The internal setup of various types of heating units can sometimes seem complex. However, by breaking down the essential components and their arrangement, it becomes much easier to grasp how these systems work. Each element plays a crucial role in maintaining the efficiency and longevity of the equipment, ensuring proper functionality and performance.

In this guide, we’ll explore the main components found in typical heating devices. By identifying and understanding the purpose of each section, you’ll gain valuable insights into how these systems operate and how to maintain them effectively. We’ll also touch upon key details that can help in troubleshooting and repairs.

Heater Overview

This type of heating system is widely recognized for its efficiency in warming large pools. It utilizes a powerful mechanism designed to maintain water temperature at a desired level, ensuring consistent comfort for users. This model’s robust construction and advanced technology offer reliable performance in various environments, making it an essential component for many pool owners.

| Feature | Description |

|---|---|

| Heating Capacity | Designed to handle large volumes of water, ensuring quick and even heating. |

| Energy Efficiency | Incorporates systems that minimize energy consumption while maximizing output. |

| Durability | Built with high-quality materials to withstand exposure to weather and frequent use. |

| Control Features | Offers intuitive controls for adjusting temperature and monitoring performance. |

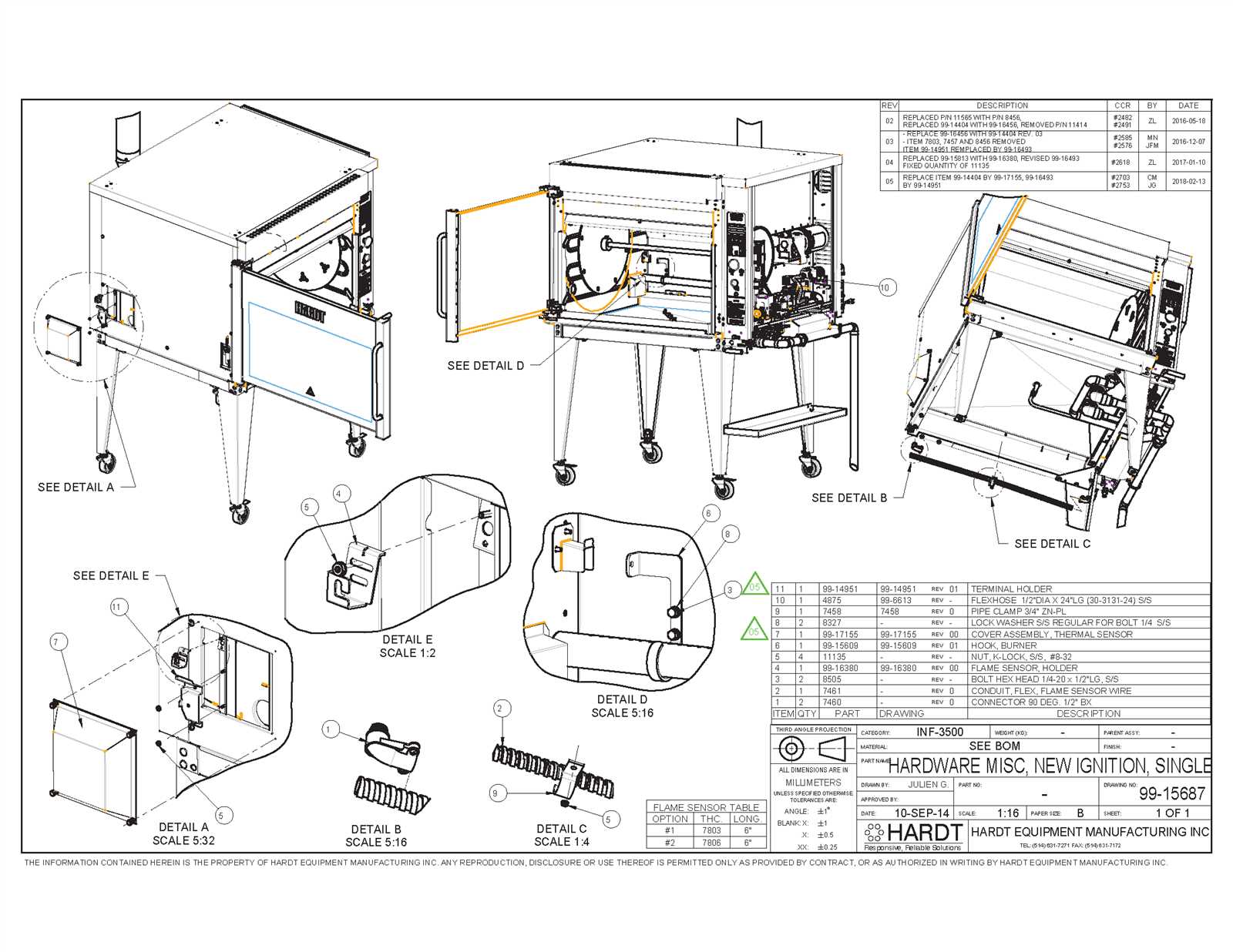

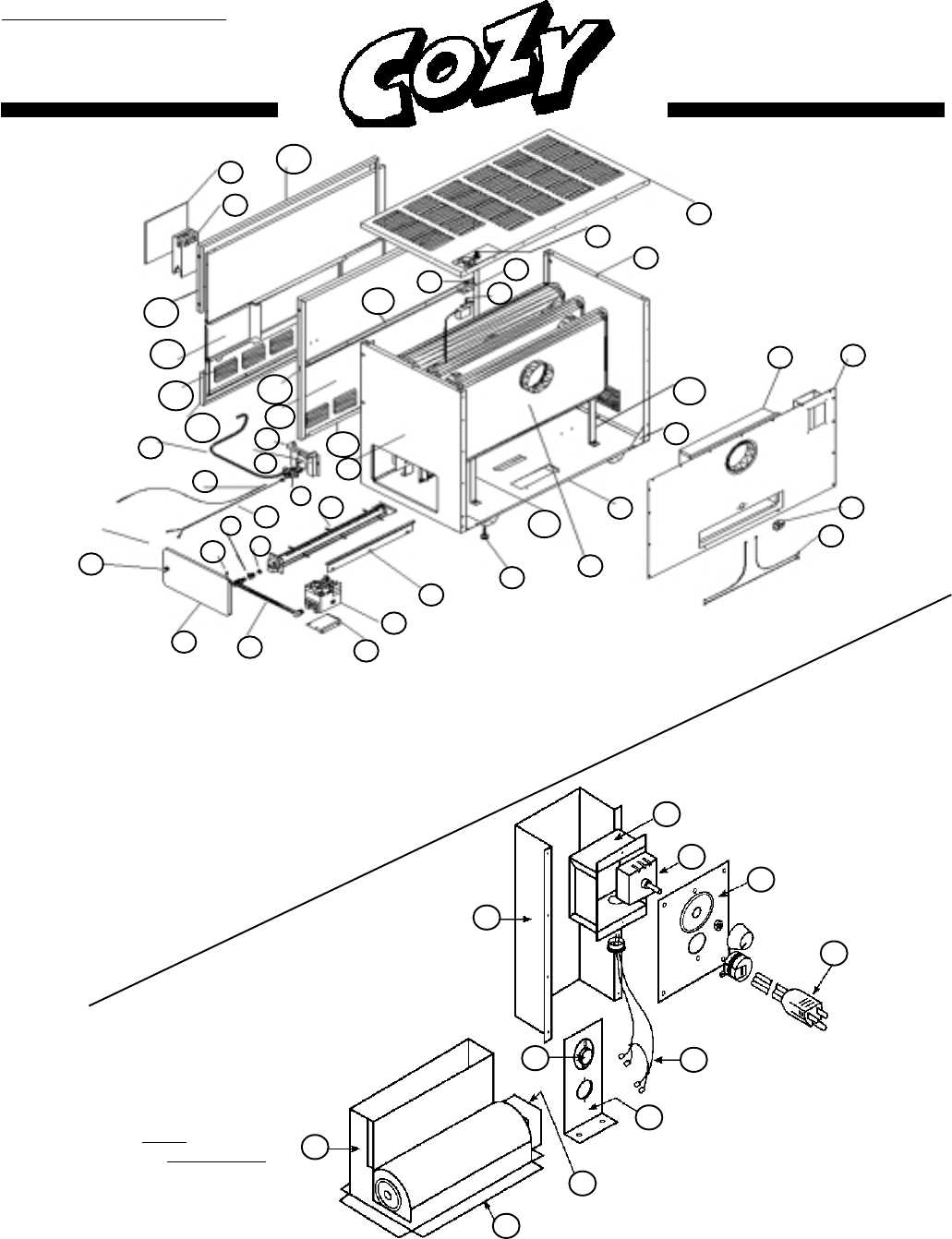

Main Components of the Heating System

This section outlines the essential elements that ensure the efficiency and functionality of this specific heating system. Each part plays a critical role in maintaining the overall performance and safety of the unit, working together to deliver reliable heat generation and distribution.

