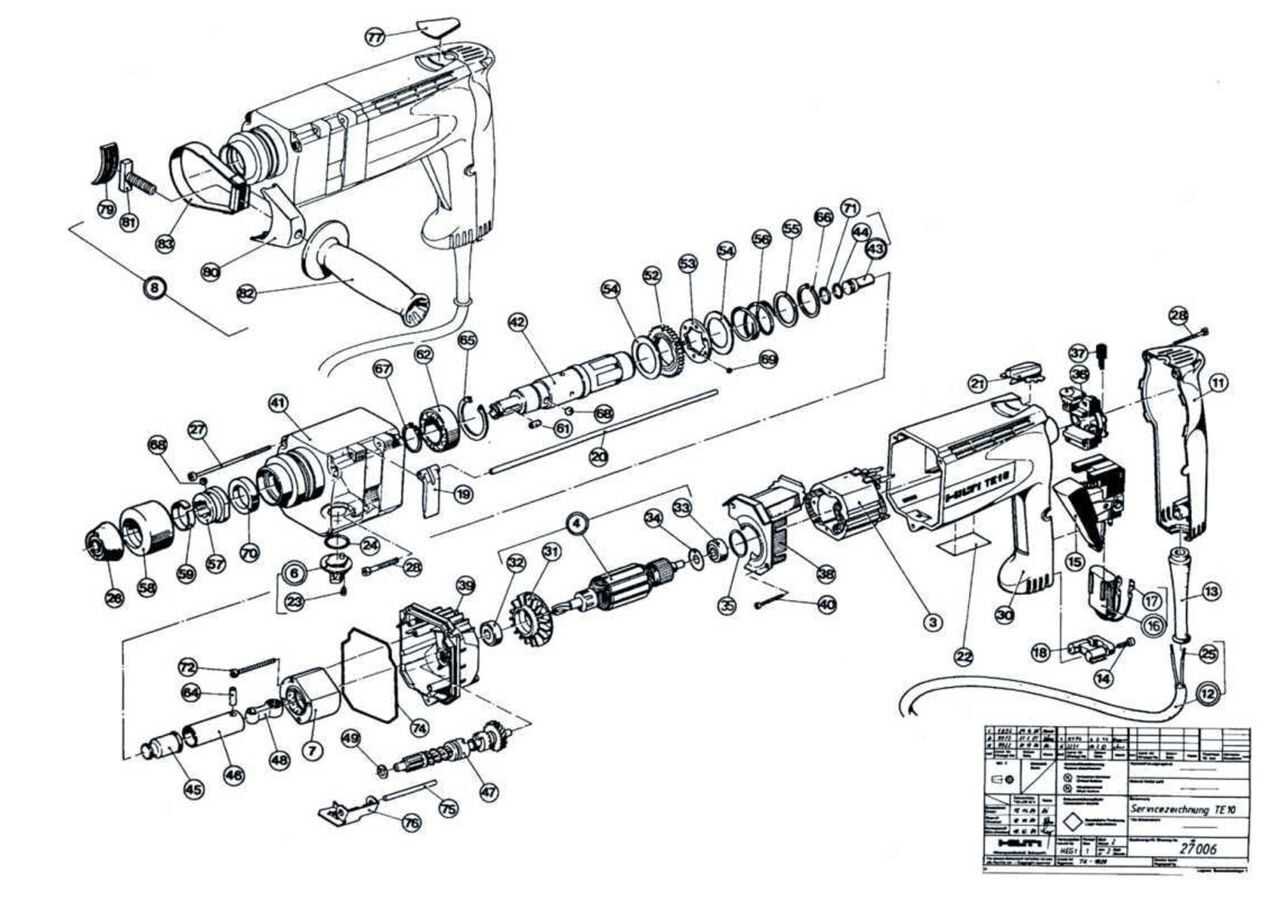

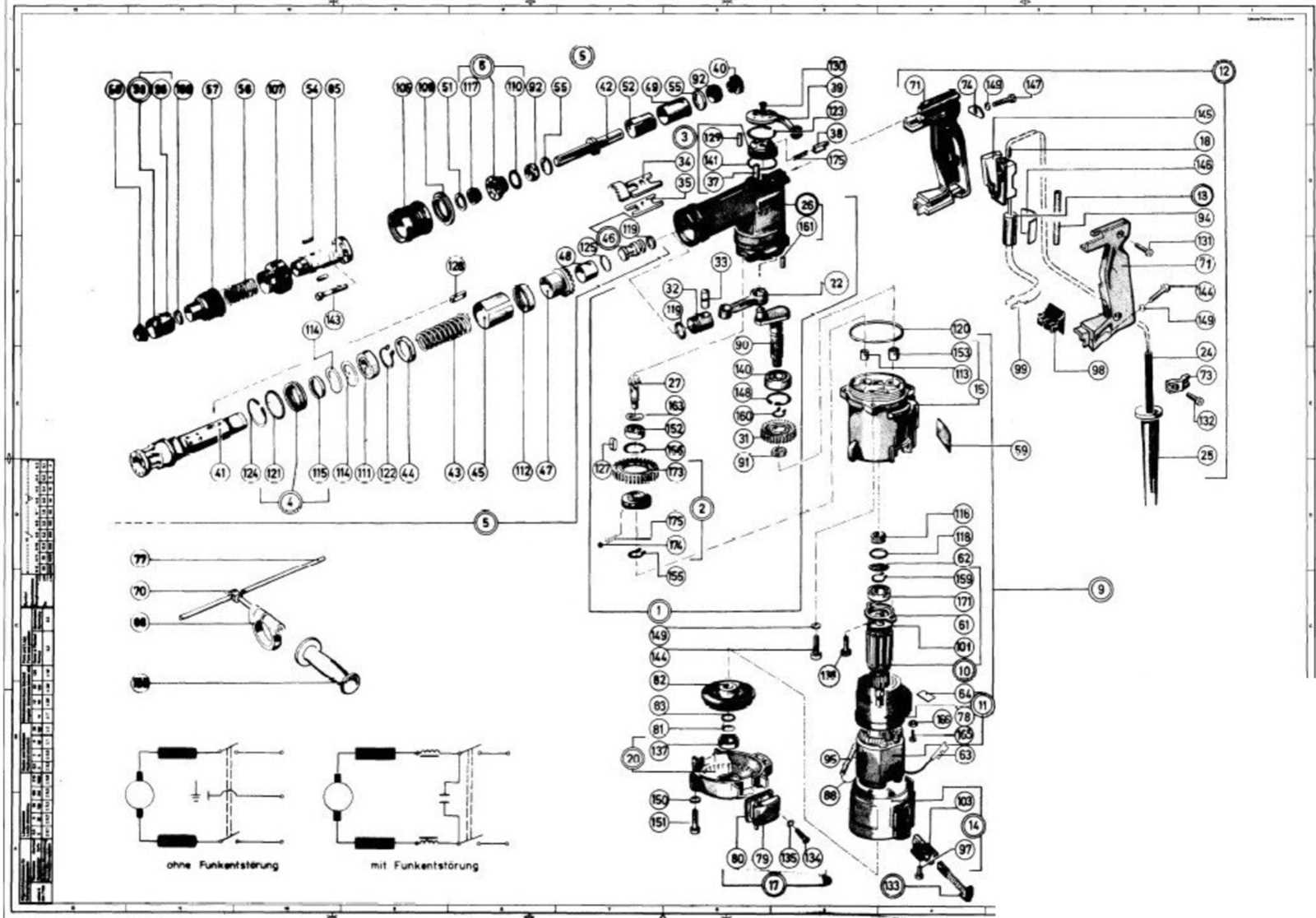

Understanding the internal structure of power tools is essential for proper maintenance and repair. By gaining insights into how different elements interact and function, users can ensure longer operational life and efficient use.

