Understanding the intricate layout of agricultural machinery is essential for efficient operation and maintenance. This section delves into the various elements that make up these vital tools, focusing on their arrangement and functionality. By familiarizing oneself with these components, users can enhance their proficiency in handling such equipment.

Farmers and operators often seek detailed illustrations to assist in identifying and managing these crucial pieces. A comprehensive visual representation serves as a valuable resource, enabling easier navigation and troubleshooting during repairs or upgrades. Knowledge of these parts empowers users to maintain their machinery effectively, ensuring optimal performance during demanding tasks.

By examining the configuration of these tools, one can gain insights into their design and usage. This exploration not only aids in understanding the equipment’s capabilities but also promotes safer and more efficient handling practices in the field.

This section provides a comprehensive overview of a specific agricultural machinery model, focusing on its structure, functionality, and essential components. Understanding these elements is crucial for users seeking to maintain and operate the equipment effectively.

Key Features

- Durability and strength

- Efficiency in operation

- Adaptability to various conditions

Operational Overview

The machinery is designed to streamline the process of gathering and packaging crop materials. Its mechanisms allow for smooth operation, ensuring optimal performance in the field.

Maintenance Considerations

- Regular inspection schedules

- Replacement of worn components

- Proper lubrication practices

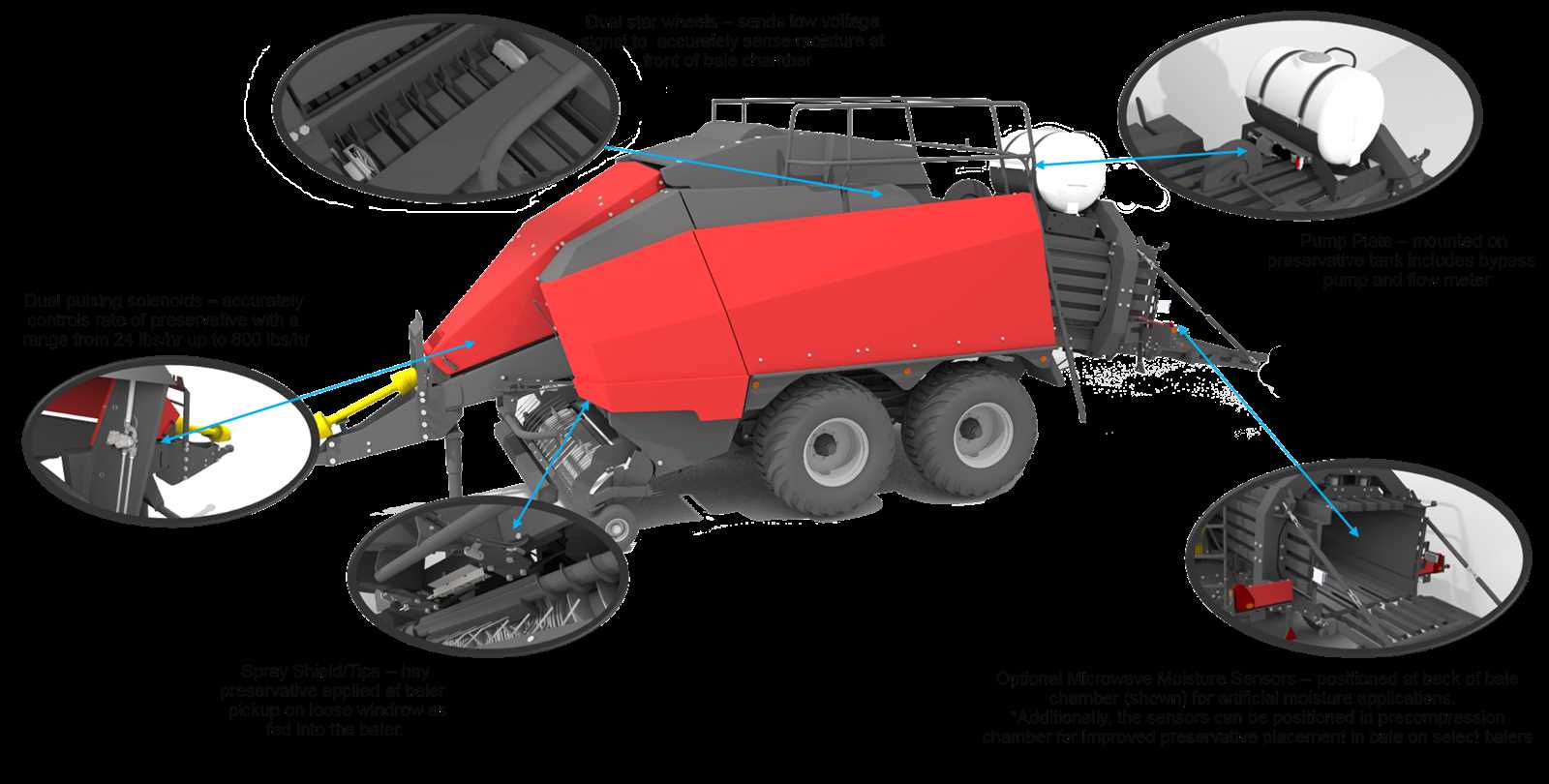

Key Components of the Round Baler

Understanding the essential elements of a cylindrical harvesting machine is crucial for efficient operation and maintenance. This section outlines the primary parts that contribute to the functionality and performance of these agricultural tools.

Essential Parts and Their Functions

- Feeding System: This section collects and directs the crop material into the machine for processing.

- Compression Chamber: Here, the collected material is compacted into a uniform shape, facilitating storage and transport.

- Twine or Netting System: This mechanism secures the formed unit, ensuring it remains intact during handling.

- Drive Mechanism: Provides power to the various components, enabling the operation of the machine.

- Chassis: The frame that supports the entire structure, providing stability and durability.

Maintenance Considerations

- Regularly inspect the feeding system for blockages and wear.

- Ensure the compression chamber is free from debris to maintain efficiency.

- Check the twine or netting components for any damage or fraying.

- Lubricate the drive mechanism to prevent mechanical failures.

- Monitor the chassis for signs of rust or structural weakness.

