In the realm of accessible hydration solutions, a comprehensive exploration of essential elements is crucial for effective maintenance and functionality. Recognizing the various components involved not only enhances user experience but also ensures longevity and reliability of these systems. A thorough understanding of each element aids in troubleshooting common issues and optimizes performance.

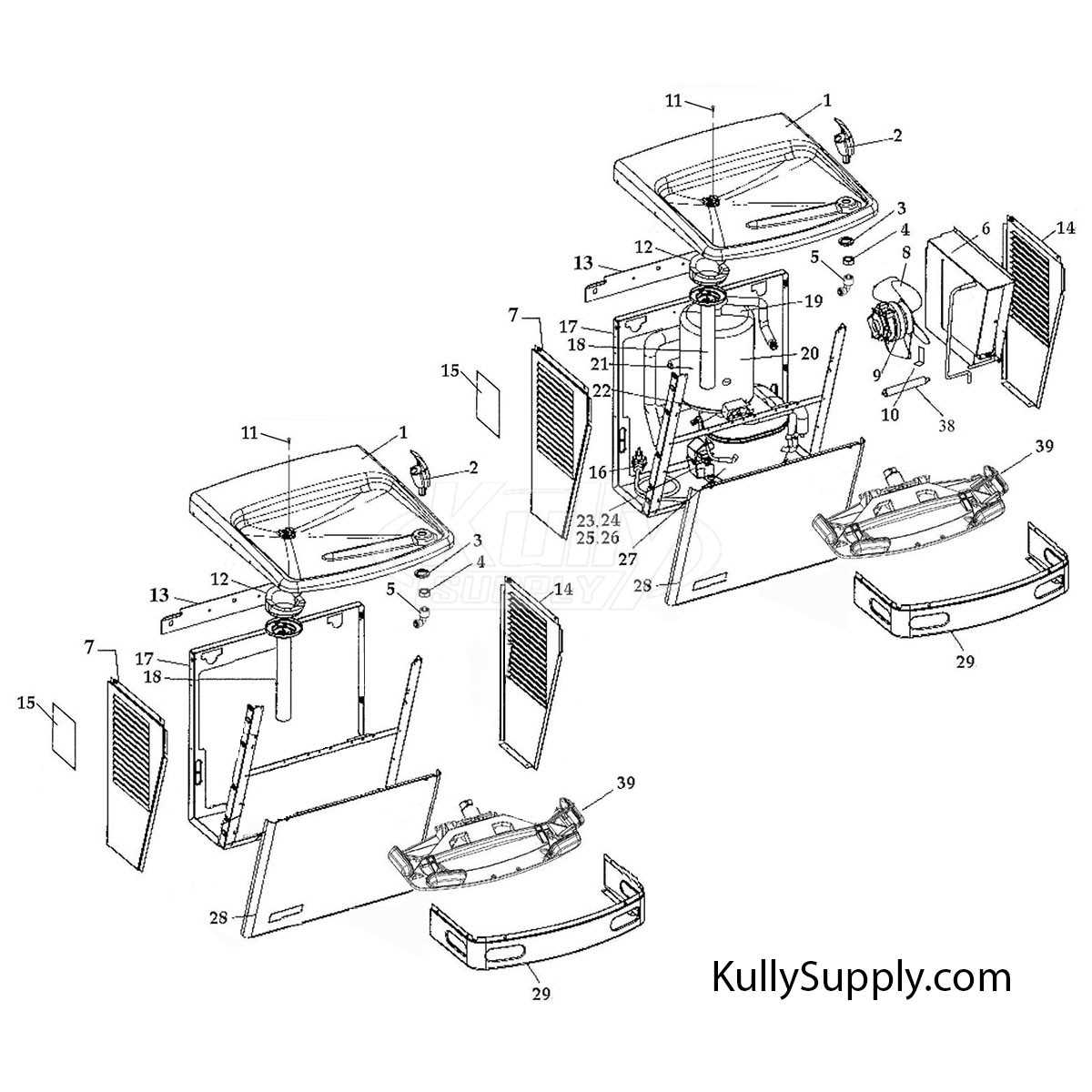

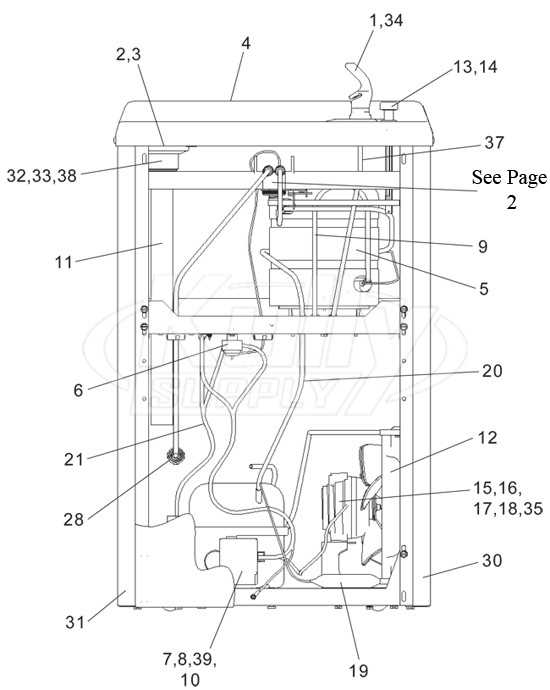

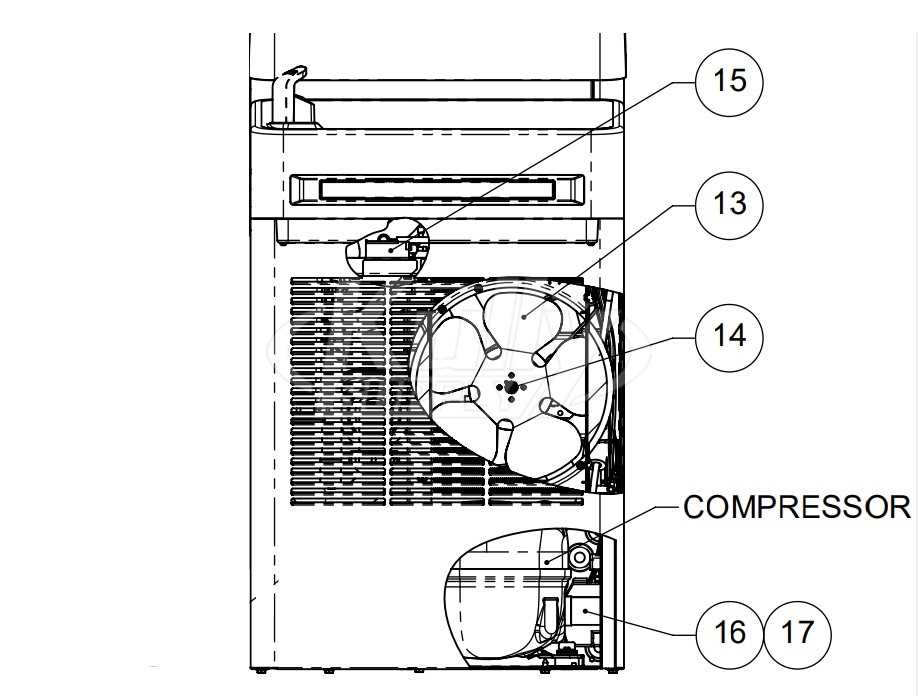

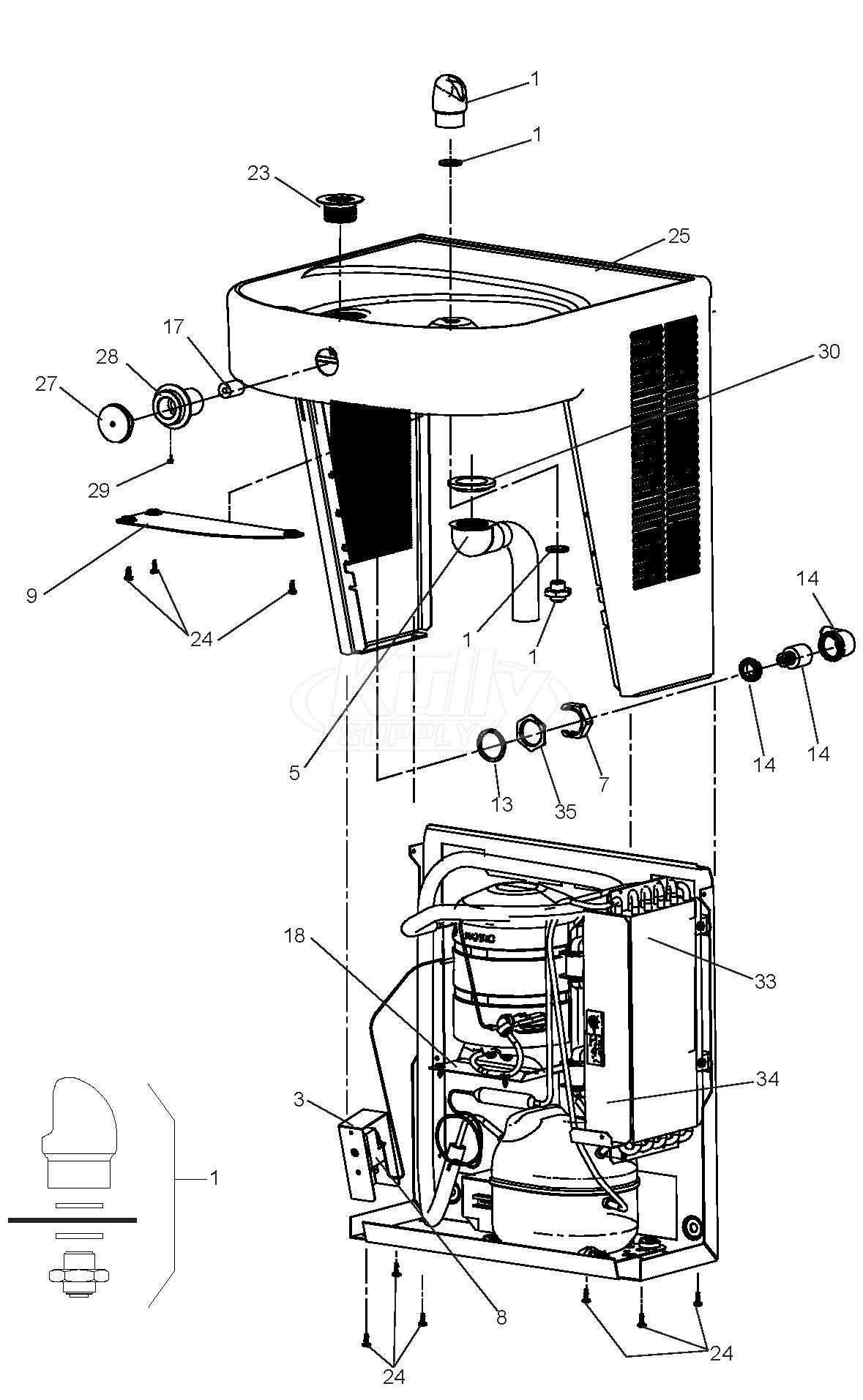

Visual aids play a pivotal role in grasping the arrangement and interaction of these critical elements. By examining a detailed schematic, one can gain insight into the structure and connections that facilitate the delivery of fresh water. Such illustrations serve as valuable references for technicians and facility managers alike.

Additionally, knowledge of individual components empowers users to address problems proactively. This awareness can lead to timely repairs, reducing downtime and maintaining the availability of hydration resources. Emphasizing the importance of understanding these integral parts cultivates a more sustainable approach to water access in public spaces.

