The effective operation of swimming pool systems relies heavily on the intricate assembly of various components designed to control and direct water flow. A comprehensive understanding of these elements is crucial for maintaining optimal performance and ensuring longevity. By delving into the layout of these mechanisms, pool owners and technicians can identify issues, perform necessary repairs, and enhance overall efficiency.

Exploring the inner workings of these assemblies reveals how each piece contributes to the system’s functionality. This knowledge empowers users to make informed decisions regarding maintenance and upgrades. Furthermore, familiarity with these configurations aids in troubleshooting potential complications that may arise during usage.

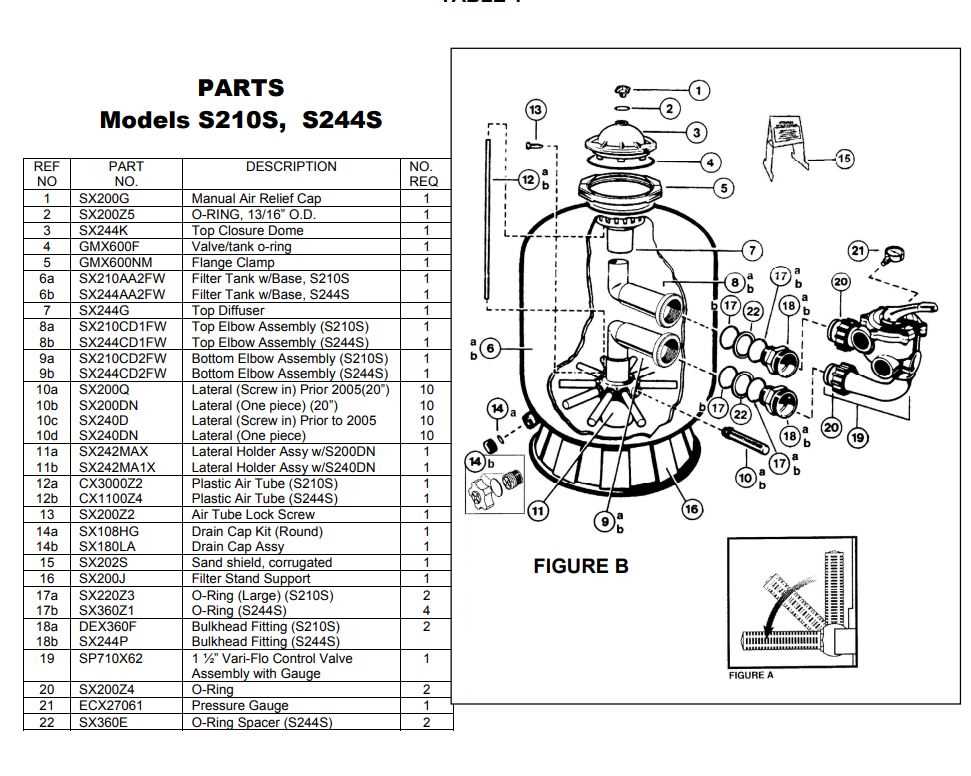

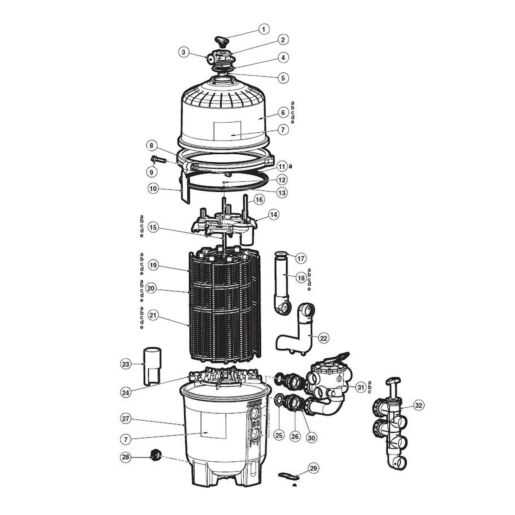

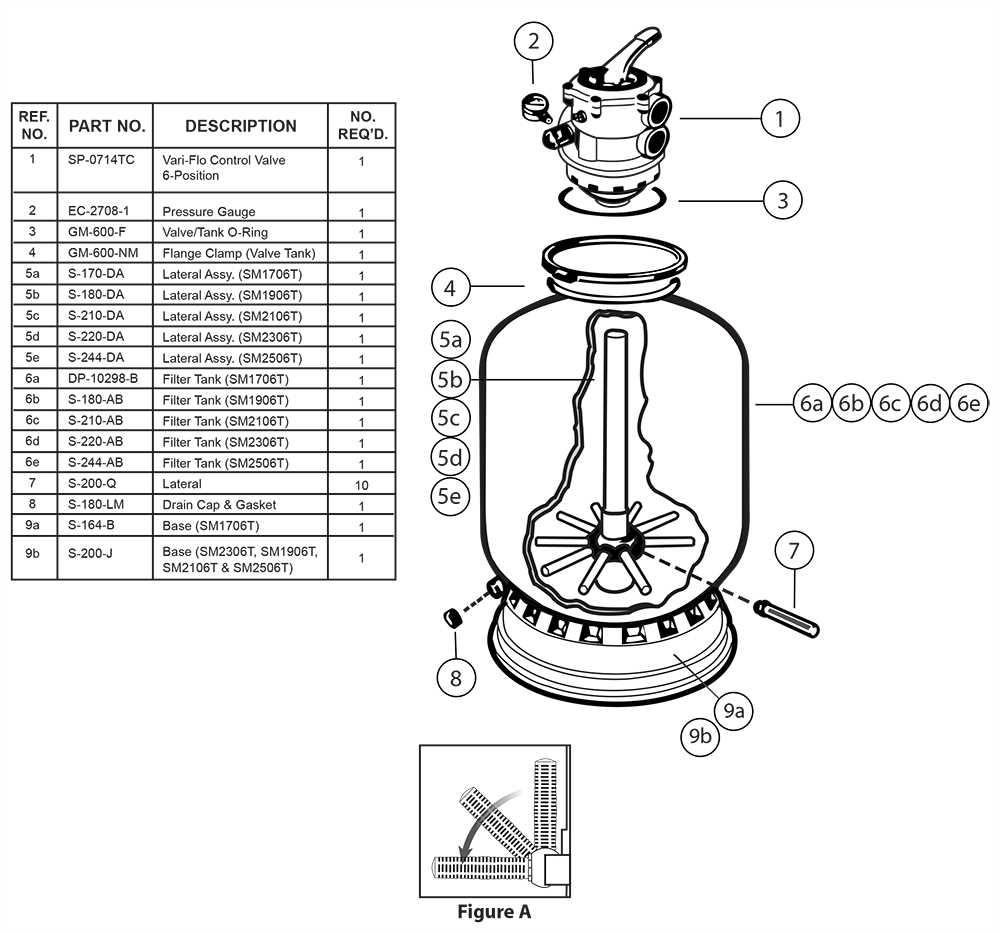

In this section, we will present a detailed illustration that highlights the essential components of these water control mechanisms. With this visual guide, you will gain insights into the arrangement and function of each segment, enabling you to navigate the complexities of your swimming pool setup with confidence.