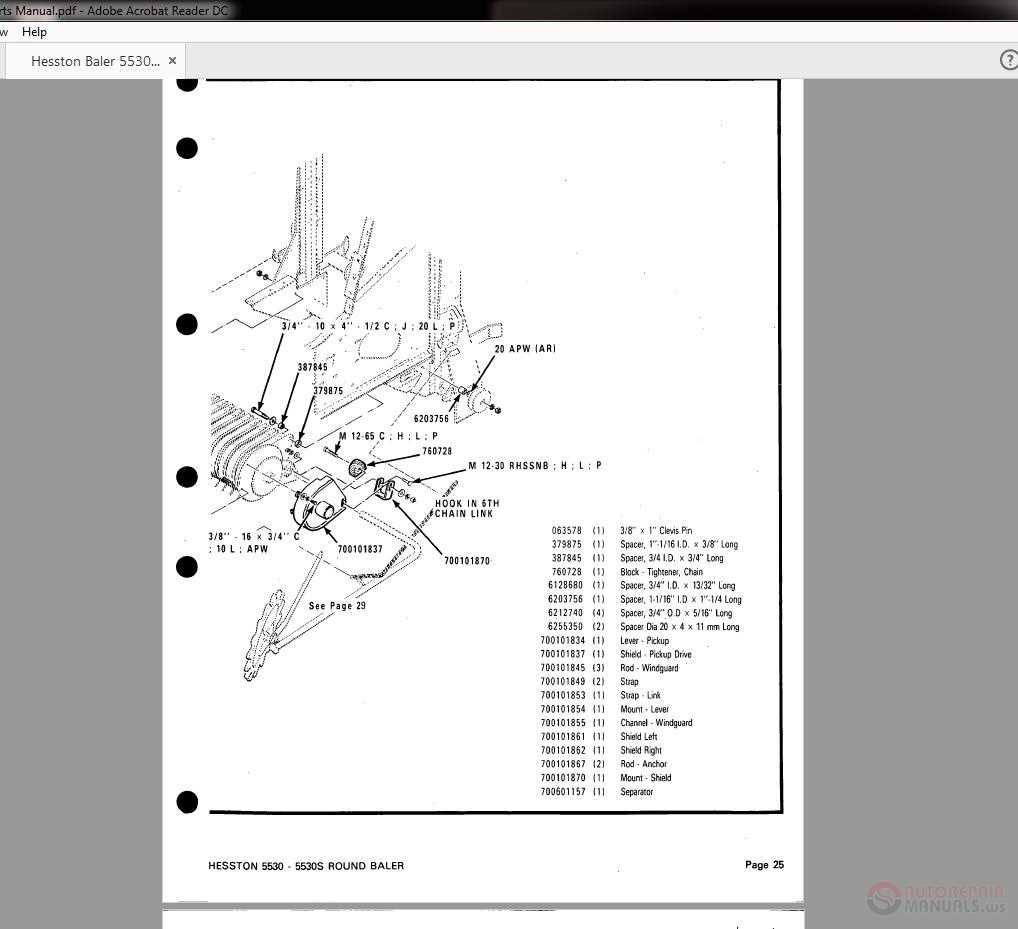

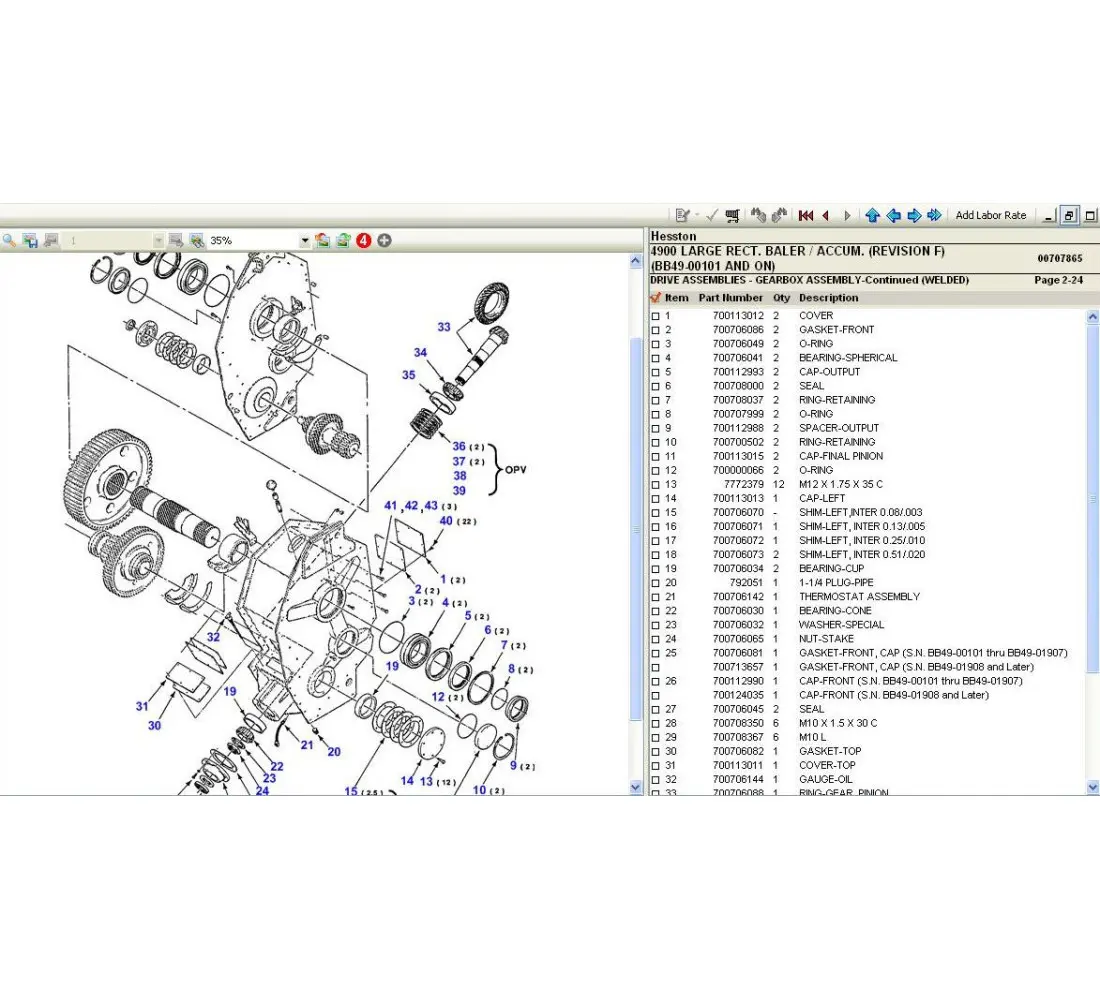

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for efficient maintenance and repairs. Visual representations serve as essential tools, aiding users in identifying individual elements and their interconnections. These illustrations enhance comprehension, ensuring that operators and technicians can execute tasks with accuracy.

Facilitating Maintenance Tasks

Detailed visual guides simplify the process of upkeep. They allow users to locate specific components quickly, reducing downtime during repairs. A clear reference helps in identifying wear or damage, promoting timely replacements and ensuring optimal performance.

Enhancing Communication

Visual aids promote better communication among team members. When discussing maintenance procedures or troubleshooting issues, referring to these guides fosters clarity and understanding. This collaboration minimizes errors, leading to more effective problem-solving and teamwork.

| Benefit | Description |

|---|---|

| Quick Identification | Enables easy recognition of components for repairs. |

| Reduced Downtime | Speeds up maintenance tasks, keeping operations running smoothly. |

| Improved Safety | Helps in recognizing parts that may pose risks during repairs. |

Commonly Used Replacement Parts

In the maintenance of agricultural machinery, certain components are frequently replaced due to wear and tear. Understanding which items are essential for optimal performance can enhance the efficiency of your equipment and prolong its lifespan.

Here are some of the most commonly replaced components:

- Belt assemblies: Vital for transferring power and ensuring smooth operation.

- Rollers: Essential for guiding and aligning materials during processing.