Understanding Haws Drinking Fountain Components

Familiarity with the elements of a water dispensing unit is essential for effective maintenance and repair. Each component plays a crucial role in the overall functionality, contributing to the efficiency and reliability of the system. By gaining insight into these components, users can ensure optimal performance and longevity of the unit.

Reservoir: This integral section stores water, ensuring a constant supply for dispensing. Its design is crucial for maintaining temperature and hygiene standards.

Spigot: Often the most visible part, this outlet controls the flow of water. Various styles may offer different features, such as push-button activation or sensor-based operation, enhancing user convenience.

Filter: Many systems incorporate filtration mechanisms to improve water quality. This component removes impurities, contributing to a safer drinking experience.

Drainage System: Proper drainage is vital for preventing overflow and maintaining cleanliness. A well-designed drainage system directs excess water away, reducing the risk of spills and contamination.

Mounting Hardware: The structural integrity of the unit relies on appropriate mounting. This hardware secures the system in place, ensuring stability during use.

Control Mechanisms: These elements govern the operation of the system, including flow rate and temperature settings. Understanding these controls is essential for users who seek to customize their experience.

By comprehensively understanding these components, individuals can make informed decisions regarding installation, troubleshooting, and routine upkeep, ultimately enhancing the overall user experience.

Overview of Haws Fountain Models

This section provides an insightful look into the various models produced by a leading manufacturer of hydration stations, focusing on their unique features, designs, and functionalities. Each model is engineered to meet diverse needs, whether for public spaces, schools, or industrial environments, ensuring easy access to refreshing water for everyone.

Model Variations

The range of available designs includes freestanding units, wall-mounted options, and specialized versions for outdoor settings. Each variation is tailored to specific applications, balancing aesthetic appeal with practicality. The selection process often hinges on factors such as location, user capacity, and maintenance requirements, ensuring that the chosen model aligns with the intended purpose.

Innovative Features

Many models incorporate advanced technology, such as touchless activation and filtration systems, enhancing usability and hygiene. These innovations not only improve user experience but also promote sustainability by encouraging increased water consumption while minimizing waste. Understanding these features is crucial for selecting the most suitable unit for any given environment.

Importance of Regular Maintenance

Consistent upkeep of water dispensing systems is essential to ensure their longevity and efficient operation. Regular checks and servicing not only prevent malfunctions but also enhance the user experience by providing clean and safe hydration options. Neglecting maintenance can lead to costly repairs, compromised functionality, and potential health risks, making it vital for establishments to prioritize routine inspections.

Benefits of Preventative Care

Implementing a preventative maintenance schedule helps identify minor issues before they escalate into significant problems. By addressing wear and tear proactively, facilities can save on unexpected repair costs and downtime. Additionally, regular servicing contributes to the overall cleanliness and safety of the system, ensuring that users have access to fresh and uncontaminated water.

Enhancing Efficiency and Sustainability

Well-maintained systems operate more efficiently, reducing water waste and energy consumption. This not only aligns with environmental sustainability goals but also lowers operational costs. Regular maintenance checks can optimize the performance of components, contributing to a more eco-friendly approach while ensuring that hydration systems remain reliable for daily use.

Common Issues with Drinking Fountains

Public hydration stations often encounter a range of common problems that can affect their functionality and user experience. Understanding these issues is essential for ensuring that these essential fixtures remain operational and accessible to everyone. This section explores frequent complications and potential solutions to maintain these vital resources effectively.

Frequent Complications

Several recurring complications can arise with hydration units, including leaks, low pressure, and contamination. Identifying these issues early can prevent further damage and ensure a continuous supply of clean water.

| Issue | Description | Potential Solutions |

|---|---|---|

| Leaks | Water pooling around the base or components indicates a malfunction that requires attention. | Check seals and connections; replace any damaged parts. |

| Low Pressure | Weak water flow can frustrate users and deter usage. | Inspect filters and valves; clean or replace as necessary. |

| Contamination | Unpleasant taste or odor can indicate impurities in the water supply. | Regularly clean surfaces and inspect the water source for quality. |

Maintenance Tips

Regular upkeep can significantly reduce the likelihood of complications. Routine inspections, timely repairs, and adherence to cleanliness standards will promote the longevity and reliability of these hydration sources.

