In the realm of winter management, having a comprehensive grasp of the essential mechanisms and their interrelations is crucial for optimal performance. When facing inclement weather, the effectiveness of any distribution system relies heavily on the understanding of its intricate components and their respective functions. This knowledge not only enhances operational efficiency but also extends the lifespan of the machinery involved.

Detailed illustrations serve as invaluable resources, providing insights into the arrangement and functionality of various elements. By examining these representations, users can better diagnose issues, perform maintenance, and ensure that every piece works harmoniously. The clarity offered by such visuals is indispensable for anyone seeking to maintain their equipment in peak condition during the harsh winter months.

Furthermore, familiarity with the layout of these essential systems allows operators to make informed decisions regarding upgrades or replacements. As winter approaches, being equipped with the right information can significantly impact safety and efficiency, ultimately leading to smoother operations in challenging conditions.

Understanding Henderson Salt Spreaders

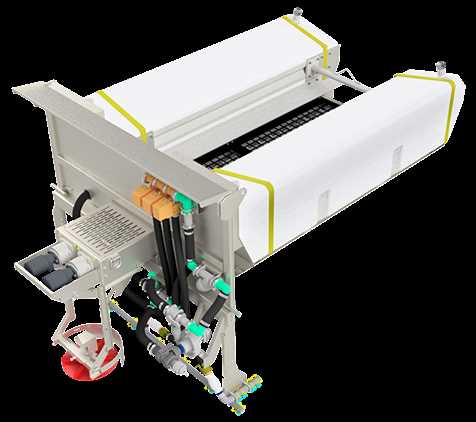

This section delves into the essential components and functionalities of a popular equipment type used for winter maintenance. These machines play a crucial role in ensuring road safety during icy conditions by distributing materials uniformly across surfaces. A thorough grasp of their operation and assembly can significantly enhance efficiency and performance.

The mechanisms involved in these devices are designed to optimize the application of granular substances. Familiarity with their structure helps operators troubleshoot issues and maintain equipment effectively. Below is a summary of the core elements typically found in these machines:

| Component | Description |

|---|---|

| Hopper | The main container for holding the material before distribution. |

| Auger | A rotating screw mechanism that conveys the material from the hopper. |

| Spinner | A device that flings the material outwards, ensuring even coverage. |

| Controls | Systems used to adjust the flow rate and operation of the unit. |

| Frame | The structural support that houses all components and ensures stability during operation. |

Understanding these elements allows users to maximize the potential of the equipment, ensuring that it operates efficiently and effectively in harsh winter conditions. Proper maintenance and familiarity with each part contribute to a reliable performance and longevity of the machinery.

