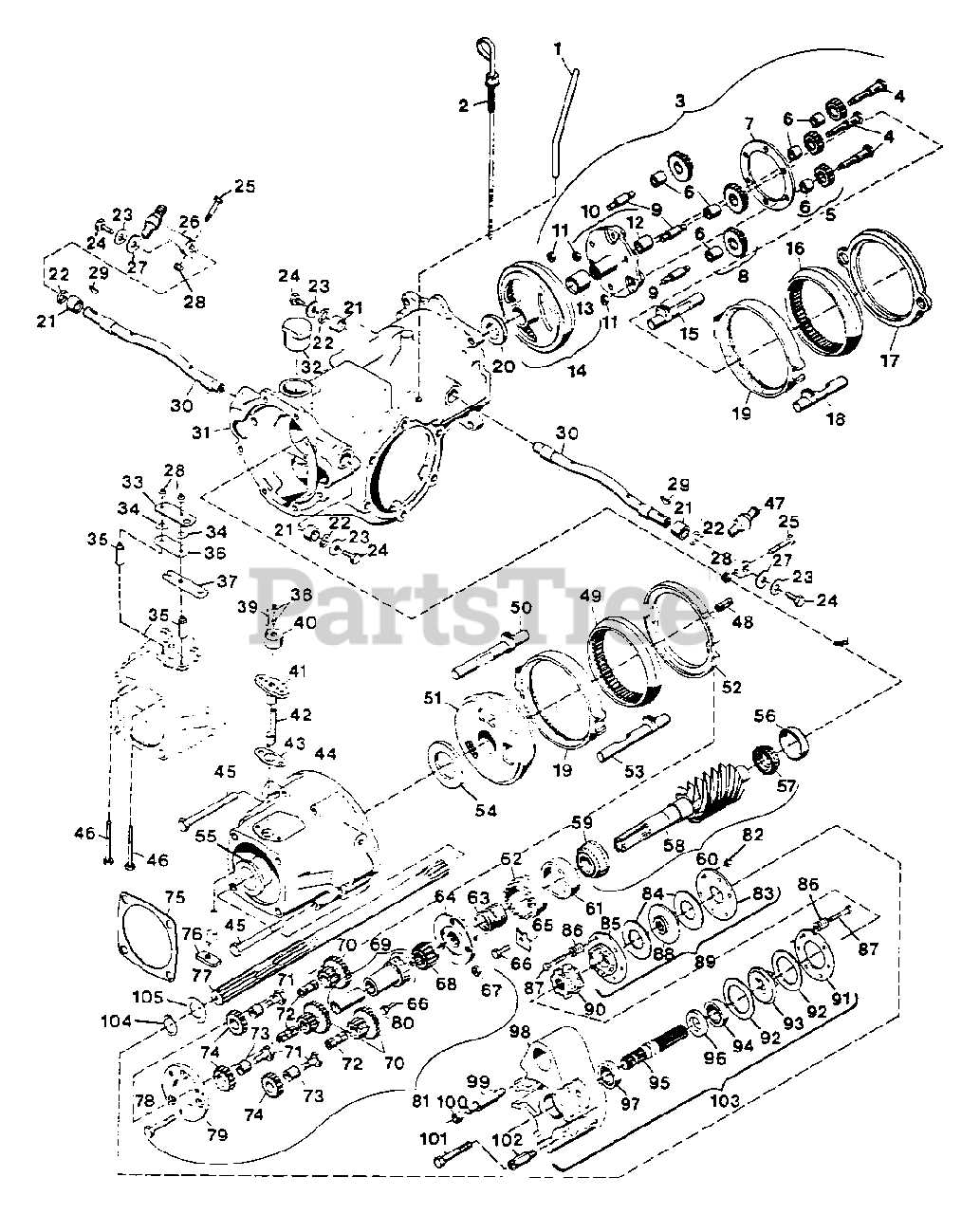

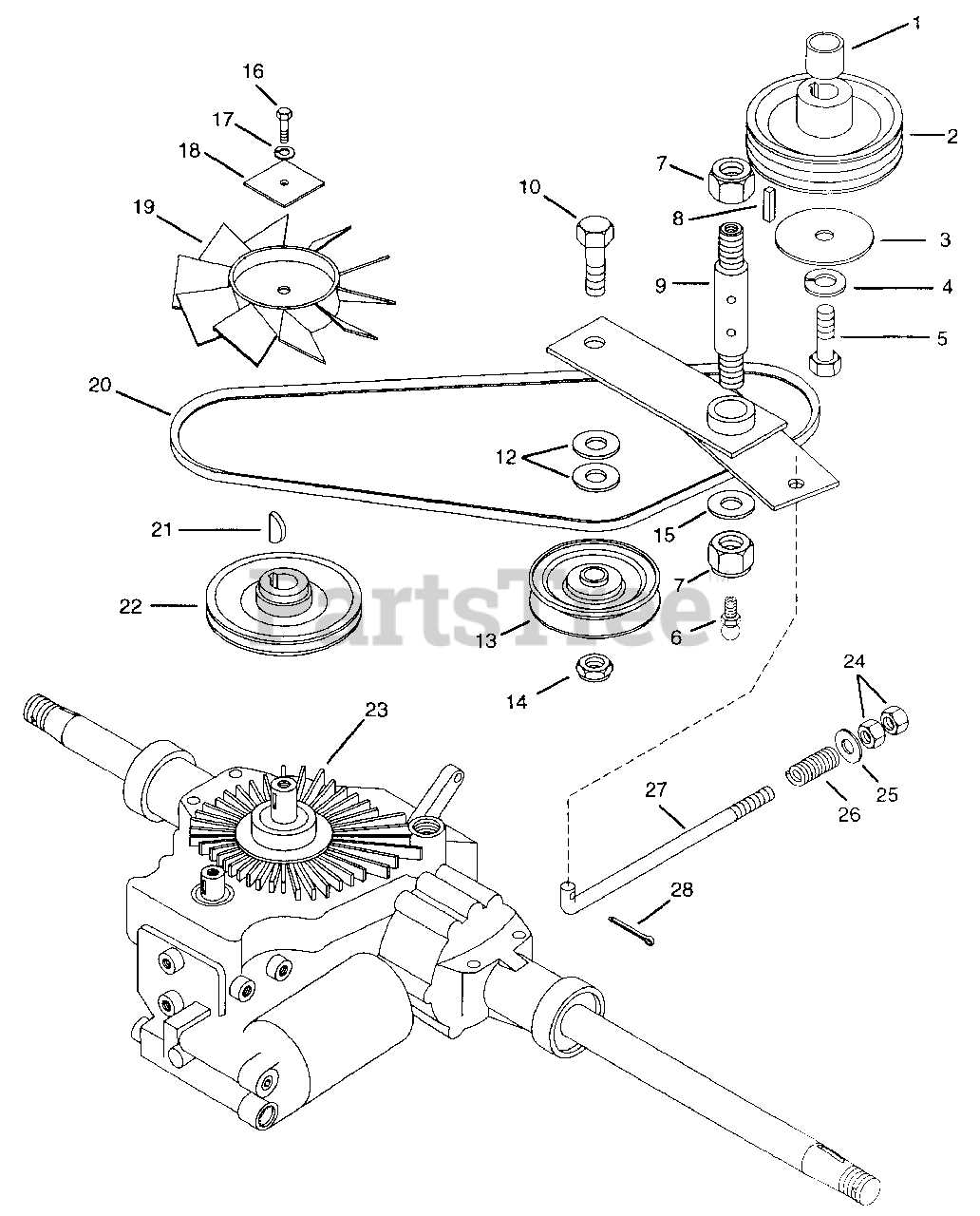

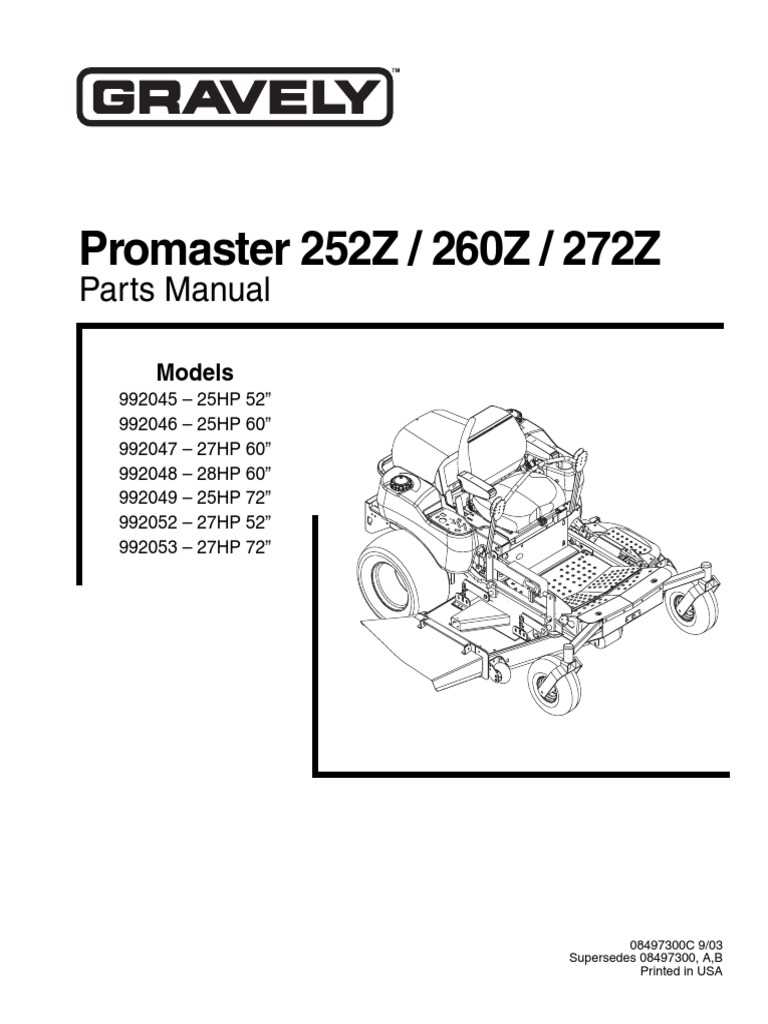

