The efficient operation of any power tool hinges on understanding its internal mechanisms and individual elements. This section delves into the intricate structure of the TE 17 model, highlighting how each component interacts to ensure optimal performance. By gaining insight into these essential elements, users can enhance their maintenance practices and improve overall functionality.

From the outer casing to the intricate inner workings, every segment plays a crucial role in the device’s efficiency. Recognizing the significance of each element not only aids in troubleshooting but also fosters a deeper appreciation for the technology at play. The harmonious collaboration of these components is vital for achieving desired outcomes in various applications.

In this exploration, we will provide a comprehensive overview of the key elements that constitute the TE 17 tool. By breaking down its structure and functionality, users will be equipped with the knowledge to navigate its complexities confidently. This understanding empowers individuals to make informed decisions regarding maintenance and repairs, ultimately extending the lifespan of their equipment.

This section explores the essential elements that contribute to the functionality and efficiency of the tool. Understanding these components is crucial for users aiming to maximize performance and ensure proper maintenance.

- Motor Assembly: The heart of the device, responsible for powering its operations.

- Housing: Provides protection and structural integrity, safeguarding internal components.

- Trigger Mechanism: Facilitates user control, allowing for precise operation and adjustments.

- Bit Holder: Secures various attachments, enabling versatility in applications.

- Vibration Dampening System: Reduces user fatigue by minimizing vibrations during extended use.

Each of these components plays a significant role in enhancing the overall performance, ensuring that the tool operates smoothly and efficiently in various tasks.