Key Components of Salt Spreaders

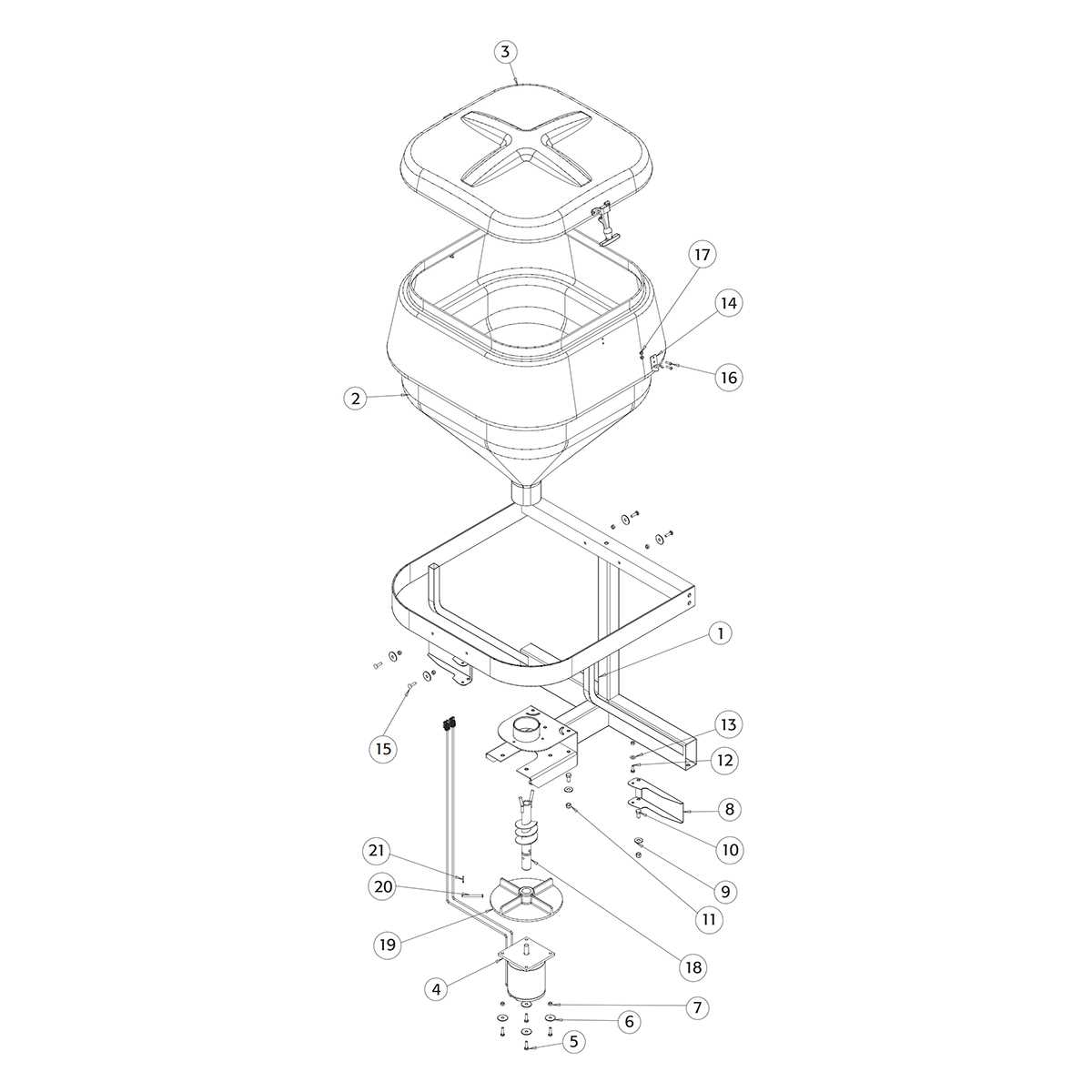

Understanding the essential elements of a material distribution system is crucial for effective operation and maintenance. Each component plays a vital role in ensuring even application and optimal performance during harsh weather conditions. Familiarity with these elements allows operators to troubleshoot issues and enhance efficiency.

1. Hopper: The hopper serves as the storage unit for the substance to be distributed. Its design facilitates easy loading and ensures a consistent flow of material during operation.

2. Agitator: An agitator is responsible for keeping the contents within the hopper well-mixed. This ensures that the material does not clump together, allowing for a smooth and uniform distribution process.