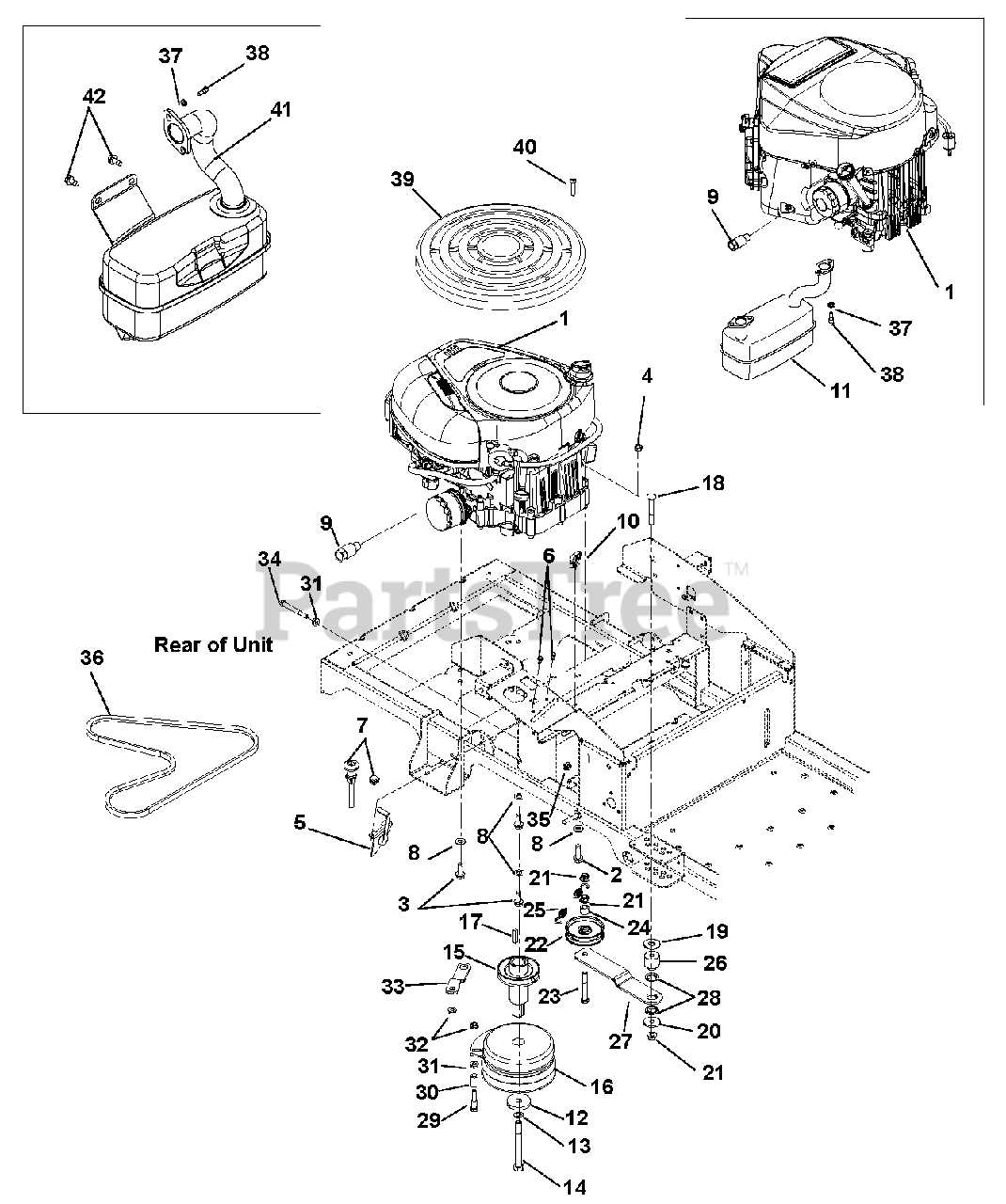

When it comes to maintaining outdoor machinery, having a clear visual representation of its components can be invaluable. This overview not only aids in identification but also enhances your ability to troubleshoot and perform necessary repairs.

