In the realm of modern agriculture, efficient machinery plays a pivotal role in optimizing productivity. Understanding the intricate elements that make up such equipment is essential for ensuring smooth operation and longevity. This section delves into the various components of a specific model, shedding light on their functions and interconnections.

Farmers and technicians alike benefit from having a clear visual representation of the machine’s layout. By familiarizing themselves with the arrangement and role of each component, they can easily identify potential issues and perform necessary maintenance. This knowledge is vital for enhancing operational efficiency and minimizing downtime.

Additionally, grasping the relationship between different elements can lead to informed decisions regarding repairs or upgrades. With the right insights, users can maximize the effectiveness of their equipment, ultimately contributing to better yields and a more successful farming operation.

Understanding the Hesston 540 Baler

The machine in focus is a vital tool in modern agriculture, designed for efficiency and ease of use. Its functionality revolves around compacting and packaging various types of forage, making it an essential piece of equipment for farmers aiming to optimize their harvesting processes. By employing innovative mechanisms, this equipment ensures that bales are formed uniformly, enhancing the quality and ease of transportation.

Key Features and Benefits

Among its numerous advantages, this machinery offers enhanced durability and reliability, making it suitable for various field conditions. The incorporation of advanced technology aids in monitoring performance, allowing operators to maintain optimal output while minimizing downtime. Furthermore, its user-friendly design ensures that even those with limited experience can operate it effectively.

Maintenance and Care

To maximize longevity and performance, regular maintenance is crucial. This includes checking hydraulic systems, ensuring proper lubrication, and inspecting belts and chains for wear. Implementing a routine care schedule not only extends the machine’s lifespan but also ensures consistent operation, reducing the risk of unexpected failures during peak usage times.