This section provides an overview of the key components that make up a high-performance rotary hammer drill. We’ll break down the essential elements, their functions, and how they work together to deliver optimal performance. This knowledge is particularly useful for troubleshooting and ensuring that your tool continues to operate smoothly.

Detailed information on each component helps users quickly identify and resolve issues, enhancing both efficiency and precision in repairs or replacements.

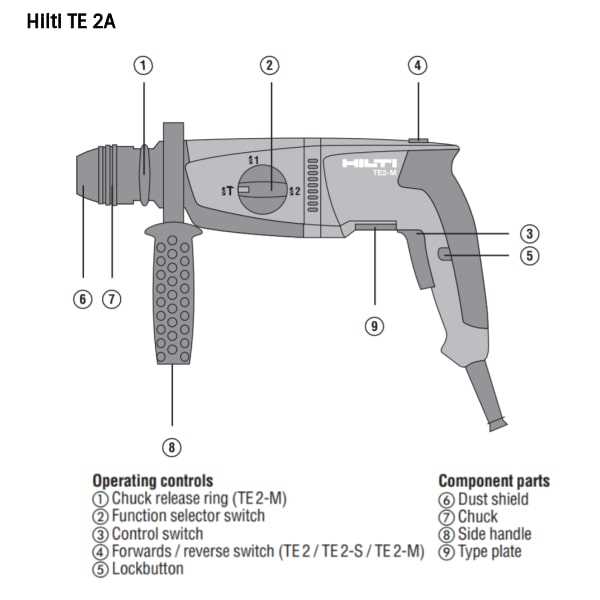

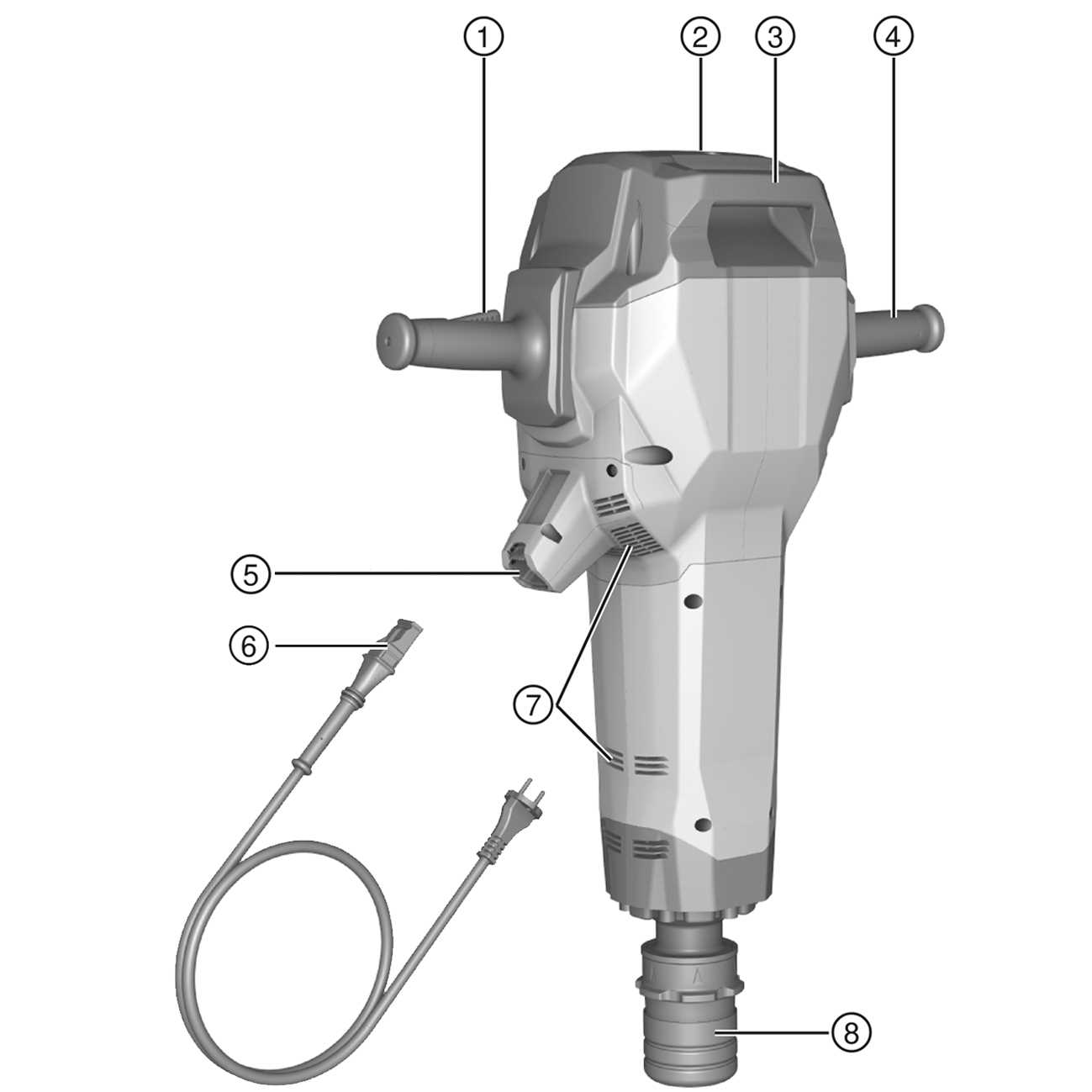

Overview of the TE 2 Components

The TE 2 tool is designed with a variety of essential elements that contribute to its functionality and performance. Each component plays a critical role in ensuring the device operates efficiently, providing reliable power and precision for various tasks.

Below is a detailed look at the key features and structural elements:

- Motor Housing: Protects the internal mechanism and ensures optimal performance.

- Handle and Grip: Ergonomically designed to provide comfort and control during use.

- Chuck System: Allows for quick and secure attachment of different drill bits.

- Ventilation System: Keeps

Main Body Structure Breakdown

The central framework is composed of several interconnected components designed to provide durability and efficient operation. Each section plays a crucial role in maintaining the stability and performance of the equipment. Understanding the layout of these elements is essential for proper maintenance and troubleshooting.

Component Description Core Casing The external shell that houses all internal mechanisms, offering protection and structural integrity. Trigger System Controls the activation of the device, connecting to internal circuits for smooth operation. Rotary Mechanism Enables rotational movement, driving the tool’s main functions with precision. Understanding the Motor Assembly