Every piece of equipment is made up of various elements that work in harmony to ensure optimal performance. By examining the intricate layout of these elements, users can gain insights into their functionality and significance in the overall operation.

Whether you are a seasoned technician or a casual user, delving into this visual guide will provide you with the ultimate knowledge needed to enhance the longevity and efficiency of your machine. Understanding how each part interrelates can significantly streamline maintenance tasks and improve your overall experience.

Understanding Gravely Parts Diagram

Comprehending the intricacies of machinery components is crucial for efficient maintenance and repair. This section delves into the visual representations that aid in identifying and understanding various elements of equipment. These illustrations serve as invaluable tools for users, facilitating a clearer grasp of each component’s role and interrelations.

Such visual guides not only simplify the identification process but also enhance the overall functionality of the machinery by promoting informed decision-making during repairs. Knowledge of these components can lead to better performance and longevity of the equipment.

| Component Name | Description | Function |

|---|---|---|

| Blade | Cutting element of the device | To trim and maintain grass or other vegetation |

| Engine | Power source | Drives the machinery and powers various functions |

| Chassis | Frame of the equipment | Provides structure and stability |

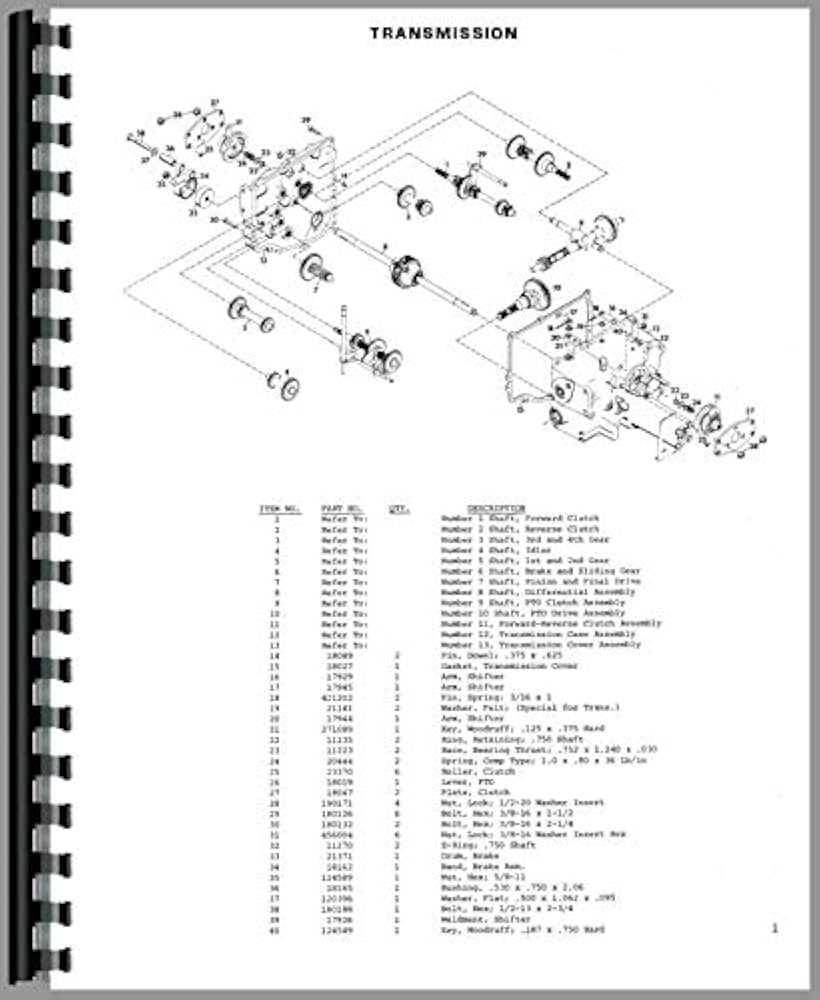

| Transmission | Mechanism for power transfer | Transfers energy from the engine to the wheels |

| Wheels | Mobility components | Enables movement across different terrains |

By familiarizing oneself with these illustrations, operators can effectively troubleshoot issues, ensuring smooth operation and minimizing downtime. Mastery of this knowledge ultimately leads to greater efficiency and reliability in using the equipment.

Importance of Accurate Diagrams

Precise representations play a crucial role in ensuring the efficiency and functionality of machinery. These illustrations serve as essential guides for maintenance and assembly, reducing the likelihood of errors during repairs or modifications.

Benefits of Detailed Representations

- Enhances understanding of complex systems.

- Facilitates quick identification of components.

- Promotes effective communication among technicians.

Consequences of Inaccurate Visuals

- Increased risk of operational failures.

- Extended downtime due to misunderstandings.

- Potential safety hazards for operators.

Key Components of Gravely Equipment

The functionality and efficiency of outdoor machinery rely heavily on several crucial elements that work in harmony. Understanding these components is essential for optimal operation and maintenance. Each part plays a significant role, contributing to the overall performance and reliability of the equipment.

