Understanding the internal structure of high-powered tools is essential for maintaining and optimizing their performance. Knowing how each element functions within the system ensures long-lasting durability and reliable operation. This section will provide a detailed look into the essential elements and how they work together.

By exploring the arrangement of the key components, users can easily identify the areas that may require adjustments or replacements. Whether you’re performing regular maintenance or troubleshooting specific issues, this knowledge will enhance your ability to keep the equipment running smoothly.

In this guide, we will also cover the most critical elements and their connections, offering a comprehensive understanding of how each piece plays a role in the overall functionality of the device.

Overview of Hilti DX A41 Components

The functionality of high-performance tools relies on the precise assembly of various mechanical elements. These tools are designed to work efficiently, ensuring durability and safety in demanding environments. Understanding the structure of such devices can help in maintenance and optimization of their use.

| Component | Description |

|---|---|

| Firing Mechanism | Responsible for the controlled release of energy, allowing the tool to perform its primary function. |

| Barrel Assembly | Houses the moving parts that interact with the material during operation, ensuring smooth functionality. |

| Trigger Unit | Initiates the process by releasing the energy required for the tool’s performance. |

| Safety Features | Integrated systems that prevent unintended operation, protecting the user from potential hazards. |

| Fastener Guide | Ensures accurate placement and alignment of fasteners during use, contributing to precision work. |

Key Features of the DX Tool

The DX tool is designed to meet the needs of professionals working in demanding environments. Its unique capabilities make it an efficient choice for tasks requiring precision and durability. Below are some of the main characteristics that set it apart from other options on the market.

- Reliable Performance: The tool consistently delivers high-quality results even in tough conditions, ensuring smooth operation and accuracy.

- Durable Build: Constructed with robust materials, this device is built to withstand frequent use and challenging environments.

- Ergonomic Design: With a focus on user comfort, the tool is easy to handle, reducing fatigue during prolonged use.

- Advanced Safety Features: Equipped with several safety mechanisms, it offers enhanced protection for the user during operation.

- Versatility: Suitable for a wide range of applications, making it an ideal tool for various industries and tasks.

Maintenance Tips for Hilti DX A41

Proper care and regular upkeep are essential for ensuring the longevity and optimal performance of any construction tool. By following consistent maintenance routines, you can prevent unexpected breakdowns and extend the life of your device.

| Maintenance Task | Frequency | Key Benefits |

|---|---|---|

| Clean after each use | Every session | Prevents buildup of debris and ensures smooth operation |

| Inspect moving parts | Weekly | Identifies wear early to avoid costly repairs |

| Lubricate mechanisms | Monthly | Reduces friction and prolongs mechanical life |

| Check fasteners and seals | Quarterly | Ensures tight connections and prevents leaks |

Adhering to these guidelines will help in maintaining the func

Common Issues with Powder-Actuated Tools Components

Powder-actuated devices are highly efficient, but they can experience several common challenges during regular use. These issues often arise from wear and tear, improper handling, or maintenance oversight, affecting the overall performance and safety of the tool.

Trigger Malfunctions

One frequent problem involves the trigger mechanism, which may become unresponsive due to debris or misalignment. Regular cleaning and inspection can help prevent this issue from escalating into a safety hazard.

Firing Pin Wear

Another issue commonly reported is the wearing out of the firing pin, which may cause misfires or reduced power. Ensuring timely replacement and using the correct fasteners can prolong the lifespan of this essential component.

Proper maintenance and consistent attention to detail are crucial in minimizing these and other problems, helping to maintain the tool’s functionality and efficiency over time.

Replacing Worn-Out Components in a Fastening Tool

Over time, various elements of a fastening device may begin to show signs of wear, especially with frequent use in demanding environments. Replacing these aging components is essential to maintain the efficiency and safety of the tool during operation. Ensuring proper upkeep can extend the tool’s lifespan and prevent unexpected malfunctions.

Identifying Key Areas for Replacement

When examining the tool for worn elements, pay special attention to high-friction areas that endure the most stress during use. These parts are more likely to degrade over time and should be replaced regularly to avoid impacting the overall performance of the equipment.

Steps to Replace Worn Elements

Once the necessary parts are identified, follow the recommended guidelines for removal and installation. It’s important to ensure that new components are properly fitted and aligned to restore the tool to optimal working condition. Regular inspections and timely replacements are key to preventing further damage.

