Understanding the arrangement and design of mechanical elements is essential for maintaining efficiency and ensuring proper functionality. Each component plays a critical role in the overall system, and knowing how they interact allows for a deeper appreciation of the machine’s complexity. In this section, we will explore how various elements are interconnected, contributing to the smooth operation of the system.

The detailed illustration of these components helps users identify key elements and their relationships within the framework. By analyzing the connections and layout, one can gain insights into both the construction and potential troubleshooting areas. This knowledge enhances the ability to diagnose issues effectively and make informed decisions during repairs or modifications.

As we delve deeper into this guide, we will highlight the critical aspects of the structure, offering clear insights into the role of each part. This approach will help in visualizing the entire mechanism as a cohesive system rather than a collection of separate elements, ultimately facilitating a better understanding of its operation.

Understanding the Components of the GT275

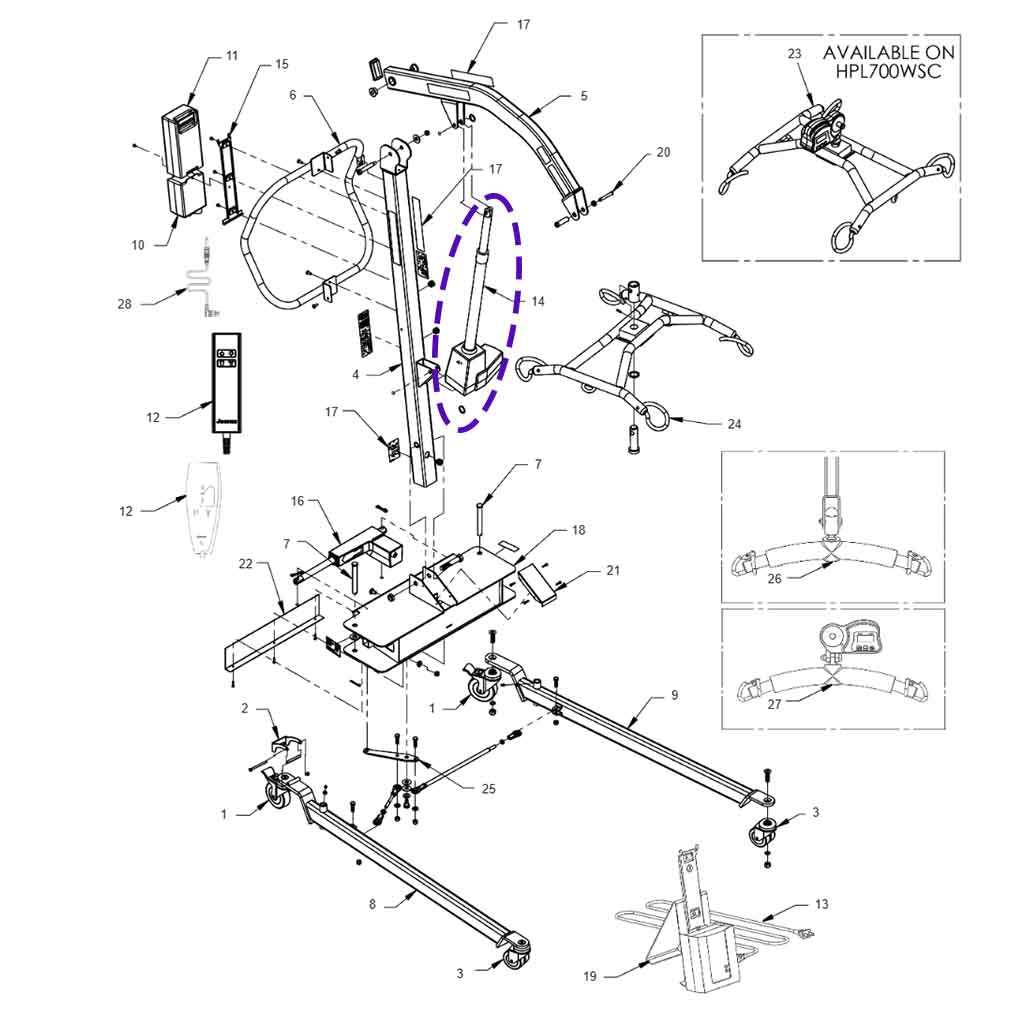

The intricate system under consideration comprises a variety of elements, each playing a vital role in ensuring proper functionality. These interconnected parts work together to maintain the overall performance, creating a complex yet efficient structure that is key to the equipment’s operation. Understanding the arrangement of these elements provides valuable insight into its functionality and helps diagnose potential issues.