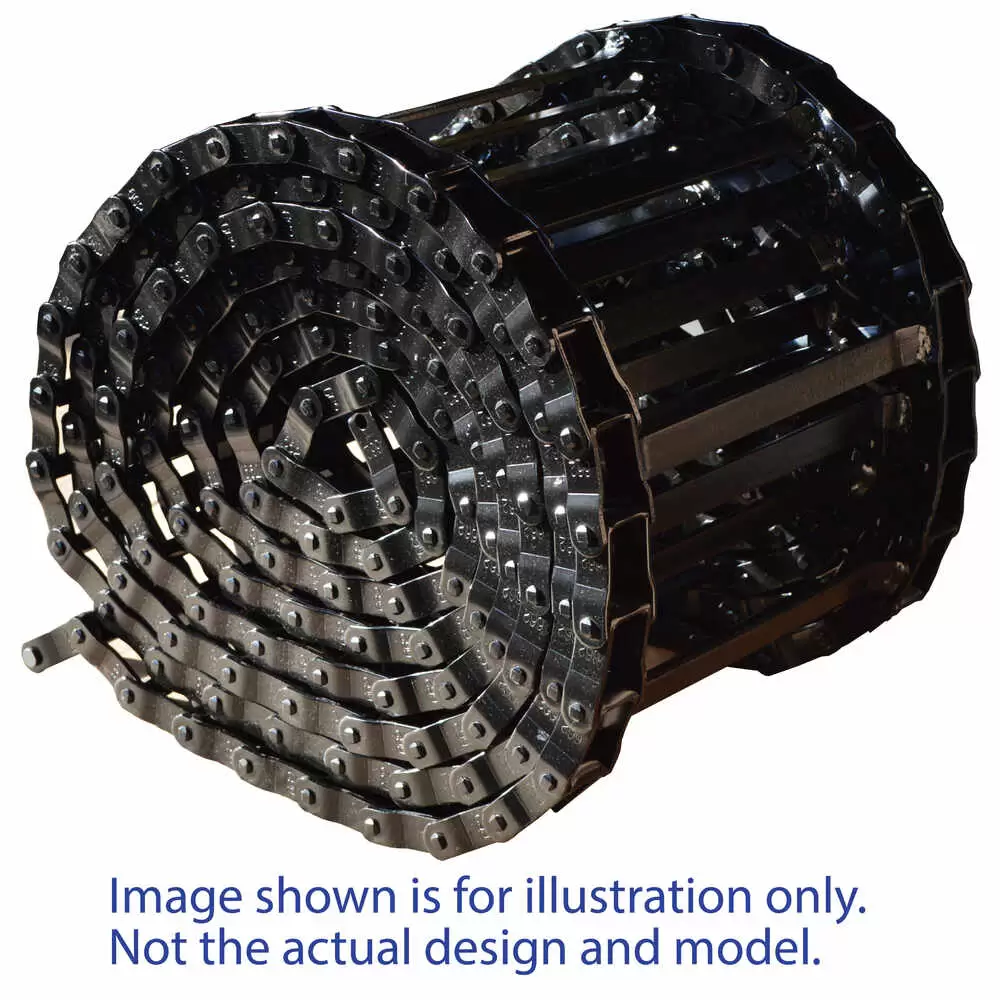

3. Spreading Mechanism: This component is essential for dispersing the material onto the surface. It typically involves rotating discs or belts that control the spread width and rate, adapting to various conditions and requirements.

4. Control System: An intuitive control system allows operators to adjust settings according to specific needs. It can include manual levers or electronic controls that enable precise regulation of the application rate.

5. Chassis: The chassis is the framework that supports all other components. Its sturdy construction ensures stability and durability, allowing the system to endure challenging environments.

6. Tires and Traction: Proper tires are vital for maintaining grip and mobility. They allow the unit to navigate different terrains effectively, which is especially important during winter operations.

By comprehensively understanding these critical components, operators can ensure their equipment operates efficiently and meets performance expectations in any situation.

Benefits of Using Henderson Models

Utilizing advanced equipment for distributing materials offers numerous advantages, enhancing efficiency and performance in various applications. These models are designed with user-centric features that streamline operations, making them a preferred choice for many professionals in the field.

Enhanced Efficiency

One of the primary benefits of employing these systems is their ability to significantly increase operational efficiency. With precise mechanisms, they ensure an even application of materials, minimizing waste and maximizing coverage.

Durability and Reliability

Another key advantage is the robust construction of these units. Built to withstand harsh conditions, they provide reliable performance over time, reducing the need for frequent maintenance or replacements. This reliability translates to lower operational costs and greater peace of mind for users.

| Feature | Benefit |

|---|---|

| Precision Control | Even material distribution |

| Robust Design | Long-lasting performance |

| User-Friendly Interface | Easy operation and adjustment |

| Versatile Applications | Suitable for various materials and environments |

Common Maintenance Practices Explained

Regular upkeep is essential for ensuring optimal performance and longevity of equipment. Implementing effective maintenance routines can prevent unexpected failures and enhance overall efficiency.

- Routine Inspections: Regular checks help identify wear and tear before they escalate into major issues.

- Lubrication: Keeping moving parts well-lubricated reduces friction and prolongs lifespan.

- Cleaning: Removing debris and contaminants is crucial to maintaining functionality and preventing corrosion.

- Component Replacement: Timely replacement of worn components is vital for consistent performance.

By following these essential practices, users can ensure their equipment remains in peak condition and ready for use when needed.

Identifying Replacement Parts Easily

Finding the correct components for your equipment can be a daunting task, but it doesn’t have to be. With a systematic approach, you can simplify the process of identifying what you need for effective maintenance and repairs.

Start by organizing your resources. Keep manuals, guides, and online references in a designated folder, both physically and digitally. This ensures you have immediate access to critical information.