Exploring Different Fastening Elements

The choice of fastening components plays a crucial role in ensuring the durability and strength of any construction project. Various elements are designed to provide secure and reliable connections between different surfaces, making them essential in both residential and industrial applications. Understanding the wide array of fastening options available can greatly enhance the efficiency and safety of any installation process.

Anchors are widely used for attaching materials to hard surfaces such as concrete or masonry. They offer a solid grip and can withstand significant loads. Another common element is the screw, which provides flexibility in adjusting tightness and strength. Fasteners like nails are often used for quick and efficient installation, though they may not offer the same level of durability as other methods. Each type of fastening element has its own unique set of advantages, suited for different scenarios.

When selecting the right fastening method, it is important to consider factors such as load-bearing capacity, environmental conditions, and the materials being joined. This helps ensure that the connection will perform optimally over time.

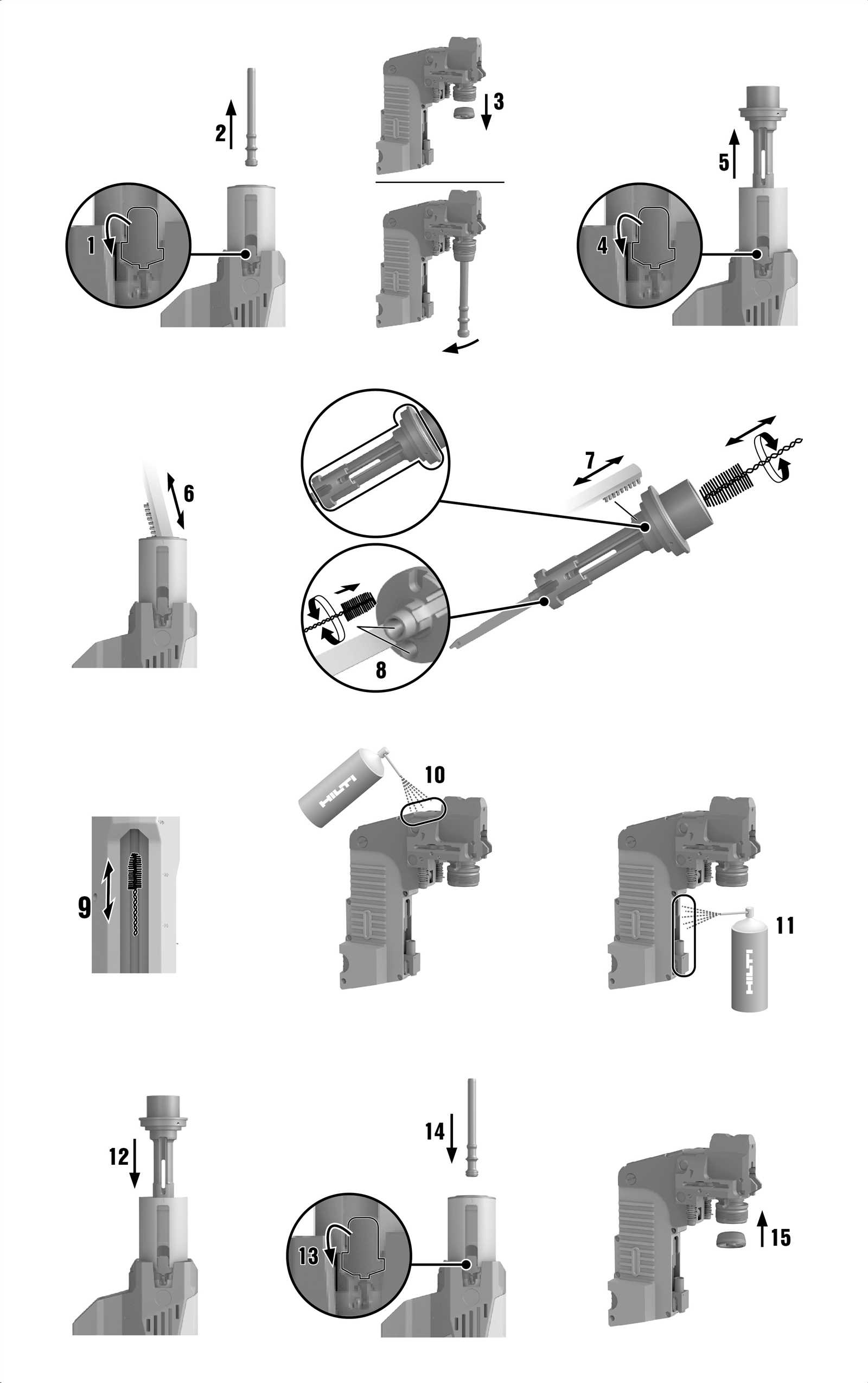

How to Disassemble the Hilti DX A41

To successfully dismantle the tool, it is important to follow a systematic approach. Each component must be carefully detached to avoid damaging any internal mechanisms. Begin by ensuring the tool is unloaded and free from any external power sources. A step-by-step guide will help maintain the tool’s integrity while allowing for an effective disassembly process.

The following table outlines the essential steps for disassembling the tool:

| Step | Action |

|---|---|

| 1 | Remove any accessories or attachments to prevent obstruction during disassembly. |

| 2 | Unscrew the outer casing using an appropriate tool to expose the internal mechanisms. |

| 3 | Disconnect the spring-loaded components, ensuring you handle them with care to avoid damage. |

| 4 | Carefully remove the internal components in a sequence that ensures no parts are left behind or damaged. |

| 5 | Inspect each part for wear or damage, and note any necessary replacements for reassembly. |

Cleaning and Lubrication for Optimal Performance

Regular maintenance is crucial for ensuring the long-term efficiency and reliability of any tool. Proper cleaning and lubrication not only prevent wear and tear but also enhance the overall performance, reducing the likelihood of malfunction and downtime. These steps are vital for keeping the equipment in top condition, ensuring it operates smoothly and efficiently over time.

Cleaning Process

Keeping the tool free from dust, debris, and other contaminants is essential. Accumulated dirt can affect the internal mechanisms, causing unnecessary strain and reducing the lifespan of the components. Regular cleaning removes these particles and helps maintain the tool’s functionality. Use appropriate cleaning agents and methods based on the material and design of the equipment.