Core Elements Overview

At the heart of the system lies a series of essential components, each with a specific function. These primary parts include elements responsible for movement, control, and regulation. The interaction between these components ensures smooth performance, helping to achieve the intended outcome with precision.

Supporting Mechanisms

Around the core elements are various auxiliary mechanisms designed to enhance the system’s overall efficiency. These supporting parts handle tasks such as stabilization, energy distribution, and safety, allowing the equipment to operate in a balanced and controlled manner. A deeper understanding of these mechanisms can offer insights into optimizing the entire system.

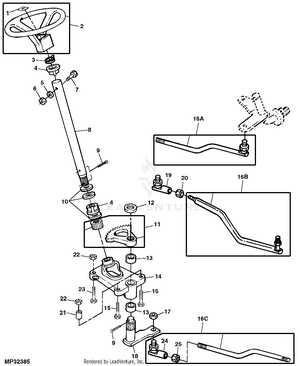

Detailed Breakdown of Key Elements

The following section provides a comprehensive exploration of the fundamental components within the system. Each element plays a crucial role in maintaining the overall functionality, contributing to the efficiency and performance of the structure as a whole. By understanding how these key features interact, one can gain deeper insights into the system’s operational integrity.

Primary Functional Components

The core structure is built upon several primary components that serve distinct purposes. These include control units that manage the flow of operations, connectors responsible for seamless communication between different segments, and power sources that ensure consistent energy supply. Each of these elements is integral to the system’s stability and reliability.

Supporting Mechanisms

In addition to the primary elements, several secondary mechanisms work behind the scenes to support the main operations. These include protective casings that safeguard sensitive components, cooling systems that regulate temperature, and fastening elements that secure various parts in place. Together, they form a cohesive framework that ensures durability and resilience.

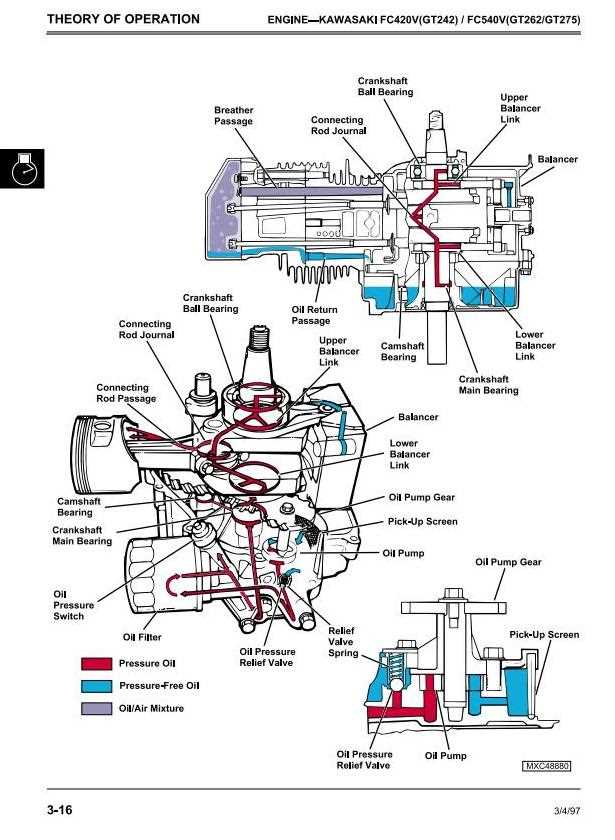

Exploring the Internal Structure of the GT275

Understanding the intricate layout of this mechanical marvel offers insight into its efficient design and performance. Each component works in harmony to deliver smooth functionality, ensuring optimal performance under various conditions. This section delves into the essential elements that comprise the machine, shedding light on how they interact to form a cohesive and reliable system.

