In the world of power tools, comprehending the intricacies of machinery is crucial for both efficiency and maintenance. Each tool comprises a variety of elements that work together seamlessly to deliver exceptional performance. Analyzing these elements not only aids in troubleshooting but also enhances the longevity of the equipment.

By exploring the arrangement and function of each individual piece, users can gain valuable insights into how to optimize their tools. Whether for repairs or upgrades, a clear understanding of the configuration can lead to improved operational outcomes and increased productivity.

Furthermore, having access to a visual representation of the components facilitates a deeper grasp of the assembly process. This knowledge empowers users to tackle any challenges that may arise, ensuring that they can achieve the ultimate results in their projects.

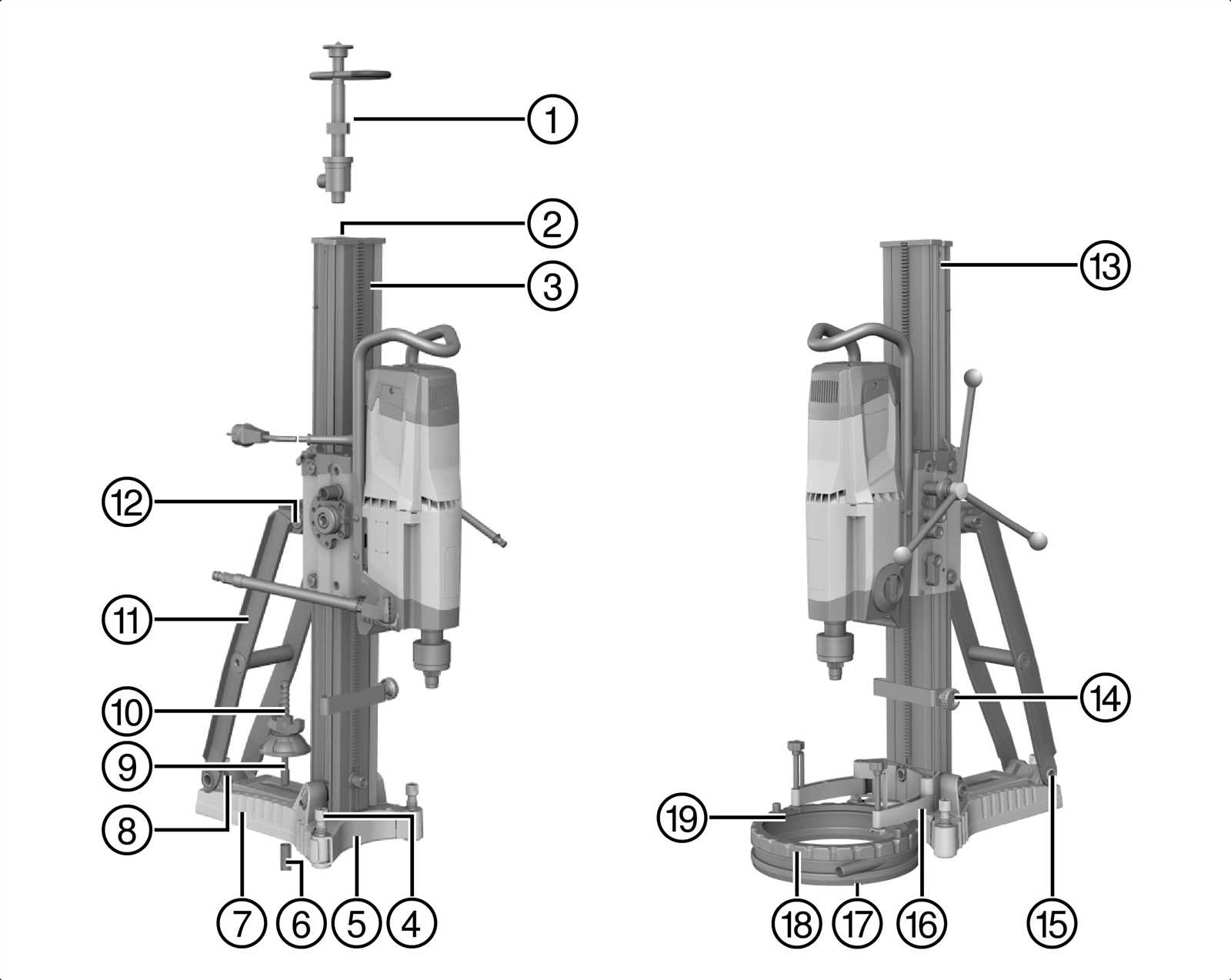

Understanding Hilti DD 200 Components

Exploring the essential elements of this powerful drilling system reveals the intricacies that contribute to its overall functionality. Each component plays a vital role in ensuring efficiency and precision during operation, enhancing the user experience significantly.