- Bearings: Crucial for reducing friction and supporting moving parts.

- Chains: Important for power transmission between various parts.

- Hydraulic hoses: Necessary for fluid transfer in hydraulic systems.

- Seals and gaskets: Key to preventing leaks and maintaining pressure.

Regularly inspecting and replacing these components can help maintain the functionality and reliability of your machinery.

Understanding the Baler’s Mechanism

To comprehend how this agricultural equipment functions, it’s crucial to explore its core systems and components. The process involves transforming loose materials into compact forms, which can then be easily stored or transported. By learning how each element interacts within the machine, one can enhance efficiency and maintain optimal operation.

Main Operating Components

The equipment relies on several key elements that work in sync to achieve the compression of materials. These include the intake system, the compression chamber, and the tying mechanism. The intake system gathers and feeds the materials, while the chamber ensures their tight packing, and the tying system secures the final product.

Flow of Material through the Machine

Once the materials enter, they pass through the intake section and are gradually pushed into the chamber. Here, rotating mechanisms compress the contents. Once the desired size and d

Maintenance Tips for Longevity

To ensure optimal performance and extend the operational life of your equipment, regular care and proper upkeep are essential. By consistently following key practices, you can prevent unnecessary wear and avoid potential breakdowns that may disrupt work.

Lubrication: Make sure all moving components are well-lubricated. Frequent application of the appropriate lubricants reduces friction and helps parts operate smoothly, preventing early failure.