| Component | Function |

|---|---|

| Main Assembly | Provides the foundation for the entire system, supporting the core elements. |

| Power Unit | Drives the system with energy, enabling movement and functionality. |

| Control Mechanism | Regulates the operation, ensuring precise and smooth performance. |

| Support Structures | Stabilize and reinforce key areas, maintaining the system’s durability. |

How Different Parts Work Together

Understanding how various elements function in unison is key to maintaining optimal performance. Each component contributes to the overall system, ensuring smooth and efficient operation. By recognizing the role of each piece, it’s possible to see how they influence each other and create harmony within the mechanism.

For instance, when one section initiates movement, another might regulate the flow or control the pressure, leading to a balanced output. This interplay between different sections ensures that the system remains stable, with each unit playing a critical role in its operation.

In many cases, these interactions are finely tuned, with even small adjustments to one area significantly affecting the entire system. It’s crucial to understand these relationships, as they help diagnose issues and prevent potential failures. By analyzing how each element connects and collaborates, one can ensure long-term reliability and efficiency.

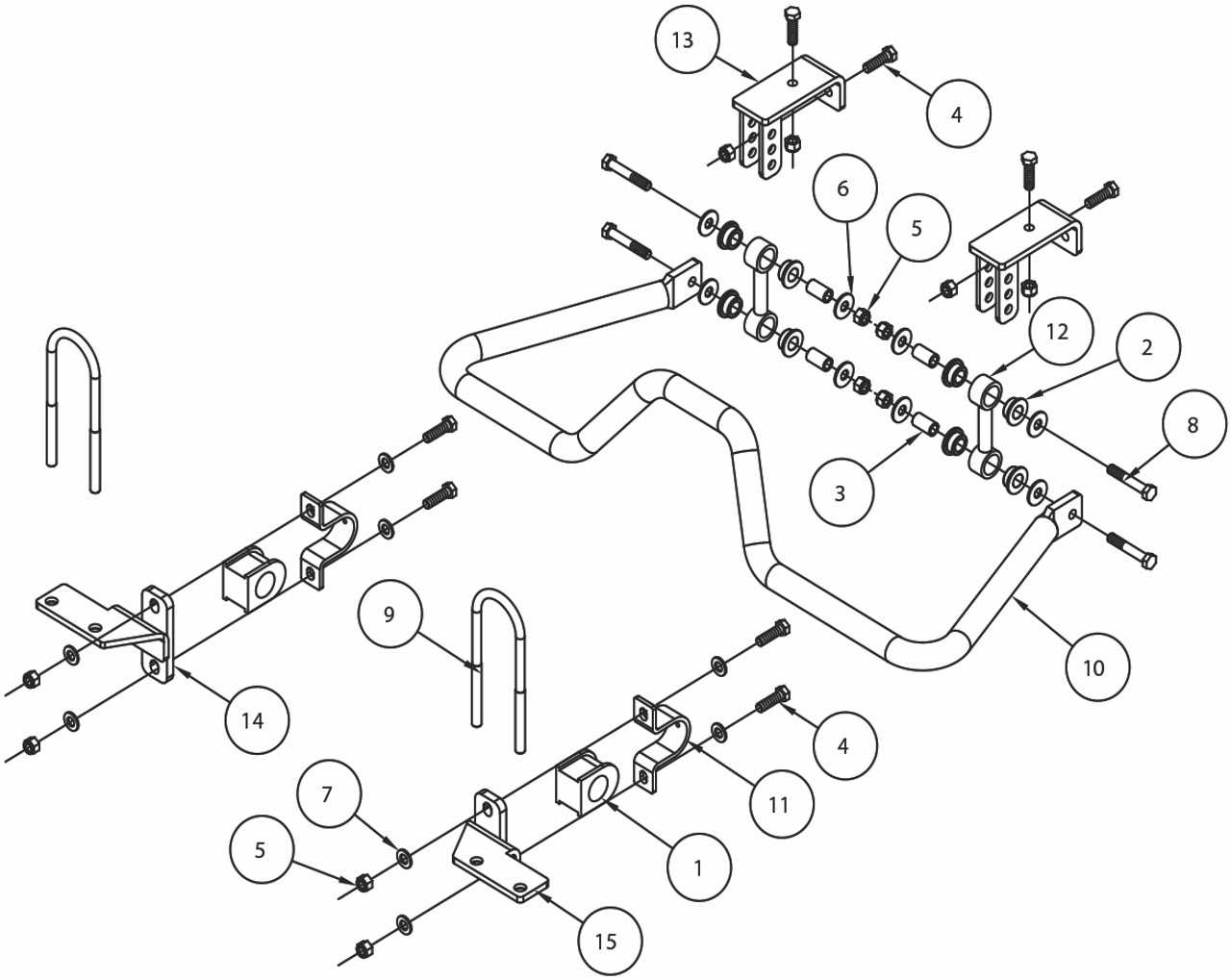

Comprehensive Guide to GT275 Assembly

The following section offers a thorough walkthrough of assembling this model, focusing on the precise arrangement of each element and how they interconnect for optimal functionality. Understanding the layout of various components ensures a smooth and efficient process while highlighting essential steps for proper configuration.

| Step | Description | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Prepare all elements, ensuring they are clean and ready for installation. Arrange them in an organized manner to streamline the process. | ||||||||||||

| 2 | Start by attaching the foundational parts, securing them firmly while maintaining alignment. This serves as the base for the entire build. | ||||||||||||

| 3 | Proceed with connecting the internal mechanisms. Ensure all fasteners are tightly secured and that moving parts are functioning without obstruction. | ||||||||||||

| 4 | Install the outer casing, making sure it fits securely over the internal structure, with no gaps or misalignments. | ||||||||||||

| 5 | Perform a final inspection to confirm that all elements are correctly

Step-by-Step Assembly Instructions