How to Identify Faulty Parts

Understanding how to detect malfunctioning components is crucial for maintaining optimal performance of your hydration units. Regular assessments can help you recognize issues before they escalate, ensuring longevity and reliability. Here, we’ll explore key indicators that suggest certain elements may need replacement or repair.

Common Signs of Malfunction

Look for noticeable discrepancies such as leaks, irregular water flow, or unusual noises. These symptoms often signal that a particular component is not functioning as intended. For example, if water pressure fluctuates unexpectedly, it may point to a problem with the valve or other internal mechanisms.

Conducting a Visual Inspection

A systematic visual inspection can reveal wear and tear on critical elements. Examine seals, gaskets, and fittings for signs of deterioration or damage. Additionally, check for any corrosion or buildup that may impede functionality. This proactive approach allows for early detection and prompt action to resolve any issues.

Replacement Parts for Haws Fountains

Maintaining functionality and aesthetics in public hydration stations is crucial for ensuring user satisfaction and hygiene. Regular updates and repairs can prolong the lifespan of these installations and enhance their efficiency. This section focuses on the essential components required for servicing and upgrading these units.

Identifying Necessary Components

Understanding the specific elements that require replacement is vital for effective maintenance. Commonly, the most frequently needed items include valves, filters, and fittings. Each plays a pivotal role in the overall operation, and timely replacement can prevent further complications.

Finding Quality Substitutes

When seeking out replacements, it is imperative to choose high-quality substitutes that ensure compatibility and reliability. Many suppliers offer an extensive range of options designed to fit various models, allowing for seamless integration and optimal performance.

Installation and Maintenance Tips

Proper installation is key to the effective operation of these components. Following the manufacturer’s guidelines and utilizing the right tools can significantly ease the process. Additionally, routine checks can help in identifying wear and tear before they lead to more significant issues, ensuring that the stations remain functional for all users.

Tools Needed for Repairs

When it comes to maintaining and fixing essential water dispensing units, having the right tools is crucial for a successful outcome. Proper equipment not only ensures efficiency but also minimizes the risk of damage during the repair process. Below is a list of tools that are commonly needed to carry out effective repairs.

- Screwdrivers: A set of both flathead and Phillips screwdrivers is essential for loosening and tightening screws.

- Wrenches: Adjustable wrenches or socket sets help in securing nuts and bolts.

- Pliers: Needle-nose and standard pliers are useful for gripping, twisting, and cutting wire or small components.

- Utility Knife: A sharp utility knife is handy for cutting through seals or old tubing.

- Replacement Parts: Keep a selection of common components on hand for quick replacements.

Before starting any repair work, ensure that all necessary tools are gathered to streamline the process. This preparation will help in addressing any issues effectively and efficiently.

Step-by-Step Repair Process

Repairing a water dispenser requires a systematic approach to ensure that all components are functioning properly. This section outlines a methodical procedure to address common issues, enabling you to restore the unit to its optimal condition effectively.

1. Gather Necessary Tools and Materials

Before beginning any repairs, it’s essential to collect all the tools and materials you will need. Typically, you might require screwdrivers, wrenches, replacement components, and cleaning supplies. Having everything ready at hand will streamline the repair process and reduce downtime.

2. Assess and Identify the Problem

Start by examining the unit thoroughly to determine the nature of the malfunction. Look for visible signs of wear, leaks, or any unusual noises during operation. Once the issue is identified, refer to the user manual for troubleshooting guidelines specific to your model, which will provide valuable insights into potential causes and solutions.

After gathering all necessary information and materials, you can proceed with the repair steps to ensure a successful resolution of the problem.

Tips for Efficient Troubleshooting

Effective problem resolution requires a systematic approach to identify and address issues efficiently. By following a structured method, you can minimize downtime and enhance performance. Below are key strategies to optimize your troubleshooting process.