The motor assembly is a crucial component that powers the entire tool, ensuring efficient performance during operation. By comprehending its structure and function, one can better maintain and troubleshoot it when necessary. The arrangement of its individual parts allows for smooth motion and precise control.

Main Components of the Motor Assembly

- Armature: This rotating part is vital for converting electrical energy into mechanical motion, driving the overall operation.

- Brushes: These elements ensure consistent electrical contact, maintaining steady power flow to the moving parts of the motor.

- Bearings: These support the rotation of the motor, reducing friction and allowing for smooth, efficient movement.

Functionality and Maintenance

Each element of the motor assembly plays a

Detailed View of the Gear Mechanism

The gear system plays a crucial role in transferring energy efficiently within the tool. It ensures that rotational motion is converted and adjusted for optimal performance during operation. Understanding the internal structure of the gears allows for better insight into the functioning and durability of the device.

Core Components of the mechanism include precision-engineered wheels, which work together to maintain balance between speed and force. These wheels are designed to endure high levels of stress, ensuring consistent and reliable functionality over time.

Maintenance and proper lubrication of these elements are essential for extending the life of the tool. Regular inspection can help prevent excessive wear and potential failure of the gear system, maintaining its efficiency.

Electrical Connections and Wiring Layout

Understanding the electrical setup is crucial for ensuring the proper operation and reliability of power tools. The internal wiring, along with carefully placed connections, forms the backbone of any machine’s functionality. Incorrect configurations can lead to performance issues or even potential hazards.

In this section, we will explore the essential steps to follow when assessing or replacing the internal cabling and connectors. By reviewing the proper arrangement of these components, you’ll ensure optimal performance and longevity of your equipment.