Main Elements

The core components include the motor assembly, which drives the drilling process, and the gearbox that optimizes torque and speed. Additionally, the cooling system is crucial for preventing overheating, ensuring longevity and reliability.

Attachments such as drill bits and extension rods enhance versatility, allowing for a range of applications. Understanding these accessories can help users maximize performance and adapt to various project requirements effectively.

Overview of DD 200 System

The system in question represents a highly efficient solution designed for core drilling applications. Its innovative technology ensures reliability and precision, making it an essential tool for professionals in various construction and renovation projects.

Key Features

- Powerful motor designed for optimal performance

- Durable components that withstand rigorous usage

- Versatile attachments for different drilling needs

- Integrated safety features to enhance user protection

Applications

- Installation of electrical and plumbing systems

- Creating openings in concrete structures

- Environmental and geological investigations

- Renovation tasks requiring precise core drilling

This versatile equipment stands out for its ease of use and adaptability, making it suitable for both seasoned contractors and newcomers in the field.

Importance of Parts Diagrams

Understanding the components of any machinery is crucial for effective maintenance and repair. Visual representations serve as a vital tool for technicians and users alike, enabling them to quickly identify and address issues.

- Enhances troubleshooting capabilities

- Facilitates ordering of replacement items

- Aids in reassembly after repairs

- Promotes safety by highlighting critical components

In summary, these visual guides are essential for ensuring the longevity and optimal performance of equipment.

Main Components of the Drill

This section explores the essential elements that make up a high-performance drilling tool, focusing on their functionality and significance in achieving precise results. Understanding these core parts allows users to appreciate the intricacies of operation and maintenance.

Motor and Power Supply

The motor serves as the heart of the device, driving the drilling mechanism. A reliable power supply ensures consistent performance, allowing for effective energy transfer during operation.

Drilling Mechanism

At the core of any drilling apparatus is its mechanism, which includes the chuck, bit, and drive shaft. The chuck securely holds the drill bit, while the bit determines the size and type of hole created. Together, these components work in harmony to deliver optimal drilling efficiency.

Exploring Drill Accessories

Drilling tools are essential for a variety of tasks, and understanding their complementary accessories can significantly enhance performance and efficiency. These attachments not only extend the capabilities of your equipment but also ensure precision and safety during operation.

Types of Attachments

There are several types of accessories available, each designed for specific applications. Core bits are ideal for creating clean holes in tough materials, while drill stands provide stability and accuracy for vertical drilling tasks. Additionally, adaptors enable compatibility between different tool types, enhancing versatility.

Choosing the Right Accessory

Selecting the appropriate accessory is crucial for achieving optimal results. Consider the material you are working with and the desired outcome. Using the right tools not only boosts productivity but also prolongs the lifespan of your primary drilling device.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair tasks. These illustrations serve as guides, helping users identify and locate various elements within a machine or tool. Mastering the ability to interpret these visuals can greatly enhance your troubleshooting skills and streamline the repair process.

Begin by familiarizing yourself with the layout of the illustration. Each section typically corresponds to a specific area of the equipment, showcasing individual pieces and their arrangement. Pay attention to labels and legends, which often provide vital information about each component’s function and specifications.

Look for symbols or numbers that indicate how parts connect or interact with one another. These notations can clarify the assembly process, making it easier to understand how to disassemble or reassemble the tool. Additionally, observe any arrows or lines that illustrate movement or flow, as they can indicate the operational dynamics of the system.

Finally, take note of any color coding or shading, which might signify different categories or statuses of components. By synthesizing all this information, you can develop a comprehensive understanding of the mechanical structure, leading to more efficient repairs and maintenance tasks.

Common Issues and Solutions

In any machinery or equipment, challenges may arise that hinder optimal performance. Understanding these common problems and their solutions is crucial for effective maintenance and operation. This section will explore typical issues encountered with various models, along with practical remedies.