This section provides a comprehensive guide for assembling your unit efficiently. Following these instructions will ensure that all components fit together seamlessly, contributing to optimal performance. Each step is designed to be clear and straightforward, making the process accessible for users at various skill levels. Preparation and ToolsBefore you begin, gather all necessary tools and components. Having everything at hand will streamline the assembly process. Ensure you have a clean workspace to avoid losing small pieces. The recommended tools typically include a screwdriver, pliers, and any specific items mentioned in the user manual. Assembly ProcessStart with the base and attach the primary sections, ensuring each piece clicks or screws into place securely. Proceed to connect any additional elements, paying attention to alignment and fit. Refer to your manual for the correct sequence, as this will help you avoid potential issues later on. After all components are assembled, double-check connections and fittings to confirm everything is secure. Finally, conduct a thorough inspection of the entire assembly to ensure all parts are correctly positioned and functioning as intended. This careful approach will enhance durability and performance. Identifying Commonly Replaced Parts in the GT275Understanding the components that frequently undergo replacement is essential for maintaining optimal performance. Many elements within the assembly can wear out or become damaged over time, necessitating timely updates to ensure reliability and efficiency. Recognizing these items can aid in the upkeep and enhance the longevity of the equipment. Here are some of the commonly encountered components that often require attention:

Maintaining a close watch on these elements can significantly reduce downtime and enhance the overall performance of the machinery. Regular inspections and proactive replacements will ensure that the system continues to operate smoothly. Focus on Durability and MaintenanceEnsuring long-lasting performance and reliability requires a proactive approach to care and upkeep. Understanding the essential components and their interactions can significantly enhance the lifespan of your machinery. To achieve optimal durability, consider the following key areas:

In addition to these practices, engaging in scheduled maintenance can prevent unexpected downtimes and costly repairs. Implementing a systematic approach will not only enhance durability but also ensure that your equipment operates efficiently over time. The Role of Each Part in GT275 Performance