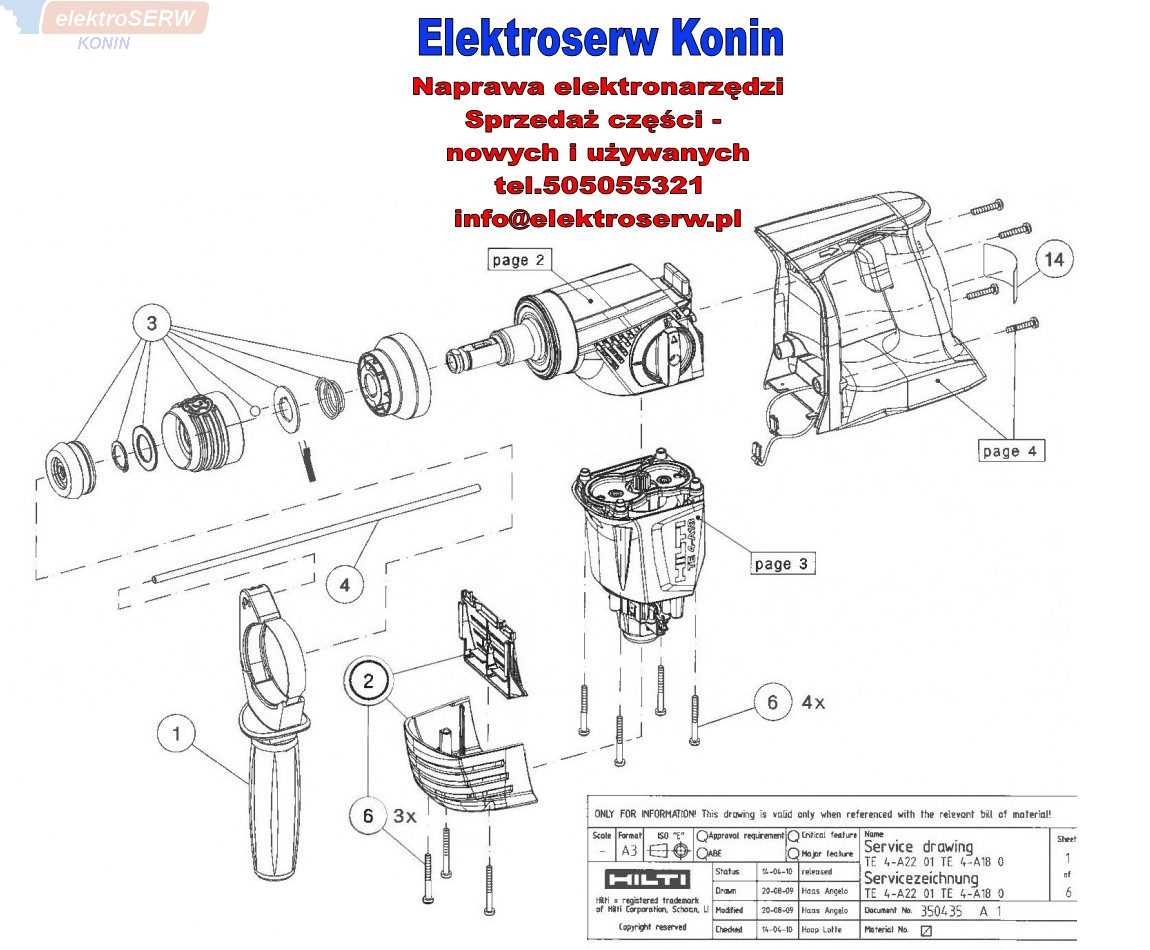

Understanding the Parts Diagram

This section aims to clarify the visual representation of components and their interrelationships within a tool. Such illustrations serve as a valuable reference for users, enabling them to identify each element and understand its function in the overall assembly.

When analyzing a visual representation, consider the following key aspects:

- Identification: Recognize each component’s name and purpose.

- Arrangement: Observe how elements are positioned in relation to one another.

- Connections: Note how different parts connect and interact within the system.

Understanding these elements can enhance your knowledge and facilitate efficient maintenance or repair tasks. By familiarizing yourself with the representation, you can ensure that you are well-prepared for any work involving the assembly.

Importance of Each Component

Understanding the significance of each element within a tool is crucial for optimal performance and longevity. Every component plays a specific role in the functionality and efficiency of the overall mechanism. Proper knowledge of these parts not only aids in effective operation but also enhances maintenance practices.

Key Roles of Individual Elements

Each element contributes uniquely to the functionality of the system. From the motor to the casing, every part is designed to work in harmony, ensuring that the equipment operates smoothly and effectively. Recognizing the purpose of these elements helps users appreciate the engineering behind the device.

Impact on Overall Performance

The performance of any mechanical system is heavily reliant on the quality and condition of its components. Deterioration or failure of one part can lead to reduced efficiency or complete breakdown. Therefore, regular inspection and understanding the role of each element can significantly prolong the life of the equipment.

| Component | Function | Importance |

|---|---|---|

| Motor | Powers the tool | Essential for operation |

| Housing | Protects internal parts | Prevents damage |

| Trigger | Controls activation | Ensures safety and precision |

| Bit | Performs the task | Critical for effectiveness |

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of your tools. By following a few straightforward guidelines, you can enhance performance and prevent premature wear and tear. Regular care not only preserves functionality but also contributes to safety during operation.

Here are some key practices to keep in mind:

- Regular Cleaning: After each use, make sure to remove dust and debris. This helps prevent buildup that can hinder performance.

- Lubrication: Periodically apply the appropriate lubricants to moving parts to ensure smooth operation and minimize friction.

- Check for Wear: Inspect components regularly for signs of damage or wear. Early detection can prevent further issues.

- Storage: Store your tools in a dry and cool environment to avoid moisture-related damage. Proper storage prolongs the life of materials.

- Calibration: If applicable, regularly calibrate your equipment to maintain accuracy and efficiency during use.

By implementing these maintenance strategies, you can significantly extend the life of your tools, ensuring they remain reliable and efficient for years to come.

Common Issues and Solutions

This section addresses frequent challenges encountered with power tools and offers practical solutions to enhance performance and longevity. Understanding these issues can help users maintain equipment effectively and ensure optimal functioning during operations.

Frequent Operational Problems

Users may face various operational difficulties, such as inadequate power output, overheating, or unusual noises during use. Identifying these problems early is crucial for avoiding further damage and ensuring safe operation.