Core Heating Element

The primary component responsible for generating warmth is the central burner. This element ignites fuel to produce the required thermal energy, which is then transferred through the system. Proper maintenance of this element is crucial for optimal operation.

Water Flow Regulator

Another vital piece is the water flow controller, which manages the movement of water through the unit. This part ensures that water is heated efficiently and distributed evenly throughout the system, preventing overheating or energy waste.

How to Identify Specific Heater Parts

Recognizing the individual elements of a heating unit can be essential for efficient maintenance and troubleshooting. It’s important to be familiar with the main components and their functions, as this knowledge helps in both repair and replacement processes.

Key Areas to Inspect

The heating system consists of several vital sections that must be carefully examined. Understanding where to look and what to focus on can simplify identifying which component requires attention.

| Component | Description |

|---|---|

| Control Panel | Responsible for regulating the temperature and settings of the heating unit. |

| Burner Assembly | Ignites the fuel source to generate heat, crucial for the system’s operation. |

| Heat Exchanger | Transfers heat from the burner to the water, ensuring efficient temperature control. |

| Thermostat | Monitors the water temperature and activates the burner when needed. |

Locating Common Problem Areas

While examining the system, certain areas often require more attention due to wear and tear. By familiarizing yourself with these parts, you can ensure quicker

Common Issues with Heating System Components

The performance of heating systems can sometimes be hindered by a variety of technical problems. Over time, certain elements may experience wear or require maintenance to function optimally. Addressing these concerns promptly ensures that the system operates efficiently and avoids larger complications.

- Burner Malfunctions: One of the primary issues can arise from the burner. Accumulation of debris or improper ignition might lead to inefficient heating or failure to start.

- Control Panel Failures: Inconsistent readings or malfunctioning buttons on the control unit can make it difficult to regulate the temperature or monitor the system’s status.

- Heat Exchanger Problems: The exchanger may become clogged or corroded, affecting its ability to transfer heat effectively, which reduces overall performance.

- Sensor Calibration Issues: Faulty or uncalibrated sensors can result in inaccurate temperature regulation, causing the system to underperform or shut down unexpectedly.

Regular maintenance and timely repairs are key to preventing these issues and ensuring that the system continues to function smoothly for years to come.

Replacing Worn-Out Heater Parts

Over time, components of a heating system may begin to wear out due to continuous use, reducing the unit’s overall efficiency. Timely replacement of these worn elements ensures that your equipment continues to operate effectively and prevents more serious issues from developing.

Here’s a basic guide to replacing damaged or deteriorated elements:

- First, switch off the power and disconnect the heating system to avoid any accidents during the process.

- Inspect the various elements of the unit, such as the heat exchanger, ignition system, and valves, for signs of wear, rust, or damage.

