In any home, maintaining a comfortable temperature during colder months is crucial. The heating unit plays a vital role in ensuring that your living space stays warm and cozy. To keep it running efficiently, it’s important to familiarize yourself with the various elements that make up the system.

This guide will walk you through the essential elements that work together to generate and distribute heat throughout your home. By gaining a basic understanding of these elements, you can identify potential issues and maintain the system’s optimal performance.

Whether you’re troubleshooting or simply looking to enhance your

Understanding the Components of a Heating System

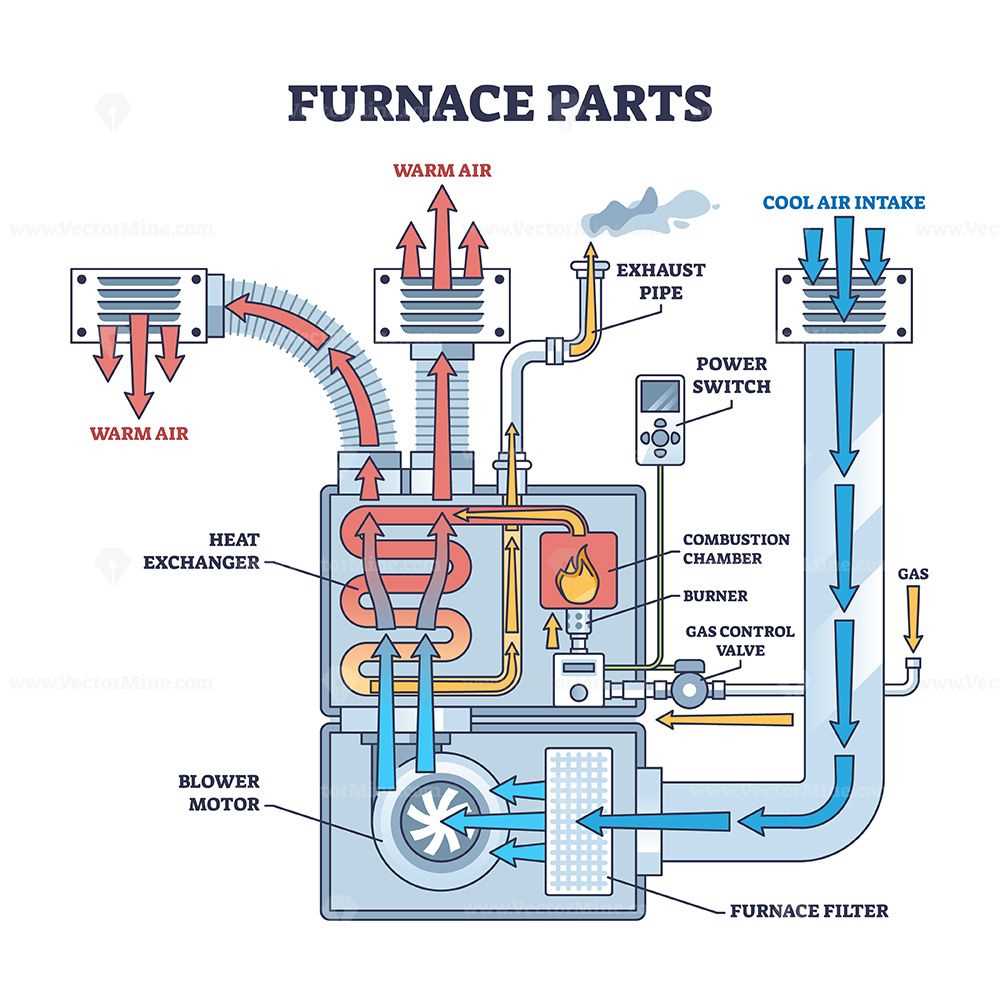

Every heating unit is made up of several essential elements that work together to generate and distribute warmth throughout a building. Each component plays a specific role in ensuring efficient and reliable operation. By familiarizing yourself with the key parts of the system, you can better understand how heat is produced, controlled, and delivered to your living spaces.