Lubrication Procedure

Lubrication is necessary to reduce friction between moving parts and prevent premature wear. A good lubricant helps the parts move freely, minimizing heat build-up and preventing rust and corrosion. Applying the right type of lubricant at regular intervals ensures that the machine operates quietly and efficiently, contributing to its overall performance.

| Component | Cleaning Method | Recommended Lubricant |

|---|---|---|

| Mechanical Parts | Wipe with a soft cloth, use air blower for dust removal | High-performance grease |

| Moving Joints | Brush off any loose debris, use compressed air | Light machine oil |

| Metal Surfaces | Use a damp cloth with mild detergent | Anti-corrosion spray |

Understanding Safety Mechanisms in Hilti DX A41

When working with powerful fastening tools, ensuring safety is paramount. Tools equipped with advanced protection features help prevent accidents and enhance user security during operation. These mechanisms are designed to reduce the risk of mishaps, such as accidental discharge or improper handling, providing peace of mind to the operator.

Key Protection Features

One of the most essential safety elements in these tools is the automatic locking system. This feature prevents the device from firing unless all necessary conditions are met, such as proper alignment and full engagement of the safety triggers. This minimizes the chance of unintentional firing, ensuring that the tool is used correctly and only when appropriate.

Enhanced User Control

In addition, tools of this type often come with an ergonomic design, allowing for better grip and more control over the device. This design is crucial in reducing the risk of accidents caused by sudden movements or slips during operation. With clear visibility of the working area and accessible safety controls, users can maintain full command over the tool, even in high-pressure environments.

Benefits of Using Genuine Hilti Parts

Using original components designed for your tool ensures optimal performance and longevity. These high-quality elements are crafted to meet the exact specifications required for efficient and safe operation. By choosing authentic parts, you minimize the risk of malfunctions and ensure that your equipment functions at peak capacity over its lifetime.

Enhanced Durability

Original components are made with premium materials that enhance the durability of the equipment. This leads to fewer replacements and repairs, reducing overall maintenance costs in the long run.

Safety and Reliability

Genuine components are tested to ensure they meet strict safety standards. Using non-authentic parts can compromise the safety features of your tool, increasing the risk of accidents or breakdowns during operation.