Key Components of the Baler

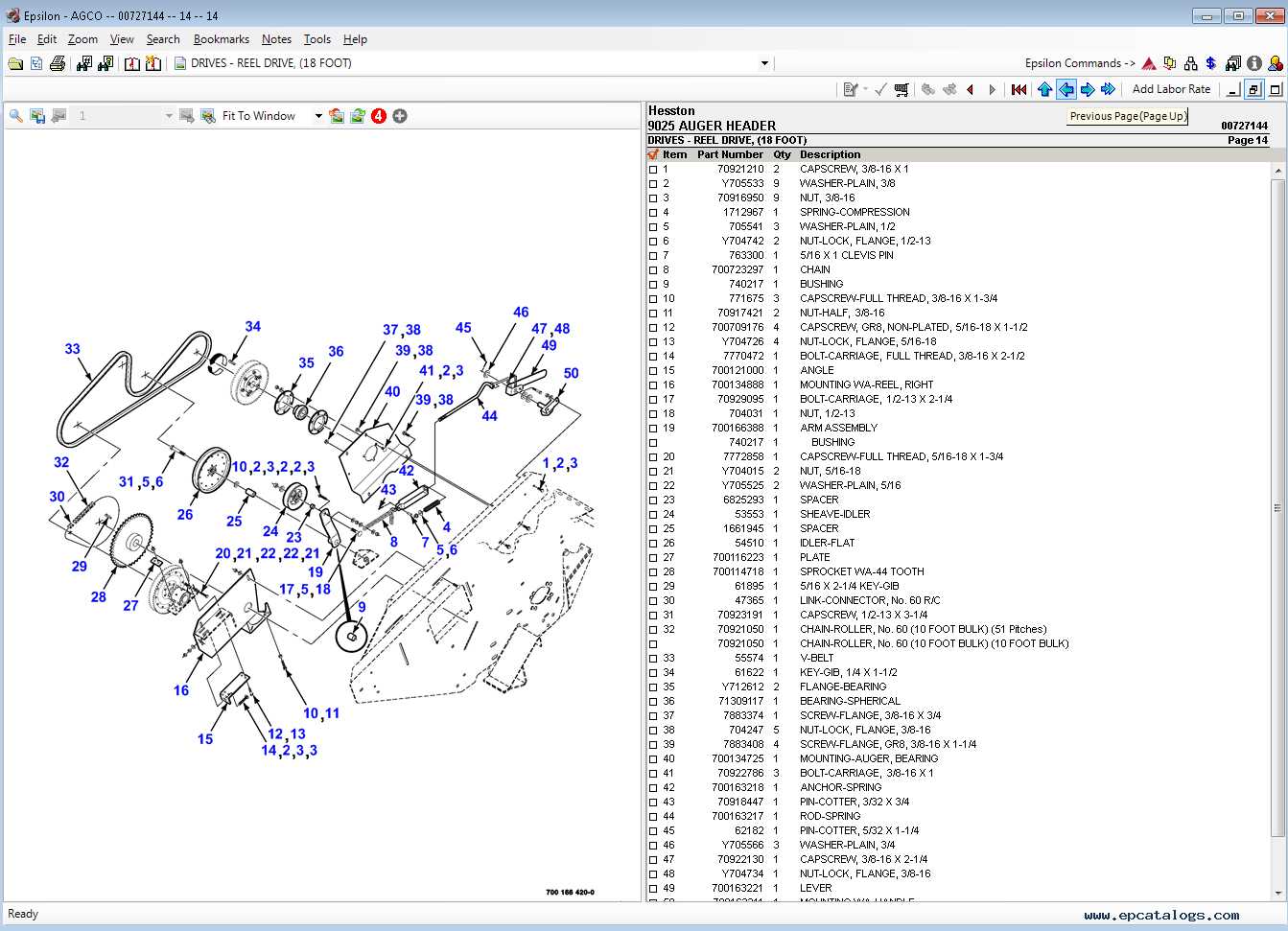

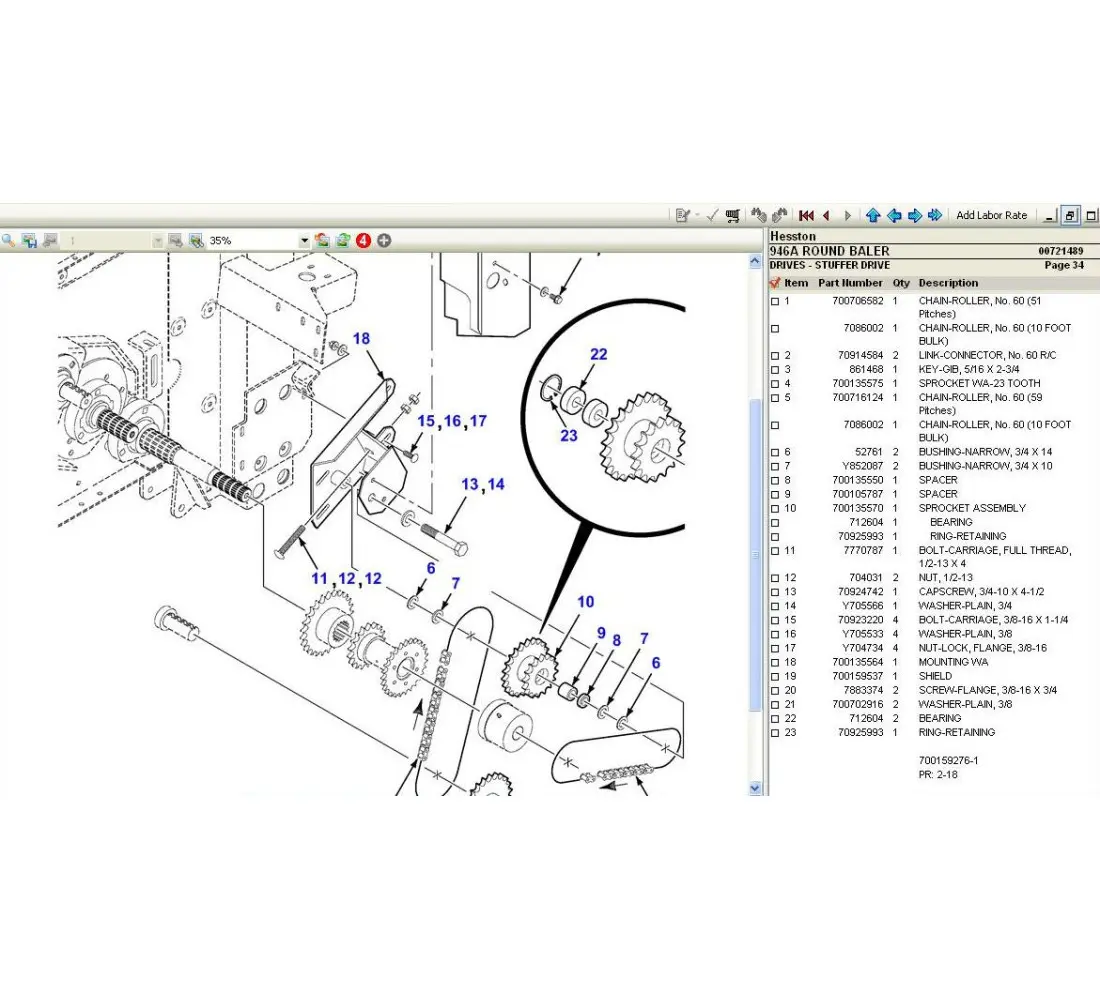

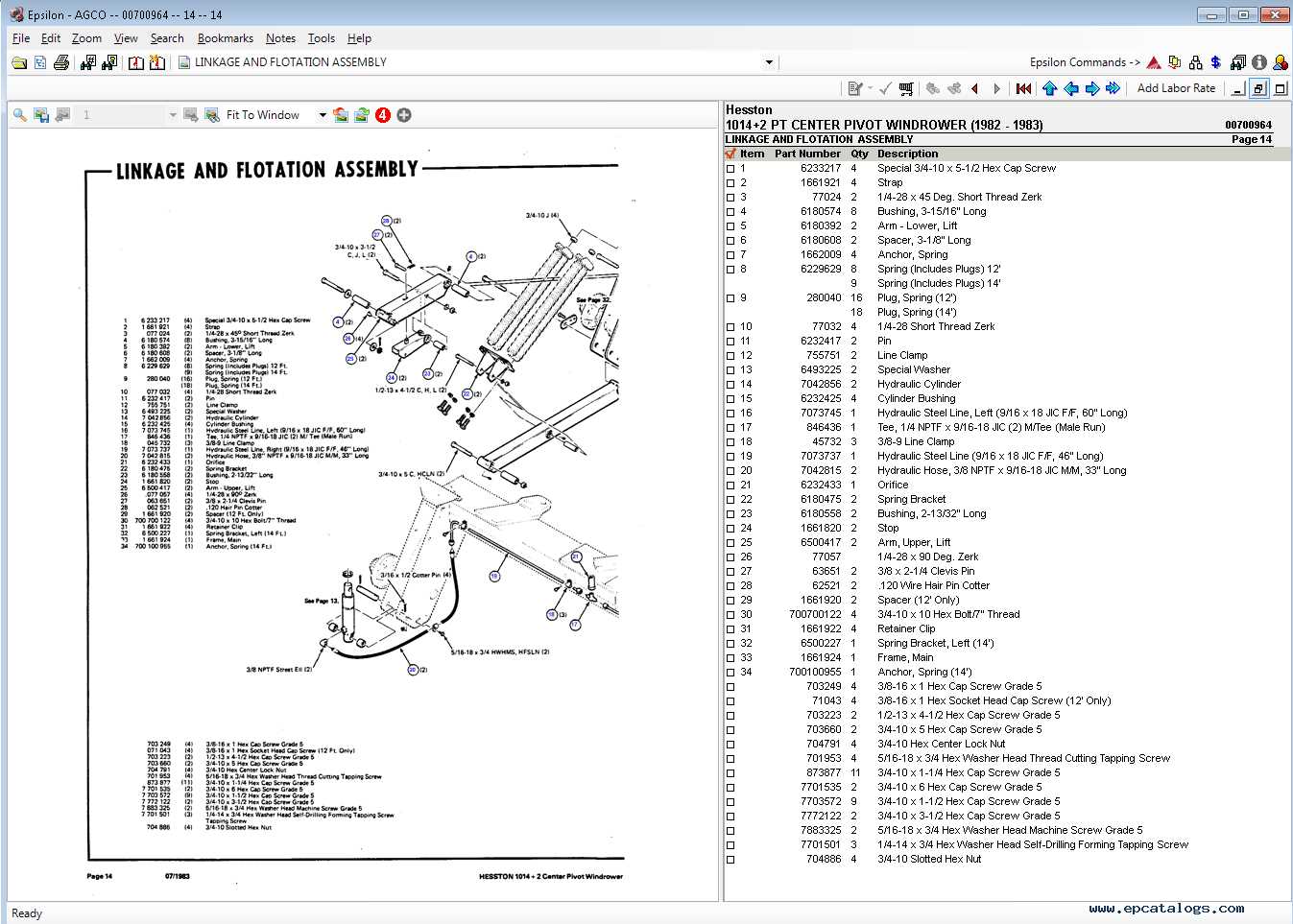

The efficiency of a hay harvesting machine relies on several essential elements that work in harmony to achieve optimal performance. Understanding these core components helps users maintain and troubleshoot the equipment effectively.

1. Feeding Mechanism

The feeding system plays a crucial role in directing the crop material into the chamber. It ensures a consistent flow, allowing for uniform compression and ultimately enhancing the quality of the final product.

2. Compression Chamber

This section of the machine is where the actual baling occurs. Within the compression chamber, crop materials are compacted and shaped into bales, facilitated by strong hydraulic forces. The design of this area greatly influences the density and size of the bales produced.

Understanding these vital components can significantly impact the overall productivity and longevity of the equipment, leading to better results in the field.