Handle and Trigger Configuration

This section focuses on the arrangement and operational features of the grip and activation mechanism of the tool. Understanding how these components interact is essential for optimizing performance and ensuring user comfort during operation.

The handle serves as the primary interface between the user and the device, allowing for precise control. The trigger, on the other hand, is a crucial element that governs the tool’s functionality. Proper alignment and adjustment of these parts are vital for effective use.

Component Description Adjustment Guidelines Grip Designed for ergonomic comfort, ensuring a secure hold during operation. Regularly inspect for wear; adjust the position for optimal reach. Activation Mechanism Controls the power delivery to the tool, impacting speed and efficiency. Ensure smooth operation; adjust sensitivity to user preference. Safety Lock Prevents accidental activation, enhancing user safety. Test functionality regularly; ensure it’s easily accessible. Chuck and Bit Holder Parts

The chuck and bit holder assembly plays a crucial role in the functionality of drilling tools. It serves as the connection between the tool’s motor and the drill bits, ensuring efficient operation and secure attachment during use. Understanding the components involved in this assembly is essential for proper maintenance and effective usage.

Component Description Chuck This device grips the drill bit securely, allowing for precise drilling and reducing slippage during operation. Bit Holder A specialized attachment that holds various types of drill bits, providing versatility for different tasks. Clamping Mechanism This mechanism ensures that the drill bit is firmly secured within the chuck, preventing any movement that could affect performance. Release Button A feature that allows for quick and easy bit changes, enhancing efficiency during work. Exploded View of the Drilling System