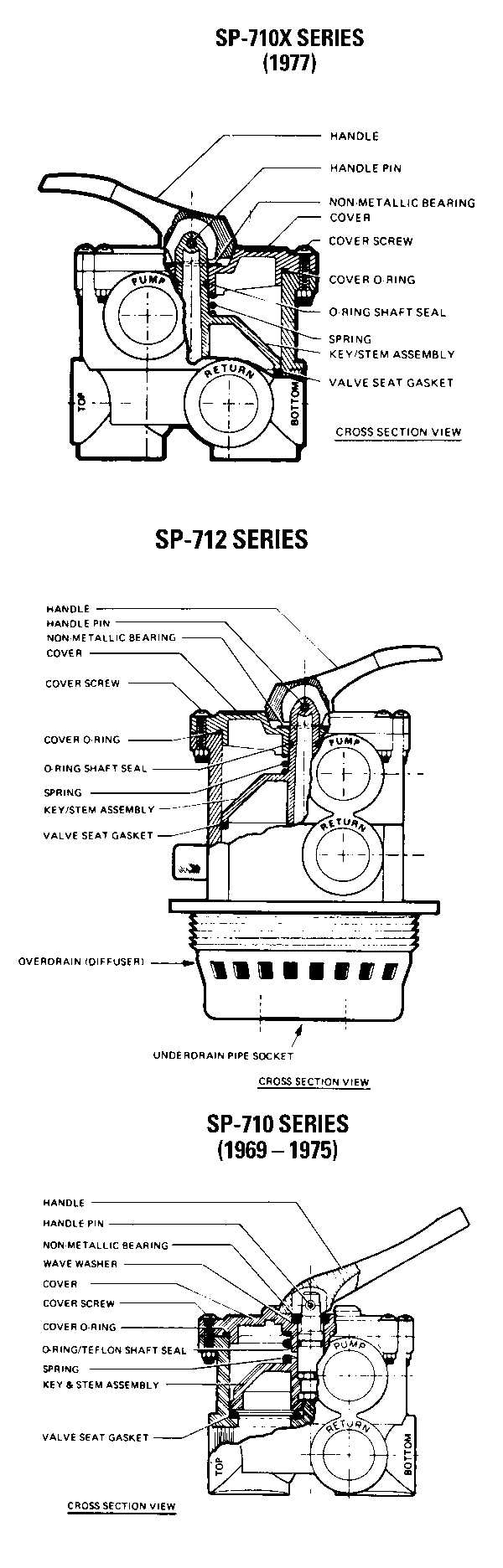

Understanding the Flow Control Mechanism

The flow control system in pool filtration plays a critical role in managing water direction and pressure. By manipulating the system’s settings, it regulates water movement, allowing for different operations like filtering, backwashing, and recirculating. Its efficiency and reliability make it an essential component in maintaining clean and safe pool water.

Flow Settings and Operations

This mechanism provides several key modes to ensure optimal water circulation. The filter mode pushes water through the filtration media, trapping impurities and debris. The backwash mode, on the other hand, reverses the flow to clean the filter by removing accumulated particles. Recirculation bypasses the filtration system entirely, directing water straight back into the pool without any filtering, often used for maintenance checks.

How the Handle Adjusts Flow

The control handle is a pivotal part of the system, allowing users to adjust between different modes. Its movement shifts internal components, opening and closing channels that direct the water flow. With a strong yet smooth operation, it ensures the correct mode is selected to suit the specific task at hand. Proper understanding of this handle’s mechanics ensures optimal performance and longevity of the filtration system.

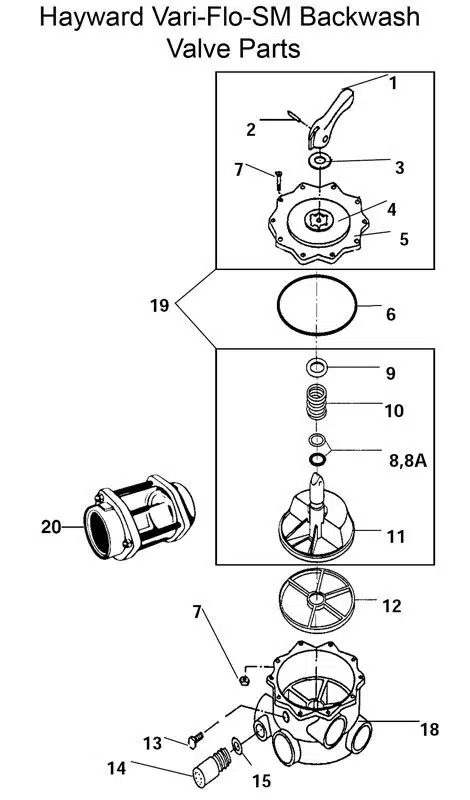

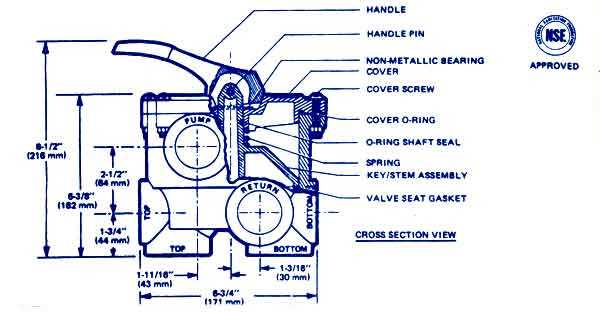

Key Components of the Hayward Vari-Flo Valve

The assembly responsible for controlling water flow in pool systems includes several essential elements that ensure smooth operation and efficient management of filtration. Understanding the primary components will help maintain the mechanism and troubleshoot common issues.

Control Lever Mechanism

The lever is a crucial part of the system, allowing users to change settings and direct the water through different functions. It engages with internal gears to adjust flow paths, providing flexibility in operation.

- Handle: This external part enables the user to manually shift the position, determining the flow direction.

- Spring: Works alongside the handle, maintaining tension and ensuring the mechanism locks securely into place.