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular upkeep and attention to detail. By following a systematic maintenance routine, you can extend the lifespan of your machinery and improve its overall performance. Here are some essential tips to help you achieve optimal longevity.

Regular Inspections

Conduct routine assessments to identify potential wear and tear. Check for any signs of damage, rust, or loose components. Early detection of issues can prevent more significant problems down the line, saving time and costs associated with repairs.

Lubrication and Cleaning

Keep moving parts well-lubricated to reduce friction and wear. Use the appropriate lubricants as specified in the manufacturer’s guidelines. Additionally, regularly clean the equipment to remove debris and residue that can hinder performance. A clean machine operates more efficiently and is less prone to breakdowns.

By implementing these maintenance strategies, you can ensure your machinery remains in top condition, providing reliable service for years to come.

Identifying Common Wear Parts

Understanding the components that experience frequent wear is crucial for maintaining optimal performance in agricultural machinery. Recognizing these elements can help in ensuring that the equipment operates efficiently and extends its service life.

Key Components to Monitor

Several elements are particularly prone to wear and tear during operation. Regular inspection and timely replacement of these components can prevent costly repairs and downtime.

| Component | Symptoms of Wear | Recommended Action |

|---|---|---|

| Drive Belts | Cracks, fraying, or loss of tension | Replace immediately to avoid slippage |

| Roller Bearings | Excessive noise or rough operation | Lubricate or replace if damaged |

| Chains | Stretching or rusting | Adjust tension or replace as needed |

| Knives | Chipping or dull edges | Sharpen or replace to maintain cutting efficiency |

Maintenance Tips

Implementing a regular maintenance schedule focused on these components will significantly enhance equipment reliability. Always consult the manufacturer’s guidelines for specific maintenance intervals and recommendations.

Safety Features and Protocols

Ensuring the well-being of operators and bystanders is paramount when working with agricultural machinery. Incorporating various protective mechanisms and following established protocols minimizes the risk of accidents and injuries during operation.