- Once the faulty components have been identified, purchase replacements that are compatible with your specific model.

- Follow the manufacturer’s instructions carefully when removing and installing new elements to ensure a safe and efficient replacement.

- After the installation, reconnect the system and perform a test to verify that everything is functioning correctly.

Regular maintenance and timely replacement of worn-out elements are crucial to extending the lifespan of your heating system.

Understanding the Heater Control Panel

The control interface of a heating unit plays a crucial role in managing its operation and efficiency. It provides users with the means to regulate temperature settings, monitor performance, and ensure safe functioning. Familiarizing oneself with the various components and functions of this interface is essential for optimal use and maintenance of the heating system.

Key Components

The main features of the control panel typically include temperature adjustment buttons, operational indicators, and safety features. Each button and display serves a specific purpose, allowing users to customize their heating experience according to personal preferences and environmental conditions.

Operational Guidelines

To maximize the effectiveness of the heating system, users should adhere to the operational guidelines provided within the control panel. This may involve setting the desired temperature, utilizing timers for efficient energy use, and regularly checking indicator lights to ensure proper functionality. Understanding these elements can lead to enhanced performance and longevity of the unit.

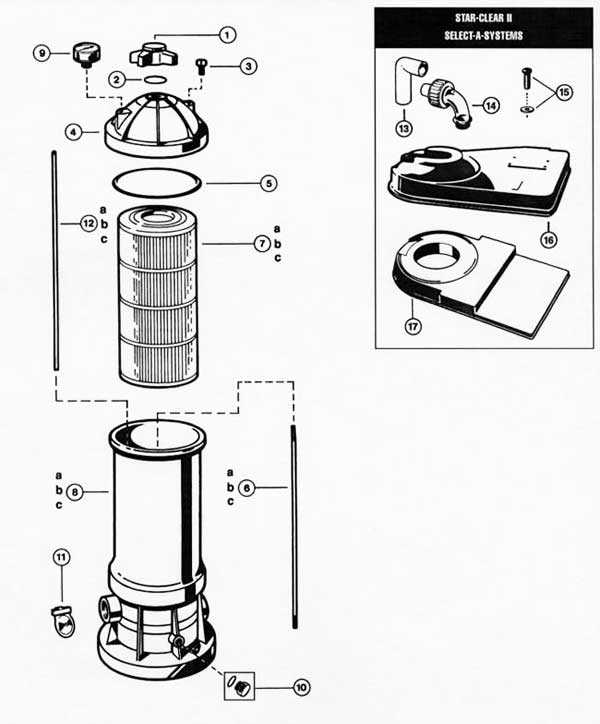

Heat Exchanger and Its Maintenance

A heat exchanger plays a crucial role in various systems by facilitating the transfer of thermal energy between two or more fluids. Proper maintenance of this component ensures efficiency and longevity, minimizing operational costs and downtime. Regular inspections and servicing are essential to maintain optimal performance and prevent potential issues.

Importance of Regular Maintenance

Routine maintenance of the heat exchanger is vital for ensuring its effectiveness. Neglecting this aspect can lead to reduced efficiency, increased energy consumption, and eventual system failures. By adhering to a structured maintenance schedule, operators can identify and address issues early, ensuring the system operates smoothly.

Common Maintenance Practices

Several practices can enhance the performance and lifespan of the heat exchanger. These include cleaning, inspecting for leaks, and checking fluid levels. Additionally, monitoring the pressure and temperature differentials helps in assessing the unit’s functionality.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Visual Inspection | Monthly | Check for leaks, corrosion, and physical damage. |

| Cleaning | Quarterly | Remove debris and scale to enhance heat transfer efficiency. |

| Fluid Level Check | Monthly | Ensure proper fluid levels for optimal operation. |

| Pressure Testing | Annually | Test for leaks and ensure structural integrity. |

Safety Features and Components

Ensuring the safety of pool heating systems is paramount for both operational efficiency and user protection. Various elements contribute to creating a secure environment, minimizing risks associated with temperature control and equipment malfunction. These safety mechanisms not only enhance the overall performance but also provide peace of mind to users.