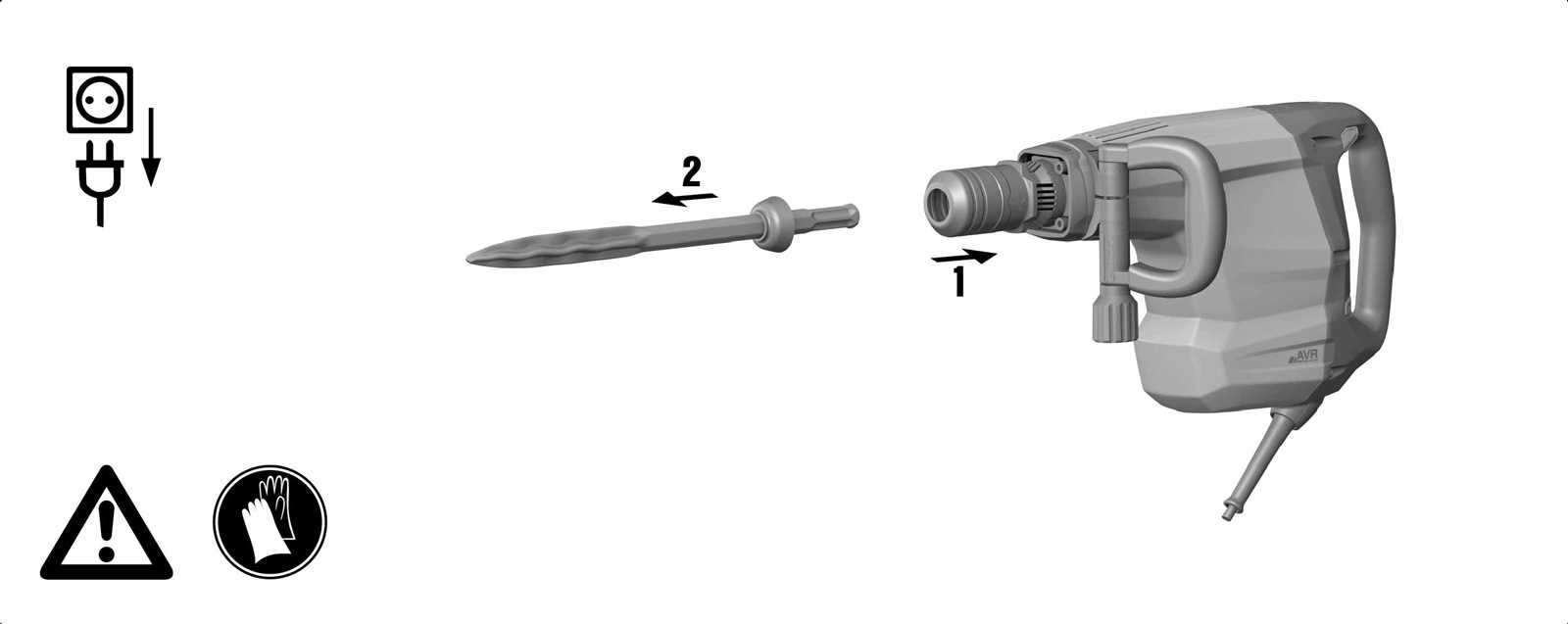

This section presents a detailed examination of the drilling assembly, providing a comprehensive overview of its individual components and their arrangement. Understanding this structure is essential for efficient operation and maintenance.

Components Overview

The drilling mechanism consists of several key elements, each contributing to the overall functionality. Here are the primary components:

- Drill Bit

- Chuck

- Motor Housing

- Gearbox

- Trigger Mechanism

- Power Supply

Assembly Configuration

Each part plays a crucial role in the drilling process. The configuration allows for optimal performance and precision. The following sequence outlines the assembly:

- Attach the drill bit to the chuck.

- Secure the chuck within the motor housing.

- Connect the gearbox to the motor housing.

- Integrate the trigger mechanism for activation.

- Ensure the power supply is properly linked.

Impact System Components Analysis

The efficiency of a power tool is often determined by the synergy of its internal mechanisms. Understanding the various elements that contribute to the functionality of these systems can provide insights into their performance and durability. Each component plays a crucial role in ensuring optimal operation, which is essential for achieving desired results in various applications.

Key Elements of the Impact Mechanism

At the core of any impact-driven tool lies the driving mechanism, which generates the necessary force for effective performance. This mechanism typically comprises a motor that powers a rotating shaft, translating energy into impactful action. Additionally, a carefully designed transmission system helps to modulate the speed and torque, allowing for versatile use across different tasks.

Durability and Maintenance Considerations

To maintain the longevity of these tools, regular inspection and care of the individual elements are vital. Components such as bearings and gears must be adequately lubricated to prevent wear and ensure smooth operation. Understanding the role of each element not only aids in efficient functioning but also enhances safety during use, making maintenance a key aspect of tool management.

Cooling and Ventilation Elements

Effective management of temperature and airflow is crucial in any mechanical system. Properly designed cooling and ventilation components play a significant role in maintaining optimal operating conditions, thereby enhancing performance and longevity. These elements work together to regulate heat dissipation and ensure the efficient circulation of air within the unit.

Importance of Airflow Management

Airflow management is essential for preventing overheating and ensuring that machinery operates smoothly. By facilitating the movement of air, these components help to dissipate heat generated during operation. Without adequate ventilation, equipment may suffer from decreased efficiency or even damage due to excessive temperatures.

Design Considerations

When designing cooling and ventilation systems, several factors must be taken into account. Material selection, orientation, and size of the components significantly influence their effectiveness. Additionally, the overall layout should promote unobstructed airflow while minimizing noise and energy consumption, contributing to a more efficient operational environment.

Maintenance and Repair Parts List

Ensuring the longevity and optimal performance of your equipment requires regular upkeep and timely replacements. This section provides a comprehensive overview of essential components that are crucial for maintaining functionality and addressing any malfunctions.

Essential Components for Maintenance

- Replacement Brushes

- Motor Bearings

- Power Cords

- Switch Assemblies

- Fasteners and Screws

Common Repair Items

- Seals and Gaskets

- Filters and Screens

- Housing Covers

- Torque Limiting Clutches

- Drive Shafts

Regularly reviewing and updating your maintenance inventory is essential for minimizing downtime and ensuring that you have the necessary items readily available for swift repairs.