Key Safety Mechanisms

Modern machinery often includes features such as emergency stop buttons, protective guards, and interlock systems. These elements serve to prevent unauthorized access to hazardous areas and ensure that the equipment ceases operation in emergencies. Regular inspections of these safety components are essential to maintain their effectiveness.

Operational Guidelines

Adhering to established operational procedures significantly enhances safety. Operators should undergo thorough training on the machinery’s functions and safety features. Additionally, utilizing personal protective equipment (PPE) and following manufacturer guidelines during operation can further reduce the likelihood of accidents.

Operation Guidelines for Efficiency

Maximizing productivity in agricultural machinery requires adherence to specific operational practices. Implementing effective strategies ensures optimal performance and longevity of equipment, ultimately enhancing yield and reducing downtime.

Regular Maintenance

- Conduct routine inspections to identify wear and tear.

- Lubricate moving parts to minimize friction and prevent breakdowns.

- Check and adjust tension settings to optimize functionality.

Operational Best Practices

- Familiarize yourself with the user manual for specific guidance.

- Monitor environmental conditions to adjust settings accordingly.

- Train operators to ensure safe and efficient handling of the equipment.

By following these guidelines, users can enhance the efficiency and reliability of their machinery, ensuring a successful operation throughout the season.

Troubleshooting Common Issues

Understanding and resolving common challenges in agricultural machinery can enhance efficiency and prolong the lifespan of equipment. This section aims to guide users through typical problems encountered during operation, helping to identify and rectify issues effectively.

Here are some frequent issues and their possible solutions:

- Inconsistent Bale Formation:

- Check the tension settings to ensure they are properly adjusted.

- Inspect the feeding system for blockages or wear that might affect material intake.

- Verify that the rollers are clean and functioning correctly.

- Jamming:

- Clear any debris that may be obstructing the feed mechanism.

- Examine the belts for damage or wear that could hinder performance.

- Ensure that the pickup system is operating smoothly and is free of obstructions.

- Unusual Noises:

- Listen for grinding or clunking sounds that may indicate loose or damaged components.

- Inspect bearings and gears for wear and replace as necessary.

- Check for any misalignment in moving parts that could lead to excess friction.

- Poor Material Compaction:

- Adjust the pressure settings to improve compaction efficiency.

- Examine the condition of the chamber for any wear that may affect performance.

- Verify that the material being processed is suitable for the equipment specifications.

By following these troubleshooting steps, users can effectively address common operational challenges, ensuring smooth and efficient performance of their machinery.

Upgrading Parts for Performance

Enhancing the components of agricultural machinery can significantly boost its efficiency and overall functionality. By investing in superior materials and advanced technologies, operators can experience improved output, reduced downtime, and greater reliability during operation. This approach not only enhances productivity but also extends the lifespan of the equipment, making it a worthwhile investment for any agricultural professional.

Benefits of Upgraded Components

Upgrading various components can lead to enhanced performance metrics. For instance, improved drive systems can result in increased speed and torque, while high-quality bearings can minimize friction, allowing for smoother operation. Furthermore, the integration of modern technologies, such as precision sensors and automated controls, can enhance accuracy and streamline processes.

Considerations for Selection

When selecting upgraded components, it is crucial to consider compatibility with existing machinery. Assessing the specifications and ensuring that new elements align with the current system will prevent any operational disruptions. Additionally, choosing parts from reputable manufacturers can provide peace of mind regarding durability and performance. Investing in quality not only contributes to immediate gains but also ensures long-term reliability and efficiency.

Comparing Models and Specifications

Understanding the various models and their technical details is essential for selecting the right machinery for agricultural tasks. Each variant offers distinct features that cater to different operational needs, enabling users to make informed choices based on efficiency, capacity, and performance metrics.

When evaluating machinery options, one should consider factors such as bale size, weight, and the materials used in construction. These specifications can significantly impact the machine’s durability and effectiveness in handling various crops. Additionally, assessing the power requirements and compatibility with existing equipment can streamline the integration process and enhance overall productivity.