- Understand the System: Familiarize yourself with the components and their functions. Knowledge of how each element interacts will aid in pinpointing problems quickly.

- Gather Information: Collect relevant data before attempting to diagnose the issue. This may include operational history, user feedback, and any error codes that may have appeared.

- Inspect Visual Cues: Examine the system for any visible signs of malfunction, such as leaks, corrosion, or wear. These indicators can often lead to the root cause of the problem.

Once you have a preliminary understanding of the situation, consider the following steps:

- Prioritize Issues: Focus on the most critical problems first, as these may significantly impact functionality.

- Test Components: Isolate and test individual elements to determine their operational status. This method helps to identify which parts may be underperforming.

- Utilize Documentation: Reference user manuals or service guides to understand common issues and recommended solutions. This resource can provide valuable insights into specific troubleshooting procedures.

- Consult Experts: When in doubt, reach out to professionals or technical support. Their expertise can offer guidance that saves time and resources.

By adopting these strategies, you can enhance your troubleshooting efforts, leading to quicker resolutions and improved reliability of the system.

Understanding Water Flow Mechanism

The process of water movement within a system is essential for ensuring a steady supply of hydration. By examining the underlying principles of how fluids are directed, one can gain insights into the factors that influence efficiency and reliability. This understanding is crucial for maintaining optimal functionality in various setups designed for public use.

At its core, the mechanism relies on a combination of pressure dynamics, gravity, and structural design. Water is transported from a source through pipes and valves, where specific configurations dictate the flow rate and direction. Understanding these elements can aid in troubleshooting and optimizing the system for better performance.

| Component | Function | Impact on Flow |

|---|---|---|

| Pressure Regulator | Maintains consistent water pressure | Prevents fluctuations that can disrupt flow |

| Control Valve | Manages the opening and closing of water passages | Directs flow to specific outlets or stops it completely |

| Piping | Transports fluid from one location to another | Affects flow rate based on diameter and material |

| Spout | Dispenses water for access | Determines the spread and volume of released fluid |

Comprehending these elements allows for more effective management of the hydration systems. Regular maintenance and evaluation can ensure longevity and performance, ultimately enhancing user experience and satisfaction.

Comparing Haws to Other Brands

When assessing various manufacturers of hydration solutions, it is essential to analyze their offerings in terms of durability, design, functionality, and customer satisfaction. The choice of a reliable unit significantly impacts user experience and overall satisfaction. This comparison sheds light on how one brand stands out amidst its competitors, highlighting key aspects that may influence purchasing decisions.

Durability and Build Quality

One of the most critical factors in selecting a hydration unit is its longevity. Certain brands utilize premium materials that withstand wear and tear better than others. Consumers often report that some options are more prone to damage over time, which can lead to increased maintenance costs. Evaluating the construction quality helps determine which products are likely to offer a better return on investment.

Functionality and Features

Functionality varies significantly across different brands. While some prioritize aesthetic appeal, others focus on user-friendly features that enhance the overall experience. Innovative technology may include touchless operation, customizable settings, or advanced filtration systems. Understanding these functionalities can guide potential buyers in selecting a model that best fits their needs.

Resources for Further Assistance

Finding the right support can significantly enhance your understanding and resolution of any issues related to your hydration systems. Whether you are looking for detailed guides, troubleshooting tips, or expert advice, various resources are available to help you navigate your inquiries effectively.

- Manufacturer’s Website: Check the official site for comprehensive manuals, FAQs, and specific guidance related to maintenance and repairs.

- Online Forums: Engage with communities on platforms like Reddit or specialized forums where users share experiences, solutions, and best practices.

- Customer Support: Reach out directly to customer service for personalized assistance and expert recommendations.

- Instructional Videos: Utilize platforms like YouTube to find visual tutorials that can simplify complex tasks and provide step-by-step instructions.

By leveraging these resources, you can gain deeper insights and practical solutions tailored to your unique requirements.