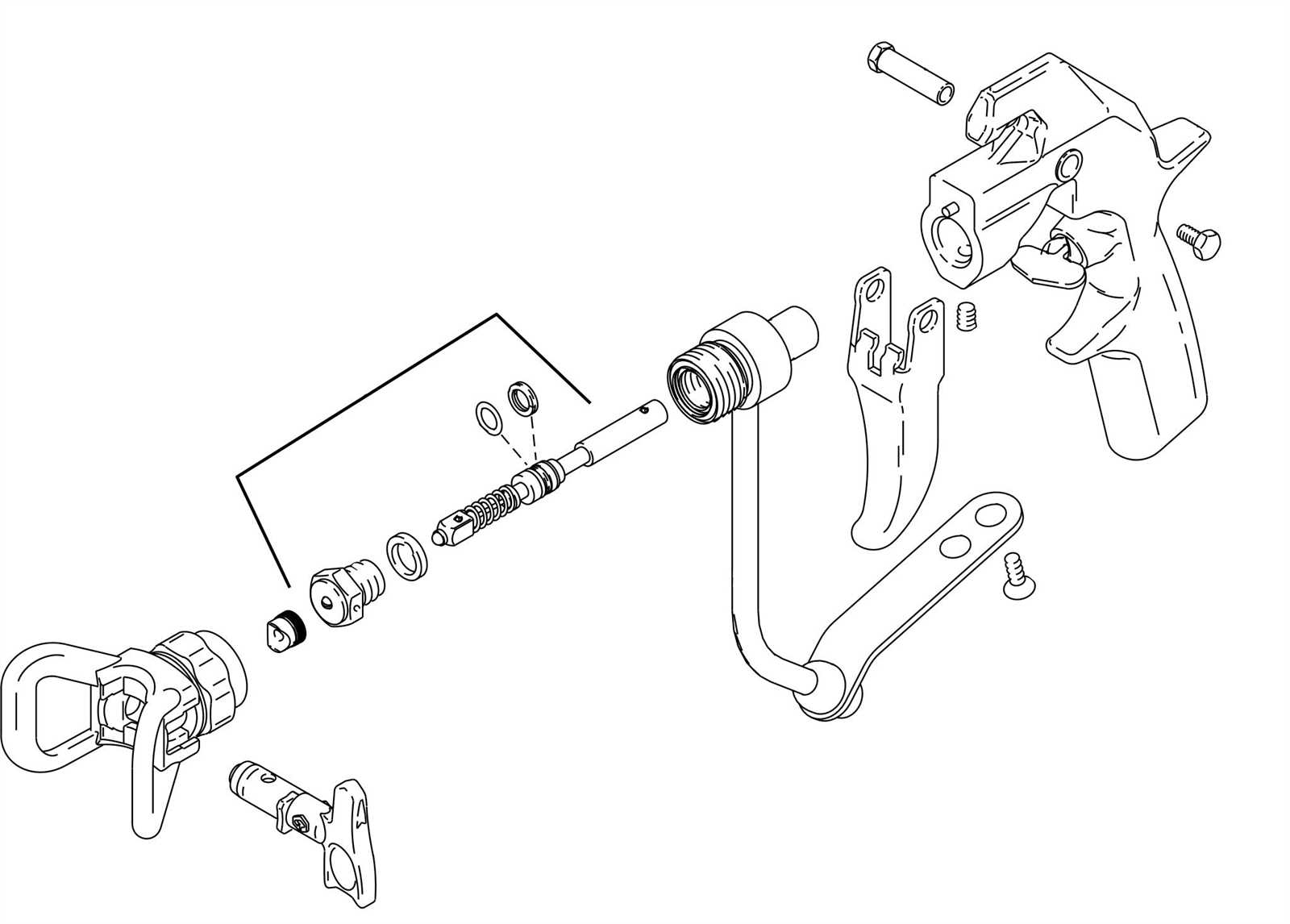

Graco Sprayer Assembly Instructions

Assembling your equipment correctly is crucial for optimal performance and longevity. Following a clear and systematic approach ensures that each component is securely fitted and functions as intended. This guide provides step-by-step instructions for putting together your device efficiently.

- Gather Your Tools:

Before starting the assembly, ensure you have all the necessary tools at hand, including:

- Screwdriver

- Wrench

- Pliers

- Safety goggles

- Prepare the Workspace:

Choose a clean, well-lit area to work. Lay out all the components clearly, ensuring nothing is missing.

- Identify Components:

Familiarize yourself with each part included in the kit. Understanding what each piece does will facilitate smoother assembly.

- Start with the Base:

Begin assembling from the base. Attach the main body to the support structure, securing it with the appropriate screws.

- Attach the Handle:

Next, fix the handle to the main body. Ensure it is firmly attached to allow for easy maneuverability.

- Install the Delivery System:

Connect the delivery mechanism according to the included instructions. Ensure all connections are tight to prevent leaks.

- Final Assembly Check:

Once all components are assembled, double-check each connection and part for security. Look for any loose fittings.

- Test the Equipment:

After assembly, perform a test run in a safe environment to ensure everything operates correctly.

Following these instructions will help you assemble your device effectively, ensuring it is ready for use in your projects.

Using the Parts Diagram Effectively

Understanding the visual representation of components is crucial for successful maintenance and repairs. A well-structured illustration not only aids in identifying individual elements but also enhances the overall efficiency of the assembly process. By utilizing this resource wisely, users can streamline their workflow and minimize the risk of errors.