Moreover, it’s beneficial to analyze user reviews and performance data across different models to identify which design elements contribute most to reliability and ease of use. This comparative approach allows for a deeper insight into the advantages and limitations of each option, ultimately guiding users toward the best fit for their operational needs.

Best Practices for Storage

Proper storage of agricultural machinery components is essential for ensuring longevity and optimal performance. Effective techniques not only protect equipment from environmental damage but also facilitate easy access and organization when needed.

1. Clean Before Storage: Always clean the components thoroughly before storing them. Remove dirt, debris, and any residue that could lead to corrosion or other forms of deterioration. This step helps maintain the integrity of the materials.

2. Dry Completely: Ensure that all parts are completely dry before storage. Moisture can lead to rust and other moisture-related issues. Utilize air dryers or leave components in a well-ventilated area to facilitate drying.

3. Use Appropriate Containers: Store components in suitable containers that provide protection from dust and moisture. Plastic bins or covered shelves can prevent exposure to harmful elements while allowing for organized storage.

4. Climate Control: If possible, store equipment in a climate-controlled environment. Maintaining a stable temperature and humidity level minimizes the risk of damage due to extreme conditions.

5. Regular Inspections: Periodically check stored components for any signs of wear or damage. Early detection of issues allows for timely repairs and prolongs the lifespan of the equipment.

6. Labeling and Organization: Clearly label storage containers and organize components by type or function. This practice streamlines the retrieval process and reduces the likelihood of misplacing essential parts.

By adhering to these best practices, one can enhance the durability and reliability of agricultural machinery components, ensuring they remain in excellent working condition for years to come.

Aftermarket Parts Overview

In the world of agricultural machinery, the availability of alternative components plays a crucial role in maintaining operational efficiency and reducing costs. These supplementary items are designed to replace or enhance original equipment, providing farmers and operators with a variety of options to ensure their machinery remains functional and reliable.

One of the key advantages of aftermarket solutions is the potential for improved performance. Many manufacturers focus on innovation, creating enhancements that can lead to increased durability and better overall results in fieldwork. Additionally, these components often come at a more competitive price, allowing users to make cost-effective decisions without sacrificing quality.

It is essential to consider compatibility when selecting these alternatives. Ensuring that the chosen items fit seamlessly with existing machinery is vital for optimal performance. Researching reputable suppliers and reading customer reviews can provide valuable insights into the reliability of various options available in the market.

Resources for Replacement Parts

Finding suitable components for machinery maintenance is crucial for optimal performance and longevity. Several reliable sources can provide essential items, ensuring that your equipment runs smoothly. This section outlines various avenues to obtain high-quality replacements.

Online Retailers

Numerous online platforms specialize in agricultural machinery components. These websites typically offer a wide range of products, competitive prices, and user-friendly interfaces for easy navigation.

Local Dealers

Visiting local distributors can also be beneficial. They often carry a selection of essential items and can provide valuable advice on compatibility and installation.

| Source Type | Examples |

|---|---|

| Online Retailers | AgriSupply, Tractor Supply Co., eBay |

| Local Dealers | John Deere, Kubota, local farm equipment shops |

Impact of Proper Setup

Achieving optimal performance in agricultural machinery relies heavily on precise configuration and alignment. Ensuring that each component functions harmoniously can greatly enhance efficiency and productivity. Neglecting this crucial aspect can lead to a variety of operational issues, including uneven material distribution and increased wear on essential mechanisms.

Efficiency Gains

When equipment is set up correctly, it maximizes output and minimizes downtime. Proper alignment reduces the risk of mechanical failures and extends the lifespan of the machine. Additionally, a well-configured system often results in smoother operation, allowing for faster processing and reduced fuel consumption.

Maintenance and Longevity

Regular adjustments and routine checks are vital for maintaining optimal performance. By ensuring that every aspect of the machinery is correctly calibrated, operators can avoid costly repairs and maintain consistent productivity. Investing time in proper setup not only improves immediate functionality but also contributes to long-term reliability and operational success.