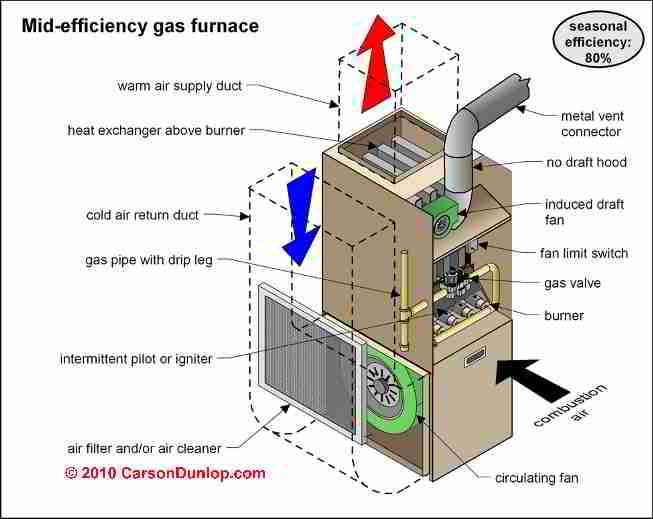

Burner: The burner is responsible for igniting the fuel and initiating the heat production process. It works in coordination with other elements to ensure the combustion is efficient and safe.

Heat Exchanger: This part transfers the energy generated from combustion into warm air, which is then circulated through the ventilation system.

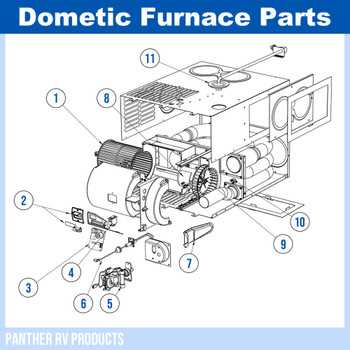

Main Elements in a Heil Furnace System

The key components of a heating system are crucial for ensuring efficient and reliable operation. Each element works together to maintain a comfortable indoor environment, providing warmth when needed. Understanding these components allows for better maintenance and troubleshooting.

Heating Core

The central heating unit is responsible for generating heat, which is then distributed throughout the space. It relies on various mechanisms to convert energy into warmth, ensuring consistent temperature control. Regular inspection of this core element helps prevent issues.

Air Distribution

Once heat is generated, it needs to be delivered effectively to different areas. A network of