Typical Challenges

- Insufficient power output

- Overheating during extended use

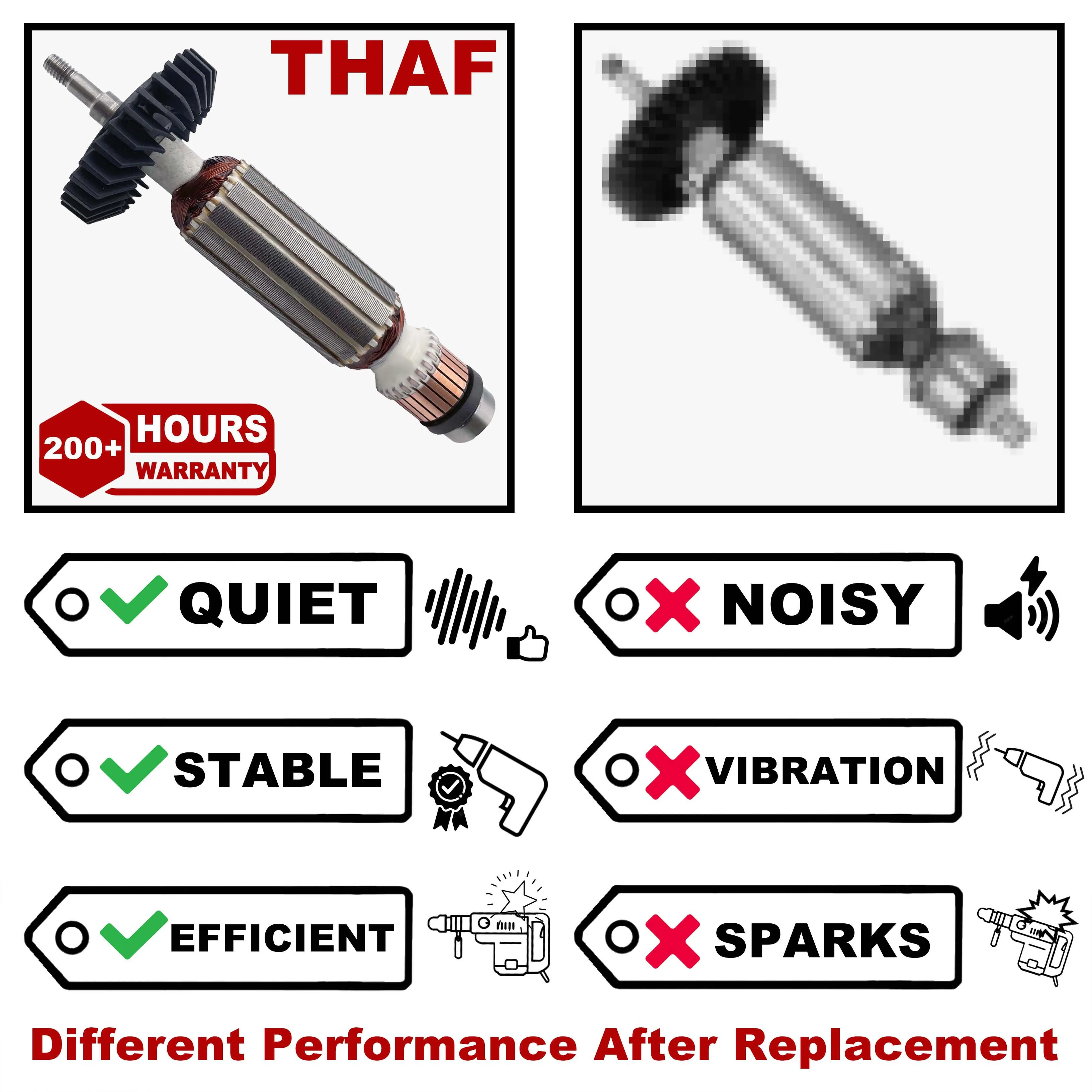

- Frequent wear of components

- Inconsistent performance

Practical Solutions

- Power Output: Check the power supply and ensure all connections are secure. Consider inspecting internal components for wear or damage.

- Overheating: Allow the device to cool between uses and ensure ventilation is not obstructed. Regularly clean air filters and vents.

- Component Wear: Schedule routine inspections and replace worn parts promptly. Use compatible replacement items to maintain efficiency.

- Inconsistent Performance: Verify that settings are correctly adjusted for the task. Examine calibration and make necessary adjustments.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the prolonged efficiency of any equipment. By following a few simple practices, users can significantly extend the lifespan of their tools while maintaining optimal performance. This section outlines key maintenance strategies that can help you achieve these goals.