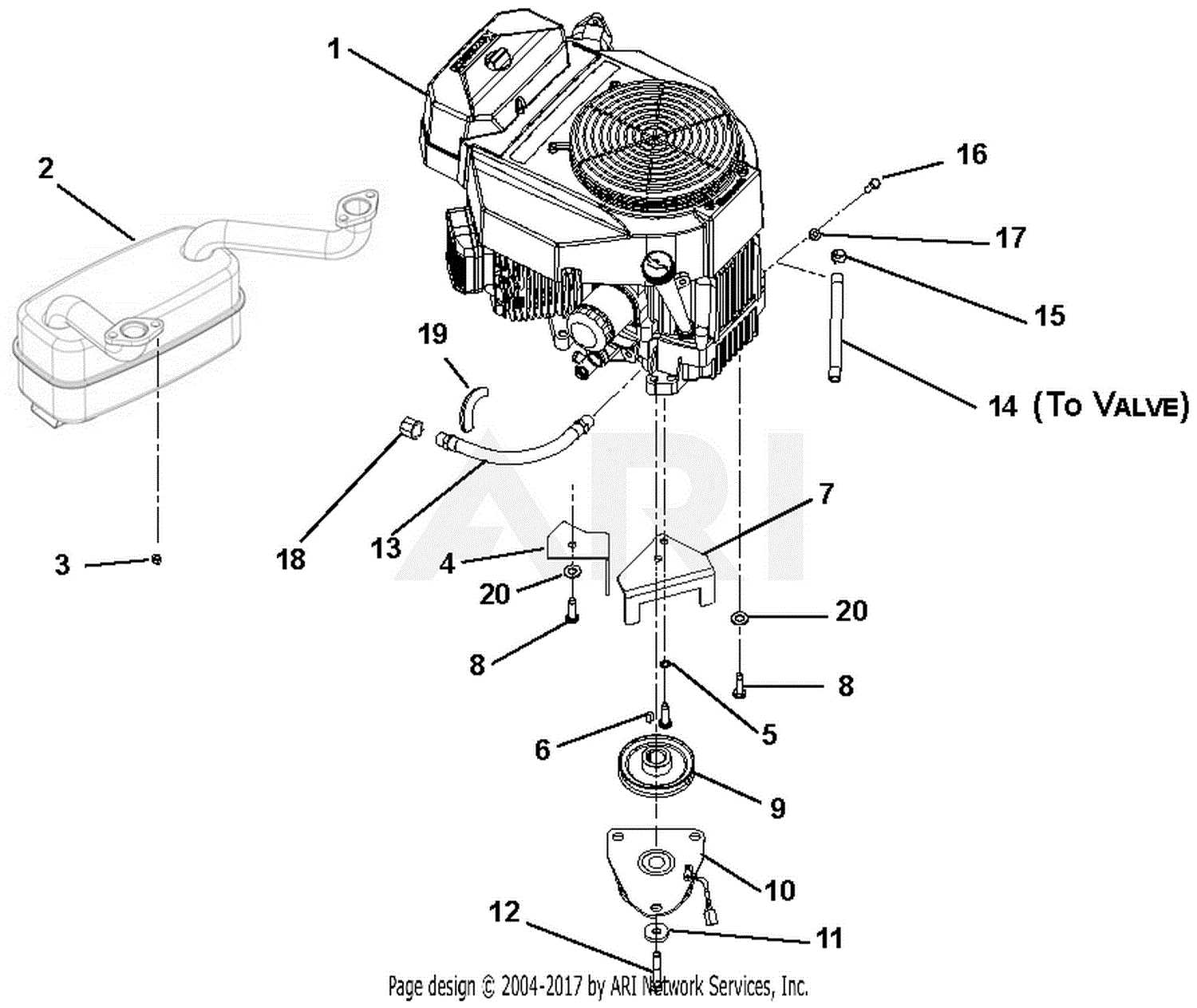

Power Systems

At the heart of any machinery lies its power system. This includes the engine, which provides the necessary energy to operate various functions. The choice of engine can greatly influence the durability and capability of the equipment. Ensuring proper maintenance of this system is vital for peak performance.

Control Mechanisms

Another essential aspect is the control mechanisms, which allow operators to manage different functionalities. These can include steering systems, throttle controls, and gear shifters, all designed to enhance user experience and control precision. Regular inspection of these components ensures smooth operation and minimizes the risk of malfunction.