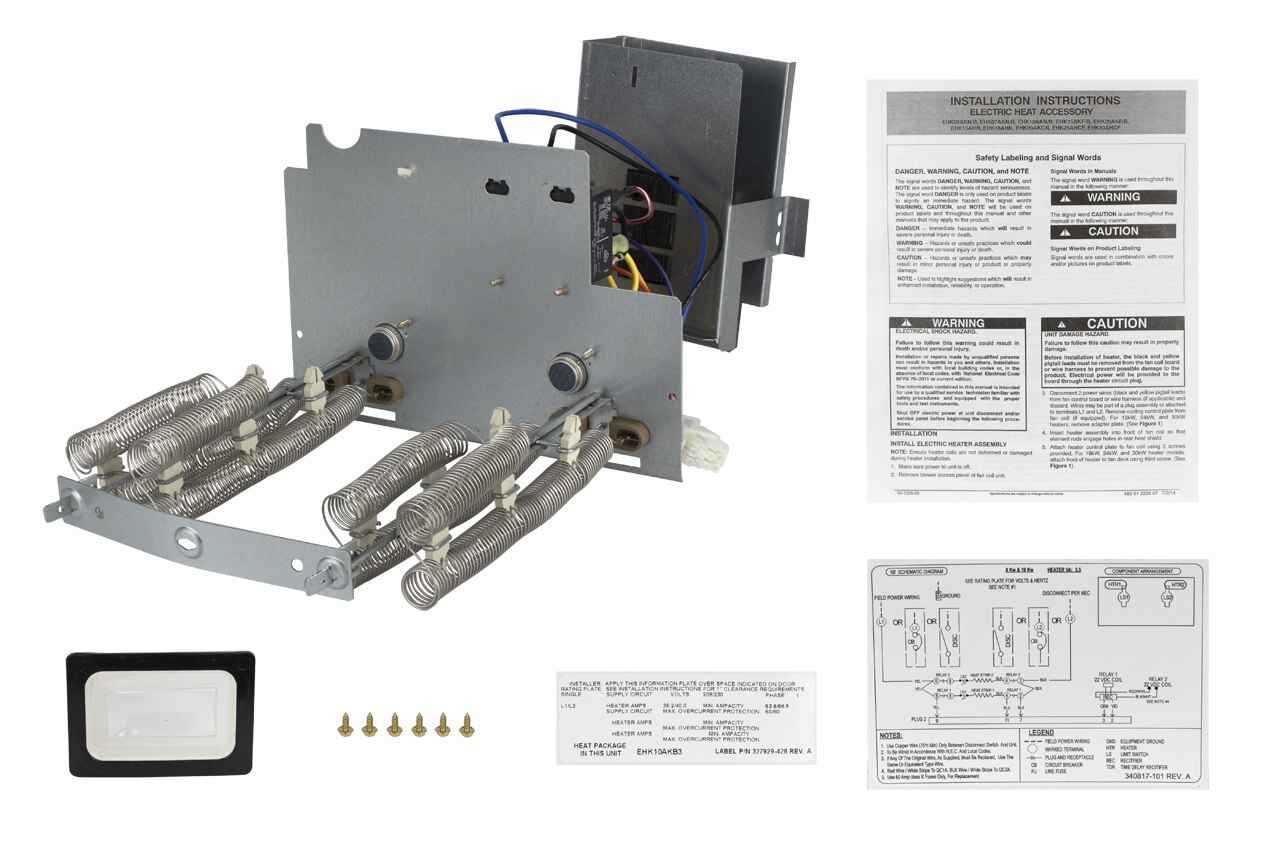

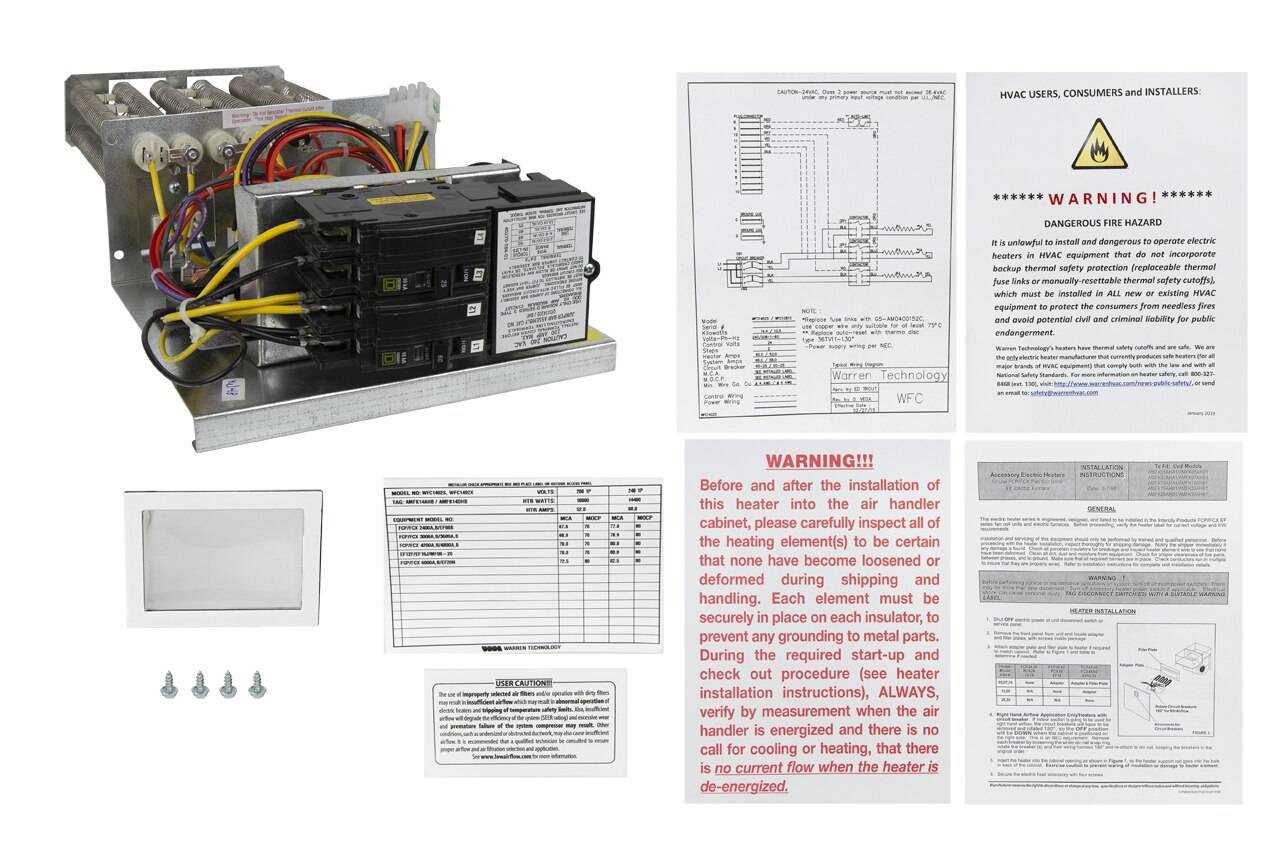

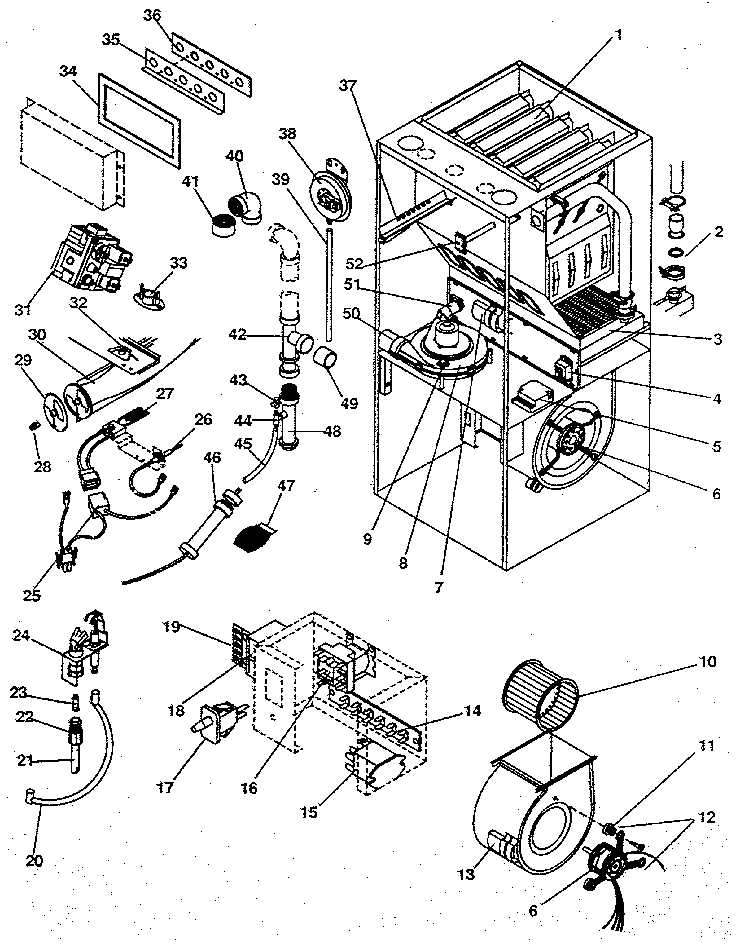

Commonly Replaced Furnace Parts

When maintaining heating systems, certain components tend to wear out faster due to regular use. Recognizing these frequently swapped-out items can help ensure the unit runs efficiently and prevent unexpected breakdowns during colder months.