Sealing and Gasket System

To prevent leaks and ensure proper functionality, several sealing elements are integrated into the design. These components ensure that water moves only in the desired direction without escaping.

- Spider Gasket: A multi-port seal responsible for keeping sections isolated during operation.

- O-Ring: Helps create a tight seal between various internal segments to prevent leaks.

How the Multiport Valve Regulates Pool Water Flow

The mechanism that controls the movement of water in your pool is essential for maintaining its cleanliness and balance. By adjusting the pathways for water circulation, it ensures efficient filtration, backwashing, and waste removal. Understanding how this system directs water to different components helps pool owners optimize performance and extend the life of their equipment.

Flow Distribution Through Multiple Settings

Each setting on the control unit manages water flow in distinct ways. When positioned to circulate, it sends water directly through the filtration system and back into the pool, bypassing waste pathways. During backwash, the system reverses flow to flush debris from the filter. Additionally, settings such as rinse and waste help either clear the filter after backwashing or divert water directly out, preventing contamination during maintenance tasks.

Seamless Functionality for Comprehensive Care

This system simplifies the process of managing various pool maintenance routines. Switching between functions like filtering, draining, and recirculating is made easy with a single mechanism, ensuring that water flow remains consistent and reliable. The ability to manage water pathways with minimal effort provides an efficient and hassle-free pool care experience.

Identifying Common Hayward Vari-Flo Valve Parts

Understanding the components of a pool filtration system is essential for proper maintenance and repair. Each piece plays a crucial role in directing the flow of water, ensuring that the system functions efficiently and without leaks. In this section, we will explore the most frequently encountered parts, explaining their purpose and how they contribute to the overall system.

Core Components

At the heart of the system are the main sections responsible for managing water flow. These elements include rotating controls, seals, and various connectors that help adjust the direction of the water, either for filtration, backwashing, or other processes. The efficiency of the system depends largely on the integrity of these components.

Supporting Elements

Additional pieces, such as gaskets and pressure gauges, work to prevent leaks and monitor the system’s performance. These smaller elements, though often overlooked, play a vital role in maintaining stability and ensuring smooth operation. Regular inspection of these elements can prevent more significant issues down the line.

How to Replace the Spider Gasket in Your Filter Control Valve

In maintaining your pool or water filtration system, periodic replacement of essential components ensures optimal performance. One crucial element is the spider gasket, which forms a tight seal within the control mechanism, preventing leaks and ensuring efficient operation. Here’s a step-by-step guide to replacing this vital gasket.

1. Preparation: Begin by turning off the filtration system and ensuring the valve is in the closed position. This prevents accidental water flow and allows safe access to the gasket.

2. Disassembly: Carefully remove the cover or lid of the valve using appropriate tools, exposing the internals. Take note of the orientation of the old gasket to ensure correct placement of the new one.

3. Removal: Gently pry out the old spider gasket using a flat-headed screwdriver or a suitable tool. Be cautious not to damage the seating surface of the valve where the gasket sits.

4. Cleaning: Thoroughly clean the gasket seating area, removing any debris or residue that could affect the seal of the new gasket.

5. Installation: Place the new spider gasket into the designated groove, ensuring it fits snugly and evenly. Press it gently into place, ensuring it sits flat and flush with the valve surface.

6. Reassembly: Replace the valve cover or lid, securing it tightly to prevent any leaks. Double-check all connections and fittings.

7. Testing: Turn on the filtration system and carefully observe for any leaks around the valve. Verify that the valve operates correctly through its various settings.

8. Maintenance: Periodically inspect the spider gasket for wear and tear, replacing it as necessary to maintain peak performance of your filtration system.

By following these steps, you can effectively replace the spider gasket in your filter control valve, ensuring reliable operation and prolonging the life of your filtration system.

Maintenance is crucial for prolonging the operational life of your valve system. Regular upkeep not only enhances durability but also ensures consistent performance over time. By adhering to a routine maintenance schedule, you can prevent premature wear and maintain optimal functionality of your equipment. This section provides essential tips to help maximize the lifespan of your valve assembly, promoting efficiency and reliability in your system.

Troubleshooting Flow Control Mechanism Leaks

Leaks in a multiport system can cause significant performance issues, leading to water waste and potential damage. Identifying the source of the problem and addressing it promptly is key to maintaining optimal functionality. This guide will help you diagnose common sources of leakage and outline steps to resolve the issue efficiently.

First, inspect the seal areas. If there’s a worn or misaligned seal, replacing it can often solve the problem. Another frequent cause of leaks is damage to the internal components due to wear over time or improper installation. It’s crucial to verify the condition of the diverter and other internal parts.