Regular Cleaning

Keeping your equipment clean is vital for preventing dust and debris from causing wear and tear. After each use, take a moment to wipe down the surfaces and remove any buildup. Use appropriate cleaning solutions and tools to avoid damaging sensitive components. Regularly check for clogs in air filters and vents, ensuring that airflow remains unobstructed.

Scheduled Inspections

Implement a routine inspection schedule to identify any signs of wear or damage early on. Pay close attention to moving parts and electrical connections. Replace worn components promptly to avoid further issues. Keeping a maintenance log can help track repairs and replacements, making it easier to plan future upkeep.

Replacement Parts Availability

Ensuring the accessibility of essential components is crucial for maintaining operational efficiency in any equipment. Users often seek reliable sources to obtain these necessary elements, ensuring minimal downtime and optimal performance.

Where to Find Components

- Authorized Distributors

- Online Marketplaces

- Specialty Tool Retailers

- Manufacturer’s Official Website

Factors Influencing Availability

- Demand Trends

- Geographical Location

- Supplier Relationships

- Model Popularity

Understanding these factors can help users navigate the search for replacements effectively.

Step-by-Step Assembly Guide

This section provides a comprehensive approach to assembling your equipment efficiently and correctly. Following a clear sequence of steps ensures that all components fit together seamlessly, enhancing the overall functionality and longevity of the machine.

Preparation Steps

Before you begin the assembly, gather all necessary components and tools. Ensure your workspace is clean and well-organized to prevent any parts from being misplaced. Review the components list and familiarize yourself with each element.

| Component | Quantity |

|---|---|

| Base Unit | 1 |

| Motor Assembly | 1 |

| Drilling Head | 1 |

| Power Cable | 1 |

| Safety Guard | 1 |

Assembly Instructions

Start by attaching the motor assembly to the base unit, ensuring that all screws are tightened securely. Next, connect the drilling head, aligning it properly with the motor. Once these components are in place, proceed to attach the power cable, checking that all connections are firm and insulated. Finally, install the safety guard to complete the assembly, ensuring it is properly secured to prevent any accidents during operation.

Upgrades and Enhancements

In the realm of advanced machinery, continual improvement is vital for maximizing efficiency and performance. Upgrading components can lead to significant enhancements in functionality, reliability, and user experience. These modifications can transform standard equipment into superior tools, better suited to meet the demands of modern projects.

Innovative features often incorporate the latest technology, allowing for enhanced precision and ease of use. For instance, ergonomic designs and improved materials can reduce fatigue during prolonged operation, while upgraded motor systems may deliver increased power and speed.

Furthermore, integrating smart technology offers users valuable insights through real-time monitoring, optimizing maintenance schedules, and extending the lifespan of equipment. Ultimately, investing in enhancements ensures that tools remain competitive and aligned with industry standards.

Safety Features of Hilti DD 200

When operating powerful machinery, ensuring user protection is paramount. This equipment incorporates several innovative safety mechanisms designed to minimize risks and enhance operational security.

Emergency Stop Button: A prominent feature, this button allows for immediate cessation of operations in case of unforeseen incidents, safeguarding the user and bystanders.

Overload Protection: This system monitors the device’s performance, automatically shutting it down to prevent damage or injury due to excessive force or misuse.

Ergonomic Design: The user-friendly layout not only facilitates comfortable handling but also reduces strain, thereby promoting safer operation during prolonged use.

Safety Clutch: In the event of a binding situation, this mechanism disengages the drive, preventing potential harm to the operator and extending the tool’s lifespan.

Protective Shields: These barriers are strategically placed to deflect debris and safeguard users from potential hazards, ensuring a secure work environment.

With these essential features, the equipment promotes a culture of safety while enhancing productivity and confidence during operation.

Resources for Further Learning

Expanding your knowledge in the field of construction tools and their components is essential for both beginners and seasoned professionals. Numerous resources are available to help you enhance your understanding of equipment functionality, maintenance, and innovation.

Books and Manuals

Consider exploring comprehensive texts that cover tool operation and maintenance, offering in-depth insights and practical tips.

| Title | Author | Publication Year |

|---|---|---|

| Construction Tools Handbook | John Smith | 2020 |

| Understanding Power Tools | Jane Doe | 2018 |

Online Resources

Various websites and online platforms provide tutorials, forums, and expert advice. Engaging with these communities can enhance your practical skills.