Key Components to Inspect

Some elements require more attention and are more prone to wear. By keeping an eye on these, you can extend the life of the equipment and maintain its performance.

- Ignition systems are vital for starting the heating process. Faulty igniters may cause issue

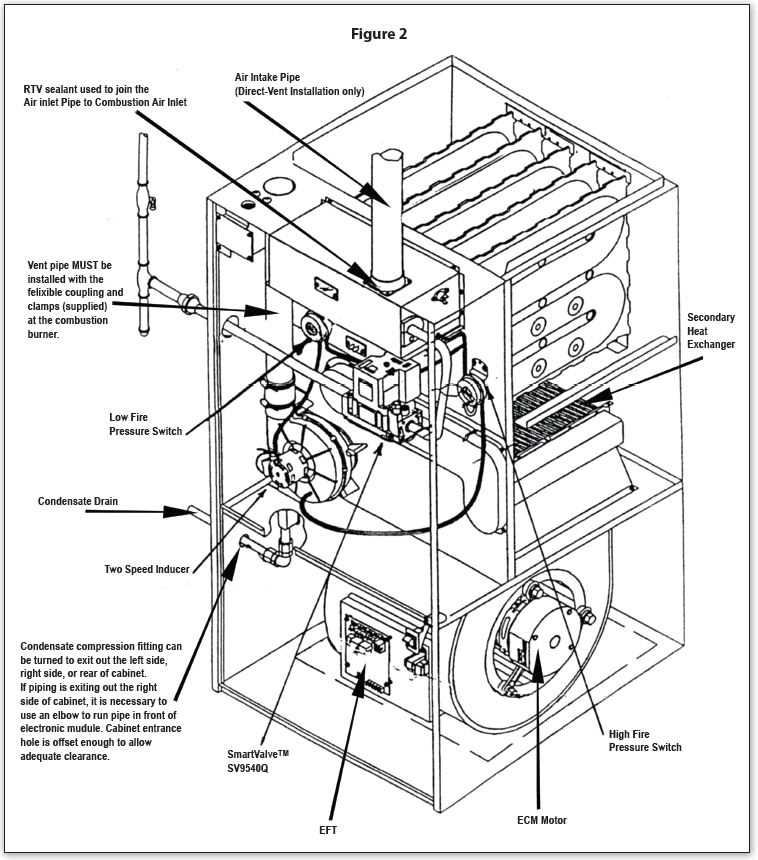

Key Functions of Blower Assembly

The blower assembly plays a vital role in ensuring efficient air movement within a heating system. Its primary task is to distribute air evenly, which helps maintain optimal temperature and air circulation throughout the entire environment. By pushing air through the system, it ensures that the heating process reaches every corner of the space effectively.

Air Circulation Management: The assembly is responsible for managing the movement of air. This component pulls in cooler air, pushes it through the heating elements, and then redistributes the warmed air into the space.

Efficiency Boost: Another crucial function is enhancing the overall efficiency of the heating process. By

Identifying the Heat Exchanger

One of the key elements responsible for transferring warmth efficiently is the heat exchanger. This component plays a critical role in ensuring the overall system operates at its peak performance. Proper identification and understanding of this part is essential for maintaining the unit’s effectiveness.

Shape and Location: Typically, the heat exchanger can be recognized by its distinctive shape, often tubular or in a series of metal plates. It is positioned within the core of the unit where the warm air or gas passes through.

Materials and Function: Built from durable materials like steel or aluminum, the

Role of the Control Board in Operation

The control board plays a vital role in ensuring the proper function of the entire system. It acts as the brain, managing the various processes by receiving signals from different sensors and components. This enables efficient and safe operation by regulating temperature, airflow, and other critical elements.