Thermal Regulation Mechanisms

One of the key aspects of safety in heating systems is the integration of thermal regulation components. These devices monitor and control the water temperature, preventing overheating that could lead to potential hazards. By maintaining optimal temperatures, these mechanisms ensure that the system operates within safe limits, protecting both the equipment and the users.

Automatic Shutoff Systems

Automatic shutoff systems serve as an essential safety feature in heating devices. When certain thresholds are reached, these systems automatically disengage the unit, reducing the risk of damage or accidents. This proactive approach not only safeguards the equipment but also helps to prevent unsafe conditions that may arise from prolonged operation beyond recommended parameters.

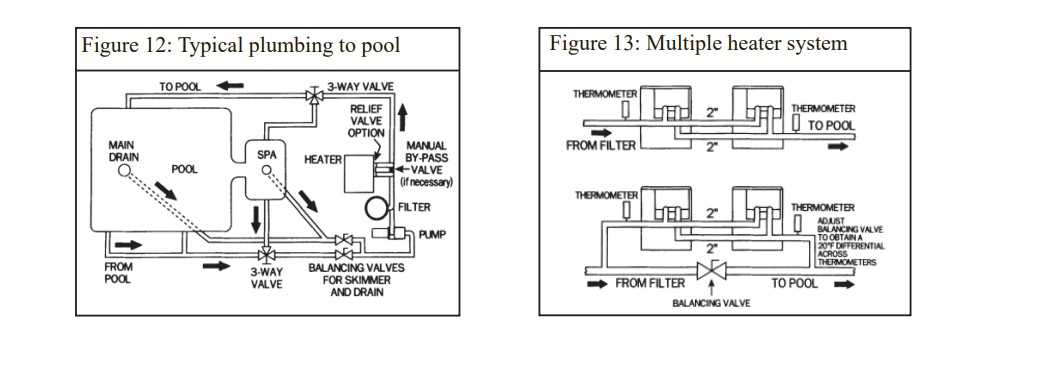

Valve Operation and Replacement

Understanding the functionality and maintenance of control mechanisms in aquatic systems is essential for ensuring optimal performance. These components play a crucial role in regulating the flow of water, thus impacting the overall efficiency of the entire setup. This section will delve into the operation of these devices, highlighting the significance of timely replacements and effective troubleshooting methods.

Operational Principles

Control mechanisms are designed to manage water flow based on specific requirements. Their operation typically involves opening or closing pathways to facilitate or restrict movement. Regular monitoring is vital to ensure they function correctly, preventing potential issues such as leaks or flow irregularities.

Replacement Procedures

When a valve shows signs of wear or malfunctions, prompt replacement is necessary. This process involves several steps to ensure proper installation and functionality:

| Step | Action |

|---|---|

| 1 | Turn off the water supply to the system. |

| 2 | Drain any remaining water from the valve. |

| 3 | Remove the old valve using appropriate tools. |

| 4 | Install the new valve securely in place. |

| 5 | Turn the water supply back on and check for leaks. |

Cleaning and Servicing Recommendations

Proper maintenance is essential for the longevity and optimal performance of your equipment. Regular cleaning and servicing can prevent malfunctions and ensure smooth operation. This section outlines key practices to keep your system in excellent condition.

| Task | Frequency | Description |

|---|---|---|

| Filter Cleaning | Weekly | Remove and rinse the filter with clean water to eliminate debris and contaminants. |

| Inspect Seals | Monthly | Check all seals and gaskets for wear or damage; replace if necessary to prevent leaks. |

| Check Connections | Monthly | Examine all electrical and plumbing connections for tightness and signs of corrosion. |

| Lubricate Moving Parts | Quarterly | Apply suitable lubricant to moving components to ensure smooth operation. |

| Professional Service | Annually | Schedule a comprehensive check-up by a qualified technician to identify and resolve potential issues. |