Effective Resolutions

To tackle common challenges, consider the following solutions:

| Issue | Solution |

|---|---|

| Insufficient power | Check the power source and ensure proper voltage; inspect connections for wear or damage. |

| Overheating | Allow the tool to cool down; ensure ventilation is unobstructed and avoid extended use without breaks. |

| Unusual noises | Inspect for loose components; lubricate moving parts and tighten any fasteners. |

Replacing Parts: A Guide

Maintaining the efficiency of your tool is crucial for optimal performance. Understanding how to exchange components can significantly enhance its lifespan and functionality. This guide offers essential insights into the process of replacing various elements to ensure your equipment operates at its best.

Essential Steps for Replacement

- Begin by identifying the component that needs replacement.

- Gather necessary tools, ensuring they are compatible with the equipment.

- Disconnect the tool from its power source for safety.

- Carefully remove the old component, taking note of its positioning.

- Install the new component, ensuring it is securely in place.

- Reconnect the tool to the power source and test its functionality.

Safety Precautions

- Always wear appropriate safety gear, such as gloves and goggles.

- Work in a well-lit area to avoid accidents.

- Refer to the manufacturer’s guidelines for specific instructions.

- Dispose of old components properly to minimize environmental impact.

Tools Needed for Repairs

When undertaking maintenance or fixing issues with equipment, having the right tools is essential for achieving effective results. Proper tools not only facilitate the repair process but also ensure safety and efficiency.

Here is a list of essential items that should be on hand:

- Wrenches: Useful for loosening and tightening bolts.

- Screwdrivers: Various types are necessary for different screw heads.

- Pliers: Ideal for gripping, twisting, and cutting wires.

- Utility Knife: Handy for cutting through various materials.

- Measuring Tape: Important for precise measurements during repairs.

- Safety Gear: Includes gloves and goggles to protect against hazards.

By preparing these tools beforehand, you can streamline the repair process and minimize complications.

Where to Find Replacement Parts

Locating new components for your equipment can be crucial for maintaining optimal performance. Numerous sources are available for acquiring high-quality replacements that fit your specific model.

Consider checking the following options for sourcing the necessary items:

| Source | Description |

|---|---|

| Official Retailers | Authorized sellers often provide genuine components with warranties and customer support. |

| Online Marketplaces | Websites like Amazon or eBay offer a variety of aftermarket and original components, often at competitive prices. |

| Local Hardware Stores | Nearby shops may carry a selection of universal items that can serve as alternatives for specific models. |

| Manufacturer’s Website | The official site may list available components along with manuals and installation guides. |

| Specialized Distributors | These companies focus on specific tools and may offer unique options tailored to your equipment needs. |

Assembly Instructions for Users

This section provides essential guidelines for assembling your tool effectively. Following these instructions will ensure that the device operates efficiently and safely, allowing for optimal performance during usage.

Preparation Steps

Before starting the assembly process, gather all necessary components and tools. Ensure that your workspace is clean and well-lit to facilitate a smooth workflow. Familiarize yourself with each item, as this will help streamline the assembly process.

Assembly Process

Begin by connecting the main body to the handle, ensuring a secure fit. Next, attach the required accessories, following the manufacturer’s recommendations for placement. Check each connection for stability to prevent any issues during operation. Finally, perform a thorough inspection to confirm that all elements are correctly assembled.

Adhering to these assembly instructions will enhance the longevity and functionality of your device, providing a seamless experience for users.

Frequently Asked Questions

This section aims to address common inquiries related to the functionality and maintenance of a specific tool model. Understanding these aspects can enhance user experience and ensure efficient operation.

What should I do if my tool is not functioning properly?

If the equipment is not performing as expected, first check for any visible issues such as damage or blockages. Consult the user manual for troubleshooting steps or consider contacting customer support for assistance.

How often should I perform maintenance on my device?

Regular upkeep is essential for optimal performance. It is generally recommended to conduct maintenance after a specified number of uses or at least once every few months, depending on the frequency of usage.

Where can I find replacement components?

Replacement components can typically be found through authorized dealers or online retailers specializing in tools and accessories. Ensure that you are purchasing genuine parts for compatibility and reliability.

Is there a warranty available for this tool?

Many manufacturers offer warranties that cover defects in materials and workmanship. Review the warranty details provided with your purchase for specific coverage information and duration.