Understanding the function of each component in a system is crucial for optimizing its overall effectiveness. Each element plays a significant role in ensuring smooth operation, enhancing efficiency, and maximizing output. By exploring these roles, we can gain insights into how to achieve peak performance. Here are the primary elements and their contributions:

By examining these vital components, we can better understand how each contributes to the overall functionality and performance of the system. This knowledge is key to identifying areas for improvement and ensuring longevity. How Individual Components Affect FunctionalityEach element within a system plays a critical role in determining its overall performance. The interactions between these elements can significantly influence how effectively the entire assembly operates. Understanding the contributions of each component helps in optimizing functionality and enhancing reliability. Connections between various parts are crucial. A strong link ensures efficient energy transfer and minimizes potential disruptions. Conversely, weak or faulty connections can lead to significant performance issues, including unexpected shutdowns or inefficiencies. Power regulation is another vital aspect. Components responsible for managing energy flow must be precisely calibrated to maintain optimal operating conditions. If these units fail to perform, it can result in insufficient power delivery, causing the entire system to falter. Moreover, control mechanisms are essential for maintaining system stability. These elements monitor conditions and make necessary adjustments, ensuring that everything functions harmoniously. If any of these controls are compromised, it can disrupt the entire process, leading to reduced efficacy. Lastly, the materials used in constructing individual components can greatly impact durability and performance. High-quality materials are often more resilient, resulting in longer lifespans and better overall function. In contrast, inferior materials may wear out quickly, compromising the integrity of the system. Material Specifications of GT275 ComponentsThe selection of materials for various components plays a crucial role in ensuring their durability, performance, and overall efficiency. Each element within this system is crafted from specific substances that not only meet functional requirements but also adhere to safety and regulatory standards. Metals are often favored for their strength and resistance to wear. For instance, aluminum alloys are commonly used in structural components due to their lightweight nature and excellent corrosion resistance, making them ideal for prolonged exposure to various environmental conditions. Additionally, plastics and composites have become increasingly popular, offering versatility and cost-effectiveness. These materials provide a good balance of strength and flexibility, allowing for complex shapes and designs that enhance the overall functionality of the components. Thermal stability is another critical consideration. Materials must withstand a range of temperatures without degrading or losing integrity. This is especially important in high-performance applications where thermal expansion and contraction can affect operational efficiency. Finally, chemical resistance is essential for components that come into contact with various fluids or environmental agents. Selecting the right materials ensures that parts maintain their performance and longevity, contributing to the reliability of the entire assembly. Insight into Build Quality and Design

The excellence of a device lies not only in its performance but also in the meticulous craftsmanship and thoughtful architecture that define its overall integrity. An exploration into the construction and aesthetic aspects reveals how these elements contribute to functionality and user experience. Each component plays a crucial role in ensuring durability and efficiency, reflecting the manufacturer’s commitment to quality. Design choices significantly influence the operational effectiveness of the system. A well-structured assembly enhances both the longevity of the device and the ease of maintenance. Evaluating materials, assembly methods, and ergonomic features provides insights into the product’s reliability and user satisfaction.

Troubleshooting GT275: Key Components to InspectWhen addressing issues with this equipment, it’s crucial to focus on its essential elements. Identifying and examining these components can significantly enhance the efficiency of your troubleshooting efforts. By narrowing down potential problems, you can save time and ensure proper functionality. Power SupplyThe first area to check is the power supply. Ensure that it delivers the appropriate voltage and current required for optimal operation. A malfunctioning power source can lead to various issues, including intermittent failures or complete inoperability. Utilize a multimeter to verify the output and confirm that all connections are secure. Control Systems

Next, pay attention to the control systems. Inspect any electronic interfaces and control boards for visible signs of damage, such as burnt traces or loose connectors. Regular maintenance of these components can prevent many common operational problems. Ensure that firmware is up to date, as outdated software can lead to unexpected behavior and performance issues. |