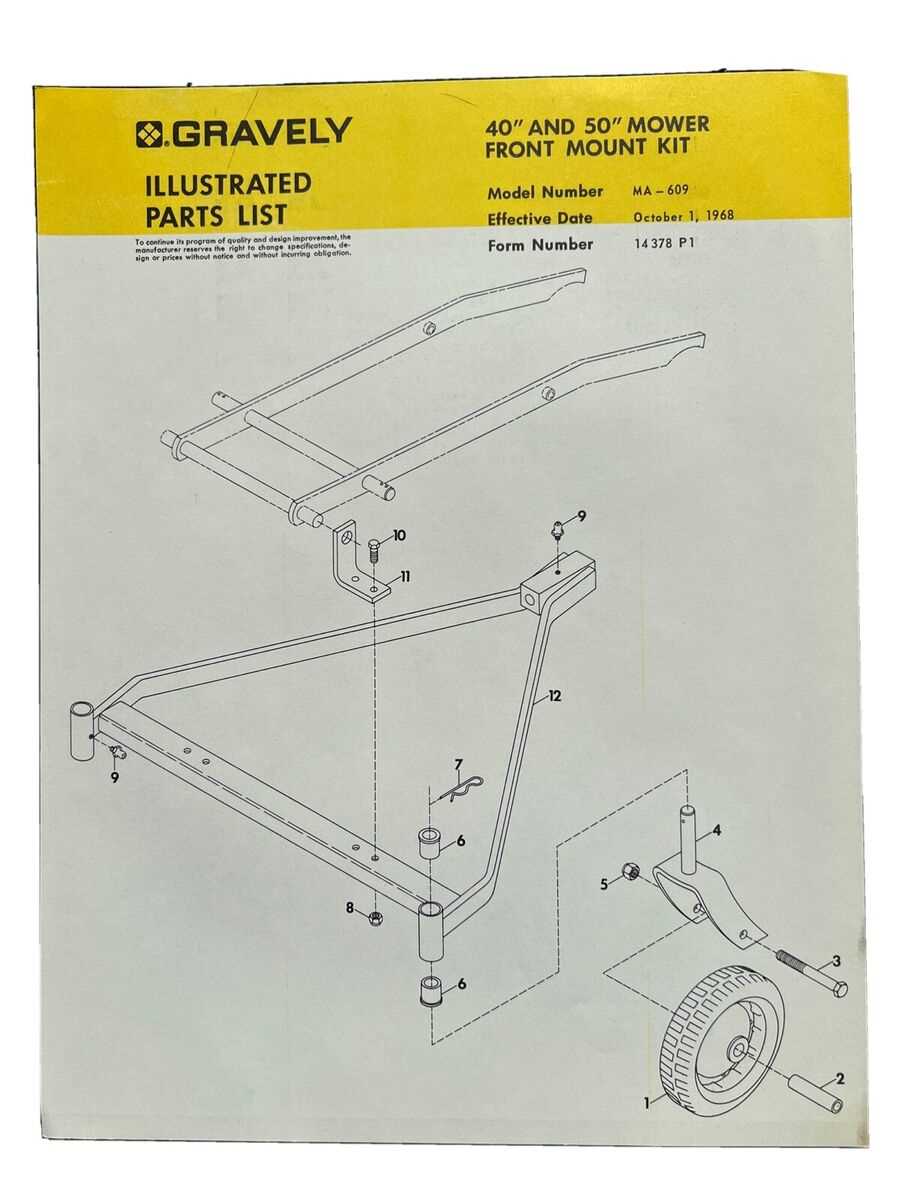

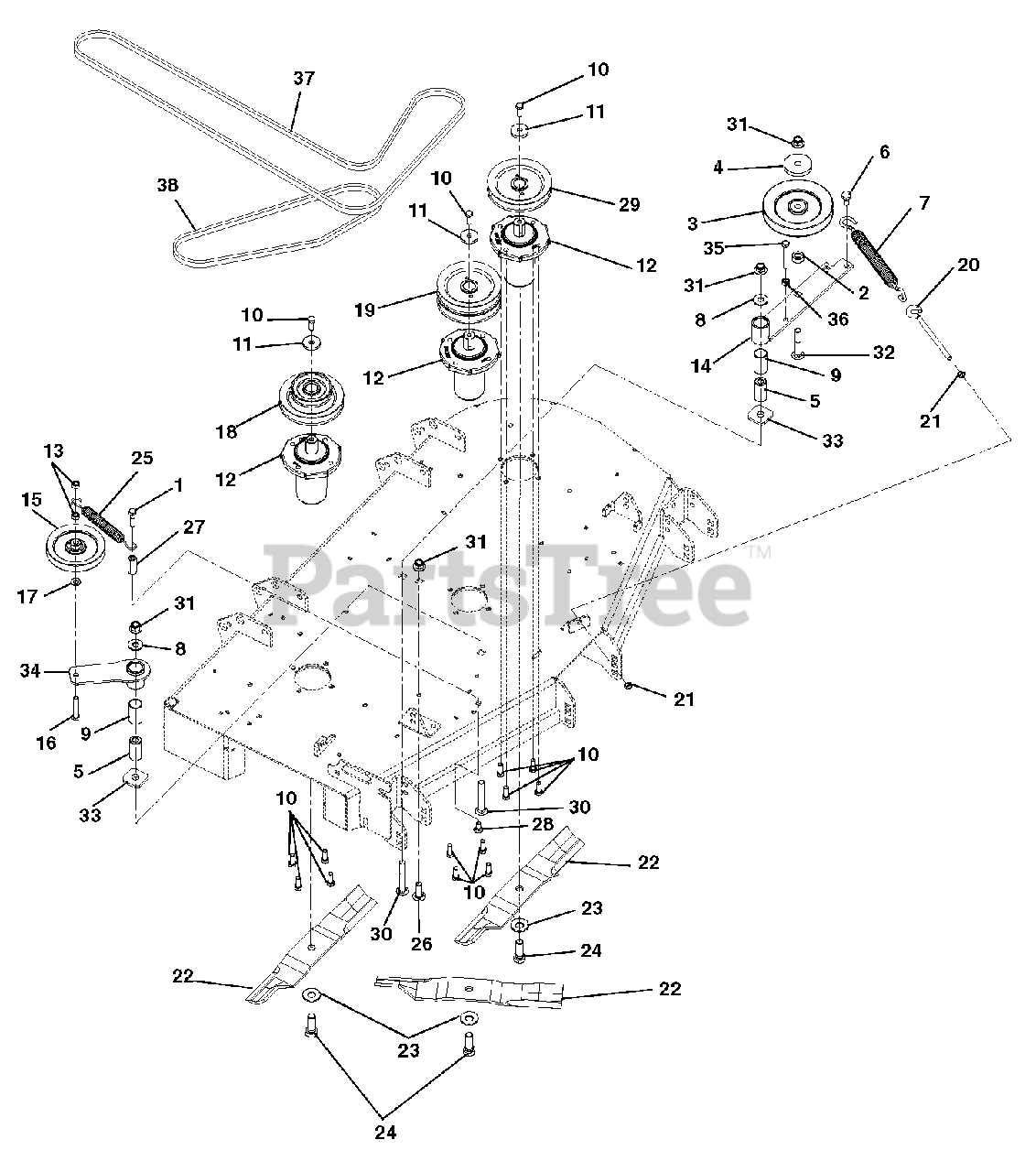

How to Read a Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repair. This guide will help you interpret the symbols and layout, making it easier to identify each element and its function.

1. Familiarize Yourself with the Legend: Most illustrations include a key that defines the symbols used. Reviewing this section will provide clarity on what each mark represents.

2. Observe the Layout: Components are typically organized in a logical manner, often reflecting their physical arrangement in the machine. Take note of how parts relate to one another.

3. Identify Groupings: Look for clusters of related items, which can indicate assembly sections or areas of interest for specific repairs. This will help you prioritize your work.

4. Pay Attention to Annotations: Many visual aids feature notes or arrows that offer additional information, such as assembly order or special instructions. These insights are crucial for successful repairs.

5. Use for Reference: Once you’ve mastered reading the illustration, keep it handy during disassembly or reassembly to ensure accuracy and efficiency.

Common Issues with Parts Identification

Identifying components for machinery can often lead to various challenges. Whether it’s due to outdated information, unclear labeling, or simply the complexity of the machinery itself, users may find it difficult to locate the correct items needed for repairs or maintenance. This section explores some frequent obstacles faced during the identification process.

Ambiguity in Labels

One of the primary difficulties arises from ambiguous or inconsistent labeling. When identifiers are not clear, it can result in confusion, leading to the selection of incorrect components. Here are some common issues:

- Inconsistent terminology across different manuals.

- Missing or faded labels on the components themselves.

- Variations in naming conventions between manufacturers.

Outdated Information

Another significant issue stems from the use of outdated resources. As equipment evolves, so do the specifications and requirements for parts. Users may encounter:

- Old manuals that do not reflect current designs.

- Online resources that have not been updated.

- Discontinued components that are no longer in production.

To overcome these challenges, it is essential to consult reliable and up-to-date resources, and when in doubt, seek assistance from knowledgeable professionals.

Benefits of Regular Maintenance

Consistent upkeep of machinery plays a vital role in enhancing performance and longevity. By engaging in routine checks and servicing, users can prevent minor issues from escalating into major failures, ensuring smooth operation and reliability.

Improved Efficiency

Regular attention to equipment helps maintain optimal performance levels. Machines that are well-cared for operate more efficiently, leading to reduced fuel consumption and lower operational costs.