Below is a table summarizing typical leakage areas and their recommended solutions:

| Leakage Area | Possible Cause | Recommended Solution |

|---|---|---|

| Top cover | Worn gasket | Replace the gasket |

| Handle section | O-ring damage | Inspect and replace the O-ring |

| Outlet connections | Poor sealing or cracked connection | Re-seal or replace damaged components |

Regular maintenance and inspection are essential to ensure the system remains leak-free. Addressing issues early can extend the lifespan of the mechanism and improve overall efficiency.

Signs Your Multi-Function Control Valve Needs Replacement

Over time, the indicators that your versatile control mechanism may require replacement become increasingly evident. Understanding these signs can prevent operational issues and maintain system efficiency.

1. Operational Inefficiency

- Decreased efficiency in managing fluid flow and pressure.

- Difficulty in adjusting settings or positions.

- Irregular or inconsistent operation modes.

2. Physical Wear and Tear

- Visible corrosion, rust, or degradation on external surfaces.

- Cracks, fractures, or brittleness in the structure.

- Loose or damaged components affecting sealing and alignment.

Identifying these signs promptly can facilitate timely replacement, ensuring continued optimal performance and longevity of your control system.

Step-by-Step Guide to Valve Disassembly

Disassembling a pool filtration system component requires careful attention to detail and proper handling. This guide outlines the process to safely take apart key components for maintenance or repair. By following these steps, you can ensure each part is handled correctly and prepared for reassembly.

Step 1: Turn Off the Power

Before starting, make sure all electrical power to the system is turned off. This is crucial to avoid accidents during the process. Ensure the water flow is stopped as well to prevent leaks.

Step 2: Drain the System

Locate the drainage plug or valve and carefully release any water still present in the system. This prevents spills and makes handling the parts easier.

Step 3: Remove the Cover

Using the appropriate tools, unscrew the bolts or clamps securing the top cover. Once loose, gently lift the cover off. Be cautious of any seals or O-rings that may need to be replaced later.

Step 4: Detach Internal Components

With the cover removed, you will now see the internal mechanisms. Carefully lift them out, noting the order of the pieces. It is recommended to take photos during this step to help with reassembly later.

Step 5: Inspect for Wear and Tear

Examine each component for any signs of damage or excessive wear. Look for cracks, corrosion, or worn-out seals. Replace any parts that are compromised to ensure proper functioning when reassembled.

Step 6: Clean and Prepare for Reassembly

Once all components have been inspected, clean them thoroughly to remove any debris, scale, or buildup. This step is essential for smooth operation when the system is put back together.

Choosing the Right Vari-Flo Valve Model

Selecting the appropriate model for your system can significantly enhance performance and efficiency. Various options exist, each tailored for specific applications and conditions. Understanding your requirements, including flow rates and operational contexts, is essential for making an informed choice.

Consider the unique characteristics of your setup. Evaluate factors such as the size of your equipment, the type of fluids involved, and any potential environmental influences. These elements will guide you toward the most suitable variant for optimal functionality.

Additionally, assessing compatibility with existing infrastructure is crucial. Ensure that the chosen model integrates seamlessly with your current system to avoid complications during installation and operation. This can help to minimize downtime and maintenance costs, ensuring a smoother experience overall.

Finally, consult with industry professionals or resources to gather insights on the best options available. Their expertise can provide valuable information on performance, durability, and cost-effectiveness, empowering you to select a model that meets your specific needs effectively.

Importance of Proper Vari-Flo Valve Positioning

Correct alignment of the multi-position switch is crucial for the efficient operation of any water management system. This component plays a significant role in directing the flow of water and ensuring optimal performance across various settings. Proper positioning not only enhances functionality but also contributes to the longevity of the system.

When the mechanism is set incorrectly, it can lead to several issues, including:

- Reduced efficiency in filtration processes.

- Increased wear and tear on system components.

- Potential damage due to improper flow direction.

- Inadequate cleaning or circulation of water.

To maximize the effectiveness of the setup, consider the following guidelines:

- Always follow the manufacturer’s recommendations for positioning.

- Regularly inspect the component for any signs of wear or misalignment.

- Adjust settings based on the specific requirements of the system’s operation.

- Keep the area around the component clean and free from debris.

By maintaining the correct orientation, users can ensure optimal performance, minimize maintenance costs, and extend the lifespan of the entire system.