Inspection: Conduct routine inspections to check for any signs of wear, loose connections, or damage. Early detection of minor issues can prevent them from escalating into costly repairs.

Cleaning: Regular cleaning is vital to remove dirt, debris, and other contaminants that can cause mechanical blockages or corrosion over time. Keep ke

Identifying Parts in Diagrams

Understanding how to recognize components within technical illustrations can significantly improve maintenance and repair efforts. Diagrams are essential tools for showcasing the placement and function of various mechanical elements. Being able to pinpoint specific sections helps ensure accuracy during assembly or troubleshooting.

Visual Clarity: Look for labels and symbols that indicate different sections or assemblies. These markers are usually designed to provide a clear view of individual items, assisting users in identifying the correct part for their needs.

Systematic Approach: Start by analyzing the overall structure and then focus on smaller elements, moving from the general to the detailed. This method allows for an efficient breakdown of the illustration, reducing the chances of misinterpretation or confusion.

How to Source Genuine Parts

When it comes to maintaining your machinery, ensuring that you obtain authentic components is crucial for performance and longevity. It is essential to find reliable suppliers who specialize in high-quality equipment replacement items. This process requires attention to detail, ensuring compatibility and durability for the specific model you’re working with.

Trusted Suppliers and Retailers

Begin by researching well-established suppliers that offer certified products. Look for authorized retailers with a solid reputation, as they are more likely to provide original equipment and offer warranties. Compare various vendors to find the best options in terms of reliability, availability, and pricing.

Online Resources and Manufacturer Support

Another effective method for sourcing components is by using online resources. Many platforms provide detailed listings of equipment-specific items, often including user reviews and ratings. Addi

Troubleshooting Common Issues

When operating machinery, it’s crucial to identify and address frequent malfunctions to ensure smooth functioning. Understanding these potential problems early can save time and prevent further damage to the equipment.

Equipment Jamming

One of the most typical issues is jamming, which can occur when debris or material blocks essential components. To resolve this, regularly inspect and clean key parts, ensuring that all mechanisms are free of obstructions. If the blockage persists, refer to the user manual for detailed disassembly instructions or seek professional assistance.

Inconsistent Performance

Another common issue is inconsistent machine output, which may result from worn-out parts or improper adjustments. Regular maintenance and timely replacement of worn components can significantly improve efficiency. Additionally, verify that all settings are configured according to the manufacturer’s recommendations to avoid performance fluctuations.

Safety Precautions During Repairs

When performing maintenance, it is essential to prioritize safety at all stages. Repairs on large machinery can be hazardous, especially without proper precautions. Always ensure that all power sources are disconnected before starting any work. Keep the workspace well-lit and organized to minimize the risk of accidents.

Personal Protective Equipment (PPE)

Before handling any mechanical components, wear the appropriate protective gear. This includes gloves, safety goggles, and durable footwear to shield from sharp or heavy parts. Ensuring that PPE is worn at all times can significantly reduce the likelihood of injury.

Stabilizing the Equipment

Before conducting any repair, make sure the machinery is properly stabilized. Use chocks or supports to prevent movement, and ensure that no one is near potentially dangerous areas. Stabilization is key in avoiding unexpected shifts that could lead to injury.

Benefits of Using Original Parts

Choosing authentic components for your machinery ensures optimal performance and longevity. Original equipment is specifically designed to meet the technical requirements of the system, providing reliable operation and reducing the risk of unexpected failures.

Enhanced Durability

Genuine parts are made from high-quality materials, ensuring they withstand the rigors of heavy usage. This durability means fewer replacements and lower maintenance costs over time.

Improved Efficiency

- Ensures proper fit and function for better overall performance

- Reduces downtime due to fewer mechanical issues

- Optimizes the machine’s operational capacity

By sticking with original components, you guarantee that your equipment continues to run smoothly, delivering efficient and consistent results.