Extended Lifespan

Routine maintenance significantly prolongs the lifespan of equipment. Timely interventions can prevent wear and tear, allowing machines to serve their purpose effectively for many years.

| Maintenance Activity | Benefit |

|---|---|

| Lubrication | Reduces friction and wear |

| Filter Changes | Improves air and fluid quality |

| Visual Inspections | Identifies potential issues early |

| Adjustments | Ensures proper operation |

Sources for Quality Replacement Parts

Finding reliable sources for high-quality components is crucial for maintaining the efficiency and longevity of machinery. Access to trustworthy suppliers ensures that replacements meet the necessary standards and performance expectations.

Consider the following options when searching for dependable components:

- Authorized Dealers: Official dealers often provide genuine items that guarantee compatibility and performance.

- Online Retailers: Numerous e-commerce platforms offer a wide selection of alternatives, with customer reviews aiding in the decision-making process.

- Local Repair Shops: Established workshops frequently stock essential replacements or can order them directly from manufacturers.

- Manufacturer Websites: Many producers have online catalogs showcasing available items, along with specifications and pricing.

By exploring these avenues, one can ensure the acquisition of quality components that uphold the integrity of the machinery.

Tips for DIY Repairs

Engaging in do-it-yourself maintenance can be rewarding, allowing you to save money and gain a deeper understanding of your equipment. Here are some essential tips to help you navigate the repair process effectively and safely.

| Tip | Description |

|---|---|

| Gather Tools | Ensure you have all necessary tools before starting, including wrenches, screwdrivers, and pliers. |

| Consult Manuals | Refer to user manuals or guides for specific instructions tailored to your machinery. |

| Take Notes | Document each step you take, including disassembly, to simplify reassembly. |

| Wear Safety Gear | Always use appropriate safety equipment, such as gloves and goggles, to protect yourself. |

| Test Before Finalizing | After repairs, run tests to ensure everything functions correctly before concluding the process. |

Safety Considerations During Repairs

When undertaking maintenance or repair tasks, ensuring a safe working environment is paramount. Proper precautions not only protect the individual performing the work but also extend the lifespan of the equipment being serviced. Understanding and adhering to safety protocols can significantly reduce the risk of accidents and injuries.

Personal Protective Equipment (PPE) is essential. Always wear appropriate gear such as gloves, goggles, and sturdy footwear to shield yourself from potential hazards. Depending on the nature of the task, additional protection like earplugs or respirators may be necessary to safeguard against noise and harmful fumes.

Before beginning any work, familiarize yourself with the equipment. Reviewing the manufacturer’s guidelines ensures you understand the specific safety measures relevant to the model in use. Additionally, keep the workspace organized and free from clutter to minimize tripping hazards and maintain efficiency.

During repairs, disconnecting power sources is crucial. Always ensure that machines are turned off and, if applicable, unplugged before performing any maintenance. This simple step can prevent unexpected start-ups that could lead to serious injuries.

Finally, stay vigilant and avoid distractions. Concentration is key when working with machinery; a moment of inattention can have severe consequences. By prioritizing safety, you can ensure a smoother repair process and a safer working environment.

Upgrades and Customization Options

Enhancing the performance and appearance of your equipment can significantly elevate its functionality and aesthetic appeal. Exploring various enhancement avenues allows users to tailor their machines to better suit specific tasks and personal preferences.

Performance Enhancements

There are several avenues to boost the efficiency and power of your machine:

- Engine Upgrades: Consider a higher horsepower engine for increased torque and better performance on challenging terrain.

- Transmission Modifications: Upgrading to a more advanced transmission system can improve speed and responsiveness.

- Attachment Options: Utilizing specialized attachments can expand the versatility of your equipment, allowing for various tasks.

Aesthetic Customization

Personalizing the look of your machinery can enhance its visual appeal:

- Color Variants: Choose from a range of colors to match your personal style or branding.

- Decals and Graphics: Adding custom decals or graphics can give your equipment a unique identity.

- Comfort Features: Upgrading seats and controls can improve user experience and make long hours of operation more enjoyable.

By considering these options, you can create a machine that not only performs better but also reflects your individuality and preferences.

Resources for Further Learning

Expanding your knowledge on machinery maintenance and troubleshooting can greatly enhance your skills and efficiency. This section provides valuable references and tools that will aid in your understanding and mastery of equipment repair and upkeep. Whether you are a beginner or looking to refine your expertise, these resources will serve as a helpful guide.

Online Tutorials and Courses

There are numerous platforms offering comprehensive tutorials and courses tailored to machinery handling. Websites such as Udemy and Coursera provide structured lessons ranging from basic to advanced levels. These courses often include video lectures, interactive quizzes, and practical exercises, enabling you to learn at your own pace.

Books and Manuals

Books can be an excellent source of in-depth knowledge. Consider exploring titles that focus on mechanical systems and maintenance strategies. Repair and Maintenance of Heavy Equipment and Understanding Small Engine Technology are great examples. Additionally, manufacturers often provide detailed manuals that include specifications and maintenance guidelines, making them essential resources for effective learning.