Key Functions of the Control Board

The control board is responsible for coordinating essential tasks, such as controlling the ignition sequence, monitoring temperature sensors, and managing system timing. It ensures that each component works in harmony, activating certain parts only when conditions are optimal.

Interaction with Other Components

The control board interacts with various sensors and

How the Ignition System Works

The ignition system is a critical component responsible for starting the heating process in a system. It ensures that the correct elements are activated in a precise sequence to initiate combustion. Without proper ignition, the entire process would fail to deliver the necessary warmth.

At the heart of this mechanism lies an electronic igniter or pilot flame, which is triggered by a signal from the control board. Once initiated, this igniter or flame starts the reaction that produces heat. Safety measures are also integrated to monitor and regulate the process, ensuring that everything functions smoothly and securely.

Explaining the Limit Switch Functionality

The limit switch plays a crucial role in managing temperature control within heating systems. It acts as a safety device, ensuring that the system doesn’t overheat during operation. When temperatures reach a certain threshold, the switch intervenes to prevent further heat buildup, thus protecting the equipment and the surrounding environment.

Main Purpose of the Limit Switch

Primarily, this component monitors the temperature and automatically adjusts the system’s operation. If it senses that the temperature has exceeded safe limits, the switch shuts off the heat source to avoid potential damage.

Examining the Flame Sensor’s Purpose

The flame sensor plays a crucial role in ensuring safe and efficient operation of heating systems. Its primary function is to detect the presence of a flame, which is essential for the combustion process. By continuously monitoring the flame, this component helps to prevent dangerous situations that could arise from a malfunctioning heating unit.

When the sensor identifies that a flame is present, it sends a signal to the control system, allowing the heating mechanism to function properly. Conversely, if the flame goes out unexpectedly, the sensor will interrupt the operation to prevent the release of unburned fuel. This automatic response not only protects the system but also enhances safety for users.

Understanding the importance of this device can lead to better maintenance practices. Regular inspections and timely replacements of the flame sensor can ensure that heating systems operate at their best, reducing the risk of inefficiencies and potential hazards. Therefore, recognizing the flame sensor’s function is vital for anyone involved in the upkeep of heating solutions.

Details on Furnace Capacitors

Capacitors play a crucial role in ensuring the efficient operation of heating systems. These components store electrical energy and release it when needed, helping to maintain optimal performance. Understanding their functionality and significance can aid in troubleshooting and enhancing system reliability.

Functionality of Capacitors

Capacitors function by accumulating and discharging electrical energy, which is essential for starting and running motors within the heating system. By providing the necessary energy surge during startup, they help ensure smooth operation and prevent unnecessary wear on other components.

Signs of Failure

Identifying signs of capacitor failure can prevent more extensive damage to the heating system. Common indicators include unusual noises, fluctuating temperatures, or the inability to start. Regular maintenance and inspection can help catch these issues early, ensuring the longevity of the entire system.

Troubleshooting Common Furnace Component Issues

Addressing common problems with heating systems requires a systematic approach to identify and resolve underlying issues. By understanding the typical components and their functions, users can efficiently troubleshoot malfunctions and ensure optimal performance.

Several signs indicate potential malfunctions within the system. Recognizing these symptoms early can prevent further complications and costly repairs. Below is a summary of common issues, possible causes, and recommended solutions.

Symptoms Possible Causes Recommended Solutions No heat Thermostat malfunction, power supply issues, or blocked filters Check the thermostat settings, ensure the unit is receiving power, and replace or clean filters as necessary. Unusual noises Loose components or debris in the unit Inspect and tighten any loose parts, and clear any debris from the system. Frequent cycling Improper thermostat settings or airflow restrictions Adjust the thermostat settings and ensure vents are not blocked. Unpleasant odors Burning dust or electrical issues Allow the system to run to burn off dust, and if odors persist, consult a professional. By systematically examining these common issues and implementing the suggested solutions, individuals can maintain their heating systems effectively and avoid unnecessary disruptions.