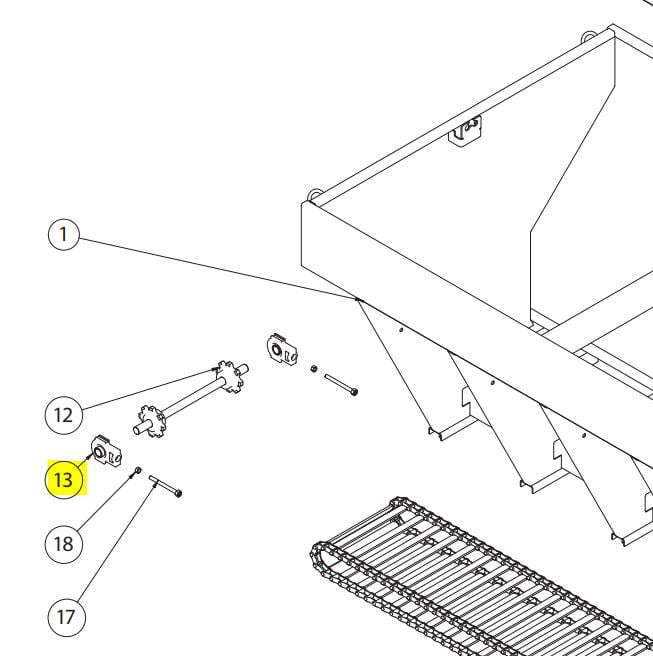

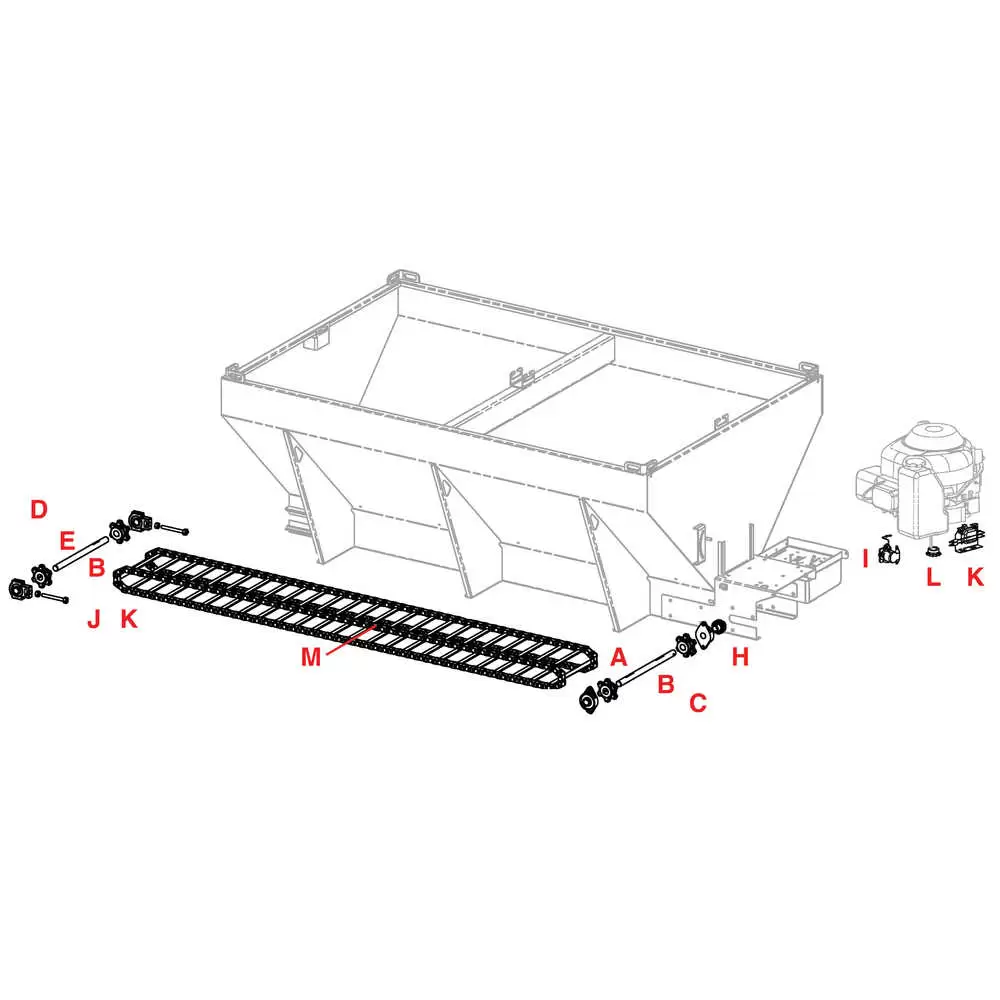

Utilize visual aids such as exploded views or schematics. These illustrations provide a clear depiction of how each element fits together, making it easier to pinpoint specific items.

Lastly, engage with communities–forums, social media groups, or local repair shops can be invaluable. Sharing experiences and insights will not only help you identify the right components but also enhance your overall understanding of the machinery.

How to Read Parts Diagrams

Understanding visual representations of components is crucial for efficient maintenance and repairs. These illustrations serve as guides, enabling users to identify individual elements and their functions within a larger system. Mastering the art of interpreting these visuals can significantly streamline the repair process and enhance overall efficiency.

Identify Key Elements

Begin by recognizing the essential features of the illustration. Look for labels that denote specific items, and pay attention to any accompanying numbers or codes. These indicators often correlate with a detailed list, providing further context on each component’s role and specifications.

Follow the Structure

Most visuals are organized in a logical manner, typically outlining the assembly from top to bottom or left to right. Observing this arrangement can help you understand how parts interact with each other. Pay close attention to connections and groupings, as they reveal how the entire system functions cohesively.