To maximize the benefits of the visual reference, start by familiarizing yourself with its layout. Identify key sections and how they relate to the overall unit. This foundational knowledge will serve as a guide during troubleshooting or assembly tasks.

When seeking to replace or repair a specific component, reference the associated numbers or labels within the illustration. This method ensures you acquire the correct item and helps avoid compatibility issues. Additionally, maintain a checklist of components, marking those that require attention. This practice promotes organization and ensures no essential elements are overlooked.

Lastly, do not hesitate to consult supplementary resources or user manuals for further clarification on each component’s function. Combining these tools with the visual aid can significantly improve your understanding and execution of any maintenance or assembly work.

Differences Between Graco Models

When exploring various models within a specific brand, it is essential to recognize the distinct features that set each version apart. These differences can significantly influence performance, usability, and overall user experience. Understanding these variations can help consumers make informed decisions tailored to their specific needs and preferences.

Each model typically offers unique specifications that cater to different applications and project requirements. Factors such as power output, nozzle size, and tank capacity can vary widely, impacting efficiency and the quality of the finish. Below is a comparison table highlighting key differences between several models:

| Model | Power Type | Nozzle Size | Maximum Pressure (PSI) | Capacity (Gallons) |

|---|---|---|---|---|

| Model A | Electric | 0.015 inches | 3000 | 1.5 |

| Model B | Gas | 0.017 inches | 3200 | 2.0 |

| Model C | Electric | 0.013 inches | 2800 | 1.0 |

| Model D | Gas | 0.019 inches | 3400 | 2.5 |

Understanding Paint Sprayer Accessories

When it comes to achieving flawless results in your projects, the right accessories can make a significant difference. These additional components enhance functionality and versatility, enabling users to tailor their equipment for specific tasks. Familiarity with these tools can elevate your work quality and efficiency.

Nozzles are essential for controlling the spray pattern and flow rate. Different shapes and sizes allow for fine-tuning the application process, whether you’re covering a broad surface or executing detailed work. Selecting the appropriate nozzle can lead to a smoother finish and reduced overspray.

Filters play a crucial role in maintaining a clean application. They prevent debris from clogging the system, ensuring a consistent flow and preventing imperfections in the finish. Regularly replacing these filters can extend the life of your equipment and enhance performance.

Hoses provide the necessary connection between the paint reservoir and the application tool. They come in various lengths and diameters, allowing for flexibility in movement and reach. Using the right hose can help reduce pressure loss and improve overall efficiency during operation.

Cleaning Kits are vital for maintaining your equipment. A thorough cleaning regimen after each use prevents residue build-up and prolongs the lifespan of your tools. Investing in a quality cleaning kit ensures that all components are properly maintained and ready for future use.

Understanding these accessories and their functions is key to optimizing your workflow. By selecting the right tools, you can achieve professional-quality results while enhancing the longevity of your equipment.

Safety Precautions When Using Sprayers

When operating spraying equipment, ensuring safety should be a top priority. Proper handling techniques and precautionary measures can significantly reduce the risk of accidents and injuries. Understanding the associated hazards and implementing safety protocols will create a secure working environment for both the user and those nearby.

Personal Protective Equipment (PPE) is essential. Always wear appropriate gear, including gloves, goggles, and masks, to protect against potential exposure to harmful substances. Ensure that clothing covers exposed skin and is resistant to the materials being utilized.

Before commencing work, conduct a thorough inspection of the equipment. Check for any signs of wear or damage that could compromise functionality. Make sure all connections are secure, and replace any worn-out components immediately.

It is also crucial to work in a well-ventilated area to avoid inhaling fumes or vapors. If working indoors, use exhaust fans or open windows to promote airflow. Avoid using the equipment near open flames or sparks, as many substances can be flammable.

Lastly, familiarize yourself with the manufacturer’s instructions and operational guidelines. Understanding the equipment’s functionality and safety features will help prevent misuse and enhance overall safety during operation.

Upgrading Your Graco Sprayer

Enhancing your equipment can significantly improve its performance and extend its lifespan. Whether you’re a professional or a DIY enthusiast, upgrading your device can lead to more efficient operations and better results. Here are several ways to elevate your tool to the next level.

- Replace Worn Components: Regular use can lead to wear and tear. Inspect and replace any worn parts to maintain optimal performance.

- Upgrade the Nozzle: Consider switching to a high-quality nozzle. This can enhance the application precision and achieve a smoother finish.

- Invest in a Better Hose: A flexible and durable hose can improve maneuverability and reduce the chances of kinks and leaks.

- Enhance the Pump System: Upgrading to a more efficient pump can increase pressure and flow rate, allowing for quicker and more uniform coverage.

- Utilize Advanced Filters: Installing better filters can prevent clogging and ensure a clean application, which is crucial for professional results.

Implementing these enhancements can provide significant benefits, making your tasks more manageable and effective. Always consult the manufacturer’s recommendations for compatibility when selecting upgrades.

Frequently Asked Questions About Graco

This section addresses common inquiries related to one of the leading brands in the field of spray equipment. Here, we aim to provide clear and concise answers to enhance user understanding and improve overall experience with their devices.

What should I consider when selecting a model?

When choosing a device, consider factors such as the type of projects you plan to undertake, the materials you will be using, and the level of experience you possess. Understanding the specifications of various models can help you select one that best fits your needs.

How do I maintain my equipment for optimal performance?

Regular maintenance is crucial for ensuring longevity and efficiency. Always clean your tools after each use, check for wear and tear, and replace any worn components promptly. Following the manufacturer’s guidelines for upkeep can significantly enhance performance.