Troubleshooting Common Issues

When operating any type of distribution machinery, encountering challenges is not uncommon. Understanding these potential issues can help you efficiently address them, ensuring optimal performance and longevity of your equipment. This section outlines typical problems and provides practical solutions.

-

Inconsistent Material Flow:

If the material is not dispersing evenly, check for blockages in the chute or hopper. Ensure that the feed mechanism is functioning properly and that the settings are adjusted for the material type.

-

Operational Noise:

Unusual sounds during operation may indicate worn components or loose fasteners. Inspect moving parts for signs of wear and tighten any loose connections.

-

Poor Coverage:

If the spread area is inadequate, verify that the calibration settings match the desired output. Also, assess the distribution pattern and adjust the spread width accordingly.

-

Power Issues:

Inconsistent power can hinder performance. Check electrical connections, and ensure that the power supply meets the operational requirements of the equipment.

By systematically addressing these common issues, operators can enhance functionality and maintain the efficiency of their distribution systems. Regular maintenance and inspections are key to preventing future problems.

Comparing Henderson to Other Brands

When evaluating different manufacturers in the market, it becomes essential to identify unique features and advantages that set them apart. Each brand brings its own strengths and weaknesses, influencing performance, durability, and user satisfaction. Understanding these distinctions can guide users in making informed choices that best meet their operational needs.

Performance and Efficiency

Performance metrics often highlight the effectiveness of various models. Efficiency in application can be critical, especially in challenging conditions. Some brands emphasize speed and consistency, while others focus on innovative technology that enhances usability.

| Brand | Performance Rating | Efficiency | User Feedback |

|---|---|---|---|

| Brand A | 4.5/5 | High | Positive |

| Brand B | 4.0/5 | Medium | Mixed |

| Brand C | 4.8/5 | High | Excellent |

Durability and Maintenance

Another critical factor is the longevity and upkeep of equipment. While some manufacturers use higher quality materials that resist wear and tear, others might require more frequent maintenance. Analyzing user experiences can reveal insights into which options provide the best long-term value.

Importance of Quality Components

When it comes to machinery and equipment, the significance of using high-grade elements cannot be overstated. Superior components not only enhance performance but also ensure longevity and reliability. Investing in quality parts leads to fewer breakdowns and reduced maintenance costs, ultimately benefiting both efficiency and productivity.

Durability and Performance

High-quality materials contribute significantly to the durability of equipment. When components are crafted with precision and attention to detail, they can withstand harsh conditions and frequent use. This resilience translates to consistent performance, allowing operators to rely on their machines during critical tasks. Choosing well-manufactured elements reduces the likelihood of failures, which can disrupt operations and incur additional expenses.

Cost-Effectiveness Over Time

While it may be tempting to opt for cheaper alternatives, investing in quality components often proves to be more economical in the long run. Lower-grade options may seem cost-effective initially but can lead to frequent replacements and increased downtime. By prioritizing superior elements, organizations can enjoy greater reliability and lower overall operational costs, making it a smart choice for any business.

Where to Buy Replacement Parts

Finding the right components for your equipment can be a crucial task to ensure optimal performance. Various sources are available to help you acquire the necessary items, whether for maintenance or repairs. Understanding where to look can save you time and effort.

Online Retailers: Numerous websites specialize in selling components. These platforms often provide detailed descriptions and customer reviews, allowing you to make informed decisions.

Local Distributors: Checking with nearby distributors can be beneficial. They may carry the required items in stock or can order them for you, often providing quicker access than online shopping.

Manufacturer’s Website: Directly visiting the manufacturer’s official site can lead you to genuine components. This ensures compatibility and quality, crucial for maintaining the integrity of your equipment.

Second-Hand Market: For those on a budget, exploring second-hand options through classifieds or online marketplaces may yield suitable alternatives. Just ensure that the quality meets your needs before purchasing.

With these avenues, you can effectively locate the items you require and keep your equipment in top condition.

Tips for Seasonal Preparation

Preparing for seasonal changes is essential for ensuring optimal performance of your outdoor equipment. Proper maintenance and thoughtful organization can enhance functionality and extend the lifespan of your tools.

Inspect and Maintain Equipment

Start by thoroughly examining all components for wear and tear. Clean and lubricate moving parts to prevent rust and ensure smooth operation. Regular checks help identify potential issues before they become serious.

Organize Storage Space

Designate a specific area for your gear to avoid clutter and confusion. Utilize storage bins and labels to categorize items effectively. A well-organized space facilitates easy access and promotes efficient workflow.